This chapter documents and assesses available best practices and technologies that can be employed to mitigate the release of microplastics from textiles and tyres into the environment. The chapter follows a life-cycle approach, discussing options implementable at the design and manufacturing, use and end-of-life phases, as well as options for the end-of-pipe capture of microplastics.

Policies to Reduce Microplastics Pollution in Water

3. Mitigation technologies and best practices

Abstract

3.1. Introduction

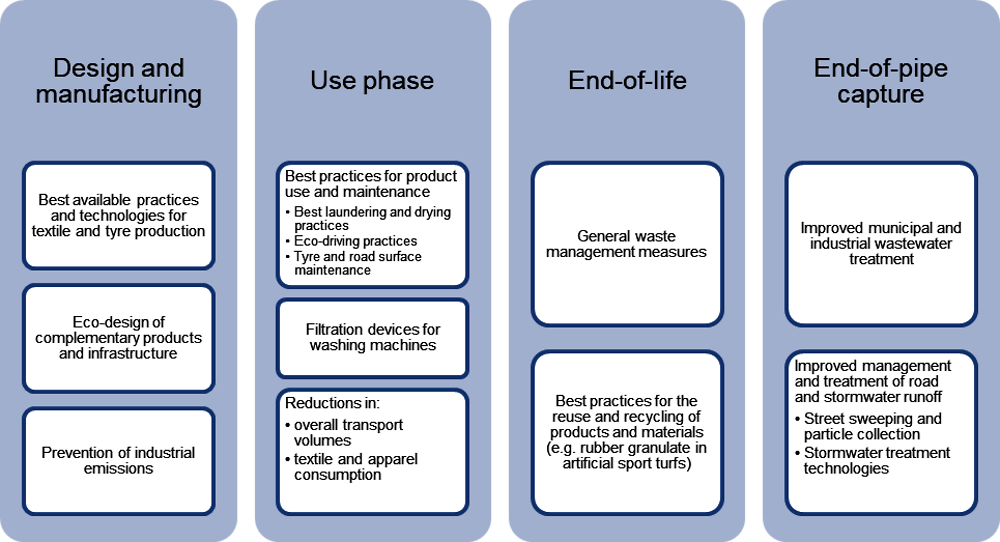

The present chapter aims to provide a stocktake of knowledge and techniques currently available to mitigate the leakage of microfibres and TRWP into the environment. These include several mitigation best practices, actions and technologies implementable during different stages of the lifecycle of textile products and vehicle tyres, as outlined in Figure 3.1. The chapter is structured as follows: Sections 3.2 and 3.3 present and assess the available mitigation best practices and technologies that can be implemented throughout the lifecycle of textile products and tyres (design and manufacturing, use and end-of-life), while Section 3.4 documents and assesses options for the end-of-pipe capture of microplastics.

Figure 3.1. Overview of microplastics mitigation entry points and actions (for textiles and tyres)

Source: Authors’ own elaboration

3.2. Technologies and best practices implementable during the textile lifecycle

The sections below report and assess relevant best practices and mitigation technologies applicable throughout the lifecycle of textiles. Best practices and relevant mitigation technologies implementable at the design and manufacturing stage are discussed in Section 3.2.1, including also eco-design options for the detergent and washing machine industries and potential mitigation solutions for industrial emissions. Section 3.2.2 assesses mitigation actions implementable at the use stage, i.e. the uptake of best use practices and of mitigation technologies, while Section 3.2.3 outlines relevant end-of-life measures to prevent the leakage of textile waste into the environment as well as measures to extend the lifecycle of garments and reduce waste generation. Where knowledge is available, considerations on costs and potential trade-offs or synergies with other environmental objectives are also discussed.

3.2.1. Product design and manufacturing

Best practices and technologies for textile design and manufacturing

The textile design and manufacturing phase holds a large potential for microfibre mitigation, as it offers the opportunity to reduce overall microfibre release at source and to mitigate emissions into a variety of entry-pathways, including emissions into air occurring during wearing and everyday use (De Falco et al., 2020[1]). Several parameters in textile manufacturing influence the amounts of microfibres released during use, from the choice of fibre and yarn type, the fabric structure, the finishing treatments employed and the post-manufacturing processes. Table 3.1 presents and assesses a number of preferable parameters and processes for textile production in line with microfibre mitigation, as identified by available research.

Although the objective of this section is to assess and compare best practices aimed at minimising microfibre shedding, policy decisions will need to place this issue within a holistic approach taking into account considerations on the broader systemic environmental and climate issues associated with fast fashion. Decisions on manufacturing practices will also have to consider other areas for environmental impacts (e.g. climate impacts, land use, chemicals use and water pollution, resource use), social implications (e.g. jobs disruption and creation, labour rights protection) and risks for potential burden-shifting.

Table 3.1. Overview of best practices and technologies relevant for the minimisation of microfibre shedding and implementable during textile design and manufacturing

|

Mitigation measure |

Relevant stages |

Best practices / technologies |

|

|---|---|---|---|

|

Description |

Benefits (+) and Disadvantages (-) |

||

|

Optimisation of fibre, yarn and fabric characteristics |

Yarn formation |

Yarns made of continuous filaments (fibres of indefinite length) are to be preferred to yarns made of short staple fibres since short fibres can more easily slip away due to the mechanical actions of washing and wearing (De Falco et al., 2020[1]; Carney Almroth et al., 2018[2]; Dalla Fontana, Mossotti and Montarsolo, 2020[3]). |

+ Easy implementation + Also prevents the release of microfibres to air + Less expensive production process + Fibre production method already increasing in use - Leads to changes in fabric properties |

|

Yan and fabric formation |

Compact yarn and fabric structures, like highly twisted yarns and woven fabrics, are preferable to looser textile structures, such as poorly twisted yarns and knitted fabrics (De Falco et al., 2020[1]; Carney Almroth et al., 2018[2]; Yang et al., 2019[4]). |

+ Textile features already in use + Also prevents the release of microfibres to air - Leads to changes in fabric properties - Higher production costs |

|

|

Optimisation of the finishing treatments applied |

Textile finishing |

Protective coatings: the application of a thin layer on the surface of the fabric can protect the fabric from the mechanical and chemical stresses it undergoes during a washing process (EU MERMAIDS, 2015[5]). Coatings have been developed on polyamide fabrics with an efficiency of more than 80% in microfibres reduction by using pectin (De Falco et al., 2018[6]) and biodegradable polymers (De Falco et al., 2019[7]). |

+ Also prevents the release of microfibres to air + Opportunity to substitute with less-hazardous finishings and implement circular practices + Extended fabric lifetime - Leads to changes in fabric properties - Certain textile auxiliaries can contribute to chemical pollution and should be avoided - Implementation and costs strongly depend on the type of treatment developed |

|

The avoidance of mechanical finishing treatments napping, raising, shearing and brushing, which are employed to obtain textile surfaces composed of loose short cut fibres and are thus associated with higher shedding (Sillanpaa and Sainio, 2017[8]; Cai et al., 2020[9]; Pirc et al., 2016[10]; Roos, Levenstam Arturin and Hanning, 2017[11]), could mitigate microfibre emissions. |

+ Also prevents industrial emissions of microfibres + Also prevents the release of microfibres to air - Where the processes are unavoidable (e.g. for the production of fleece, pile, velvet), microfibre removal and collection may be required |

||

|

Best garment manufacturing and post-manufacturing practices |

Fabrication and tailoring |

Laser cutting should be preferred over scissor cutting to prevent the release of microfibres from the edge of the fabrics (Roos, Levenstam Arturin and Hanning, 2017[11]; Cai et al., 2020[9]). |

+ Better efficiency and cost saving + Technology already in use + Lower industrial waste generation (Nayak and Padhye, 2016[12]) |

|

Post-manufacturing / distribution |

Removal of microfibres via pre-washing: the amount of microfibre released from synthetic fabrics is greater in the first washes. This is likely to be partially due to the fibre residuals from manufacturing processes. Preliminary controlled industrial washing of the textile/garment has been proposed as a mitigation measures, implementable at the end of the production phase or before distribution (EU MERMAIDS, 2015[13]). |

+ Also prevents the release of microfibres to air + Already occurring in certain cases - Variable and potentially high costs - Difficult to implement where manufacture takes place abroad in emerging economies - Requires the presence of adequate wastewater treatment systems |

|

Notes: Napping is done to obtain a fuzzy effect on the fabric surface, by raising the loose fibres (raising) and then cutting the raised nap to a uniform height (shearing) (EU MERMAIDS, 2015[13]). Brushing is a finishing treatment where brushes or other abrading devices are used to remove loose threads and enhance the final appearance of garments.

Source: Authors’ own elaboration

Research has identified several manufacturing processes in line with microplastics mitigation that are already widely employed in textile manufacturing, such as the use of continuous filaments, compact structures and laser cutting. For instance, the production of staple fibres has been decreasing in recent years in favour of continuous filaments, whose production costs less than staples (The Fiber Year, 2017[14]). However, trade-offs with desirable garment characteristics or with other environmental benefits may pose a barrier to their large-scale deployment. For instance, the use of continuous filaments and compact structures, in line with lower microfibre shedding, will affect the characteristics of the final product, in addition to also requiring higher chemical use and water consumption during manufacturing (e.g. in the case of woven fabrics which require sizing and desizing processes) (Shaker et al., 2016[15]). Similarly, a shift away from knitted and towards woven fabrics could not be easily achieved: knitted fabrics represent 57% of the world market (compared to 32% for woven fabrics) (The Fiber Year, 2017[14]) and are produced at significantly lower costs than woven ones (Shaker et al., 2016[15]). Further research could explore the relevance of increasing the use of knitted fabrics with more compact features, such as highly twisted yarns.

The application of finishing treatments that create protective coatings against microfibre shedding is a key mitigation solution, yet still in the developmental phases. A promising option in terms of efficiency, costs and implementation feasibility is a coating based on pectin, a natural polysaccharide that can be recovered from waste of the agricultural and food industries at a low cost. Washing tests of fabrics treated with pectin-based coatings showed a microfibre reduction effectiveness of about 90% (De Falco et al., 2018[16]). The coating is applied on fabrics with a treatment similar to padding, a process already commonly used in industrial finishing treatments.

Coatings based on biodegradable polymers (e.g. polylactic acid and polybutylene succinate-co-butylene adipate) also showed a promising mitigation effectiveness, although currently their application may be costly and challenging to scale up at industrial level (De Falco et al., 2019[7]). Coatings based on protein-based materials inspired by squids have also been proposed, yet the production costs for the raw material could be high and their effectiveness after repeated washing cycles remains unclear (Pena-Francesch and Demirel, 2019[17]). Overall, protective coatings offer a promising technological mitigation option implementable at industrial scale during the production of textiles, however further research and testing is required in order to assess its effectiveness, implementation costs, application feasibility on different types of fabrics, compatibility with textile manufacturing processes (e.g. dyeing) and durability.

As microfibre shedding tends to decrease in subsequent washing cycles1, prewashing of synthetic fabrics has been proposed as a potentially effective mitigation measure. The main benefit of the prewashing practice at industrial level is that it provides retailers and/or consumers with products with a lower tendency to shed microfibres. Where adequate wastewater treatment systems are in place, the highest quantities of microfibres released at the beginning of fabric lifetime would be more efficiently retained at the end of manufacturing. Further, the practice could be also useful to remove microfibres from manufacturing processes entrapped in the fabrics, as well as other chemical residuals (Cesa et al., 2020[18]; Cai et al., 2020[9]; Belzagui et al., 2019[19]).

Removing microfibres at the production stage2 can be a strategic and cost-effective option to tackle the issue of microfibre shedding as upstream as possible (before these are channelled into different environmental pathways) while also synergistically targeting industrial emissions of microfibres and other pollutants. However, prewashing may be associated with high implementation costs and a variable mitigation potential. Depending on the local context, the effective implementation of this practice may require the update of the current industrial wastewater treatment infrastructure with technologies able to retain microfibres with adequate efficiency. Thus, this mitigation best practice may be challenging and costly to implement in SMEs in emerging economies, where the majority of textile manufacturing takes place. In light of these challenges, it has been suggested that policy could also envision that the pre-washing of textile products manufactured abroad takes place in the importing country under controlled conditions. In sum, pre-washing has a high mitigation potential, however further tests are required to evaluate its implementation feasibility at different entry points (i.e. textile manufacturing, fabric manufacturing, or retail), as well as to further investigate whether the decrease in microfibre emissions occurs independently from the specific characteristics of different fabrics.

In general, as point-source emissions are easier to manage than diffuse ones, the design and manufacturing of textiles and garments generally offers large opportunities for cost-effective reductions in microfibre emissions. However, persisting knowledge gaps pose a barrier to the development and implementation of the identified mitigation best practices and technologies. Further research is currently required to more reliably assess the cost-effectiveness and implementation feasibility of the available mitigation options, as well as to evaluate the potential trade-offs with the preservation of desirable environmental benefits or garment characteristics.3

The lack of standardised methodologies and the lack of transparency along the textile value chain have been identified as key barriers to the investigation and implementation of best manufacturing practices. Firstly, the lack of common measurement standards for microfibre shedding renders test results difficult to compare and aggregate, limiting possibilities to draw conclusions on the manufacturing parameters which influence microfibre shedding during use. Secondly, the complex and geographically dispersed nature of textile and apparel value chains provides challenges to the adequate provision of product information further downstream (Niinimäki et al., 2020[20]). Knowledge and data gaps in the manufacturing history of fabrics (e.g. production steps, chemicals used, etc.) pose challenges to the evaluation of the effect of specific production processes on microfibre release and, therefore, to the identification of best design and manufacturing practices. For these reasons, collaboration between researches and textile industries could be beneficial and instrumental in accelerating research and industrial-scale deployment (see Chapter 5).

Prevention of industrial emissions

As outlined in Chapter 2, microfibres were found in relevant concentrations in industrial wastewater (Xu et al., 2018[21]) and in water and sediments sampled in textile industrial areas (Deng et al., 2020[22]). Given there is currently insufficient information to reliably quantify and characterise the release of microfibres occurring during manufacturing, there is a need for textile producers to collect data on industrial microfibre emissions in order to adequately inform mitigation action.

It has been suggested that in-line vacuum systems could be added to capture loose fibres via air filtration and exhaustion after processes such as brushing, sanding and raising (Carney Almroth et al., 2018[2]). The EU MERMAIDS project recommended to handle carefully mechanical finishings which generate many loose microfibres, such as napping (EU MERMAIDS, 2015[13]). Textile manufacturing facilities could be fitted with treatment systems of water and air dedicated to the removal of microfibres, although such systems have not yet been developed or presented. Implementation steps are expected to be long and potentially to bear high costs for the textile industry, given the existing technological barriers. Options for the improved treatment of industrial wastewater effluents are discussed in Section 3.4.1.

Best practices for the production of laundry detergents and washing machines

Detergent and washing machine manufacturers may also be important players in the mitigation of microfibre emissions. Available research has identified several entry points for the identification of best practices for microfibre pollution mitigation implementable during the production of detergents and washing machines, as summarised in Table 3.2.

Table 3.2. Overview of microfibre mitigation actions relevant for detergent and washing machine manufacturers

|

Industrial sector |

Best practices / technologies |

|

|---|---|---|

|

Description |

Benefits (+) and Disadvantages (-) |

|

|

Detergent production |

Focusing production on liquid light duty detergents, since heavy-duty detergents are more aggressive and cause a greater release of microfibres, especially powder ones (EU MERMAIDS, 2015[13]). |

+ Better fabric care - Possible additional production costs for the relevant industry - Possible additional carbon footprint and costs for transportation |

|

Developing detergents effective at low temperatures and during short washing cycles (Cotton et al., 2020[23]). |

+ Synergic action with the best practice for laundry of low washing temperature and time - Possible additional production costs for the relevant industry |

|

|

Research and development for new additives to improve the mitigation effect of detergent products on microfibre release during the washing cycle. |

+ By preventing fibre breakage, the fabric care is improved and the textile life prolonged. - Possible additional production costs for the relevant industry |

|

|

Washing machine production |

Development of built-in filtration systems that retain microfibres. |

+ Compared to external filtration systems, the correct functioning of the machine could be better controlled. - Possible additional production costs for the relevant industry |

|

Preference for front-load washing machines over top-load ones. Top-load washing machines usually have central agitators that spin to rub textiles against each other in order to wash them, likely causing higher abrasion of garments and higher fibre release compared to the rotating drum of front-load washing machines (Hartline et al., 2016[24]). |

+ Better fabric care - Costs of production conversion for top-load machines manufactures |

|

|

Development of washing machines that use lower volumes of water (Kelly et al., 2019[25]; Lant et al., 2020[26]). |

+ Lower water consumption - Possible higher production costs for the industry |

|

Source: Authors’ own elaboration

The use of detergents and softeners can influence the microfibre shedding degree of clothing and also directly contribute to the release of intentionally-added microplastics. The development of products aligned with the prevention of fibre loss, such as detergents that are effective at low temperatures and during short laundry cycles, while also efficiently cleaning the fabric, can potentially contribute to microplastics pollution mitigation, although solutions may take time to be developed. It will be crucial that new detergents and additives do not contain intentionally-added microplastics or harmful substances available for release into the environment. A synergic action between innovation in detergent production and in the application of finishing treatments during textile manufacturing should also be taken into consideration to ensure that the laundry cycle does not provoke the detachment of coatings and that an overall microfibre reduction effect is achieved.

At the level of washing machines production, there is scope for adapting the design of products in order to help mitigate the generation and emission of microfibres during laundering. However, currently, there are no reports of washing machines available on the market with a tested effectiveness in mitigating microfibre emissions.4 Washing machines able to both maintain the correct functioning of the machine and mitigate microfibre releases into wastewaters (e.g. via built-in filtration systems) may take time to be developed and tested.

In both cases, the implementation of these mitigation actions may take time and could bear substantial costs for the relevant industries, from R&D to manufacturing, potentially also resulting in higher consumer prices. However, as for textile design and manufacturing, the development of solutions at the industry level can hold large potential for mitigation as well as for easier implementation and monitoring via adequate policy intervention.

3.2.2. Textile use stage

Best practices for maintenance and care

The use of garments contributes to microfibre pollution in two ways: it causes the release of microfibres into air (De Falco et al., 2020[1]; Dris et al., 2017[27]) and it causes fabric abrasion and tear that can lead to microfibre emissions during washing. Although further research is required in order to correlate practices aimed at improving fabric durability with microfibre release, several practices aligned with adequate textile care and improved durability of fabrics are expected to also minimise microfibre generation during laundering and drying, as summarised in Table 3.3. These include reducing the frequency of washing cycles, washing full loads and at low temperatures, preferring liquid to powder detergents, using fabric softeners (except for fabrics which can be damaged by the use of softeners, such as outdoor apparel) and avoiding tumble-drying.

Key barriers to implementation are a lack of consumer awareness and knowledge on the environmental consequences of microfibre pollution, as well as on the available mitigation measures. As reported in previous sections, scientific consensus over the relative effectiveness of these practices remains uncertain, also due to the absence of standardised methodologies to quantify microfibre release. Further research is required in order to gather more and conclusive data on the parameters that influence the release of microfibres during the laundering, drying and wearing of textiles. The good outcome of such investigations will also depend on the level of collaboration between relevant stakeholders and industrial sectors.

Further research is also needed to understand how the tendency of garments to emit microfibres changes over their lifetime, particularly to understand whether there is a threshold beyond which older garments start releasing higher amounts of microfibres. Several studies have found that the release of microfibres decreases during subsequent washing cycles (Cai et al., 2020[28]; Carney Almroth et al., 2018[2]; Cesa et al., 2020[18]; Belzagui et al., 2019[19]; De Falco et al., 2019[29]; Napper and Thompson, 2016[30]; Pirc et al., 2016[10]; Sillanpaa and Sainio, 2017[8]), however this trend has mainly been observed with new garments and might differ with clothes that have been worn. One study mechanically aged some garments and found that they released more microfibres than new ones (Hartline et al., 2016[24]). Tests conducted in real household conditions found relevant quantities of microfibres released, however these cannot give indications of potential trends over the lifecycle of garments (Galvão et al., 2020[31]; Lant et al., 2020[26]).

Table 3.3. Overview of best practices to minimise microfibre shedding implementable during textile washing and drying

|

Use stage |

Best practice |

||

|---|---|---|---|

|

Description |

Benefits (+) and Disadvantages (-) |

||

|

Washing |

Fabrics should be washed less frequently and only when it is required by the level of dirt (EU MERMAIDS, 2015[32]; Napper, Barrett and Thompson, 2020[33]). |

+ Lower energy and water consumption + Better maintenance and longer lifetime of garments. |

|

|

The use of detergent favours the release and transport of microfibres (De Falco et al., 2019[29]; Yang et al., 2019[4]; Carney Almroth et al., 2018[2]). Liquid detergents should be preferred over powder ones, which are generally more harmful to textiles and enhance microfibre release1 (EU MERMAIDS, 2015[32]; De Falco et al., 2018[16]). |

+ Better fabric care by avoiding friction - Effect on the production of detergent manufacturers with related costs to adjust their products |

||

|

Fabric softeners should be used to mitigate fibre-to-fibre friction occurring during washing and reduce fibre shedding. It has been estimated that the use of softeners reduces microfibre release by 35% (De Falco et al., 2018[16]). |

+ Better maintenance and longer lifetime of garments. - Additional costs for consumers - Not suitable for all textiles types (e.g. outdoor apparel) |

||

|

Employing laundry programs that use less volumes of water and washing full loads of textiles reduces microfibre shedding (EU MERMAIDS, 2015[32]; Lant et al., 2020[26]; Kelly et al., 2019[25]). Although more research is required in this area, it is believed that high water-volume-to-fabric ratio results in a greater wettability of the fabric and consequentially higher detachment of microfibers from the yarns (De Falco et al., 2018[16]). |

+ Lower energy and water consumption - Potential trade-offs with the effectiveness of the cleaning process. |

||

|

Low washing temperatures, shorter laundry cycles and low mechanical action (i.e. centrifuge, spin) minimise the stress mechanisms that fabrics undergo during washing (De Falco et al., 2018[16]; Hartline et al., 2016[24]; Lant et al., 2020[26]; EU MERMAIDS, 2015[32]; Yang et al., 2019[4]; Zambrano et al., 2019[34]; Dalla Fontana, Mossotti and Montarsolo, 2020[3]). |

+ Lower energy and water consumption + Reduced colour loss and dye transfer to wastewaters (Cotton et al., 2020[23]) + Better maintenance and longer lifetime of garments. |

||

|

Drying |

The usage of tumble dryers is likely to enhance fibre release. Pirc et al. (2016[10]) found that during tumble drying a fleece shirt released on average 3.5 times the number of fibres released during washing. Other researchers also hypothesized that non-natural drying and over-drying could cause fabric damage and increased microfibre release (Cesa et al., 2020[18]). However, the impact of tumble-drying on microfibre release may vary depending on the textile composition and structure, and further research is required to assess it. |

+ Lower energy and water consumption - Additional costs for tumble-dryer manufacturers to find mitigation alternatives. |

|

Notes: 1: This may be due to the presence in powder detergents of inorganic compounds insoluble in water that cause more friction with textiles, or to the higher pH of powder detergents compared to liquid ones (De Falco et al., 2018[16]).

Source: Authors’ own elaboration

Capturing and filtration devices implementable at the level of washing machines

Several capturing and filtration devices have been developed to reduce microfibre release during washing processes. The majority of existing technologies are available to consumers on the market and include devices to be added to the drum of the washing machine (in-drum capturing devices), external filtration systems to be positioned at the end of the drainpipe (add-on external filters) and built-in filters. Selected examples are described in Table 3.4 according to their type, effectiveness (in terms of % of weight reduction of microfibres released) and key characteristics.

In general, several issues need to be taken into account when considering mitigation technological solutions implementable during the use phase of garments. Additional costs for the consumer are a primary concern, as also are the degree of additional maintenance required and the ease of use. In terms of user-friendliness, particular attention has been given to the need to find solutions which prevent mishandling, for instance via the rinsing of the filter in the sink and the dispersal of microfibres into household sewage. Additional concerns are the potential trade-offs that may arise with other environmental benefits, such as the energy efficiency of the laundering process, the environmental footprint of the lifecycle of filters (e.g. production, collection, reuse or recycling, disposal) as well as their durability and the need to ensure the adequate disposal of the retained microfibres (Herweyers et al., 2020[35]).

Table 3.4. Overview of capturing and filtration devices for microfibres

|

Type |

Name |

Description |

Effectiveness |

Cost |

Benefits (+) and Disadvantages (-) |

|---|---|---|---|---|---|

|

In-drum devices |

Cora Ball |

Laundry ball with stalks to catch fibres (Cora Ball, 2020[36]) |

USD $ 37.99 |

+ Ease of use (added directly to the drum with clothing) + Could reduce overall shedding - Cannot be used with delicates - Tedious cleaning process |

|

|

Guppyfriend washing bag |

A polyamide 6.6 50×74 cm washing bag |

€ 29.75 |

+ Could reduce overall shedding + Protects fabrics during washing, potentially extending their lifetime + Low price - Can limit the maximum washing load |

||

|

Add-on external filters |

Lint LUV-R Septic SAV-R and MicroPlastics LUV-R |

Filters made of a stainless steel mesh with hole diameters of 1580 µm (Lint LUV-R) or 150 µm (MicroPlastics LUV-R) |

65% (Lint LUV-R Septic SAV-R) and 87% (MicroPlastics LUV-VR) (Environmental Enhancements, 2020[39]); 80% (McIlwraith et al., 2019[37]); 29% (Napper, Barrett and Thompson, 2020[33]); 65-74% (Browne, Ros and Johnston, 2020[40]); 1 |

USD $ 145 (Lint LUV-R Septic SAV-R) USD $ 180 (MicroPlastics LUV-R) |

- Unclear cleaning and maintenance |

|

PlanetCare |

Filter based on a cartridge to be replaced after approximately 20 wash cycles |

90% (Planet Care), 79% (Slovenian National Institute of Chemistry), 73% (National Research Council of Italy, Institute for Polymers, Composites and Biomaterials) (PlanetCare[41]); |

€ 9.95 (monthly subscription) € 139.50 (for 13 cartridges) |

+ Easy installation (Swedish EPA, 2018[42]) - Used cartridges need to be sent back to the producers |

|

|

Filtrol |

Reusable mesh filter with replaceable filter bag (Filtrol, 2020[43]) |

USD $ 139.99 |

+ Easy installation - Does not retain the smallest particles (Swedish EPA, 2018[42]) - Cannot be used with fabric softeners or excessive amount of detergent |

||

|

Indikon-1 |

Filter based on a cartridge to be replaced after about 100 washes |

81% 3 |

N/A |

+ Easy maintenance: the unit tells the consumer when to change the cartridge - Used cartridges needs to be sent back to the producers |

|

|

Built-in filters |

XFiltra |

Prototype filter designed to perform three actions: filtration, pump and de-watering |

N/A |

+ Removes the need for the user to purchase, install and operate an external filter unit. + No need for cartridge replacement - Unclear maintenance needs for consumers |

Notes: The table only presents a selection of examples for which sufficient information was retrieved, however additional filtration devices may exist on the market or be in the phase of development. The information on the technologies presented also only reflects the state of knowledge at the time of writing.

1: Different versions of the Lint LUV-R (Septic SAV-R and MicroPlastics LUV-VR) filter were tested by the studies presented.

2: Similarly, different versions of the Planet Care filter were tested during its developing phase.

3: Information provided by Avril Greenaway, Cleaner Seas Group, on 4 February 2021

Key advantages of filtration devices are their commercialisation, availability for implementation and ongoing continued technological improvement. However, their use remains on a voluntary basis by the consumer, so it is difficult to control their uptake and assess their effectiveness in real-life conditions, especially where more delicate cleaning and maintenance operations are required. Furthermore, the majority of these devices have been conceived for use in household applications rather than at large scale (e.g. in industrial or commercial laundering facilities), although several models could be easily adapted to allow for larger water flows.5

Common barriers and issues to be addressed in order to allow the broader implementation of filtering technologies include:

The lack of standardised test methods to assess and compare the effectiveness of available devices. While some filters have been independently tested, a clear and reliable picture of their effectiveness and durability is not yet available. The dimensional range of the microfibres retained by filter devices needs to be investigated further. It is essential to develop standardised test methods to compare the effectiveness of filters and to assess their compatibility with washing machines and with textile laundering processes.

The need for further research on the potential trade-offs and synergies with other best practices and technologies for microfibre mitigation. For instance, although using the Guppyfriend bag can ensure better fabric care, it could potentially lead consumers to wash full loads less frequently.

The need for the provision of information on adequate maintenance practices. For some in-drum filters currently on the market, it is recommended that these are cleaned when fibres or entanglements are visible. Where maintenance or replacement of parts by the consumer is required, inadequate handling could potentially cause clogging or malfunctioning in the washing machine.

The lack of endorsement by the washing machine industry. As external filtration systems have not yet been endorsed by washing machine manufacturers, the compatibility of these devices with different types and brands of washing machines cannot be determined yet. Also, the impacts of these technological solutions on the normal functioning of the machine, notably in terms of energy/water consumption and cleaning effectiveness, are neither clear nor well documented.

The need for the adequate disposal of microfibres. It should be ensured that the disposal of microfibres, which are small in size and can be easily dispersed, is handled carefully. For instance, the PlanetCare and Indikon-1 filters use a cartridge that needs to be replaced after a certain number of washes and require customers to return the full cartridges so that these can be handled correctly. Both companies aim to reuse or recycle the used cartridges, although public information of how this aim is achieved is not yet available.

Drawing from these elements, an assessment of considerations relevant for the design of policies that mandate the adoption of filtering technologies for washing machines is included in Chapter 4.

3.2.3. Textile end-of-life stage

The current system of textile and fashion consumption is responsible for the production of more than 92 Mt of textile waste per year (Niinimäki et al., 2020[20]). The recovery of materials at the end of the life cycle of products is very low: it is estimated that 87% of the total fibre input in textile manufacturing is landfilled or incinerated and less than 1% of the materials used in textile manufacturing are recycled at the end of the lifecycle of products (EMF, 2017[46]).

Little information is currently available on the contribution of the end-of-life of textiles to overall microfibre releases. Since the mismanagement of plastic waste contributes to the emission of microplastics (see Section 1.2.2), it is likely that the inadequate management of textile waste contributes to the release of microfibres to both water and air. It is unclear to what extent recycling and reuse practices are aligned with microfibre mitigation objectives. For instance, fibre grinding, i.e. a recycling process where fibres are ground to be used in other applications such as construction, could require further evaluation with regards to microfibre release and the potential need for mitigation solutions at recycling facilities. With regards to garments made out of recycled fibres, available evidence does not provide a clear picture of trends in microfibre release in comparison with garments made of virgin fibres (Roos, Levenstam Arturin and Hanning, 2017[11]; De Falco et al., 2019[29]; Özkan and Gündoğdu, 2021[47]; De Falco et al., 2020[48]). With regards to reuse, further research is also required to ascertain whether and to what extent ageing garments have a higher tendency to shed fibres (see Section 3.2.2).

In general, further research is needed to adequately assess the impact of reuse and recycling practices on microfibre generation. Yet, given available knowledge, it is likely that the environmental benefits of reusing (or recycling) garments outweigh the potential additional microfibre leakage associated with the use of old (or recycled) garments. Reductions in textile production and waste generation, also achievable by extending the useful life of products and by keeping materials within the economy, can significantly reduce environmental impacts associated with the handling and transportation of textile waste and the demand for virgin materials.

Textile waste generation could be prevented or reduced via a number of measures, such as:

Reductions in pre-consumer textile waste generation. Between 10% and 30% of the fabric used in the manufacturing process is wasted. Additionally, incinerating unsold garments remains a common practice. Pre-production waste generation could be reduced by slowing down manufacturing rates and improving the accuracy of production via better communication between design and manufacturing (which are often in different geographical locations) (Niinimäki et al., 2020[20]). Regulatory measures can also be introduced to ban the destruction of unsold merchandise (see for instance (France, 2020[49])).

Extended lifetime of garments and reductions in post-consumer textile waste generation. A key barrier in the reduction of textile waste are practices associated with the concept of “fast fashion” (i.e. cheap manufacturing, massive production and continuous proposal of new, short-lived garments) which encourage fast disposal (Niinimäki et al., 2020[20]). Today, clothes are more and more underutilised: it is estimated that in the past 15 years, the average number of times a piece of garment is used before being thrown away has decreased by 36% (EMF, 2017[46]). Several options exist to extend the lifetime of clothing and textile materials, including creating markets for second-hand clothing. Efficient and dedicated textile collection systems are required to support reuse practices and to ensure that garments maintain their quality over their extended lifetime. Emerging business models such as product-service systems, supplier take-back schemes and sharing platforms, can play a large role in increasing the utilisation of garments and steering textile consumption towards higher sustainability (UNEP, 2020[50]).

Improved textile recycling. Several recycling practices exist for textiles and garments: conversion to cleaning and wiping rags, fibre recovery for use in new yarns, fibres re-spinning into new filaments and feedstock recycling (i.e. the polymer is broken down to its original monomers) (Piribauer and Bartl, 2019[51]). The presence of separate collection is a necessary prerequisite to enable recycling, especially to enable the larger uptake of higher value recycling opportunities. For instance, legislation in place in the EU obliges member states to collect textile waste separately by 2025 and ensure that waste collected separately is not incinerated or landfilled (EEA, 2019[52]). Measures aimed at encouraging eco-design could also facilitate end-of-life management and efficient recycling of garments, for instance by avoiding the use of multi-material textiles, which are more challenging to recycle efficiently.

3.3. Technologies and best practices implementable during the tyre lifecycle

The sections below report and assess relevant best practices and mitigation technologies applicable along the lifecycle of tyres. Section 3.3.1 discusses relevant mitigation options implementable during the design and manufacturing of tyres as well as of roads and vehicles. Section 3.3.2 assesses mitigation actions implementable during the use phase, i.e. the uptake of good practices for tyre use and maintenance and eco-driving practices, as well as broader actions aimed at reducing overall vehicle kilometres travelled. Section 3.3.3 focuses on the end-of-life phase and outlines relevant best practices for the maintenance of artificial sports turfs.

3.3.1. Product design and manufacturing

Mitigation technologies and best practices related to material design intend to reduce the tyre wear rate. This can be achieved either by optimising tyre tread and road pavement characteristics or by reducing vehicle weight (Table 3.5).

Table 3.5. Overview of mitigation actions relevant for TRWP and implementable during product design and manufacturing

|

Mitigation action |

Description |

Advantages (+) and Disadvantages (-) |

|---|---|---|

|

Optimisation of tyre tread characteristics and dimensions |

Tyre characteristics influence the tyre tread wear rate. The optimisation of tyre design in line with lower tyre tread wear, without compromising on other relevant characteristics of tyres, is expected to substantially reduce TRWP generation. |

+ Potentially high impact + Potential prolonged lifetime of tyres + No time-intensive adaptation of infrastructure needed - Currently, trade-offs with safety concerns and other desirable characteristics of tyres - Requirements for tyre design depend also on vehicle type |

|

Optimisation of road design and road surface characteristics |

Since the characteristics of roads (i.e. the road design, the texture of the pavement and the types of road markings employed) influence wear, these could be optimised to allow for lower tyre tread wear rates. |

+ Potentially high impact + Reduction in noise levels - High costs and limited implementation potential (for road pavement replacement) - Trade-offs with safety and durability concerns - Further research required in some areas (e.g. road pavement optimisation with regards to tyre wear) |

|

Reduction in vehicle weight |

A shift towards lighter vehicles (or a reversal of trends towards heavier ones) can reduce TRWP generation. |

+ No changes in infrastructure required + Lower fuel consumption - Vehicle weight depends in part on consumer preferences - Transition into e-mobility may lead to an increase in average vehicle weight and TRWP generation |

Source: (Andersson-Sköld et al., 2020[53]; OECD, 2020[54]; Pohrt, 2019[55])

Optimisation of tyre tread characteristics and dimensions

Tyre characteristics, such as the dimension and the mechanical properties of the tread, influence the tyre wear rate. Mitigation measures may target an increase in stiffness ratio between tread and carcass. For instance, a wider tread and a low tread sea volume could result in decreased TRWP generation (Klüppel, 2014[56]). Wider tyres exert less pressure against the road surface and cause less abrasion, although this is partially offset by the larger contact area with the road surface. In general, wider tyres are expected to have slightly lower abrasion rates compared to narrow tyres (Pohrt, 2019[55]).

Efforts are ongoing to improve the eco-design of tyres in line with microplastics mitigation. These generally entail optimising design parameters to enhance resistance to abrasion, as well as replacing potentially hazardous chemicals employed during production in order to minimise the toxicity of emitted TRWP. Improvements in material design should not only respond to safety concerns but also ensure tyre durability resulting in longer tyre life, potentially reducing the resource requirements for tyre production. Tyres are designed to achieve a balance between safety and environmental performances, such as abrasion, braking, wet grip, rolling resistance and noise. With current technologies, these performance characteristics are variously antagonistic to each other. The development of innovative solutions in tyre design will be required in order to see significant reductions in the rate of tyre wear whilst preserving high standards in other performance areas. Policy interventions could be considered to incentivise or mandate the development of low abrasion tyre tread materials (see Chapter 4).

Tyre type and dimension are usually selected according to the vehicle type. Global car markets have witnessed a trend towards larger and wider tyres (which are generally in line with lower tyre tread wear), yet this came with concurrent increases in the average vehicle weight and power (which generally lead to higher tyre wear) (Li, 2018[57]). As the share of e-mobility in the vehicle fleet is expected to increase in the near future, tyre design may be adapted to minimise tyre wear. Certain recent innovations aim to reduce rolling resistance and increasing the vehicle mileage in order to reduce overall tyre tread wear (Continental, 2019[58]). The use of airless tyres, which cannot be operated with incorrect pressure conditions (see Section 3.3.2), may also contribute to reducing emissions in the future.

Optimisation of road design and road surface characteristics

The design of road infrastructure and the characteristics of traffic impact tyre wear by influencing the conditions in which vehicles are operated. Road design characteristics (e.g. curves, hills) can be optimised so as to mitigate TRWP generation. For instance, tyre wear abrasion that occurs at curves may be reduced by increasing the roadway inclination in curves (Klüppel, 2014[56]). Another influencing factor is the extent to which road features lead to frequent and large speed changes, for instance due to the presence of traffic lights (Andersson-Sköld et al., 2020[53]). Further, the choice of road markings (and of the application method) can also mitigate the rate of wear (Andersson-Sköld et al., 2020[53]). Not only different types of road markings are wear-resistant to different degrees, but they also may directly contribute to microplastics pollution. Lastly, as damaged road pavements may lead to higher tyre wear, adequate road surface maintenance could substantially contribute to TRWP mitigation. Key stakeholders involved in the partial or full implementation of optimised road pavement and infrastructure characteristics are road authorities and municipalities as well as the construction industry.

The structure of the road pavement also affects tyre and road wear. Coarser textures are expected to cause higher road wear compared to smoother surfaces and asphalt roads generally cause a lower wear rate than concrete pavements (Pant and Harrison, 2013[59]). The roughness of the pavement micro-texture is the main driver of wear in the road surface, while the macro-texture has a minor influence (Andersson-Sköld et al., 2020[53]). In general, there is a trade-off between improved resistance to road wear and safety: the micro-texture may be adapted to reduce tyre wear, however this might lead to reduced friction and thereby safety.

Several studies are ongoing to address this conflict and test innovative pavements optimised for lower tyre and road wear. For example, the Danish Road Directorate has been working on developing a road pavement that reduces the rolling resistance between vehicles and road pavements, to explore solutions to reduce road transport GHG emissions. Tested pavements have shown a reduction in rolling resistance, resulting in reduced fuel consumption, without significant compromises on safety requirements and durability (Pettinari, Lund-Jensen and Schmidt, 2016[60]).

Although the implementation of such road pavements is associated with higher costs, it also leads to a lower noise level and it may benefit from higher acceptability by municipalities, road authorities and the public (Pettinari, Lund-Jensen and Schmidt, 2016[60]). This technology is not yet state-of-the-art and further research and development is needed, in particular to improve durability, before implementation will be possible. Once innovative road pavements are available, it may be advisable to apply these in areas with particularly high tyre wear abrasion rates, for instance on congested roads or on high-speed motorways. For the time being, given the well-known relationship between the state of road surfaces and rolling resistance, adequate road maintenance to preserve smooth and even surfaces can be an effective strategy to reduce the production of TRWP (ETRMA, 2018[61]).

Reductions in vehicle weight

As vehicle weight increases, so does the frictional force between tyres and road surfaces and therefore the generation of TRWP. Yet, trends in the composition of the vehicle fleet show a tendency towards a higher proportion of larger and heavier vehicles (Andersson-Sköld et al., 2020[53]). Additionally, electric vehicles also tend to be heavier than their traditional counterparts, mainly due to the weight of batteries (Timmers and Achten, 2016[62]). As a result, total emissions of TRWP are projected to increase at a higher rate than the increase in traffic (Andersson-Sköld et al., 2020[53]). The higher torque (rotational force) of electric cars compared to their traditional counterparts may also lead to increased tyre wear during acceleration (Soret, Guevara and Baldasano, 2014[63]).

Reductions in vehicle weight may be achieved by the application of advanced lightweight materials in cars (Serrenho, Norman and Allwood, 2017[64]). Aluminium alloys are commonly used as replacement materials, as they provide similar performance properties as steel with lower weight (Hirsch, 2011[65]). However, these advanced materials generally require a greater amount of energy to manufacture and recycle and further research and development is required to enable their larger uptake in vehicle production (Raabe, Tasan and Olivetti, 2019[66]). More broadly, measures aimed at encouraging or incentivising the uptake of lighter vehicles as well as reducing overall volumes of road traffic (as discussed in Section 3.2.2) may significantly contribute to reductions in air pollution and in GHG emissions, while also generating co-benefits in terms of TRWP pollution mitigation (see Chapter 4 for a discussion of relevant policy instruments).

3.3.2. Tyre use stage

Mitigation actions implementable during the use phase include the optimisation of vehicle operation parameters such as tyre pressure, wheel alignment, vehicle load, vehicle speed, driving conditions, driving behaviour and reductions in total transport volumes (Table 3.6). The advantages and disadvantages of each mitigation action are discussed below. Importantly, several mitigation best practices and technologies implementable during the use phase generate numerous synergies with other relevant benefits and environmental policy objectives.

Table 3.6. Overview of mitigation actions relevant for TRWP and implementable during the use phase of tyres

|

Mitigation action |

Description |

Advantages (+) and Disadvantages (-) |

|

|---|---|---|---|

|

Optimising vehicle maintenance |

Ensuring correct tyre pressure and/or implementing technologies to monitor it on vehicles |

Since low or incorrect inflation pressure leads to greater tyre wear (Salminen, 2014[67]; Wang et al., 2016[68]; Li et al., 2011[69]), ensuring adequate tyre pressure can limit TRWP generation. Automatized monitoring systems for tyre pressure may help to ensure optimal pressure conditions. |

+ Easy to implement: simple regular pressure check and no additional infrastructure required + Potentially high impact + Policy action already underway (e.g. requirements for pressure monitoring systems in the EU) (EC, 2010[70]). + Improved fuel efficiency |

|

Ensuring correct wheel alignment |

Incorrect wheel alignment leads to higher tyre tread abrasion (and fuel consumption). Thus, regular and/or stricter checks on the alignment of vehicle wheels can mitigate TRWP generation. |

+ Potentially high impact + Low costs (no additional infrastructure required) + Improves fuel efficiency - Requires regular vehicle inspections - Impact also depends on correct tyre pressure |

|

|

Eco-driving |

Reducing vehicle speed |

The emission of TRWPs increases with speed. Speed determines the level of mechanical stress in the tyre material and thus directly influences the degree of tyre wear (Gustafsson et al., 2009[71]; Li et al., 2011[69]; Wang et al., 2016[68]). Thus, measures aimed at reducing vehicle speed, such as the introduction and enforcement of speed limits, can mitigate TRWP generation. |

+ High impact + Low costs (no additional infrastructure needed) + Co-benefits with increased safety, lower fuel consumption and lower air pollution - Necessary measures require public acceptability - Policy measures require greater enforcement efforts - Potentially longer travel times |

|

Adapting driving behaviour |

Aggressive driving styles, rapid deceleration and complete stops generate considerable amounts of TRWP compared to gradual acceleration and deceleration. Hence, a higher uptake of eco-driving practices, including with the aid of advanced driver-assistance systems, can mitigate TRWP generation. |

+ High impact + Co-benefits with lower fuel consumption, lower air pollution, increased safety and reduced noise levels - High implementation barriers |

|

|

Reducing traffic |

Reducing traffic volumes |

Reductions in vehicle traffic via policy disincentives and/or the provision of alternative transport infrastructure can reduce the overall quantities of TRWP generated. |

+ Potentially high impact + Lower air pollution - Absent compensating measures, policy disincentives may generate distributional effects - Long implementation timeframe - Additional infrastructure potentially needed |

Optimising vehicle maintenance: tyre pressure and wheel alignment

Maintaining optimal pressure in vehicle tyres throughout their use can optimise performance as well as minimise TRWP generation. If the tyre pressure is too low, internal heat generation occurs, which increases wear (Li et al., 2011[69]). Over-inflation, on the other hand, leads to uneven tyre tread wear, which can reduce the lifespan of a tyre. In OECD countries, the share of the vehicle fleet operating with suboptimal tyre pressure could be significant. For instance, it was calculated that in Sweden one in seven cars has at least one tyre with an air pressure which is 30% too low, causing higher tyre wear (Andersson-Sköld et al., 2020[53]).

Tyre pressure monitoring systems (TPMS) have been introduced on passenger cars in several OECD countries and provide one technological solution to the problem. These are electronic systems designed to monitor tyre pressure and to report real-time information to drivers when the tyre requires to be inflated. Verschoor and de Valk (2017[72]) estimated that equipping all Dutch cars with a TPMS would lead to a 14% reduction in tyre wear. Since 2014, newly registered cars in the EU are fitted with TPMSs (EC, 2010[70]). Still, as regular pressure tests are not always performed, older vehicles registered in the EU before November 2014 may operate under non-optimal tyre pressure conditions. Where measures for TPMS have been introduced, it is expected that the number of cars operating with sub-optimal tyre pressure will decrease as older cars without pressure monitoring system are removed from the market.

Incorrect wheel alignment may increase tyre wear rates by up to 10% (Verschoor and de Valk, 2017[72]). The share of the vehicle fleet operating with incorrect wheel alignment can also be significant: in Germany, for instance, 15% of vehicles operate with incorrect wheel alignment (Kraftfahrtbundesamt, 2019[73]). Tests on wheel alignment are generally done during the change of tyres, e.g. from summer to winter tyres. In countries or regions where seasonal changes of tyres are not required, alignment checks occur less frequently. Yet, regular testing and wheel realignment is a relevant option that can increase the lifetime of tyres (without adaptation of infrastructure) and also reduce tyre wear.

Eco-driving and traffic flow management: vehicle speed and driving behaviour

Driving behaviour is one major parameter influencing the tyre wear rate. Higher speeds, fast acceleration and fast retardation and high cornering speeds in particular are associated with increased tyre wear (Pohrt, 2019[55]). Changes of direction, congestion and high-speed roads are also generally associated with higher TRWP generation (Andersson-Sköld et al., 2020[53]).

Significant reductions in TRWP can be achieved by encouraging drivers to adopt eco-driving practices, i.e. maintaining lower and constant speeds. Since tyre wear rate increases by a factor of four relative to increases in speed, speed reductions hold a high mitigation potential (Pohrt, 2019[55]). Examples of specific measures include the introduction and effective enforcement of local speed limits of cornering roads as well as of motorways, measures to improve driver awareness, the use of advanced driver-assistance systems, such as cruise control and adaptive distance control and general traffic management measures.

Speed reduction will be relevant either to reduce or better enforce existing speed limits or to introduce (nationwide or local) measures where these are not present (e.g. in Germany). Implementation costs would be relatively low as only limited infrastructure would be required, however public acceptability is likely to be the main implementation barrier to the introduction or adaptation of speed limits. For this reason, it will be important to share with the public and policymakers scientific evidence on the adverse consequences of speeding in terms of potential safety and on the environmental gains which can be achieved via speed limits.

Although measures aimed at reducing speeds are primarily driven by safety concerns, a reduction of tyre wear rates can be achieved as a co-benefit, for instance as a result of smoother driving with continuous traffic flow instead of stop-and-go traffic. These measures also generate significant synergies with environmental objectives, such as reduced fuel consumption and lower emissions of CO2 and air pollutants (e.g. NOx and particulate matter). The adoption of eco-driving practices and smart road management can reduce fuel consumption up to an average of 6.3%, with consequent reductions in CO2 emissions (Wang and Boggio-Marzet, 2018[74]). Further evidence is required in order to quantify potential reductions in tyre wear emissions achievable via improved driver awareness and traffic management.

Reducing transport volumes

Several options exist to mitigate TRWP emissions via overall reductions in traffic volumes. These are not unique to TRWP generation, rather have been discussed extensively in order to respond to needs to mitigate GHG emissions and air and noise pollution, limit sealed surfaces in urban areas in order to allow rainwater to seep away and prevent floods, decrease the amount of urban space occupied by road traffic and reduce congestion.

In order to decrease transport volumes, overall higher accessibility can be delivered by increasing the role of transport modes such as public transport, cycling and walking (which generate less TRWP per capita); ultimately increasing TRWP mitigation potential while also improving other well-being (e.g. health, equity) goals (OECD, 2019[75]). The promotion of modal shifts requires adequate infrastructural investments for sustainable transport modes, for instance via the construction of advanced railroad systems to increase ridership and capacity of public transportation systems. Urban areas can also be designed in compact ways so as to reduce dependence on private vehicle travel. In general, creating proximity between people and places is key to avoiding unnecessary trips or unnecessarily long distances and to increasing the scope for active and public transport (OECD, 2019[75]).

A reduction in total traffic and total mobility should be considered a long-term goal that requires parallel adaptations of transportation systems and urban forms. Notable drawbacks of traffic reduction measures include the need for public acceptability as well as potentially high implementation costs and the potential for distributional effects. Again, these can be greatly reduced if policy and investments are refocused on the enhancement of accessibility. To the extent that traffic reduction also reduces local air pollutants and GHG emissions, policies that seek to reduce TRWP via a reduction in vehicle-kilometres travelled also have environmental health and climate mitigation co-benefits. Furthermore, by incentivising active travel and enhancing accessibility, particularly for vulnerable population, policies that generate “avoid” and “shift” effects can also bring additional health benefits as well as contribute to more equitable access to services and opportunities (OECD, 2019[75]).

A number of cities around the world have implemented traffic reduction schemes aimed at improving air quality, quality of life and safety. For example, Strasbourg, Nurnberg, Copenhagen, Vienna and Ghent have successfully implemented traffic calming measures (EC, 2004[76]). Other options may include the re-allocation and re-design of streets, parking and road pricing, expansions and upgrades of public transport and active mode services, or incentives for the uptake of shared services. Such measures usually reduce vehicle traffic while promoting other modes of transport as cycling and public transport (Titos et al., 2015[77]). Although these measures are not typically implemented in order to mitigate microplastics, reductions in TRWP will occur as a co-benefit.

3.3.3. Tyre end-of-life stage

As discussed in Chapter 2, End-of-Life Tyres are commonly employed in material recovery applications, including for the production of rubber granulate used as infill in artificial sport pitches or in moulded surfaces used in playgrounds and outdoor facilities. The use of rubber granulate as infill material for sport pitches offers improved durability and resistance to varying weather conditions, good shock absorbance and safety characteristics, low costs and a lower need for virgin materials (Magnusson et al., 2016[78]). Yet, several studies have indicated that sport pitches may constitute a significant source of microplastics pollution (see Section 2.3.2).6

Guidelines have been developed to support the prevention of rubber granulate leakage in the design and operation of artificial turf pitches (Fidra, 2020[79]; EuRIC, 2020[80]; CEN/TR, 2020[81]). Selected options, presented in Table 3.7, include several low-cost, high-potential mitigation actions. Examples include the installation of infrastructure which prevents the emission of rubber granulate particles (e.g. side paved areas around the pitch, cattle grids and brushing stations located near the pitch entrance, drainage and filtration systems for runoff) and the routine maintenance of the pitch (EuRIC, 2020[80]; Eunomia, 2018[82]). The lack of awareness among owners and operators as well as the lack of regulatory or financial incentives may be posing barriers to a larger uptake of the identified mitigation best practices and technologies.

Table 3.7. Overview of best practices and technologies for the prevention of microplastics leakage during the operation of artificial sports pitches

|

Best practices and technologies |

Description |

Advantages (+) and Disadvantages (-) |

|---|---|---|

|

Design and installation |

||

|

Optimisation of pitch layout |

Installation of solid side pavement around the pitch, from which scattered infill material can be easily collected. |

+ Potentially high impact - Requires infrastructural changes - Mostly relevant for new pitches |

|

Installation of physical barriers around the pitch with a board at the bottom |

Physical barriers (e.g. fences, side perimeters) have proved successfully at preventing particles leaving the pitch. |

- Requires additional infrastructure + Synergy effects with safety e.g. sport equipment may not fly outside the pitch |

|

Installation of brushing stations for players’ shoes and of boot cleaning mats/grates at pitch entrance points |

The installation of brushing stations at the exit of the pitch can enable the cleaning of shoes and prevent the material from being carried away outside the pitch. The use of grates and/or scraper mats can also help with the removal of rubber granulate from players’ shoes. |

+ Low-cost structural adaptations of existing pitches + Potentially high impact + Can easily be retrofitted on existing pitches |

|

Maintenance |

||

|

Regular brushing and drag matting |

Regular brushing and drag matting of the field ensures that the dispersed infill is returned to the field |

+ Required to ensure pitch performance and player safety + Brushing also minimises compaction (and the need for additional rubber infill) + Extends lifetime of the pitch |

|

Installation of drainage slit traps |

Drainage water is collected and treated before discharge. This can be achieved via the use of traps for granulates. |

+ Potentially high impact - Can be retrofitted - Requires continued maintenance in order to be effective |

|

Separate collection and treatment of surface water |

Surface water runoff is collected separately from drainage water. It can be treated to collect particulate materials |

+ Potentially high impact - Requires additional infrastructure - Mostly relevant for future pitches |

|

Snow clearance: use of dedicated storage areas or piling on the pitch |

Removed snow should be stored in dedicated areas that allow for the collection of the infill once the snow melts. Where this is not possible, snow can be piled on (potentially winter-lined) pitches, so that microplastics mixed with snow are not dispersed. |

+ Simple adaptation of the pitch operation + Prevents a deterioration in the pitch infill + High impact where snowfall is significant - Requires space for snow storage (or the temporary reduction in the pitch size). |

Source: (EuRIC, 2020[80]; CEN/TR, 2020[81])

3.3.4. Comparison of mitigation options for tyre-based microplastics

Potential mitigation best practices and technologies for tyre-based microplastics are evaluated in Table 3.8 according to three criteria: mitigation potential, implementation efforts required and costs and the societal impact. In general, progress in tyre and pavement design in line with lower wear rates offers a high mitigation potential, although the development of optimised tyres and road pavements without compromises in safety, noise and durability may take some time. During the use phase, reduced vehicle speed, adapted driving behaviour and adequate maintenance of vehicle and tyres also have a high TRWP reduction potential. At the same time, since complete prevention of TRWP generation and emission cannot be achieved by optimized materials, end-of-pipe options may be important solutions to retain the emitted TRWP before these enter the environment. There, case-by-case designs may be required for the installation or adaptation of stormwater and road runoff treatment options, as discussed in Section 3.4.2.

Table 3.8. Assessment of mitigation best practices and technologies according to selected criteria

Values are assigned based on the three criteria: mitigation potential, implementation efforts required and costs, and the societal impact. The table is colour coded from red (higher barriers to implementation) to green (easier implementation and higher mitigation potential).

|

Mitigation potential |

Implementation efforts required and costs |

Societal impact |

Stakeholders |

|

|---|---|---|---|---|

|

Optimisation of tyre design |

High |

Medium-High |

Medium-Low |

Tyre and car manufacturing industries |

|

Optimisation of road design |

High |

Medium-High |

Medium-Low |

Public authorities, municipalities, road infrastructure developers |

|

Reductions in vehicle weight |

Medium-High |

Medium |

Medium-High |

Car manufacturing industry, consumers, state |

|

Tyre pressure optimisation |

Medium-High |

Low |

Medium |

Car and tyre manufacturing industries, consumers, public authorities |

|

Wheel alignment optimisation |

Medium |

Low |

Medium |

Consumers, public authorities |

|

Eco-driving and traffic flow management |

High |

Medium |

High |

Consumers, public authorities |

|

Reductions in total transport volumes |

Very High |

Medium-High |

High |

Public authorities, municipalities, regional transport authorities, consumers |

|

Direct particle collection and street sweeping |

Medium |

Medium |

Low |

Communities, industry |

|

Improved stormwater management and treatment |

Very High |

Medium-High |

Low |

Public authorities, municipalities |

|

Artificial turf pitch operation |

Medium-High |

Medium-Low |

Low |

Pitch operators, customers, municipalities |

Note: End-of-pipe mitigation options relevant for TRWP are discussed in Section 3.4

Source: Authors’ own evaluation based on (Andersson-Sköld et al., 2020[53]; Eunomia, 2018[82])

3.4. End-of-pipe mitigation technologies and best practices

End-of-pipe options, such as (potentially separate) wastewater and stormwater collection and treatment, constitute a last barrier to pollutants present in contaminated water sources and play a critical role in preserving water quality. The performance of end-of-pipe technologies in removing microplastics is only of recent interest and not yet fully understood. Existing treatment processes for wastewaters generally retain the majority of microplastics initially in the wastewater effluents. However, in an attempt to improve their overall performance in retaining a range of water pollutants (including microplastics), there is interest to explore ways to enhance the treatment efficiency further. Additionally, substantial quantities of microplastics enter the environment via diffuse pathways (i.e. dry and wet deposition, road and stormwater runoff). In this sense, end-of-pipe options such as improved stormwater management, generally driven by the need to manage increased runoff rates caused by urbanisation, can also contribute to the preservation of water quality.

The next sections explore existing facilities and technologies that can be adopted to enhance the capture of microplastics carried in domestic and industrial wastewaters (Section 3.4.1) and in road dust and stormwater runoff (Section 3.4.2).

3.4.1. Wastewater treatment and sewage sludge management

Treating municipal wastewaters in a wastewater treatment plant (WWTP) is the norm in OECD countries. WWTPs purify used water resources from pollutants originating from human activities and rainwater runoff before these are reintroduced into the water cycle, preventing the spread of pollutants and bacteria hazardous to human health and the environment.

Each WWTP involves selected combinations of chemical, physical and biological processes taking place simultaneously or interacting, in order to achieve a final effluent which is in line with existing regulations for water reuse or release into the environment. Depending on the stringency of the regulations in place and other location-specific characteristics (e.g. availability of space, capacity of treatment, types and concentrations of pollutants and features of the receiving water body such as the dilution capacity and sensitive uses), WWTP may be designed to have unique combinations of preliminary, primary, secondary and tertiary (and potentially additional) treatment stages. When required, old WWTPs are retrofitted (via the addition and/or replacement of some treatment units) to enable compliance with more stringent standards.

Although several knowledge gaps remain (Box 3.1), some indicative conclusions can be drawn from available data on the fate of microplastics during WWT. Table 3.9 describes the main objectives to be attained during each stage of the treatment process in a conventional setup and outlines the expected microplastics stage removal rate. Conventional WWTPs can achieve microplastics retention rates of 80-95% (by number), likely mostly attained in preliminary and primary treatment steps (e.g. screening, removal of grit and grease).7 WWTPs with tertiary treatment8 show only marginal higher efficiency at retaining microplastics compared to plants with only secondary treatment, although this might vary depending on the specific technologies in place (Talvitie, 2018[83]; Nikiema, Mateo-Sagasta and Saad, 2019[84]). The effectiveness of the process in terms of microplastics removal seems to be more affected by the size rather than type of the particle, with smaller particles being more difficult to remove (Lv et al., 2019[85]; Talvitie et al., 2017[86]).

Table 3.9. Conventional treatment of wastewater: objectives, performance in terms of microplastics removal and costs

|

Preliminary |

Primary |

Secondary |

Tertiary/Advanced |

Disinfection |

||

|---|---|---|---|---|---|---|

|

Objective |

Removal of coarse particles |

Removal of floatables, grit, grease, some suspended solid matter, heavy metals and other pollutants. |

Removal of biodegradable organic matter and suspended solids |

Removal of contaminants (e.g. nitrogen) affecting the quality or a specific use of water |

Deactivation of pathogens (e.g. bacteria and viruses) |

|

|

Typical processes employed |

Screening to remove large items Grit removal Skimming of grease Coagulation and flocculation Primary sedimentation Flotation |

Activated sludge + secondary sedimentation, Oxidation ditch Anaerobic/Anoxic/Oxic process |

Biological aerated filter (BAF) Rapid sand filter Filtering disks |

Contact with chlorine, ozone, or ultraviolet radiation |

||

|

Membrane bioreactors |

||||||

|

Performance |

||||||

|

For conventional pollutants |

Debris and floatable materials (depending on design target) |

|

BOD and TSS: typically 85%-95% removal |

|

Typically over 99% |

|

|

For MPs: cumulative [per stage] removal rate |

42 - 82% |

16 - 98% [-293%1 - 99.7%] |

79 - 99.9% [54 - 84%] |

79 - 99.9% [< 1%] |

||

|

Fate of microfibres |

Negligible removal |

Highest removal achieved during this stage, through:

|

Some removal is achieved at this stage, but exact removal mechanisms are uncertain. |

Could remove fine microfibres |

Variable, it could cause physical and chemical alteration of microplastics |

|

|

Fate of micro fragments |

Negligible removal |

Removed by sedimentation |

Trapped in flocs and removed during the secondary sedimentation |

Small particles are well removed by filtration |

Variable. Could cause physical and chemical alteration of microplastics |

|

|

Costs |

||||||

|

Investment & operational costs (US example) |

Sewer and secondary treatment plant (in the US): Average investment and O&M costs are 3,308 and 437 USD per m3/d, respectively (2017) |

Sewer and tertiary treatment plant (in the US): Average investment and O&M costs are 57,534 and 6,168 USD per m3/d, respectively (2017). |

||||

Notes: m3/d stands for cubic meters treated per day

1: Some WWTP do not involve secondary sedimentation (i.e. the clarification done after a secondary bioreactor) to enable the removal of the microplastics from the effluents. With sludge recirculation, microplastics concentrations actually increase in the treatment unit. In those cases, removal would be done in a tertiary filtration unit.

Source: Adapted from (Nikiema et al., 2020[87])

Box 3.1. Data limitations for assessing the microplastics removal rate of WWT processes

Associating a certain microplastics removal rate to specific parameters, such as the type of treatment process employed, can be challenging. This is for several reasons, including:

The quality and availability of the data. There are concerns related to the quality of some available data on microplastics’ removal in WWTPs. The majority of available studies build on one-time measures and replications are scarce. This is an issue since there could be a wide temporal and spatial variation in influent and effluent wastewater quality from one or different countries and studies.