From production through to consumption and disposal, plastics interact with the economy and the environment in a multitude of complex ways. Understanding these complexities is critical for identifying challenges and formulating effective policies. This chapter aims to quantify plastic flows in the economy and their impacts on the environment. It begins by discussing the methodology used, before presenting estimates and analysis of the key steps and impacts throughout the plastics lifecycle.

Global Plastics Outlook

2. Plastics flows and their impacts on the environment

Abstract

KEY MESSAGES

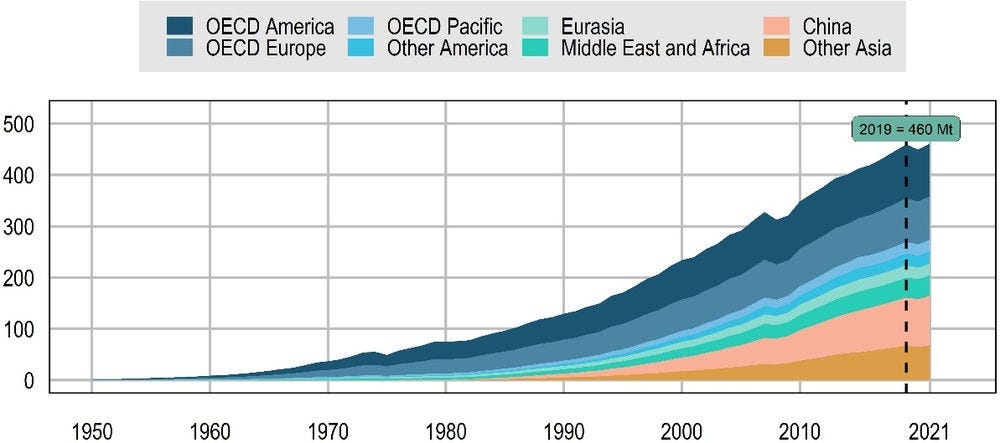

Annual global use of plastics, including fibres and additives, has been growing continuously, reaching 460 million tonnes (Mt) in 2019. Plastics in packaging, construction and transportation together account for more than 60% of the weight of plastics use.

The current use of plastics is far from circular. Of the 353 Mt of global plastic waste generated globally in 2019, only an estimated 55 Mt were collected for recycling, 22 Mt of which were disposed. Secondary plastics accounted for barely 6% of total plastics use in 2019. In total, 67 Mt of plastic waste and residues globally were incinerated in industrial facilities and 174 Mt were disposed of in sanitary landfills. The amount of mismanaged and littered plastic waste is increasing and has reached 82 Mt per year. Of this, only 3 Mt is collected for proper disposal by litter clean-up measures.

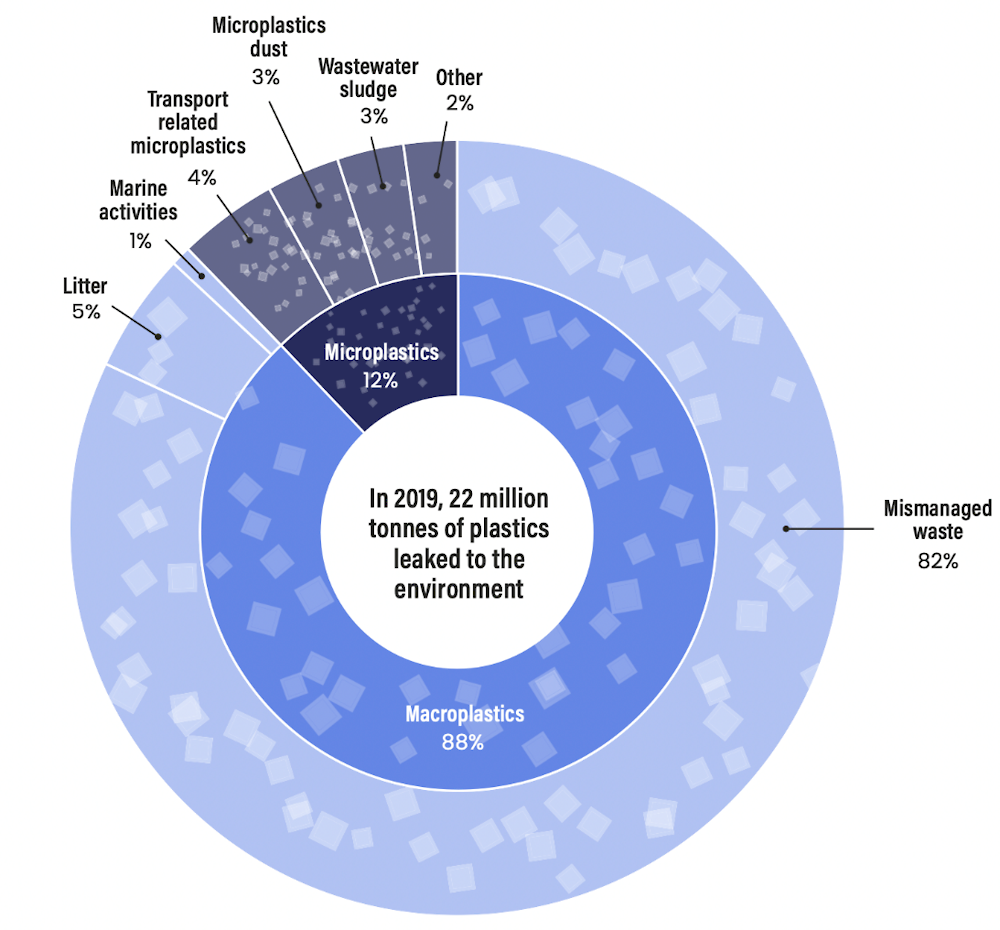

Widespread plastics use and inadequate prevention measures have led to persistent plastic leakage. In 2019 an estimated 22 Mt of plastics leaked into the environment. The largest leakage source (82%) is mismanaged waste, i.e. waste that is inadequately disposed of. Other sources are abrasion and losses of microplastics (12%), littering (5%) and marine activities (1%).

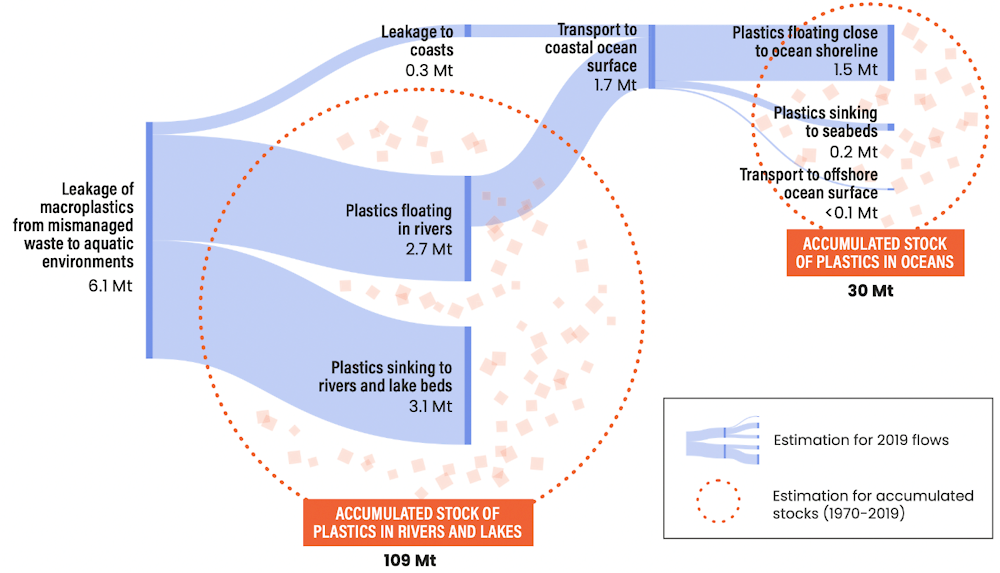

Rivers are the main route by which plastics enter the ocean, but the process can take years or even decades. In 2019, 6.1 Mt of plastic waste are estimated to have ended up in aquatic environments, of which 1.7 Mt flowed into the ocean. This brings the total accumulated stock of plastics in aquatic environments in 2019 to 139 Mt. While the estimated inflows are lower than earlier studies that do not account for the residence time of leaked plastics in rivers, the amount is still alarming.

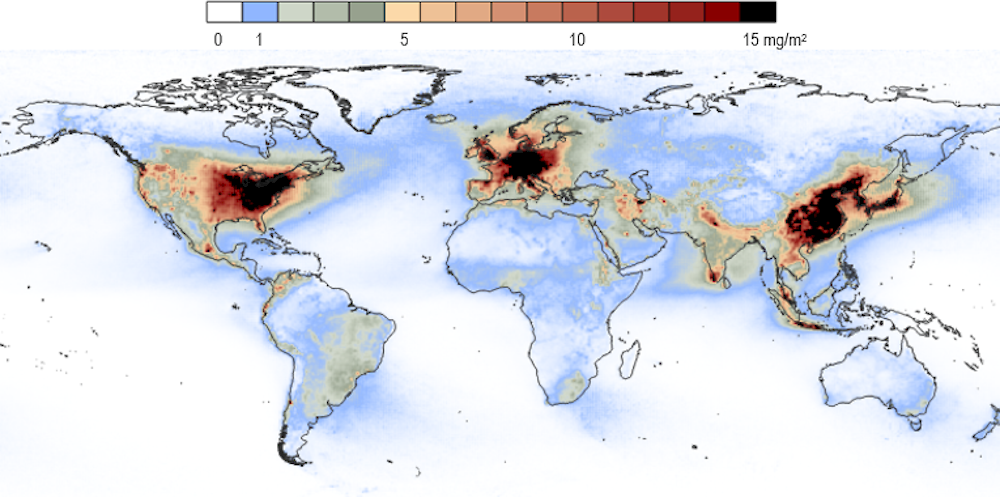

Microplastic emissions from tyre and brake wear particles add to air pollution in highly urbanised regions, but are also transported to remote places, such as the Arctic where they have implications for climate change.

Greenhouse gas emissions from the plastics lifecycle in 2019 are estimated to be 1.8 billion tonnes, or 3.4% of global emissions, with 90% of these emissions from the production and conversion of plastics from fossil fuel feedstock.

Overall, these quantified insights, combined with an emerging understanding of the environmental, health and economic impacts, underline the need for an extensive policy package and international co-operation to make plastics more circular throughout the value chain.

2.1. The methodology to compose the OECD Global Plastics Outlook Database

Although the literature offers in-depth research on plastics use and plastic waste, a number of gaps are hindering the analysis of the current situation and decision making by policy makers. The literature on plastics use is limited either to the global level (Geyer, Jambeck and Law, 2017[1]), to plastics production (IEA, 2018[2]), to a specific year across regions for a specific application or sector (Ryberg et al., 2019[3]) or to a specific region (Plastics Europe, 2020[4]). A key gap is the limited information on flows of secondary plastics. Moreover, the scope and volumes covered by the various studies differ. For example, some sources exclude fibres despite being a significant part of overall plastics.

There is also a lack of information on the management of waste across the world, and especially the management of individual waste streams such as plastics. Definitions, available data, measurement methodologies and framework conditions differ widely between countries, even for countries within the OECD. Recycling rates are often inconsistently reported, for instance national and municipal statistics tend to focus on the weight of household waste collected, and sometimes include commercial waste when it is collected by municipalities. Industrial waste statistics may include pre-consumer waste and typically rely on sampling and extrapolation using methodologies that differ in each country. Recycling can also refer to different concepts: quantities that are collected for recycling, material sent for reprocessing, or material ultimately available for use as a secondary plastic. Furthermore, reported recycling rates may give an overly optimistic view of the current status because they focus on polymers such as PET and applications such as packaging, for which recycling is already established. By contrast, recycling rates of hard-to-recycle plastics such as fibres are rarely reported. Countries with poor waste management infrastructure also have the weakest published data, making it challenging to assess the amount of mismanaged waste. This results in an incomplete view of the current international management of plastic waste.

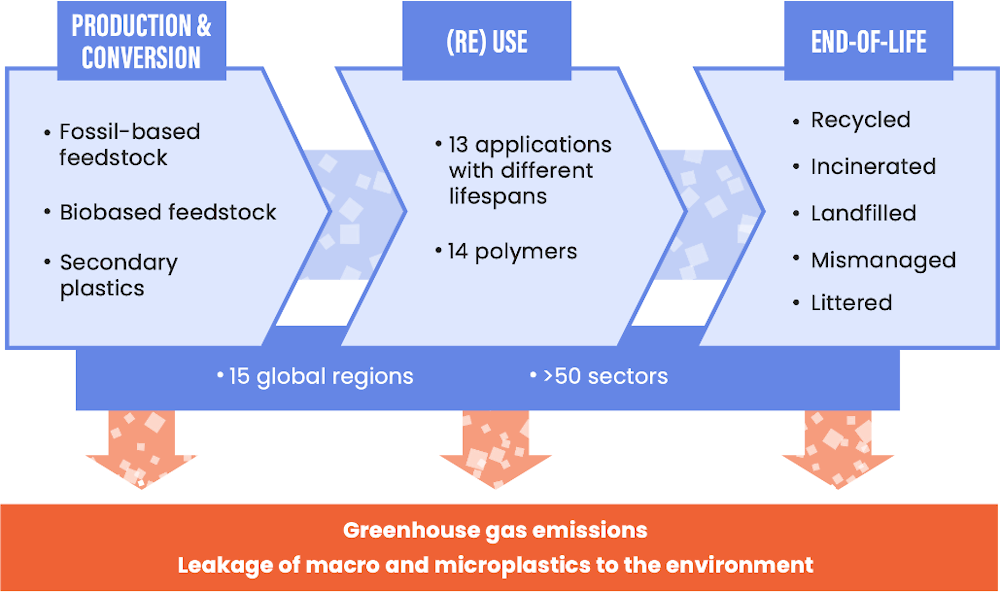

The Global Plastics Outlook aims at understanding the drivers of plastics use and the impacts on the environment in order to find the best way to reduce the environmental pressures of plastics production, waste generation and management. As a first step, the OECD has developed the Global Plastics Outlook Database1 to fill the information gaps and provide a comprehensive overview of the entire lifecycle of plastics. The database collects and reconciles data for the full lifecycle of plastics across the world: production, use, waste generation and waste management, including waste that is mismanaged or leaked to the environment (Figure 2.1).

The added value of the database is to gather plastic indicators in a coherent framework. The database was developed through a collection and reconciliation of renowned databases, review of the existing literature and expert input. This information was then integrated in an economic modelling framework, which ensures that all data sources are consistent and allows for analysis of the economic drivers and environmental effects of plastics. To this end, the OECD ENV-Linkages model (Chateau, Dellink and Lanzi, 2014[5]), based on the Global Trade Analysis Project (GTAP) database2 (Aguiar et al., 2019[6]), has been revised and expanded to link plastics data in volumes to the economic flows in the model. ENV-Linkages splits plastics production into primary plastics and secondary plastics technologies and maps plastics use by polymer and application to the model sectors.

Figure 2.1. The OECD Global Plastics Outlook Database

The data and methodology used for each step are summarised in Table 2.1 and more details are provided in Annex A. The database spans the history of the large-scale industrial production of plastics from 1950 to the present day. The database uses 2019 as reference year, since the year 2020 was impacted by COVID-19 and economic indicators as well as materials data are still uncertain for the recently-ended 2021.

Table 2.1. The OECD Global Plastics Outlook Database covers a large range of sources and methodologies

|

Category |

Variable |

Sources and assumptions |

|---|---|---|

|

Production |

Primary plastics |

OECD ENV-Linkages model, based on GTAP10 (Aguiar et al., 2019[6]). |

|

Secondary plastics |

OECD ENV-Linkages model, using Exiobase (Stadler et al., 2018[7]) and Grand View Research (2020[8]) for the cost structure; recycling shares (see below) and recycling losses from Cottom, Cook and Velis (2020[9]), Chruszcz and Reeve (2018[10]), Roosen et al. (2020[11]) and VinylPlus (2019[12]). |

|

|

Use |

Plastics use by region, application and polymer |

Volumes of plastics by polymer and application from (Ryberg et al., 2019[3]) associated with different sectors and regions in OECD ENV-Linkages model. |

|

Waste |

Plastic waste by region, application and polymer |

OECD ENV-Linkages model, based on historical consumption, and product lifespans from Geyer, Jambeck and Law (2017[1]) . |

|

Waste management end-of-life fates |

Recycling share |

Country sources (Table A.A.5), Geyer, Jambeck and Law (2017[1]), and Kaza et al. (2018[13]) for Municipal Solid Waste (MSW); rates for non-MSW assumed to match MSW. |

|

Littering share |

Jambeck et al. (2015[14]) for share in MSW; zero for non-MSW. |

|

|

Shares for other fates |

Cross-country regression based on Kaza et al. (2018[13]) 1; rates for non-MSW assumed to match MSW. |

|

|

Environmental impacts |

Total leakage of macroplastics and microplastics to the environment by category |

Based on plastics consumption, waste and waste management projections from OECD ENV-Linkages model, adapted from Ryberg et al. (2019[3]) methodology. |

|

Plastic leakage and accumulation in aquatic environments |

Based on waste management projections from OECD ENV-Linkages model, adapted from Lebreton and Andrady (2019[15]) methodology. |

|

|

GHG emissions for plastic lifecycle |

Based on plastic consumption, waste and waste management projections from OECD ENV-Linkages model, based on Zheng and Suh (2019[16]). |

1. The cross-country regressions based on the What a waste 2.0 database (Kaza et al., 2018[13]) include:

(a)

(b)

(c)

where waste_pc = MSW per capita, MIS = mismanaged waste, inc = incinerated waste, dis = mismanaged + landfilled, gdp_pc = GDP per capita, oecd = dummy for OECD economies, r = regional dummies for 15 regions of ENV-Linkages, i = country.

2.2. The global use of plastics is growing strongly

Growing populations and rising per capita incomes have seen the global use of plastics, including additives and fibres, reach 460 Mt in 2019 (Figure 2.2). The used volumes of these synthetic polymers have been increasing constantly3 and increased more rapidly than any other commodity, including steel, aluminium and cement (IEA, 2018[2]).

In 2020, the COVID-19 pandemic had significant impacts on plastics use. On the one hand, there was a rapid increase in demand for personal protective equipment (such as face masks), a shift from restaurant eating to take-away and a shift from in-store shopping to online retail. On the other, plastics use in industry and commercial sectors declined as firms faced lockdowns. On balance, plastics use declined in 2020 but rebounded largely in 2021. These impacts are examined in detail in Chapter 3.

While plastics are produced and consumed everywhere, there are important regional variations when it comes to total volumes of plastics demand. Two-thirds of current use is concentrated in OECD countries and the People’s Republic of China (hereafter China) (Figure 2.2). China represents around 20% of global plastics demand, the United States represents approximately 18%, OECD Europe represents about 18% and the rest of the OECD countries represent around 9%. However, the relative importance of each region’s plastics use has been changing, mirroring the economic dynamics of regions and countries. For instance, the share of the OECD in global consumption has been declining steadily – from 87% in 1980 to 46% in 2019. As COVID-19 was a worldwide pandemic, this share has been more or less stable since 2019. However, relatively fast economic recovery in the United States and China may have increased their share somewhat in 2021.

Figure 2.2. Global plastics use has quadrupled in 30 years, mainly driven by emerging economies

Note: See Annex A for the detailed regional breakdown of the OECD ENV-Linkages regions.

Source: OECD Global Plastics Outlook Database, https://doi.org/10.1787/c0821f81-en.

The majority of plastics in use today are virgin plastics, made from crude oil or gas. Due to the fossil-based feedstock and the high energy consumption during refining, most greenhouse gas (GHG) emissions from plastics can be attributed to the production stage (Box 2.1). Biobased plastics are a rather small group of plastics with similar characteristics to fossil-based plastics, but are derived from biomass (Box 2.2). Together fossil-based and biobased plastics can be referred to as primary plastics. Plastics made from recycled material are called secondary plastics. Secondary plastics contribute less to GHG emissions than primary plastics, but only accounted for 6% of global plastics use in 2019 (Chapter 4).

Box 2.1. Plastics emit a high amount of greenhouse gases throughout their lifecycle

Traditional plastic production uses fossil fuel feedstock which is transformed into monomers in an energy-intensive process. The OECD ENV-Linkages model uses the energy and factor intensity of economic sectors, along with their process emission intensity, to estimate the GHG emissions in the economy. Moreover, to quantify plastic-related emissions, the approach is complemented with plastics lifecycle emissions factors. Based on these calculations, the estimated GHG emissions of fossil-based plastics in 2019 were 1.8 gigatonnes of carbon dioxide equivalent (Gt CO2eq.), or 3.4% of global emissions that year.1 If the goals of the Paris Agreement are to be achieved, the growth of emissions related to plastics must cease.

Production and conversion into products account for around 90% of the lifecycle emissions of fossil-based plastics. GHG emissions from the production and conversion of polymers vary depending on the polymer considered (with a range from 2.7 to 6.3 tCO2eq. per tonne of plastics). End-of-life emissions vary significantly depending on the disposal option, with incineration the most GHG intensive (2.3 tCO2eq. per tonne of plastics). However, some emissions can be offset when energy is recovered through waste-to-energy processes (Gómez-Sanabria et al., 2018[17]). Recycling directly emits 0.9 tCO2eq. per tonne of plastic, but the use of secondary plastics can avoid emissions from primary plastics production. Sanitary landfilling is the least emission-intensive disposal alternative in terms of direct emissions, at less than 0.1 tCO2eq. per tonne of plastic, but does not generate energy that can be used elsewhere. The impact of the leakage of plastics on GHG is not incorporated in the calculations, but recent research by Shen et al. (2020[18]) based on experimental data by Royer et al. (2018[19]) estimates annual methane emissions to be roughly 2 Mt CO2eq.

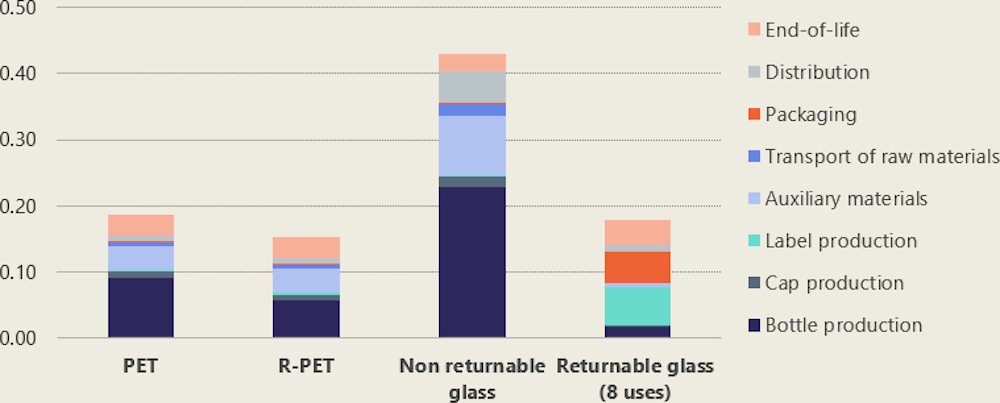

So can replacing plastics with other materials reduce the carbon footprint of consumption (Franklin Associates, 2018[20])? The response is ambivalent, partly due to the behavioural components of the use of a product as well as its end-of-life management. For example, as illustrated in Figure 2.3, the carbon footprint of a plastic bottle is not necessarily worse than its glass counterpart.

Figure 2.3. The carbon footprint of a non-returnable glass bottle is higher than a plastic equivalent

1. Greenhouse gases are aggregated using 100-year global warming potentials of 310 for N2O, 21 for CH4, and 1 for CO2 (IPCC, 1995[74]).

The variety of different polymers that can be produced accounts for the versatility of plastics (Table 2.2). Figure 2.4 provides an overview of the most commonly used polymers and their applications. Different polymers have differing properties. For example, thermoplastics can be remoulded after heating, while thermosets are irreversibly hardened. Elastomers have elastic properties and fibres can be made of various polymers but are defined by their shape. Biobased plastics are made of biomass as feedstock instead of fossil fuels (Box 2.2). In addition, polymers are usually mixed or “compounded” with a wide range of additives to further customise and improve the performance of plastics. Some of the most important functions of additives are to prevent aging, colour the plastic, make rigid material flexible, work as a lubricant, improve the impact resistance, reduce flammability and generate foam as a blowing agent.

Table 2.2. The large range of polymers allows for a multitude of plastics applications

|

Polymer |

Abbreviation |

Examples of use |

|---|---|---|

|

Polypropylene |

PP |

Food packaging, automotive parts |

|

Low-density polyethylene |

LDPE |

Reusable bags, food packaging film |

|

High-density polyethylene |

HDPE |

Toys, shampoo bottles, pipes |

|

Polyvinylchloride |

PVC |

Window frames, floor covering, pipes, cable insulation |

|

Polystyrene |

PS |

Food packaging, insulation, electronic equipment |

|

Polyethylene terephthalate |

PET |

Beverage bottles |

|

Polyurethane |

PUR |

Insulation, mattresses |

|

ABS, elastomers, biobased plastics, PBT, PC, PMMA, PTFE, … |

Other |

Tyres, packaging, electronics, automotive, … |

|

Fibres made of different polymers |

Fibres |

Textile applications but also in many other sectors |

Note: ABS stands for Acrylonitrile butadiene styrene, PBT for Polybutylene terephthalate, PC for Polycarbonates, PMMA for Poly (methyl methacrylate) (also known as plexiglas) and PFTE for Polytetrafluoroethylene.

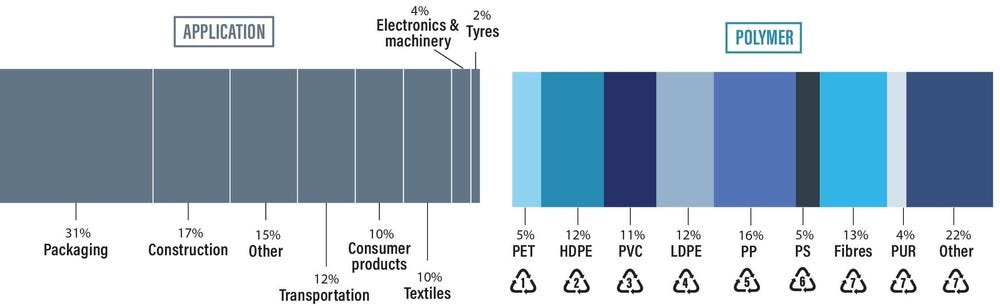

Together, packaging, construction and transportation applications account for more than 60% of total plastics use.4 The other main applications of plastics use include textiles, household consumer products and non-household or institutional products, electronics, machinery and tyres (Figure 2.4).

Figure 2.4. Global plastics use by application and polymer

Box 2.2. Biobased plastics offer potential as long as land-use impacts are managed

Biobased plastics are derived from biomass such as corn, sugarcane, wheat or residues of other processes. Their production generates fewer greenhouse gas emissions than fossil-based plastics They can be produced as drop-in resins (as a substitute together with fossil-based plastics) or as alternative resins with other characteristics. The majority of such plastics are produced for packaging (53%) and textiles (11%). Asia is the region with the largest biobased plastics production capacity (45%), followed by Europe (25%), North America (18%) and South America (12%) (European Bioplastics, 2019[22]). In 2019, biobased plastics represented around 2 Mt or 0.6% of total plastics. The volumes are growing, but not any faster than other plastic types (OECD Global Plastics Outlook Database).

Table 2.3 compares the “cradle-to-gate” (extraction, refining and production) GHG emissions of fossil and biobased feedstock. A negative result indicates that the carbon embodied in the product is greater than the carbon emitted during refining and processing. Despite the positive outlook of biobased plastics in terms of GHG emissions, their environmental impact is controversial due to their potential to drive land-use changes such as deforestation that may lead to significant GHG emissions. If tropical forest or other natural environments are sacrificed to make room for additional agricultural area, this would result in loss of biodiversity and one-off carbon emissions (Brizga, Hubacek and Feng, 2020[23]). Whether the overall carbon balance is positive depends, among others, on assumptions related to the amount of natural area that would be converted (directly for feedstock of biobased plastics or indirectly for agricultural activities that have to compete with feedstock for biobased plastics for arable land) and the method used to compare one-off losses with annual recurring benefits (Liptow and Tillman, 2012[24]; Walker and Rothman, 2020[25]).

Currently only 0.7 million hectares or 0.02% of global agricultural land is used for growing feedstock for biobased plastics (European Bioplastics, 2019[22]). Therefore, the additional pressure on agricultural land is currently negligible and will remain so in the coming years, even if high growth rates are realised.

Table 2.3. Bioplastics could reduce GHG emissions from plastics production as long as negative effects from indirect land use change are avoided

|

Material |

Fossil fuel-based polymer (kg CO2 eq./kg) |

Biobased polymer (kg CO2 eq./kg) |

|---|---|---|

|

HDPE |

1.9 – 2a |

-0.55 – -0.88b |

|

PET |

2.2 – 3c |

1 – 2.4d |

|

PP |

1.8 – 2e |

-0.2 – -0.3f |

Note: Only cradle-to-gate assessments shown in the table. Thus only extraction, refining and production are taken into account, but not the use or end-of-life stages. A negative result indicates that the carbon embodied in the product is greater than the carbon emitted during refining and processing. HDPE= high-density polyethylene; PET= polyethylene terephthalate; PP= polypropylene.

Sources: (a) Vanderreydt et al. (forthcoming[26]), (b) Tsiropoulos et al. (2015[27]), (c) Akanuma, Selke and Auras (2014[28]), Semba et al. (2018[29]), (d) Tsiropoulos et al. (2015[27]), (e) Broeren et al. (2017[30]), (f) Chen and Patel (2011[31]).

Normalised indicators, such as plastic intensity relative to GDP and plastic use per capita, allow for a comparison of plastics use across regions (Table 2.4). Regional plastics use per capita varies greatly: an inhabitant of the United States uses 255 kg of new plastics every year on average, while the average person in Sub-Saharan Africa uses less than one tenth of that amount. In contrast, the range of plastics intensity relative to GDP across the world is smaller, ranging between 2.5 and 4.5 tonnes per million USD (t/M$). OECD plastic intensity reaches 3.7 tonnes per million USD, while non-OECD countries reach 3.4 tonnes. This correlation is also found in plastics use per capita, whose OECD level is 156 kg per capita, compared to 39 kg per capita for non-OECD countries. The only outlier in this table is Sub-Saharan Africa, which has the lowest plastics use per capita (16 kg/cap), but the highest plastic intensity (4.5 t/USD M). This high intensity reflects the very low level of GDP per capita of Sub-Saharan Africa in 2019 (about five times lower than Middle East and North Africa and twice lower than India).

Table 2.4. GDP is a key driver of global plastics use

2019

|

Plastics use per capita (kg/cap) |

Plastics intensity relative to GDP (t/M$ in PPP) |

|||

|---|---|---|---|---|

|

World |

60.1 |

3.5 |

||

|

OECD |

155.8 |

3.7 |

||

|

Non-OECD |

39.3 |

3.4 |

||

|

OECD |

OECD America |

USA |

255.2 |

4.3 |

|

Canada |

202.2 |

4.3 |

||

|

Other OECD America |

65.4 |

3.6 |

||

|

OECD Europe |

OECD EU countries |

152.9 |

3.6 |

|

|

OECD non-EU countries |

124.3 |

3.5 |

||

|

OECD Pacific |

OECD Asia |

102.4 |

2.6 |

|

|

OECD Oceania |

143.9 |

3.1 |

||

|

Non-OECD |

Other America |

Latin America |

50.9 |

3.5 |

|

Eurasia |

Other EU |

103.0 |

4.1 |

|

|

Other Eurasia |

66.7 |

3.7 |

||

|

Middle East and Africa |

Middle East & North Africa |

47.1 |

2.5 |

|

|

Other Africa |

15.9 |

4.5 |

||

|

Other Asia |

China |

69.0 |

3.7 |

|

|

India |

22.1 |

2.7 |

||

|

Other non-OECD Asia |

31.7 |

3.2 |

||

Source: OECD Global Plastics Outlook Database.

2.3. Plastic waste generation depends on plastics use and product lifespans

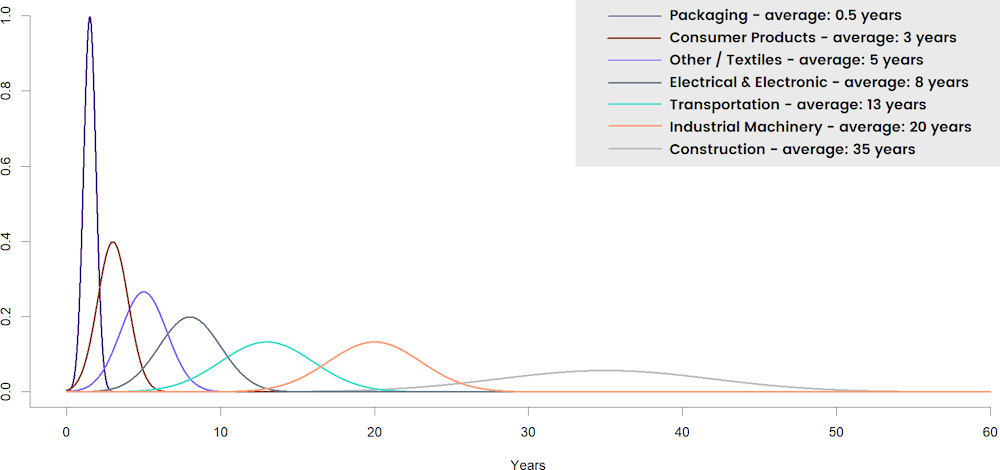

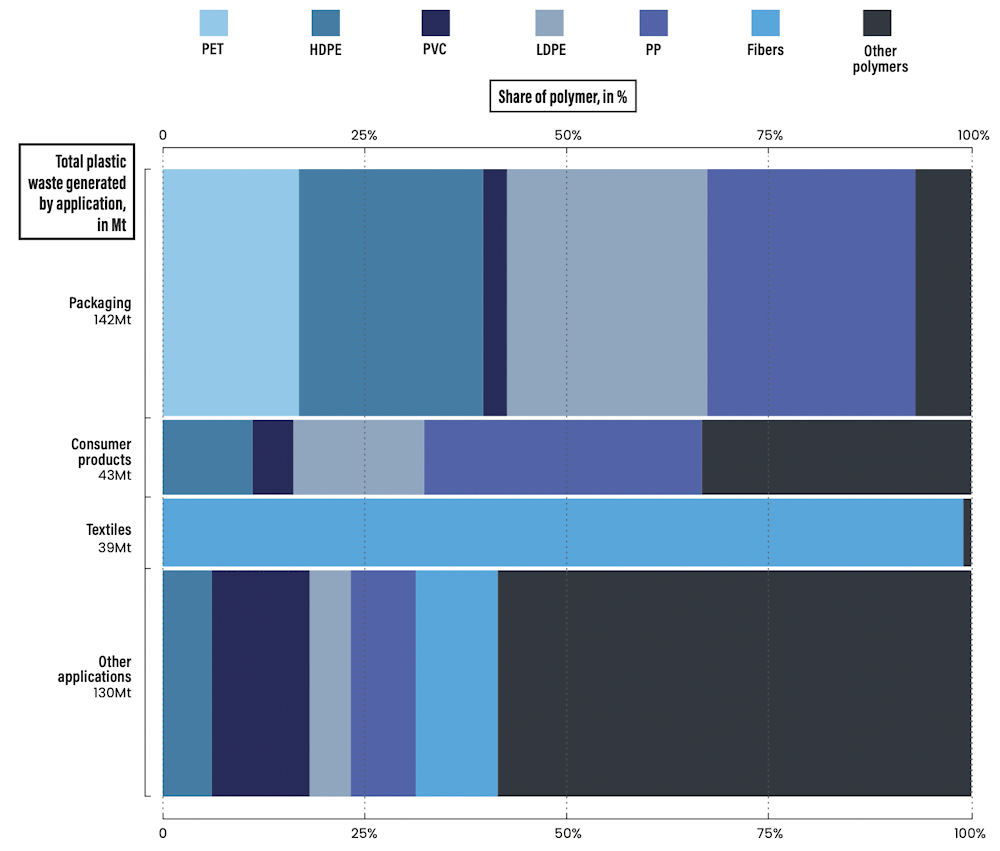

The generation of plastic waste is strongly related to how plastics are used. The overall average lifespan of a plastic product is almost ten years, though this depends on its use (Figure 2.5). Packaging has an extremely short average lifespan while plastic applications in the construction sector may be in use for several decades. Therefore, packaging waste constitutes a large share (42%) of total plastic waste generated.

Figure 2.5. Average plastic product lifespans range from six months to 35 years

The global generation of plastic waste can be estimated from the amount of plastics used in previous decades, the international trade of plastics and plastic products, as well as the average lifespan of plastics applications (see Annex A for more details on the methodology). According to the OECD Global Plastics Outlook Database, the plastic waste generated in 2019 amounted to 353 Mt.

At the waste stage, the ease of recycling and the potential mobility when lost to the environment are influenced by polymer type, dimensional shape, object size, additive mix, and the items and materials appended in assembly. Figure 2.6 highlights that the applications and polymers present in the waste stage are different than in the consumption stage. The predominance of PP, LDPE and HDPE has become even greater in the waste stage because they are often used for packaging applications with short lifetimes. Similarly, since PET is mainly used for packaging, it will become waste rapidly after its initial use. By contrast, PVC and PUR are mainly used for applications with long lifecycles. They will only enter the waste stage many years later. These long lifecycles, combined with significant growth rates of use, result in a relatively lower presence in plastic waste than in plastics use of those polymers. Conversely, the polymers with long life cycles account for a relatively high share of the stock of plastics that is present in the economy.

The OECD Global Plastics Outlook Database indicates that the OECD generates almost half of all plastic waste: the United States accounts for 21%, OECD Europe 19% and the remaining OECD countries 9%. Outside the OECD, China produces 19% of global plastic waste, India 5% and the rest of the world 27%.

In terms of waste per capita, there are stark differences across the world (Table 2.5). The United States had the largest plastic waste footprint in 2019, at 221 kg per capita, while OECD Europe had 114 kg plastic waste per capita. Japan and Korea’s plastic waste generation is relatively low for industrialised countries, averaging 69 kg per capita. Finally, China generated 47 kg of plastic waste per inhabitant in 2019, while India generated only 14 kg per inhabitant.

Figure 2.6. Almost two-thirds of plastic waste comes from relatively short-lived products such as packaging, consumer products and textiles

Note: HDPE= High-density polyethylene; PET= Polyethylene terephthalate; High-density polyethylene; PVC= Polyvinylchloride; LDPE= Low-density polyethylene; PP=Polypropylene.

Source: OECD Global Plastics Outlook Database, https://doi.org/10.1787/c0821f81-en.

Table 2.5. Per capita plastic waste generation differs strongly across the world

Kg/cap, 2019

|

Plastic waste per capita (kg/cap) |

|||

|---|---|---|---|

|

OECD |

OECD America |

USA |

220.5 |

|

Canada |

177.9 |

||

|

Other OECD America |

57.9 |

||

|

OECD Europe |

OECD EU countries |

121.6 |

|

|

OECD non-EU countries |

94.4 |

||

|

OECD Pacific |

OECD Asia |

68.9 |

|

|

OECD Oceania |

62.1 |

||

|

Non-OECD |

Other America |

Latin America |

43.4 |

|

Eurasia |

Other EU |

75.5 |

|

|

Other Eurasia |

53.0 |

||

|

Middle East and Africa |

Middle East & North Africa |

37.6 |

|

|

Other Africa |

14.5 |

||

|

Other Asia |

China |

46.6 |

|

|

India |

14.0 |

||

|

Other non-OECD Asia |

21.4 |

Source: OECD Global Plastics Outlook Database.

2.4. The quality of plastic waste management varies across the world

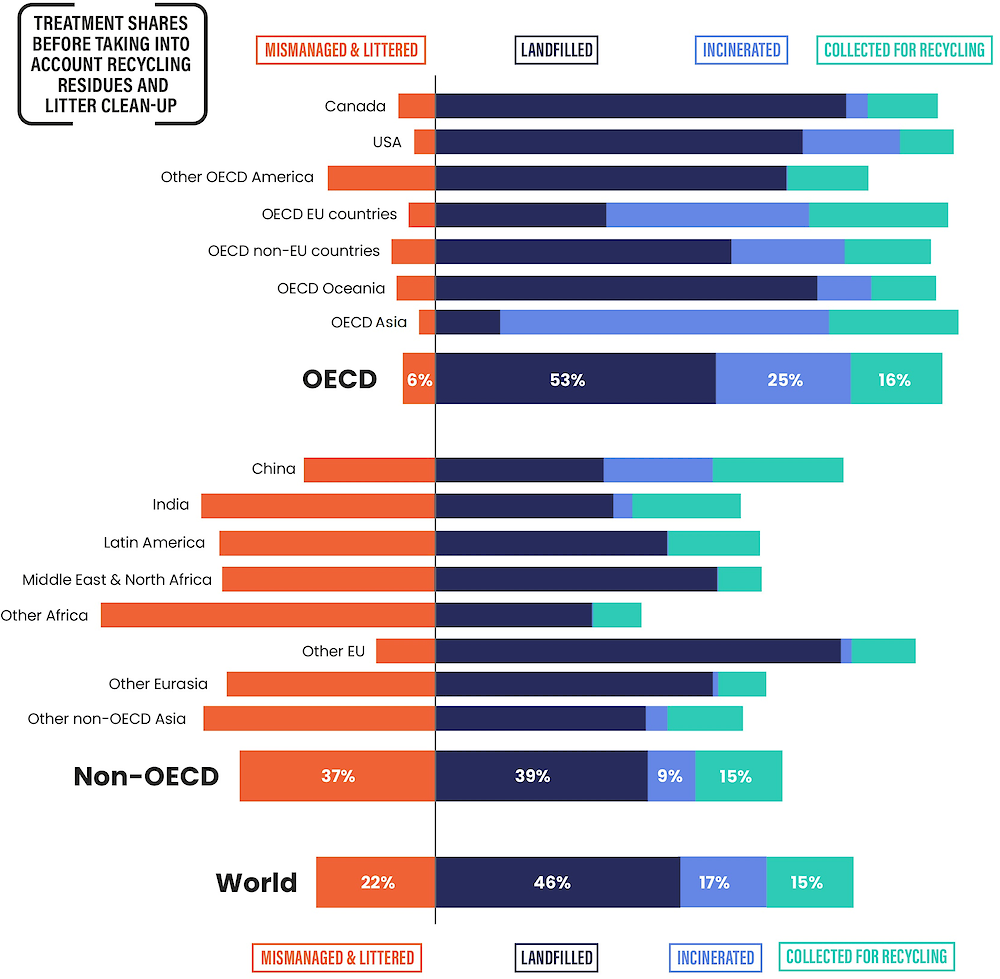

The end-of-life fate of plastics depends on the local waste management capacities and regulations. As highlighted in Figure 2.1 the OECD Global Plastics Outlook Database contains five different waste handling categories (recycling, incineration, landfilling, mismanaged waste and littered waste). In Figure 2.7, the category “collected for recycling” refers to plastic waste that is collected in order to recycle and that will, after processing, produce secondary plastics. “Incineration” refers to incineration in a state-of-the-art industrial facility. The third approach to manage plastics in a safe way is sanitary “landfilling”. Unfortunately, plastic waste is often improperly managed. The treatment category “mismanaged waste” aims at quantifying the end-of-life plastics generated in areas where state-of-the-art waste collection or treatment facilities are not in place. The plastic waste is either not collected, collected but disposed of in dumpsites, or collected for disposing in the environment, for example dumped directly into seas or open waters. Finally, “littered waste” differs from mismanaged waste because littering behaviour is not necessarily correlated to the provision of basic waste collection and disposal infrastructure. The category refers both to littering (i.e. when users discard packaging or other products into the environment), and to fly-tipping (i.e. plastic waste generators who consciously circumvent legislation to discard larger volumes of, for example, construction waste into the environment). Litter can either be collected via street sweepings and other clean-up actions or be left uncollected and leak into the environment. There are also biodegradable plastics that can be composted at the waste stage (European Bioplastics, 2019[22]) (Chapter 5), but due to the small amounts the OECD Plastics Outlook does not track this stream.

In most cases, differences in waste management capacities are related to regulations, geographical and demographic characteristics and other variables. In low-income countries, economic growth can outpace improvements in collection and disposal capacity, leading to increased volumes of mismanaged waste. By contrast, low-income countries typically have low labour costs that make collection and high-quality sorting of recyclables by manual labour economically feasible. Therefore, countries may encounter different waste management challenges depending on the stages of their economic development trajectory (Figure 2.7).

Figure 2.7. More plastic waste is mismanaged than collected for recycling

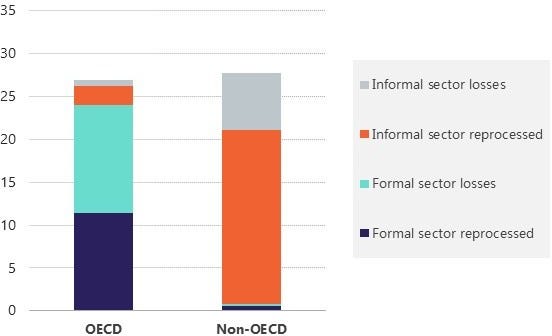

Globally, 15% or 55 Mt of plastic waste were collected for recycling in 2019.5 EU countries, as well as China, India, Japan and Korea have above-average recycling rates. Key drivers of recycling in Europe, Japan and Korea are extensive separate collection facilities and extended producer responsibility (EPR) schemes that put the onus to recycle on producers of plastic products and packaging (Chapter 6). In other parts of the world, the informal economy is the main driver of recycling, incentivised by the value of some of the plastics (Chapter 4).

The underlying regional economic drivers not only determine the volumes of plastic waste collected for recycling – they also affect the process losses from recycling (Figure 2.8). Globally, almost 40% of plastics collected for recycling, or close to 22 Mt, are lost during recycling and end up being incinerated, landfilled or mismanaged. In particular, when formal waste collection is funded by government and free to users, it typically contains large amounts of un-recyclable plastics and non-plastics which need to be removed. These are counted as recycling losses. By contrast, in informal waste systems, waste pickers selectively target high-value plastics at the point of collection, reducing the mass lost when they are cleaned and sorted to get the maximum price. Therefore, there are important regional differences in recycling both in terms of volumes as well as in practices used (see Chapter 4 for a more extensive discussion of the recycling practices and markets for secondary plastics).

Figure 2.8. Formal and informal recycling volumes and losses differ across regions

Source: OECD Global Plastics Outlook Database; Cottom, Cook and Velis (2020[9]), “Spatio-temporal quantification of plastic pollution origins and transportation (SPOT)”, https://plasticpollution.leeds.ac.uk/toolkits/spot.

Globally in 2019, 60 Mt of generated plastic waste, 6 Mt of plastic recycling residues and 1 Mt of collected litter were incinerated in industrial facilities, while 162 Mt of generated waste, 11 Mt of residues and 1 Mt of collected litter were disposed of in sanitary landfills. Whether plastic waste, especially municipal solid waste (MSW), is incinerated or landfilled depends on historic infrastructure, regulation, local population density and costs (Box 2.3). Since sanitary landfilling requires large amounts of land, densely urbanised countries and regions such as Japan and Western Europe rely heavily on incineration. However, because well-controlled incineration is almost three times more expensive than landfilling, countries and cities with more space have kept sanitary landfilling as their prime disposal method.

Box 2.3. The environmental impacts of incineration are mixed

A waste incineration plant is an industrial facility dedicated to the thermal treatment of waste. In order to minimise potentially hazardous emissions, state-of-the-art plants incorporate extensive air pollution control (APC) equipment. A range of technologies are available, but moving grate incinerators account for more than 93% of global capacity because of their ability to process waste streams with varying characteristics. Waste incineration is expensive and costs almost three times more than landfilling. The main advantage is that incineration reduces the weight and volume of waste. Indeed, the remaining ashes weigh only about 25% of the original waste and the volume can be reduced by up to 90%, which substantially limits the need for landfilling (Neuwahl et al., 2019[32]). Therefore, in megacities and urbanised areas where land is scarce and public opposition to new landfills high, waste incineration can be used to dispose of large volumes of waste.

The energy released during incineration can recovered, often referred to as waste-to-energy (WtE) or energy-from-waste (EfW). State-of-the-art WtE facilities for mixed waste can recover about 25% of the energy contained in waste as electricity, though older facilities recover substantially less (Lombardi, Carnevale and Corti, 2015[33]; Pavlas et al., 2011[34]). In addition, energy efficiency can be increased by recovering heat for use in nearby industrial processes or residential areas. Nonetheless, feedstock and operational priorities can mean that waste incineration plants operate at energy efficiencies that are substantially below coal and gas energy production plants (Pavlas et al., 2011[34]; Colmenar-Santos et al., 2018[35]). European plants recover most energy per tonne of MSW. This can be explained by a combination of regulatory measures and financial incentives, as well as the composition of incinerated waste. Lifestyles and sorting practices mean that mixed waste in Europe has a higher calorific value since it contains less organic (wet) content than elsewhere.

There are around 2 450 active waste incineration plants around the world. Together they processed approximately 400 Mt of MSW and other waste streams in 2019. Waste incinerators are strongly concentrated in OECD countries and China. Japan and Korea have many small incinerators with an average capacity of around 60 000 tonnes, compared to around 200 000 tonnes for OECD Europe, and close to 400 000 tonnes for the United States and China.

Ecoprog (2020[36]) expects that global capacity will increase by more than 3% per year in the coming decade, but with stark differences across regions. The growth will occur almost exclusively in China and non-OECD Asia. Some new capacity will come online in OECD Europe in countries such as the United Kingdom or Poland, but the overall growth is expected to be small. In Japan and Korea, gradual closure of small unprofitable incinerators will see total capacity decline slightly. The market in the US and Canada is expected to remain stable. While there are many plans to build waste incinerators outside of these regions, in the past, these types of projects have been abandoned due to financial concerns, uncertain legal frameworks, public resistance and insufficient local expertise. Therefore, growth in Africa and Latin America is expected to be small in the next decade, but might accelerate later driven by the growth of population and megacities.

Waste incinerators are typically used to treat mixed waste, including plastics. The environmental effects of (plastic) waste incineration are ambiguous. The gains of recovering energy from waste are counterbalanced by the environmental impacts of ash, residual emissions and greenhouse gases (Dijkgraaf and Vollebergh, 2004[37]; Dubois, 2013[38]). Most studies indicate that the overall environmental impact of waste incineration with energy recovery is better than landfilling, but worse than recycling (Lazarevic et al., 2010[39]; Civancik-Uslu et al., 2021[40]). Incineration also destroys the material that could feed the circular economy, which aims to close material loops and maintain the highest value of materials throughout different cycles. Another downside of incineration is that the plants are highly capital intensive, which pushes operators to use them at full capacity. Consequently, large-scale investments in waste incineration can lock-in this infrastructure for many years, leading to competition with recyclers for feedstock (UNEP, 2019[41]). This is especially true when investments are linked to heat recovery and central district heating. To speed up the transition to the circular economy, waste incineration will have to be gradually replaced by recycling and waste prevention.

For many emerging economies, lack of technical capacities, poor governance and insufficient financial resources at the municipal level are major bottlenecks in improving waste management practices. Mismanaged waste is a wide category that includes waste that has not been collected and is therefore “self-managed” by those who generate it – and who usually resort to dumping it on land, in rivers and lakes or burning it in open uncontrolled fires. Mismanaged waste can also include waste that has been collected but which is then subsequently deposited in dumpsites that do not have sufficient controls to prevent its interaction with the natural environment or human receptors. These practices mainly occur in developing countries, but they are also present in more mature economies.

Globally, approximately 79 Mt (73 Mt of waste and 5 Mt of recycling residues and 1 Mt of collected litter) are mismanaged annually. Around 43% of that amount (34 Mt) is estimated to be captured in the inner part of dumpsites where degradation and interaction with the environment is close to zero. One-third (26 Mt) is burned in open, uncontrolled fires. This is mainly done by households who have to manage their waste in the absence of waste collection services, but can also be done at dumpsites where waste is combusted deliberately to reduce volume or to recover valuable metals. It can also be burned due to accidental and spontaneous fires. The remainder is considered to be lost to terrestrial and aquatic environments (Section 2.5 and Annex A). More specifically, the University of Leeds (Box 2.4) estimates that around 10% of mismanaged waste is dumped directly onto land when there is no formal waste collection, while other important leakage pathways are waste directly dumped into aquatic environments, dumped recycling residues, losses from dumpsites and losses during collection and transport.

Littered waste is a specific category of improper waste handling that unfortunately is still a problem throughout the world, even in mature economies. The amount of littered waste was more than 4 Mt globally in 2019. An estimated 3 Mt of this litter was collected via street sweeping and other actions for disposal in an industrial incinerator or a landfill; around 1 Mt was collected but then burned in open pits or sent to dumpsites; and 1 Mt remained uncollected and is likely to have been lost to the environment (Section 2.5 and Annex A). However, as has been pointed out in Boucher et al. (2020[42]), uncollected litter is exceptionally difficult to measure.

2.5. Plastic leakage is substantial

Plastic leakage has now been documented in all the major ocean basins, beaches, rivers, lakes, terrestrial environments and even in remote locations such as the Arctic and Antarctic (OECD, 2021[43]; Eriksen et al., 2014[44]). The research strand that aims to quantify the global magnitude of plastic leakage is relatively recent, but following a seminal paper by Jambeck et al. (2015[14]), several other studies have proposed models and estimates. Some researchers have focused on quantifying global plastic waste (Geyer, Jambeck and Law, 2017[1]), while others have also attempted to understand the geographical and spatial distribution of generated and mismanaged plastic waste (Lebreton and Andrady, 2019[15]). Other studies have focused on leakage into the environment (Ryberg et al., 2019[3]; Borrelle et al., 2020[45]; Lau et al., 2020[46]; Law et al., 2020[47]). Despite these efforts, there remains an urgent need to improve the understanding of the drivers and dynamics of plastics leakage and to align existing assessment methodologies (Box 2.4).

Global leakage to the environment (terrestrial and aquatic) is estimated to be 22 Mt in 2019 (Figure 2.9).6 However, due to the variety of sources and types of leaked plastics, as well as the unintended nature of these plastic emissions into the environment, there is substantial uncertainty about each of categories of plastic leakage. Moreover, this remains a conservative estimate as only known leakage sources with sufficient data were quantified.

Figure 2.9. Global leakage of macro-and microplastics to the environment is estimated at 22 Mt

Since plastic leakage has many types and sources, leakage is often grouped into macroplastics and microplastics. Macroplastics encompass recognisable items such as littered products and packaging, while microplastics are solid synthetic polymers smaller than 5 mm in diameter (OECD, 2021[43]). Microplastics are further split into primary and secondary microplastics. Primary microplastics are plastics that are smaller than 5 mm in diameter by design, such as cosmetic scrubbing agents and biomedical uses as well as plastic pellets accidentally lost during production or handling. By contrast, secondary microplastics refer to microplastics which are formed from the fragmentation of larger plastics and are further differentiated into two categories: 1) those formed during the use phase of products, such as microplastics from tyre abrasion and synthetic microfibres from clothing and other textile products; and 2) those stemming from the degradation and fragmentation of macroplastics that have already been lost in the environment. The size of the plastic items or particles can influence, among other elements, their transport in the environment, where they are deposited and their deposition rates.

Box 2.4. State of the art in estimating the scale of the plastic leakage problem

Given that the quantification of plastic leakage is a relatively new field, studies differ in their scope, methodology and assumptions. This plurality of methods has the benefit of providing a more complete overview of the plastics issue, with each study drawing to a different aspect of the problem. However, it also means that results of earlier studies diverge and are difficult to compare. For example, Jambeck et al. (2015[48]) suggested a range of approximately 5‑13 Mt for plastics emitted yearly to the ocean. Lebreton et al. (2017[49]) estimated plastics emissions from rivers to the ocean at 1.2-2.4 Mt. Lau et al. (2020[46]) estimated leakage to the environment at around 22-39 Mt, of which around 38% was released to water. Borrelle et al. (2020[45]) estimated that approximately 19‑23 Mt entered aquatic environments. Each of these estimates uses different base years, definitions, estimations for plastics in use and methodologies, all of which limit their comparability.

The OECD Global Plastics Outlook Database complements the existing literature by providing a comprehensive overview of the amount of plastics in different lifecycle stages (Section 2.1). To include leakage estimations in the database and ensure the results of existing methodologies are more comparable, the OECD collaborated with three research groups: 1) a team from the Technical University of Denmark (DTU) that led the research underlying the Ryberg et al. (2019[3]) study; 2) experts from the University of Leeds who contributed to Lau et al. (2020[46]); and 3) Laurent Lebreton, who wrote research papers on plastics waste generation and leakage (Lebreton et al., 2017[49]; Lebreton and Andrady, 2019[15]; Lebreton, Egger and Slat, 2019[50]), and contributed to the leakage estimations in Borrelle et al. (2020[45]). These experts have refined and customised their analytical approaches (see Annex A) to make the most of the information on plastics use and waste in the OECD Global Plastics Outlook Database. Table 2.6 highlights how the complementary approaches used by these three research groups cover key aspects of plastic leakage.

Table 2.6. A complementary approach is needed to improve the understanding of plastic leakage

|

Macroplastics |

Microplastics |

||||

|---|---|---|---|---|---|

|

Fate of mismanaged waste flows |

Leakage to environment (terrestrial and aquatic) |

Leakage to aquatic environments (rivers and ocean) |

Transport and degradation in aquatic environments |

Comprehensive view of various categories |

|

|

DTU |

● |

● |

|||

|

Laurent Lebreton |

● |

● |

|||

|

University of Leeds |

● |

● |

● |

||

Reconciling the approaches has allowed key insights to be obtained. However, the lack of empirical data to validate the modelling means that these estimations are still uncertain. Table 2.7 highlights this by showing the leakage from mismanaged waste and litter together with the upper and lower bound estimations prepared for the Global Plastics Outlook. The database has taken the average of the leakage proposed by the University of Leeds (low estimate) and the Danish Technical University (high estimate) (see Annex A for more discussion). The uncertainty ranges highlight that more research is needed to get a better grip on the current challenges.

Table 2.7. Plastic leakage is substantial despite high uncertainty surrounding the estimates

|

Compartment |

Leakage from mismanaged waste and litter |

Uncertainty ranges |

|---|---|---|

|

Lost to environment (terrestrial and aquatic) |

19 Mt |

13 Mt a – 25 Mt b |

|

Lost to aquatic environments |

6 Mt |

4 Mt a – 9 Mt c |

Note: a) estimate made by University of Leeds, b) estimate made by DTU, c) estimate made by Laurent Lebreton.

Source: OECD Global Plastics Outlook Database, https://doi.org/10.1787/c0821f81-en.

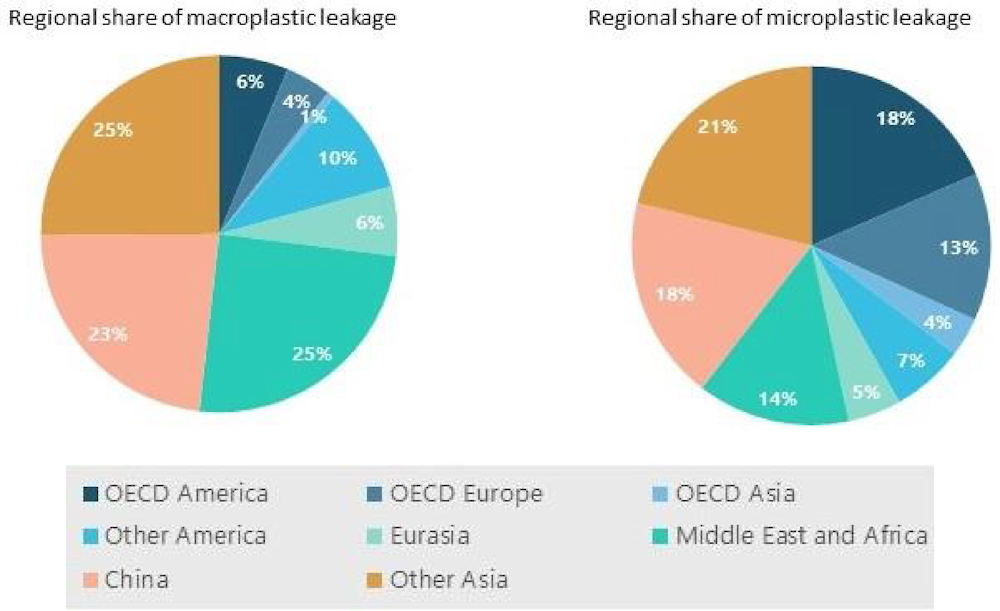

Macroplastics account for 19.4 Mt leaked to the environment in 2019, of which 11% comes from OECD countries (Figure 2.10). Mismanaged plastic waste from municipal and non-municipal sources is the main cause of leakage (18.1 Mt – Box 2.4). The second most important source of macroplastic leakage is the littering of end-of-life plastic products (1.1 Mt). Fishing activities and other marine activities also contribute substantially to the leakage of macroplastics due to the loss or discarding of nets at sea, the abrasion of other fishing gear such as dolly ropes and other non-netting waste (0.3 Mt). The potential risks and the regional distribution of these debris emissions stress the urgency to improve waste and litter management all over the world, and especially in emerging economies. Moreover, actions are needed to reduce marine leakage from fisheries.

Figure 2.10. Leakage to the environment is high in emerging economies, especially for macroplastics

Total microplastic leakage added up to 2.7 Mt in 2019, 35% of which was generated in OECD countries. The largest source of microplastic leakage is road transport: tyre abrasion (0.7 Mt), brake wear (0.1 Mt) and eroded road markings (0.2 Mt). A second important source of microplastic leakage is the “dust” from the abrasion of shoe soles, paint wear from interior and exterior surfaces, losses from construction and demolition activities and household textile dust (in total 0.8 Mt). Other sources of microplastics are accidental losses of primary pellets, i.e. small blocks of polymers ready for conversion into products, during production, transport or storage (0.28 Mt); abrasion of artificial turf for sports and other activities (0.05 Mt); wear of marine coatings on ships (0.05 Mt); loss of synthetic fibres when washing textiles containing plastics (0.01 Mt); and microbeads intentionally added to rinse-off cosmetic and personal care products such as scrubs, shampoos and detergents (<0.01 Mt).

Additional quantities of microplastics may enter the environment when wastewater sludge is spread on farmland. Wastewater treatment plants (WWTP) filter out plastics from sewage water and concentrate them in the sludge. Since sludge is commonly used as compost on agricultural fields in many countries, some of the microplastics captured during WWT may end up in terrestrial environments (Nizzetto, Futter and Langaas, 2016[51]; OECD, 2017[52]).

This study only included emission sources for which sufficient data were available. However, there could be many others to include (e.g. synthetic fibres lost during other lifecycle phases). Also, the understanding of what influences microplastic losses is still limited, so is the current understanding of the fate of microplastics once leaked into the environment. Whilst more research is needed to develop a thorough accounting of pollution levels and risks, this should not prevent policies from being implemented to reduce microplastics leakage (OECD, 2021[43]).

2.5.1. Plastics enter and accumulate in the aquatic environment through complex pathways

Transport of plastics in the environment is extraordinarily complex and the current understanding of the behaviour of plastics released into the environment is incomplete. Plastics can be transported within and released to three types of environments: terrestrial, aquatic and atmospheric. When plastics are emitted to the environment, the size, weight and characteristics of polymers determine how they are transported. For example, high-density plastics such as PVC tend to remain close to the source of leakage, while a less dense polymer such as LDPE can be transported over large distances. Regardless of density, plastic objects and articles may be hollow, trapping air which allows them to float. Their transport is also governed by local weather patterns, geography and the presence of obstacles such as dams and the built environment. It can also be influenced by extreme events such as earthquakes, tsunamis and hurricanes.

As shown in Figure 2.9, mismanaged and littered waste make up the largest share of plastics leaked to the environment. In order to investigate the amount and spatial distribution of plastics leaked into aquatic environments, the data above on the leakage to the environment of mismanaged and littered waste was used in conjunction with other modelling tools that build on work initiated by Lebreton et al. (2019[50]) and Borrelle et al. (2020[45]). This methodology takes into account the proximity of rivers to the source of emission, the presence of dams, human habitation and coastal economic activity (see Annex A for more information). Figure 2.11 presents a highly stylised view of the accumulation and mobility of macroplastics in aquatic environments even though there are still many unknowns.

Figure 2.11. Rivers accumulate leaked plastics and carry them to the ocean

Once plastics are in aquatic environments, a complex set of factors influences their transportation, including wind, precipitation patterns, river flow and oceanic currents. High-density plastics, e.g. PET or PVC, are likely to sink to lower levels of the water column close to the point of entry into rivers or seas, while low-density polymers (e.g. PE and PP) and air-filled plastic items (e.g. bottles) may stay afloat and be transported for long distances. Other effects may play a role, such as the creation of biofilms on plastics which increases overall density and probability of sinking to the river or sea bed (Schwarz et al., 2019[53]; Tosin et al., 2012[54]). Floating plastics that make it to the ocean tend to accumulate in gyres, such as the Great Pacific Garbage Patch, due to the convergence of the marine currents (GESAMP, 2015[55]).

The estimates for leakage to aquatic environments (6.1 Mt in 2019) and especially inflows into ocean (1.7 Mt in 2019) are lower than most earlier studies that estimated global leakage to water (Jambeck et al., 2015[48]; Lau et al., 2020[46]; Borrelle et al., 2020[45]) (Box 2.4). In addition to using different methodologies, two sets of assumptions drive these differences.

The first set of assumptions relates to the fate of mismanaged waste. The OECD methodology relies on detailed waste management modelling that assumes that one-third of the mismanaged plastic waste and residues is burned in open pits, either locally or in dumpsites – a practice is environmentally harmful and should be discouraged. However, it reduces the amount of plastics that can potentially end up in water (Velis and Cook, 2021[56]). In addition, the waste management modelling assumes that around 44% of all mismanaged waste is buried in the core of dumpsites, where it will remain for decades or even centuries. While this risks leakage of hazardous substances and pollution of groundwater, apart from major incidents, the volumes of plastics leaking to surface waters are small (Cook, 2020[57]). Taken together, these two assumptions imply that less than a quarter of mismanaged plastic waste will end up in terrestrial and aquatic environments, which is lower than the shares put forward by most other studies.

The second set of assumptions concerns the transport of plastics leaked to the environment. The approach used in this report estimates that around 32% of leaked plastics end up in aquatic environments (the rest accumulates in terrestrial environments). Other studies assume higher values. For example, Lau et al. (2020[46]) use a ratio of 38%. Moreover, the OECD estimations for inflow into the ocean build on detailed modelling of the transport and stock of plastics in rivers (Meijer et al., 2021[58]). The projected accumulation in rivers (109 Mt in 2019) slows down the inflow of plastics to the ocean and consequently gives, in the short term, lower estimations for the leakage to seas and ocean. Altogether, the volumes put forward in this chapter can therefore be considered to be conservative estimations.

Once in aquatic environments, plastics are transformed further. They degrade slowly through exposure to UV radiation, temperature differences and physical abrasion. As the material weathers, macroplastics will fragment into microplastics and potentially into nanoplastics. The amount of microplastics produced via the degradation of macroplastics in 2019 is estimated at 0.15 Mt in rivers and lakes, and 0.10 Mt in the ocean. The degradation is highest in rivers and lakes because these contain the largest stocks of accumulated macroplastics. In the ocean, degradation mainly occurs close to the shore where the movement of leaked plastics is intensive due to waves and currents (see Annex A for more information on the methodology).

The buoyancy of plastics also changes when they undergo degradation, fragmentation and fouling. Most fragmented plastics tend to settle below the ocean surface, ultimately reaching sediments, which are considered a final sink for plastic debris. This is supported by the finding that microplastics are much less abundant on the sea surface than larger macroplastics (Eriksen et al., 2014[44]). Some estimates suggest that over 90% of plastics that enter the ocean end up in sediments and in the lower levels of the oceanic water column (GESAMP, 2015[55]). Macroplastics probably stay longer on the surface. Research has found that large shares of plastic debris sampled on the ocean’s surface are decades-old (Lebreton, Egger and Slat, 2019[50]). The force of waves and currents around the coast may be circulating plastics above and below the waterline for a long time before plastic debris reaches the open ocean. Further research is needed to better understand the dynamics of plastics in aquatic environments and to design effective ways to prevent or remove risks.

2.5.2. Microplastics from road transport can pollute the air over wide areas

Road transport, and in particular the wear of tyres and brake pads, is one of the main sources of aerial microplastic pollution. Globally in 2019, airborne emissions from tyres were 16 times larger than emissions from brakes, but brakes are responsible for a larger share of fine particulate matter (PM2.5, i.e. particles with a diameter below 2.5 µm), which may have more severe health impacts (Evangeliou et al., 2020[59]; OECD, 2020[60]). Road transport-related microplastics are emitted mainly in large urban agglomerations, such as the eastern part of North America, continental Europe and Northeast Asia (Figure 2.12).

While the majority of microplastic emissions tends to remain close to their source, where they increase the concentration levels of PM at ground level, some particles can travel long distances, depending on the location and atmospheric conditions (Figure 2.12). Substantial amounts of deposited microplastics have been found in remote regions (Evangeliou et al., 2020[59]), including mountain regions and the Arctic (Allen et al., 2019[61]; Lusher et al., 2015[62]). In the Arctic, the light-absorbing properties of tyre wear particles may accelerate atmospheric warming, with possible consequences for the balance of the global climate (OECD, 2021[63]).

Figure 2.12. Aerial microplastic pollution from road transport is highest in highly urbanised areas

Note: The map displays total suspended PM10 (particles of diameter inferior to 10 µm), including particulate matter emissions of smaller sizes (PM1 and PM2.5).

Source: OECD Global Plastics Outlook Database.

Policies can lower transport-related microplastics emissions by reducing the amount of emissions that vehicles generate and the total number of kilometres that vehicles are driven (OECD, 2020[60]). Potential mitigation measures include incentives for producing lighter-weight vehicles, regulating tyre composition and reducing the vehicle-kilometres travelled by regulating urban vehicle access, and promoting public transport, walking and cycling in urban areas. Policy makers should also prioritise research on the magnitude and impacts of non-exhaust particulate emissions from road transport and the effectiveness of mitigation measures to address them. Standardised approaches are needed for measuring non-exhaust particulate matter and developing a better understanding of how various factors (e.g. vehicle characteristics) influence the amount of non-exhaust particulate matter generated.

2.6. Plastic leakage has a variety of environmental, health and economic consequences

The proliferation of plastics combined with poor end-of-life waste management has resulted in widespread, persistent plastic leakage. The longevity of plastics is of particular concern. For example, single-use plastic products like LDPE plastic bags and HDPE milk bottles could have estimated half-lives of 5-250 years on land and 3-58 years in marine environments (Chamas et al., 2020[64]). On the other hand, HDPE pipes need thousands of years to completely degrade, with an estimated half-life of 1 200 years (Chamas et al., 2020[64]).

In aquatic environments, the most visible negative effects on marine wildlife are the entanglement of marine organisms in floating plastic debris and increased mortality following the ingestion of macro and microplastics by marine species such as mussels, turtles, fish and sea birds. At least 690 wildlife species, as well as coral reefs, are known to be affected (Gall and Thompson, 2015[65]). However, the negative consequences of plastics extend beyond these first order impacts. Microplastics have been documented in the digestive tract of several types of mussels and fish destined for human consumption (Lusher, Hollman and Mendoza-Hill, 2017[66]). Thus, the ingestion of seafood contaminated with microplastics has also been identified as a potentially substantial exposure pathway for humans.

Microplastic contamination is not exclusive to marine environments – it has also been documented in freshwater and terrestrial environments, as well as in food and beverages, such as tap water, bottled water and beer (Kosuth, Mason and Wattenberg, 2018[67]; Mintenig et al., 2019[68]). Humans are also exposed to microplastics by inhaling airborne particles and fibres, and microplastics have been reported both in indoor and outdoor environments (Gasperi et al., 2017[69]; Allen et al., 2019[61]). The main studies of human health impacts of airborne microplastics have looked at exposure to non-exhaust road traffic emissions (Figure 2.12).

Plastics may also act as a sink and transportation media for chemicals and persistent organic pollutants (POPs), which accumulate on the surface of plastics while in seawater. Adsorbed chemicals found on sampled plastic debris include PCBs, PAHs, DDE (a breakdown product of DDT) and trace metals (Engler, 2012[70]; Teuten et al., 2007[71]).7 Plastic fragmentation may enhance leaching of chemical substances to the surrounding environment. Nanoplastics are of particular concern because their small size allows them to potentially be transferred to tissues or cells (SAPEA, 2019[72]).

Furthermore, marine plastic leakage has substantial economic costs for coastal communities due to potential negative impacts on fishing and tourism. Plastics can affect the sustainability of fisheries, while plastic leakage on beaches deters visitors, causing financial distress to local communities reliant on tourism. Beaumont et al. (2019[73]) estimate the economic costs of the loss of marine ecosystem services to be around USD 3 300 per tonne of marine plastic per year.

A major challenge posed by plastics in the environment is the considerable uncertainty about the magnitude of the damage. Firstly, there are still important gaps in the current understanding of the plastic-health-biosphere links. Secondly, there are important uncertainties surrounding the quantities of plastics entering the environment and their accumulation. Ultimately, the estimation of the exact volume of plastic leakage is secondary to the intrinsic message from all these studies: plastic leakage is a major environmental problem and it is getting worse. The longevity of plastics means that the effects of today’s plastic leakage could become much larger in the future, causing long-term and potentially irreversible additional damage. The urgency to act for policy makers as well as other societal decision makers is high.

References

[6] Aguiar, A. et al. (2019), “The GTAP Data Base: Version 10”, Journal of Global Economic Analysis, Vol. 4/1, pp. 1-27, https://doi.org/10.21642/jgea.040101af.

[28] Akanuma, Y., S. Selke and R. Auras (2014), “A preliminary LCA case study: comparison of different pathways to produce purified terephthalic acid suitable for synthesis of 100 % bio-based PET”, The International Journal of Life Cycle Assessment, Vol. 19/6, pp. 1238-1246, https://doi.org/10.1007/s11367-014-0725-2.

[61] Allen, S. et al. (2019), “Atmospheric transport and deposition of microplastics in a remote mountain catchment”, Nature Geoscience, Vol. 12/5, pp. 339-344, https://doi.org/10.1038/s41561-019-0335-5.

[73] Beaumont, N. et al. (2019), “Global ecological, social and economic impacts of marine plastic”, Marine Pollution Bulletin, Vol. 142, pp. 189-195, https://doi.org/10.1016/j.marpolbul.2019.03.022.

[45] Borrelle, S. et al. (2020), “Predicted growth in plastic waste exceeds efforts to mitigate plastic pollution”, Science, Vol. 369/6510, pp. 1515-1518, https://doi.org/10.1126/science.aba3656.

[42] Boucher, J. et al. (2020), The marine plastic footprint, IUCN, International Union for Conservation of Nature, https://doi.org/10.2305/IUCN.CH.2020.01.en.

[23] Brizga, J., K. Hubacek and K. Feng (2020), “The Unintended Side Effects of Bioplastics: Carbon, Land, and Water Footprints”, One Earth, Vol. 3/1, pp. 45-53, https://doi.org/10.1016/j.oneear.2020.06.016.

[30] Broeren, M. et al. (2017), “Environmental impact assessment of six starch plastics focusing on wastewater-derived starch and additives”, Resources, Conservation and Recycling, Vol. 127, pp. 246-255, https://doi.org/10.1016/j.resconrec.2017.09.001.

[64] Chamas, A. et al. (2020), “Degradation Rates of Plastics in the Environment”, ACS Sustainable Chemistry & Engineering, Vol. 8/9, pp. 3494-3511, https://doi.org/10.1021/acssuschemeng.9b06635.

[5] Chateau, J., R. Dellink and E. Lanzi (2014), “An Overview of the OECD ENV-Linkages Model: Version 3”, OECD Environment Working Papers, No. 65, OECD Publishing, Paris, http://dx.doi.org/10.1787/5jz2qck2b2vd-en.

[31] Chen, G. and M. Patel (2011), “Plastics Derived from Biological Sources: Present and Future: A Technical and Environmental Review”, Chemical Reviews, Vol. 112/4, pp. 2082-2099, https://doi.org/10.1021/cr200162d.

[10] Chruszcz, A. and S. Reeve (2018), “Composition of plastic waste collected via kerbside. Banbury, UK: W. a. R. A. P. (WRAP)”, https://www.wrap.org.uk/sites/files/wrap/Composition%20of%20Plastic%20Waste%20Collected%20via%20Kerbside%20v2.pdf.

[40] Civancik-Uslu, D. et al. (2021), “Moving from linear to circular household plastic packaging in Belgium: Prospective life cycle assessment of mechanical and thermochemical recycling”, Resources Conservation and Recycling, Vol. 171, p. 105633, https://doi.org/10.1016/j.resconrec.2021.105633.

[35] Colmenar-Santos, A. et al. (2018), “Technological improvements in energetic efficiency and sustainability in existing combined-cycle gas turbine (CCGT) power plants”, Applied Energy, Vol. 223, pp. 30-51, https://doi.org/10.1016/j.apenergy.2018.03.191.

[57] Cook, E. (2020), Global review on safer end of engineered life..

[9] Cottom, J., E. Cook and C. Velis (2020), “Spatio-temporal quantification of plastic pollution origins and transportation (SPOT)” University of Leeds, UK, https://plasticpollution.leeds.ac.uk/toolkits/spot/.

[37] Dijkgraaf, E. and H. Vollebergh (2004), “Burn or bury? A social cost comparison of final waste disposal methods”, Ecological Economics, Vol. 50/3-4, pp. 233-247, https://doi.org/10.1016/j.ecolecon.2004.03.029.

[38] Dubois, M. (2013), “Towards a coherent European approach for taxation of combustible waste”, Waste Management, Vol. 33/8, https://doi.org/10.1016/j.wasman.2013.03.015.

[36] Ecoprog (2020), Waste to Energy 2020/2021, https://www.ecoprog.com/fileadmin/user_upload/extract_market_report_WtE_2020-2021_ecoprog.pdf (accessed on 26 May 2021).

[70] Engler, R. (2012), “The Complex Interaction between Marine Debris and Toxic Chemicals in the Ocean”, Environmental Science & Technology, Vol. 46/22, pp. 12302-12315, https://doi.org/10.1021/es3027105.

[44] Eriksen, M. et al. (2014), “Plastic Pollution in the World’s Oceans: More than 5 Trillion Plastic Pieces Weighing over 250,000 Tons Afloat at Sea”, PLOS ONE, Vol. 9/12, p. e111913, https://doi.org/10.1371/journal.pone.0111913.

[22] European Bioplastics (2019), Bioplastics market data 2019 - Global production capacities of bioplastics 2019-2024.

[59] Evangeliou, N. et al. (2020), “Atmospheric transport is a major pathway of microplastics to remote regions”, Nature Communications, Vol. 11/1, p. 3381, https://doi.org/10.1038/s41467-020-17201-9.

[20] Franklin Associates (2018), Life cycle impacts of plastic packaging compared to substitutes in the United States and Canada: Theoretical substitution analysis, https://www.americanchemistry.com/better-policy-regulation/plastics/resources/life-cycle-impacts-of-plastic-packaging-compared-to-substitutes-in-the-united-states-and-canada.

[65] Gall, S. and R. Thompson (2015), “The impact of debris on marine life”, Marine Pollution Bulletin, Vol. 92/1-2, pp. 170-179, https://doi.org/10.1016/j.marpolbul.2014.12.041.

[69] Gasperi, J. et al. (2017), “Microplastics in air: Are we breathing it in?”, Current Opinion in Environmental Science & Health, Vol. 1, pp. 1-5, https://doi.org/10.1016/j.coesh.2017.10.002.

[55] GESAMP (2015), Sources, fate and effects of microplastics in the marine environment: a global assessment, IMO/FAO/UNESCO-IOC/UNIDO/WMO/IAEA/UN/UNEP/UNDP Joint Group of Experts on the Scientific Aspects of Marine Environmental Protection), http://www.imo.org.

[1] Geyer, R., J. Jambeck and K. Law (2017), “Production, use, and fate of all plastics ever made”, Science Advances, Vol. 3/7, p. e1700782, https://doi.org/10.1126/sciadv.1700782.

[17] Gómez-Sanabria, A. et al. (2018), “Carbon in global waste and wastewater flows – its potential as energy source under alternative future waste management regimes”, Advances in Geosciences, Vol. 45, pp. 105-113, https://doi.org/10.5194/adgeo-45-105-2018.

[8] Grand View Research (2020), Recycled Plastics Market: Market Analysis.

[2] IEA (2018), The future of petrochemicals: Towards more sustainable plastics and fertilisers, International Energy Agency, Paris, https://dx.doi.org/10.1787/9789264307414-en.

[74] IPCC (1995), Climate Change 1995: A report of the Intergovernmental Panel on Climate Change - IPCC Second Assessment.

[14] Jambeck, J. et al. (2015), “Plastic waste inputs from land into the ocean”, Science, Vol. 347/6223, pp. 768-771, https://doi.org/10.1126/science.1260352.

[48] Jambeck, J. et al. (2015), “Plastic waste inputs from land into the ocean”, Science, Vol. 347/6223, pp. 768-771, https://doi.org/10.1126/science.1260352.

[13] Kaza, S. et al. (2018), What a Waste 2.0: A Global Snapshot of Solid Waste Management to 2050, The World Bank, https://doi.org/10.1596/978-1-4648-1329-0.

[67] Kosuth, M., S. Mason and E. Wattenberg (2018), “Anthropogenic contamination of tap water, beer, and sea salt”, PLoS ONE, Vol. 13/4, https://doi.org/10.1371/journal.pone.0194970.

[46] Lau, W. et al. (2020), “Evaluating scenarios toward zero plastic pollution”, Science, Vol. 369/6510, pp. 1455-1461, https://doi.org/10.1126/science.aba9475.

[47] Law, K. et al. (2020), “The United States’ contribution of plastic waste to land and ocean”, Science Advances, Vol. 6/44, p. eabd0288, https://doi.org/10.1126/sciadv.abd0288.

[39] Lazarevic, D. et al. (2010), “Plastic waste management in the context of a European recycling society: Comparing results and uncertainties in a life cycle perspective”, Resources, Conservation and Recycling, Vol. 55/2, pp. 246-259, https://doi.org/10.1016/j.resconrec.2010.09.014.

[15] Lebreton, L. and A. Andrady (2019), “Future scenarios of global plastic waste generation and disposal”, Palgrave Communications, Vol. 5/1, p. 6, https://doi.org/10.1057/s41599-018-0212-7.

[50] Lebreton, L., M. Egger and B. Slat (2019), “A global mass budget for positively buoyant macroplastic debris in the ocean”, Scientific Reports, Vol. 9/1, p. 12922, https://doi.org/10.1038/s41598-019-49413-5.

[49] Lebreton, L. et al. (2017), “River plastic emissions to the world’s oceans”, Nature Communications, Vol. 8/1, https://doi.org/10.1038/ncomms15611.

[24] Liptow, C. and A. Tillman (2012), “A Comparative Life Cycle Assessment Study of Polyethylene Based on Sugarcane and Crude Oil”, Journal of Industrial Ecology, Vol. 16/3, pp. 420-435, https://doi.org/10.1111/j.1530-9290.2011.00405.x.

[33] Lombardi, L., E. Carnevale and A. Corti (2015), “A review of technologies and performances of thermal treatment systems for energy recovery from waste”, Waste Management, Vol. 37, pp. 26-44, https://doi.org/10.1016/j.wasman.2014.11.010.

[66] Lusher, A., P. Hollman and J. Mendoza-Hill (2017), Microplastics in fisheries and aquaculture: status of knowledge on their occurrence and implications for aquatic organisms and food safety, FAO Fisheries and Aquaculture Technical Paper. No. 615, Rome, Italy.

[62] Lusher, A. et al. (2015), “Microplastics in Arctic polar waters: The first reported values of particles in surface and sub-surface samples”, Scientific Reports, Vol. 5, https://doi.org/10.1038/srep14947.

[58] Meijer, L. et al. (2021), “More than 1000 rivers account for 80% of global riverine plastic emissions into the ocean”, Science Advances, Vol. 7/18, https://doi.org/10.1126/sciadv.aaz5803.

[68] Mintenig, S. et al. (2019), “Low numbers of microplastics detected in drinking water from ground water sources”, Science of the Total Environment, Vol. 648, pp. 631-635, https://doi.org/10.1016/j.scitotenv.2018.08.178.

[32] Neuwahl, F. et al. (2019), Best Available Techniques (BAT) Reference Document for Waste Incineration:Industrial Emissions Directive 2010/75/EU (Integrated Pollution Prevention and Control), Publications Office of the European Union, Luxembourg,, https://doi.org/doi:10.2760/761437.

[51] Nizzetto, L., M. Futter and S. Langaas (2016), Are Agricultural Soils Dumps for Microplastics of Urban Origin?, American Chemical Society, https://doi.org/10.1021/acs.est.6b04140.

[43] OECD (2021), Policies to Reduce Microplastics Pollution in Water: Focus on Textiles and Tyres, OECD Publishing, Paris, https://dx.doi.org/10.1787/7ec7e5ef-en.

[63] OECD (2021), The Economic Benefits of Air Quality Improvements in Arctic Council Countries, OECD Publishing, Paris, https://dx.doi.org/10.1787/9c46037d-en.

[60] OECD (2020), Non-exhaust Particulate Emissions from Road Transport: An Ignored Environmental Policy Challenge, OECD Publishing, Paris, https://dx.doi.org/10.1787/4a4dc6ca-en.

[52] OECD (2017), “Water: Sewage sludge production and disposal (Edition 2017)”, OECD Environment Statistics (database), https://dx.doi.org/10.1787/14780a65-en (accessed on 20 February 2020).

[34] Pavlas, M. et al. (2011), “Waste incineration with production of clean and reliable energy”, Clean Technologies and Environmental Policy, Vol. 13/4, pp. 595-605, https://doi.org/10.1007/s10098-011-0353-5.

[4] Plastics Europe (2020), Plastics - the Facts: an analysis of European plastics production, demand and waste data.

[11] Roosen, M. et al. (2020), “Detailed Analysis of the Composition of Selected Plastic Packaging Waste Products and Its Implications for Mechanical and Thermochemical Recycling”, Environmental Science & Technology, Vol. 54/20, pp. 13282-13293, https://doi.org/10.1021/acs.est.0c03371.

[19] Royer, S. et al. (2018), “Production of methane and ethylene from plastic in the environment”, PLOS ONE, Vol. 13/8, https://doi.org/10.1371/journal.pone.0200574.

[3] Ryberg, M. et al. (2019), “Global environmental losses of plastics across their value chains”, Resources, Conservation and Recycling, Vol. 151, p. 104459, https://doi.org/10.1016/j.resconrec.2019.104459.

[72] SAPEA (2019), A Scientific Perspective on Micro-Plastics in Nature and Society, Science Advice for Policy by European Academics, https://doi.org/10.26356/microplastics.

[53] Schwarz, A. et al. (2019), “Sources, transport, and accumulation of different types of plastic litter in aquatic environments: A review study”, Marine Pollution Bulletin, Vol. 143, pp. 92-100, https://doi.org/10.1016/J.MARPOLBUL.2019.04.029.

[29] Semba, T. et al. (2018), “Greenhouse gas emissions of 100% bio-derived polyethylene terephthalate on its life cycle compared with petroleum-derived polyethylene terephthalate”, Journal of Cleaner Production, Vol. 195, pp. 932-938, https://doi.org/10.1016/j.jclepro.2018.05.069.

[18] Shen, M. et al. (2020), “(Micro)plastic crisis: Un-ignorable contribution to global greenhouse gas emissions and climate change”, Journal of Cleaner Production, Vol. 254, p. 120138, https://doi.org/10.1016/j.jclepro.2020.120138.

[7] Stadler, K. et al. (2018), “EXIOBASE 3: Developing a Time Series of Detailed Environmentally Extended Multi-Regional Input-Output Tables”, Journal of Industrial Ecology, Vol. 22/3, pp. 502-515, https://doi.org/10.1111/jiec.12715.

[21] Stefanini, R. et al. (2020), “Plastic or glass: a new environmental assessment with a marine litter indicator for the comparison of pasteurized milk bottles”, The International Journal of Life Cycle Assessment, Vol. 26/4, pp. 767-784, https://doi.org/10.1007/s11367-020-01804-x.

[71] Teuten, E. et al. (2007), “Potential for plastics to transport hydrophobic contaminants”, Environmental Science and Technology, Vol. 41/22, pp. 7759-7764, https://doi.org/10.1021/es071737s.

[54] Tosin, M. et al. (2012), “Laboratory Test Methods to Determine the Degradation of Plastics in Marine Environmental Conditions”, Frontiers in Microbiology, Vol. 3, p. 225, https://doi.org/10.3389/fmicb.2012.00225.

[27] Tsiropoulos, I. et al. (2015), “Life cycle impact assessment of bio-based plastics from sugarcane ethanol”, Journal of Cleaner Production, Vol. 90, pp. 114-127, https://doi.org/10.1016/j.jclepro.2014.11.071.

[41] UNEP (2019), Waste to Energy: considerations for informed decision-making, https://wedocs.unep.org/bitstream/handle/20.500.11822/28413/WTEfull.pdf?sequence=1&isAllowed=y.

[26] Vanderreydt, I. et al. (forthcoming), European Environment Agency: European Topic Centre on Waste and Materials in a Green Economy.