This chapter analyses the challenges that the COVID-19 crisis presents for the implementation and enforcement of food safety regulation. It discusses, in particular, different approaches adopted by food safety authorities to safeguard sustained compliance with food safety regulation under unprecedented circumstances including measures aimed at third-party auditors and certification bodies that play a role in ensuring the food security objectives are achieved.

Improving Regulatory Delivery in Food Safety

3. Implementing food safety regulation and third-party certification in crisis situation

Abstract

The challenges for implementation and enforcement of food safety regulation facing COVID-19

The COVID-19 crisis has placed governments under extraordinary pressure to swiftly adjust their regulatory delivery practices, promoting safer practices in workplaces in response to the pandemic, while continuing to ensure effective compliance with rules and regulations across policy fields. Interventions were needed to provide guidance to stakeholders and adopt regulatory easement measures to ensure supply of essential goods and the continuous operation of services or alleviate the regulatory burden on market actors. Regulators have also adapted their routine functions, including inspection and enforcement arrangements, to unprecedented circumstances that restricted the movement of people and face-to-face interactions (OECD, 2021[1]).1Several regulators across different streams have leveraged on technology to remain flexible, agile and resilient and also to minimise disruptions arising in trade flows while maintaining protection for healthy and safe trade of food (OECD, 2021[1]). Overall, the crisis sheds light on the importance of the implementation phase of the regulatory governance cycle, an area identified by (OECD, 2018[2]) as a critical and often neglected link in regulatory governance, key to ensure the quality and effectiveness of regulatory policy and to meet the goals of regulations.

The crisis impacted all regulatory areas, including food safety regulation, the set of norms and procedures regulating the production, supply and sale of food with the aim to reduce the risk of unsafe food making consumers ill. Even in normal times, effective food safety compliance combines a complex set of factors: good regulation, well-designed enforcement, and, possibly most importantly, competence, knowledge, and understanding of food safety’s importance from food business operators (FBOs) (Blanc and Macrae, 2021[3]).

While there is significant diversity, fragmentation and all kind of “national peculiarities” when it comes to food safety regulatory structures (Blanc and Cola, 2017[4]), across the food supply chain, food safety governance rests on the complementary interplay of public legislation and regulation and with private standards (Kotsanopoulos and Arvanitoyannis, 2017[5]). Public authorities (including national governments, international and transnational institutions) are responsible for setting laws and regulations that define minimum food safety or marketing requirements for food operations. Food-regulation enforcement authorities - structured on a national or subnational basis - then ensure that market actors follow these requirements deploying regulatory delivery tools: inspections and enforcement.

To ensure the safety and quality of their products, food business operators (FBOs) have developed a set of private food safety standards (PFSS). Whether or not required under law, these standards are followed by a large share of the food sector, in particular suppliers integrated into large national or international supply chains, being imposed by buyers (large producers/processors, and large retailers) on their suppliers to ensure the quality and safety of products (Fagotto, 2015[6]). Many food companies implement a systematic preventive approach (based on hazard analysis and critical control points [HACCP]) for their food safety management system. These are frequently based on standards developed and managed by the food industry and operate at different levels, for instance the Safety Quality Food (SQF) standard managed by the US-based Food Marketing Institute and the British Retail Consortium Global Standards for Food Safety (BRC) standard by the British Retail Consortium. Internationally, institutions such as the Global Food Safety Initiative (GFSI) benchmark different international food safety certification programmes and auditing platforms aiming to set equivalency among standards. In addition, international standardisation organisations such as the International Standardization Organisation [ISO] also develop standards relevant for food safety (in particular the ISO 22000 standard for food safety management, including both so-called “pre-requisites” i.e. good hygiene practices, and HACCP implementation).

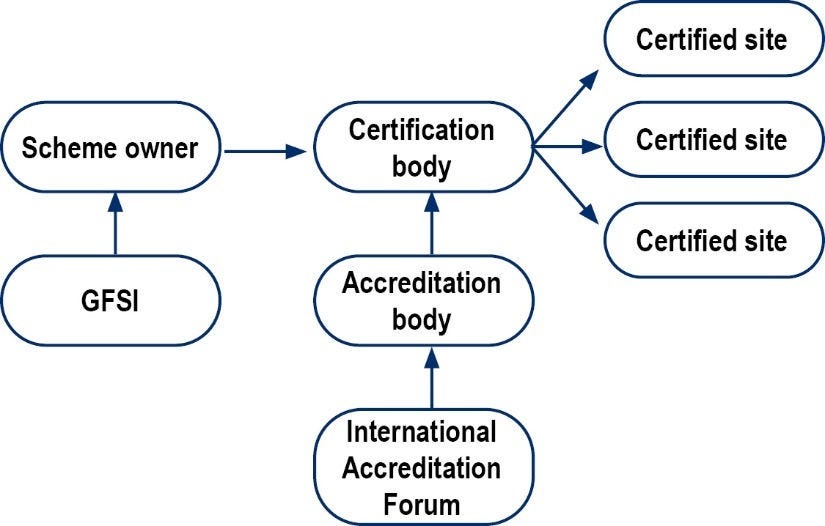

Monitoring and enforcement of PFSS involves a broad range of actors: scheme owners authorise third‑party certification bodies that carry out audits on facilities and issue certificates to attest compliance with a standard. Accreditation bodies provide an extra layer of assurance over the impartiality and capabilities of certification bodies to perform their functions (Figure 3.1).

Figure 3.1. Actors involved in monitoring and enforcement of food safety standards

The COVID-19 crisis increased complexity food safety compliance, forcing authorities to adjust their implementation and enforcement practices while also dealing with a set of additional and specific challenges – in particular, strong limitations on the possibility to conduct on-site inspections, changes in distribution and consumption patterns imposed by lockdowns, abrupt changes in both supply and demand, and the need to ensure the food industry’s continued functioning in spite of a major economic slump.

Facing food supply chains disruptions

The outbreak of the COVID-19 pandemic affected food supply and demand in complex ways, creating bottlenecks across the food supply chains, impacting farm labour, processing, transport and logistics (OECD, 2020[7]) (OECD, 2020[8]). As illustrated throughout the paper, the SDGs provide an effective framework capable of highlighting the broader implications of changing food supply and demand. In this regard safety enabler function in achieving the goal SDG 5, 8, 11, 12, 14, 15. Yet, the advancement of the SDGs might be weakened by food safety itself, for instance when regulations in this field act as non/tariff sures, having consequences on food exporters in developing countries who have limited capacity and resources to comply with them. The OECD Agricultural Policy Monitoring and Evaluation 2020 discusses the wide set of agriculture and food policy responses introduced by governments in response to the virus and associated mitigation measures that included mobility restrictions (Box 3.1). These responses were varied and included the provision of various forms of support to actors along the food chain, initiatives to keep food and agricultural supply chains moving, and support to consumers and vulnerable populations, among other. Several countries took active steps to facilitate trade, although some countries also introduced export restrictions in efforts to ensure availability on domestic markets.

Box 3.1. Agriculture and food related measures taken by governments in response to the COVID-19 crisis

The OECD Agricultural Policy Monitoring and Evaluation 2020 identifies a diverse set of agriculture and food related measures that have been taken by governments in response to the crisis, focusing on agricultural production, the functioning of the food chain and consumer demand. A review of the more than 400 collected policy responses suggests seven broad categories of measures:

1. Sector-wide and institutional measures – including declaration of essential sector and measures related to the functioning of the government.

2. Information and co-ordination measures – such as websites and campaigns, monitoring the agriculture market, co-ordination with the private sector and international co-ordination.

3. Measures on trade and product flows – including trade easing measures, logistics and transport facilitation measures, trade restricting measures, rechannelling product flows, and facilitating internal market integration.

4. Labour measures – notably measures to ensure the health of workers and agriculture labour measures.

5. Agriculture and food support measures – such as general financial sectoral support, specific product support and administrative and regulatory flexibility.

6. General support applicable to agriculture and food – including those provided by overall economic measures and social safety nets.

7. Food assistance and consumer support – including food assistance and market measures in support of consumers.

Source: (OECD, 2020[9]).

Responding to changes in consumer preferences

The downfall in consumption of food away from home triggered shifts in consumer demand with food supplied to supermarkets in lieu of restaurants and other food service establishments. A survey of the impact of COVID-19 in consumer food behaviours in ten EU countries, showed an overall 45% increase in online shopping compared to the pre-COVID-19 period with particular rises in food delivery and bulk purchases (EIT Food, 2020[10]). The EIT data also showed changes in consumer product preferences from the loss of income, an increase in preference for fruit, vegetables and flour, followed by dairy products and poultry, a shift towards pre-packaged food and more attention to date of packaging/best before/expiry date freshness of products for freshness and avoidance of artificial flavours and additives.

The increase in online grocery shopping and food delivery impacted packaging and labelling requirements overseen by food regulation authorities while at the same time calling for special supervision of this trade channel to ensure control food safety and prevent fraudulent practices. The pivot to online food shopping and delivery has increased pressure over food regulators to ensure that new food sellers entering the market meet food safety requirements.2

Minimising contamination risks among food sector workforce

Food businesses faced particular challenges to control COVID-19. As many manufacturing facilities, locations such as food processing and packing plants, where individuals work in close proximity and physical distance is hard to observe, face particular obstacles in control of infectious diseases. Several countries saw infection clusters in meat and poultry processing and packaging plants leading at times to a temporary closure of facilities or high absenteeism. Data from the US Centers from Disease Control and Prevention showed that between April and May of 2020, 16 233 workers in meat and poultry processing facilities were infected with COVID-19 (Waltenburg et al., 2020[11]).

Food processing plants outside the meat and poultry business were also affected by virus outbreaks. For instance, in February 2021 over 200 workers in an ice-cream factory in Germany tested positive for COVID-19 (The Germany Eye, 2021[12]). The fact that COVID-19 outbreaks among these workers can rapidly affect large numbers of persons increased pressure for targeted guidance and regulatory intervention to reduce the risk for COVID-19 spreads in food plants.

Reacting to communication needs

Since the early days of the pandemic, food safety authorities responded to an increasing number of queries and questions from a range of actors, including other authorities, the food industry, consumers, and stakeholders (FAO/WHO, 2020[13]). Initially, communication efforts were largely aimed at mitigating concerns about COVID-19 being a food borne disease – the European Food Safety Authority (EFSA) and the US FDA were among the regulators issuing notes on this regard. More often, communication efforts have centred on guiding businesses and consumers around the regulatory easement measures adopted to facilitate the operations of food business and industries.

Reducing food safety incidents to ease pressure in health systems

The COVID-19 outbreak subjected health systems to an overwhelming and sudden surge in the number of patients in need of urgent treatment. This made the need for preventing foodborne illness particularly acute to avoid burdening an already stressed emergency medical system during a global health crisis. Yet continuous implementation of the SDGs (as opposed to them being side-lined by the presence of COVID-19 and potentially regress the progress until today) can support sustained recovery. This is particularly true when referring to SDGs such as SDG 3 “Good health and Well-being“ which calls for research and development of vaccines and strengthening capacity for early warning and risk reduction (OECD, 2020[14]). It is too early to assess the impact of COVID-19 over the incidence of foodborne contamination: sudden disruptions in supply chains and workforce availability could have led to increased risks and contamination, but improved hygiene could have been a countervailing force, and data points in conflicting directions. The International Food Safety Authorities Network (INFOSAN) has recorded engaged in 127 events in 2020 compared to 84 in 2019, but some national data suggests decreased incidence for at least the first part of 2020.3 Variations from previous years could be observed from the increased health safety measures for COVID-19 that offer protection for foodborne diseases, such as handwashing, while at the same time under-reporting could occur from a decrease in doctor consultations and potentially less reporting from laboratories.

Adapting operational arrangements

(WHO and FAO, 2020[15]) identified additional operation challenges facing food authorities, as they implemented business continuity plans to ensure continued enforcement of and compliance with food regulations at times dealing with reduced staff capacity to maintain fully functioning inspection activities, as personnel were assigned to national COVID-19 emergency response teams, staff working from home, and staff illness and self-isolation. A similar challenge was noted for food laboratories with food testing capacities reduced as staff were reallocated to COVID-19 clinical testing.

The next section of this chapter discusses the different measures implemented by food safety authorities and stakeholders during the COVID-19 crisis to safeguard sustained compliance with food safety regulation across the broad range of actors that play a role in ensuring the food security objectives are achieved.

Rebooting enforcement of food safety regulation

Administrations responded to the COVID-19 crisis using a range of regulatory instruments, including primary and secondary legislation, as well as adopting non-legislative changes to implement urgent reforms impacting a range of policy areas such as public health, emergency response systems, competition legislation (OECD, 2020[16]). The responses seek, for instance, to ensure that supply chains continue to provide urgently needed goods or to secure the continuity of services. Overall, a number of these measures were implemented following a risk-based approach that prioritised preserving inspection and enforcement efforts in areas where critical risks were the greatest or where inspections were required based on complaints.

This section discusses the different approaches available to food safety authorities to safeguard sustained compliance with food safety regulation during the crisis. Some of these approaches can be studied to propose lessons and possible good practices in the field of food security going forward.

Regulatory easing measures

Many countries swiftly instituted temporary administrative and regulatory flexibilities as part of their crisis response aiming to ease the operations of business and industries. This involved resorting to a range of regulatory instruments, primary and secondary legislation, at times passed using emergency legislation or fast-tracked procedures (OECD, 2020[16]), as well as non-legislative action. Food safety regulation was part of this trend.

In some countries, regulators introduced adjustment to labelling requirements to help keep at bay the impact of supply chain disruptions on product availability. In the United States, the Department of Health and Human Services Food and Drug Administration (FDA) issued a set of guidance allowing for temporary labelling flexibilities under certain circumstances. The agency allowed manufacturers to make minor formulation changes without reflecting them on the package label (U.S. Food and Drug Administration, 2020[17]). To meet increased demand for eggs, the FDA issued temporary flexibility guidance on certain packaging and labelling requirements for eggs sold in retail food establishments (U.S. Department of Health and Human Services Food and Drug Administration, 2020[18]). Additional guidance on labelling was issued to allow restaurants to sell packaged food to consumers directly, or to other businesses for sale to consumers (U.S. Food and Drug Administration, 2020[19]). Similar guidance was passed by the US Department of Agriculture allowing for labelling flexibilities to the Country of Origin Labeling (COOL) requirements to enable the redistribution of food products intended for food service to be sold directly to consumers (U.S. Department of Agriculture, 2020[20]). The Canadian Food Inspection Agency (CFIA) also provided flexibility for certain labelling requirements for foodservice packaged products deemed to have no impact on food safety, as part of a broader temporary suspension of some low-risk suspended activities (Canadian Food Inspection Agency, 2020[21]). Denmark temporarily waived labelling requirements of country of origin and accepted the retail sale of pre-packaged foods without labelling in Danish provided that it complied with the requirements of the Food Information Regulation (Danish Veterinary and Food Administration, 2020[22]).

In-person inspections or other compliance activities were at times scaled-back or halted. Some countries chose to restrict controls to high-risk situations focusing exclusively on critical safety issues, so as to minimise possible virus exposure for inspectors and workers. The CFIA’s business continuity plan activated in March 2020, prioritised critical activities while temporarily suspending low-risk activities, such as food inspections and investigations not related to food safety, surveillance or sampling activities (food, plant and animal), inspections of preventive control plans and plant and animal inspections in areas of low risk and labelling and domestic facility inspections (Canadian Food Inspection Agency, 2020[23]). In March 2020, the US FDA postponed most foreign facility inspections and all domestic routine surveillance facility inspections while maintaining only all mission-critical assignments (for instance, domestic for-cause inspection) (U.S. Food and Drug Administration, 2020[24]).

Food safety authorities adjusted the requirements applicable to third parties responsible for evaluating compliance with food regulation through certification or audit mechanisms. Some countries provided flexibility on regulations requiring accreditation bodies and third-party certification bodies to perform certain onsite observations and examinations that were ill advised due to health concerns or unviable due to travel restrictions. The US FDA issued a temporary policy in this regard applicable to participants in the US Accredited Third-Party Certification Program under which accredited third-party certification bodies conduct food safety audits and issue food or facility certifications to eligible foreign entities for specific purposes (U.S. Food and Drug Administrator, 2020[25]). Regulators also extended certain certificates based on risk assessment of products or facilities. The CFIA allowed for flexibility in Certification Bodies inspection frequency for renewal certification under the Canada Organic Regime. Poland extended the validity of health certificates for livestock and the deadlines for livestock identification (OECD, 2020[9]). Private actors involved in the implementation of food safety regulation took similar flexibility measures. For instance, the GFSI allowed for certificate extension of six month under specific circumstances (GFSI, 2020[26]).

Governments introduced measures to minimise COVID-19 contamination risks safeguarding agriculture and food workforce and to ensure the availability of seasonal labour. Workplace safety is typically overseen by occupational safety and health authorities. Still in a number of countries food safety regulators joined cross-government efforts to provide guidance on special workplace safety and health practices. In the United Kingdom, special guidance for all workplaces involved in the manufacturing, processing, warehousing, picking, packaging, retailing and service of food, aimed to reduce the risk of COVID-19 entering the workplace, spreading within and from the workplace to the wider community and also aimed to reduce the impact of the virus on output and production of the food industry (Public Health England and the UK Department of Environment Food and Rural Affairs, 2020[27]). The UK Food Standards Authority (FSA) provided special guidance to help stakeholders understand how to work safely in the food manufacturing and agricultural sectors during the pandemic (UK Food Standards Agency, 2020[28]) (UK Food Standards Agency, 2020[29]). In the United States, the FDA and the Occupational Safety and Health Administration (OSHA) developed a checklist for human and animal food operations regulated by the FDA to use when assessing operations during the public health emergency, especially when re-starting operations after a shut down or changes in the status of the pandemic (FDA and OSHA, 2020[30]). The checklist is aimed at persons growing, harvesting, packing, manufacturing, processing, or holding human and animal food regulated by FDA, including: produce, seafood, milk, eggs, grains, game meat, and other raw materials or ingredients, as well as their resulting human or animal food products. The document also served to provide information for foreign facilities that manufacture, process, pack, or hold food for consumption in the US. A section of the checklist is focused on food safety, including on food safety or HACCP plans, personnel, suppliers and incoming Ingredients, and current good manufacturing practices (CGMPs) requirements. Additional special guidance issued by the corresponding US authorities in consultation with the FDS centred on meat and poultry and seafood processing workers and employers (CDC and OSHA, 2021[31]) and (CDC and OSHA, 2021[32]).

Deployment of new technologies to enforce food safety regulations

Recent years have seen a growing interest in the potential of new digital technologies, enabled by the increasing use of mobile tools, Machine Learning and Big Data, to increase regulatory capacity particularly in the area of inspections and enforcement (OECD, 2021[1]). The OECD Regulatory Enforcement and Inspections Toolkit includes a criteria on information integration notes that Information Communication Technology (ICT) tools should be used to make work more efficient and targeting better (OECD, 2018[33]). The toolkit encourages the use of automated planning (based on risk criteria and risk profile of establishments recorded in the database), mobile tools for inspectors (laptop/tablet or smartphone based tools including check-lists, mobile applications or other instruments to directly record the inspection findings, look up additional information etc.), and geographical information systems (Box 3.2).

Box 3.2. Using technology to support risk-based and outcomes-focused regulatory delivery

Outcomes-focused checklists within the “Rating Audit Control” (RAC) project in Italy

The RAC project in Italy, funded by the European Commission and implemented by the OECD, aims at supporting regional and national governments in improving the business environment and investment climate and the efficiency of the use of public funds through improved regulatory predictability and confidence, and reduced burden on lower-risk activities. To achieve better outcomes in regulatory delivery, inspection methods and practices on the ground are being transformed, consistency of inspections improved, and efforts towards clearer and more understandable regulatory requirements for business operators undertaken.

One key tool to achieve this goal is work on risk-based checklists for inspections, which are being prepared in different regulatory areas and in particular in the food safety domain so as to ensure development and consistency in methods, and to make a valuable contribution to improving matters in terms of outcomes. New checklists are being adapted to regional realities. They include a risk-based scoring system, and their results are being linked to an update in risk rating. By including the “static” risk of the establishment, its “dynamic” risks (actual risk management, such as the use of HACCP in food safety), and its compliance history (including measures imposed by inspectors because of violations leading to immediate risks), they yield a comprehensive picture of the establishment in terms of actual level of risk, and of most significant elements that need to be addressed to achieve the desired outcomes in terms of regulatory goals.

Machine learning and risk indicators

While defining risk abstractly is relatively straightforward, developing robust methods to predict the level of risk of different businesses or establishments is far more difficult. Until recently, challenges in data availability and methods for analysis meant that defining risk criteria and their relative weights based on “data mining” or similar mathematical approaches was mostly reserved to tax and customs inspections (where the objects of regulation and control are inherently numerical, and computerisation was done earliest and in the most systematic way) – in technical, safety and similar fields, risk identification and weighting was done through a combination of scientific and technical findings, regulators’ experience and “trial-and-error”, but in a much less systematic and precise way.

The spread of information management systems to record inspection results, and thus the increasing availability of detailed historical data, combined with advances in data processing power and analytical tools (e.g. machine learning) now make it increasingly possible. In Italy, the region of Campania is currently piloting the use of Machine Learning for risk assessment in food safety controls.

In addition to such work to better assess “operational-level” risk, work at the “strategic level” is also increasingly data-driven. In 2017, Canada’s CFIA launched a review of its risk management model in order to ensure the allocation of resources where it can have the greatest impact on reducing risks. The first challenge of the model is to enable comparison among different kinds of risks, which entails converting different types of risks into comparable data. Based on this, the Agency is able to consider trade-offs among all of them, across different organisational levels This work has entailed considerable efforts to gather and consolidate data from all parts of CFIA’s work.

Along similar lines, the Risk Assessment Directorate of Environment and Climate Change Canada has developed the Threat-Risk Assessment (TRA) model, based on a large review of available data to estimate the probabilities and potential impact of known sources of harms for the environment. Data is gathered from the industry, government partners and international actors. Outcomes from the strategic risk assessment are used by the Climate Change and Environment of Canada for project planning and allocation of resources. Likewise, it is shared with enforcement officers to inform their work.

Sharing and using data to better manage risks

A number of Italian regions and institutions have, in recent years, worked on improving data sharing, analysis, and usage, to reduce the burdens and inefficiencies created by duplications and lack of coordination between different services, and better support regional economies.

In Campania, in addition to the existing GISA system to plan and manage all food safety inspections, the region partnered with the University of Naples Parthenope to develop MytiluSE, a system to predict the quality of waters so as to secure safety of mussels produced in the bay of Naples. Rather than expending large resources on ex post controls to find potential contamination, the system works pre-emptively, enabling to know which days the harvesting of mussels would be unsafe. Once fully operational, it can both inform producers and guide inspectors’ work. Developing the system involved investigating the currents of the bay of Naples, mapping contamination sources, and developing a reliable predictive model, but it is potentially completely transformative for regulatory delivery. It was also adapted to predict air pollution by fumes, which can affect feed for bovine herds. The predictive approach for mussels is not only better for the economy and public service efficiency, but it also avoids health hazards far more effectively, because microbiological testing and sampling takes time, and results can come too late (leading to potential contaminations from other products harvested the same day).

Notes: https://documents.worldbank.org/en/publication/documents-reports/documentdetail/490491468159916971/risk-based-tax-audits-approaches-and-country-experiences; https://www.oecd.org/tax/administration/33818656.pdf%20https://www.oecd.org/tax/forum-on-tax-administration/publications-and-products/hnwi/42490764.pdf.

Source: OECD work in Italy (publications forthcoming 2021), direct interviews with and presentations from CFIA and Environment and Climate Change Canada and Montella R, Riccio A, di Luccio D, Mellone G, de Vita, C G (2020), MytiluSE: Modelling mytilus farming System with Enhanced web technologies, Università degli Studi di Napoli Parthenope, Sciences and Technology Department, commissioned by Campania.

The pandemic increased experimentation with new technologies for regulatory inspections and enforcement, as they provide tools that can help cut through some of the obstacles posed by mitigation measures such as widespread restrictions on travel and mobility, workplace social distancing rules and temporary closure of business. As surveillance of compliance with food safety regulations remained crucial, a number of authorities adapted their “intervention toolkit” following a risk-based approach to ensure compliance using a range of mechanisms, including remote inspections, “record audits” and hybrid inspections, to enable the continuity of verification activities. However, this leap has been unequal, with a significant gap in the usage of new technologies between advanced economies, which could adapt faster than middle- and low-income economies.

Some authorities responsible for the enforcement of food safety regulations recalibrated their approaches to inspections and relied on remote tools to ensure surveillance continuity. Key enforcement activities such as on-site inspections were particularly impacted by the outbreak of COVID-19, facing difficulties and restrictions for travelling between and within the borders of countries, accessing food processing and packaging facilities, as well as the need to safeguard inspectors and firm’s workforce from health hazards and observing authorities’ recommendations. To sort some of these obstacles a number of authorities relied on remote inspections, where visits or checks are conducted by an authorised official in real time using technology without travelling to the site (Box 3.3).4 Inspections may also take a hybrid form, combining activities that take place remotely, such as interviews and record review, with on-site activities, or setting up inspections that take place remotely and on-site on a later date. This has also been handled as an emergency measure by the EC in its Implementing Regulation (EU) 2020/466.5

Box 3.3. Virtual inspections experiments

With new urgency because of the constraints on movement and the need to minimize contagion risks in the COVID-19 context, virtual audits and inspections are under consideration or discussion in a number of countries and institutions, or being piloted to test their reliability and applicability. This is particularly important in food safety, because food production and supply are essential activities that cannot be suspended fully, and food safety inspections are both important to prevent food contamination, but also sources of potential risks of contagion. Challenges in doing such checks remotely include the difficulty to spot “hidden” problems, assurance against fraud, requirements for equipment, training and competence of staff in the facility to provide a “remote view”, and of inspecting staff to analyse and challenge the results, etc. In addition, other risks (such as occupational safety and health) cannot be easily observed from outside, and even though they may not strictly belong to “food safety”, they nonetheless can have a major negative impact if left unchecked. Such remote audits or inspections are being discussed or trialled in Canada and Italy. On the side of private certification, the GFSI has decided to allow the use of remote audits in certain specific cases and situations (https://mygfsi.com/blog/gfsi-remote-auditing-benchmarking-requirements-updates/): both auditor and audited must agree to use it, the technical conditions must be met, and remote auditing can only apply to a part of the audit but not the entirety of it (thus, it reduces contact while not eliminating it).

Source: OECD, Digitizing Regulatory Delivery using Emerging Technologies – A Review of Current Practices, 2021 (forthcoming) – direct interviews with regulators in Italy and Canada – GFSI website.

In Canada, the CFIA was given special funding to hire, train and equip specialized staff to conduct critical inspections and to develop flexible ways to carry out enforcement activities, notably via the use of digital tools (CFIA, 2020[34]). In April 2020, the US FDA shifted to remote inspections for its Foreign Supplier Verification Programs (FSVP) for Importers of Food for Humans and Animals, which sets certain risk-based activities that importers need to perform to verify that food entering the US has been produced in compliance with applicable US safety standards (FDA, 2020[35]). The agency shifted to reviewing records on electronic format and conducting a limited number of remote inspections, prioritising the inspections of FSVP importers of food from foreign suppliers whose onsite food facility or farm inspections were postponed due to the health emergency.

The increased use of remote verification tools extended to third party audits and certification. In Canada, where the CFIA uses third party oversight system for implementation of the Canada Organic Regime which includes Conformity Verification Bodies (CVBs) and CFIA accredited Certification Bodies (CBs), the agency postponed all planned audits and developed criteria for remote audits to reduce the need for on-site activity by CVBs. Scheme or standard owners, and benchmarking organisations, followed a similar path. For instance, the GFSI amended its benchmarking requirements to allow for the use of ICT as part of the GFSI benchmarked certification audits. The benchmarking document from GFSI provides that the full audit objectives be met and all parts of the audit process completed effectively and as a combined process, while it allows the certification program owners to define the parts of the audit that may be carried out remotely, it requires certain minimum content for the on-site portion, and sets 30 day window for the completion of a full audit, extendable for a maximum of 90 days (GFSI, 2020[26]).

Considerations for the way forward

The response of authorities responsible for enforcement of food safety regulation to the COVID-19 crisis highlights certain considerations for regulatory delivery in this field going forward:

Regulatory easing measures put in place during the crisis are unlikely to have undergone ex ante regulatory impact assessment or stakeholder consultation, still authorities should not forgo the use of good regulatory management tools to ensure scrutiny of these measures’ impacts. Ex post review should be emphasised to assess whether these measures are delivering on their goals and should be kept in the aftermath of the crisis (OECD, 2020[16]). The OECD Best Practice Principles of Reviewing the Stock of Regulation (OECD, 2020[36]) emphasise the importance of relying on clear objectives, data and monitoring processes to assess the impact of regulations. This could form the basis for a review of these emergency easing measures which, if found to have an overall positive impact on economic activity and create no or only negligible additional risks, could be then converted into permanent regulatory changes (or, conversely, reversed if they are found to have created major harms or risks). Additionally, as seen in many countries, the broadening of the scope of traditional regulatory impact assessments can contribute to a coherent SDG implementation, via, for instance, the introduction of Sustainability Impact Assessments (e.g., SIA).

Pivoting to hybrid and remote inspections presents challenges. Food safety regulators or the corresponding standards owners need to authorise the changes, whether temporarily or permanently, select the supporting technology and provide appropriate guidance and information to inspectors and firms. In addition, inspectors and auditors need to be properly trained and managed to ensure that they have the relevant technical skills to carry out remote inspections.

Once travel and mobility restrictions are eased or lifted and on-site inspections are authorised to resume, regulators in charge of enforcement and certifiers will need to prepare for an increase in activity and set a risk-based approach to set priorities for inspections. Staff may need to be specially allocated to deal with the backlog of inspections in high-risk establishments.

Lessons from the adjustments to face the challenges posed by COVID-19 will feed into the approach of inspection and certification bodies to the use of new technologies for food safety oversight. For instance, one of the core elements of the new FDA Blueprint for the Future notes that a smarter approach to inspections includes “Conduct proof-of-concepts to evaluate the feasibility of using remote, virtual, and/or component inspections of foreign and domestic firms with a demonstrated history of compliance for agency prioritization purposes” (FDA, 2020[37]). The blueprint notes that experience of remote inspections conducted for some importers during the pandemic will feed into the FDA’s assessment. It also highlights the need to modernise inspection and reporting processes leveraging on mobile inspection technology and digital reporting tools.

Overall, some of the practices observed around the implementation of food safety regulation during the pandemic could have positive spillovers to strengthen less developed food safety regulatory frameworks, notably in developing countries where they could help address resources and capacity constraints as well as constraints in human resource expertise.

Inspection functions should be co-ordinated and, where needed, consolidated to ensure a better use of public resources, minimise the burden on regulated subjects, and maximise effectiveness. Facing staff and resource constrains, remote or hybrid inspections conducted under adequate frameworks could help increase the efficiency of the system and enhance the allocation of expert resources;

Food safety inspectors need to be trained and require substantial technical knowledge. Greater collaboration between inspection and certification bodies, and increased reliance on third-party assessment, can help enhance the skills and tools of inspectors building on the expert competences from third-party certifiers;

Greater focus on supporting food safety culture and increased attention on management attitudes as an essential part of food safety inspections;

Information sharing is key to ensure an optimal use of enforcement resources. Inspection and certification bodies could leverage resources available to third party bodies, particularly evidence and data, to ensure that their surveillance activities are evidence-based and measurement based.

References

[4] Blanc, F. and G. Cola (2017), “Inspections, risks and circumstances. Historical development, diversity of structures and practices in food safety”, in Studi Parlamentari e di Politica Costituzionale.

[3] Blanc, F. and D. Macrae (2021), “Food Safety Compliance”, in The Cambridge Handbook of Compliance.

[21] Canadian Food Inspection Agency (2020), Information regarding certain labelling requirements for foodservice products during the COVID-19 pandemic, https://www.inspection.gc.ca/covid-19/cfia-information-for-industry/foodservice-products-during-the-covid-19-pandemic/eng/1587075946413/1587075946772 (accessed on 28 January 2021).

[23] Canadian Food Inspection Agency (2020), The CFIA is prioritizing critical activities during COVID-19 pandemic, https://www.inspection.gc.ca/covid-19/cfia-information-for-industry/critical-activities-during-covid-19-pandemic/eng/1587076768319/1587076768647.

[32] CDC and OSHA (2021), Interim Guidance: Meat and Poultry Processing Workers and Employers, https://www.cdc.gov/coronavirus/2019-ncov/community/organizations/meat-poultry-processing-workers-employers.html (accessed on 6 February 2021).

[31] CDC and OSHA (2021), Interim Guidance: Protecting Seafood Processing Workers from COVID-19, https://www.cdc.gov/coronavirus/2019-ncov/community/guidance-seafood-processing.html (accessed on 6 February 2021).

[34] CFIA (2020), Government of Canada provides $20 million to safeguard Canada’s food supply by supporting critical food inspection services, https://www.canada.ca/en/food-inspection-agency/news/2020/04/government-of-canada-provides-20million-to-safeguard-canadas-food-supply-by-supporting-critical-food-inspection-services.html (accessed on 28 January 2021).

[22] Danish Veterinary and Food Administration (2020), Coronavirus and food - retail, supermarkets and manufacturing companies, https://www.foedevarestyrelsen.dk/Leksikon/Sider/Coronavirus-og-foedevarer-Detail-supermarkeder-produktionsvirksomheder.aspx (accessed on 9 February 2021).

[10] EIT Food (2020), COVID-19 Impact on Consumer Food Behaviours in Europe, European Institute of Innovation & Technology (EIT).

[6] Fagotto, E. (2015), “Are we being served? The relationship between public and private food safety regulation”, in Havinga, T., D. Casey and F. van Waarden (eds.), The Changing Landscape of Food Governance, Edward Elgar Publishing, http://dx.doi.org/10.4337/9781784715410.00022.

[13] FAO/WHO (2020), COVID-19 and Food Safety: Guidance for competent authorities responsible for national food safety control systems, http://www.fao.org/3/ca8842en/CA8842EN.pdf.

[35] FDA (2020), FDA To Temporarily Conduct Remote Importer Inspections Under FSVP Due to COVID-19, https://www.fda.gov/food/cfsan-constituent-updates/fda-temporarily-conduct-remote-importer-inspections-under-fsvp-due-covid-19 (accessed on 8 February 2021).

[37] FDA (2020), New Era of Smarter Food Safety FDA’s Blueprint for the Future, FDA, https://www.fda.gov/media/139868/download (accessed on 9 February 2021).

[30] FDA and OSHA (2020), Employee Health and Food Safety Checklist for Human and Animal Food Operations During the COVID-19 Pandemic, https://www.fda.gov/media/141141/download.

[26] GFSI (2020), Update on Temporary Audit Measures During Covid-19 Pandemic, https://mygfsi.com/news_updates/update-on-temporary-audit-measures-during-covid-19-pandemic (accessed on 4 February 2021).

[5] Kotsanopoulos, K. and I. Arvanitoyannis (2017), “The Role of Auditing, Food Safety, and Food Quality Standards in the Food Industry: A Review”, Comprehensive Reviews in Food Science and Food Safety, Vol. 16/5, http://dx.doi.org/10.1111/1541-4337.12293.

[1] OECD (2021), “Digital opportunities for Sanitary and Phytosanitary (SPS) Systems and the trade facilitation effects of SPS Electronic Certification”, OECD Food, Agriculture and Fisheries Papers, No. 152, OECD Publishing, Paris, https://dx.doi.org/10.1787/cbb7d0f6-en.

[9] OECD (2020), Agricultural Policy Monitoring and Evaluation 2020, OECD Publishing, Paris, https://dx.doi.org/10.1787/928181a8-en.

[14] OECD (2020), Building a coherent response for a sustainable post-COVID-19 recovery, OECD Publishing, Paris, https://dx.doi.org/10.1787/d67eab68-en.

[8] OECD (2020), COVID-19 and the food and agriculture sector: Issues and policy responses, OECD Publishing, Paris, https://dx.doi.org/10.1787/a23f764b-en.

[7] OECD (2020), “Food Supply Chains and COVID-19: Impacts and Policy Lessons”, Comparing crises: Great Lockdown versus Great Recession, http://dx.doi.org/10.4060/ca8833en.

[16] OECD (2020), Regulatory quality and COVID-19: Managing the risks and supporting the recovery, OECD Publishing, Paris, https://dx.doi.org/10.1787/3f752e60-en.

[36] OECD (2020), Reviewing the Stock of Regulation, OECD Best Practice Principles for Regulatory Policy, OECD Publishing, Paris, https://dx.doi.org/10.1787/1a8f33bc-en.

[33] OECD (2018), OECD Regulatory Enforcement and Inspections Toolkit, OECD Publishing, Paris, https://dx.doi.org/10.1787/9789264303959-en.

[2] OECD (2018), OECD Regulatory Policy Outlook 2018, OECD, Paris, https://dx.doi.org/10.1787/9789264303072-en.

[27] Public Health England and the UK Department of Environment Food and Rural Affairs (2020), Guidance for food businesses on coronavirus (COVID-19), https://www.gov.uk/government/publications/covid-19-guidance-for-food-businesses/guidance-for-food-businesses-on-coronavirus-covid-19 (accessed on 28 January 2021).

[12] The Germany Eye (2021), Corona outbreak in ice cream factory, https://thegermanyeye.com/content/amp/corona-outbreak-in-ice-cream-factory-3989.html?__twitter_impression=true&s=03 (accessed on 2 March 2021).

[20] U.S. Department of Agriculture (2020), USDA Announces Labeling Flexibilities to Facilitate Distribution of Food to Retail Locations, https://www.ams.usda.gov/content/usda-announces-labeling-flexibilities-facilitate-distribution-food-retail-locations.

[18] U.S. Department of Health and Human Services Food and Drug Administration (2020), Temporary Policy Regarding Packaging and Labeling of Shell Eggs Sold by Retail Food Establishments During the COVID-19 Public Health Emergency, https://www.fda.gov/regulatory-information/search-fda-guidance-documents/temporary-policy-regarding-packaging-and-labeling-shell-eggs-sold-retail-food-establishments-during (accessed on 28 January 2021).

[24] U.S. Food and Drug Administration (2020), Coronavirus (COVID-19) Update: FDA Focuses on Safety of Regulated Products While Scaling Back Domestic Inspections, https://www.fda.gov/news-events/press-announcements/coronavirus-covid-19-update-fda-focuses-safety-regulated-products-while-scaling-back-domestic (accessed on 28 January 2021).

[17] U.S. Food and Drug Administration (2020), Temporary Policy Regarding Certain Food Labeling Requirements During the COVID-19 Public Health Emergency: Minor Formulation Changes and Vending Machines, https://www.fda.gov/regulatory-information/search-fda-guidance-documents/temporary-policy-regarding-certain-food-labeling-requirements-during-covid-19-public-health (accessed on 28 January 2021).

[19] U.S. Food and Drug Administration (2020), Temporary Policy Regarding Nutrition Labeling of Certain Packaged Food During the COVID-19 Public Health Emergency, https://www.fda.gov/regulatory-information/search-fda-guidance-documents/temporary-policy-regarding-nutrition-labeling-certain-packaged-food-during-covid-19-public-health (accessed on 28 January 2021).

[25] U.S. Food and Drug Administrator (2020), Temporary Policy Regarding Accredited Third-Party Certification Program Onsite Observation and Certificate Duration Requirements During the COVID-19 Public Health Emergency, https://www.fda.gov/regulatory-information/search-fda-guidance-documents/temporary-policy-regarding-accredited-third-party-certification-program-onsite-observation-and (accessed on 28 January 2021).

[29] UK Food Standards Agency (2020), Adapting agricultural and primary production operations during COVID-19, https://www.food.gov.uk/business-guidance/adapting-agricultural-and-primary-production-operations-during-covid-19 (accessed on 28 January 2021).

[28] UK Food Standards Agency (2020), Adapting food manufacturing operations during COVID-19, https://www.food.gov.uk/business-guidance/adapting-food-manufacturing-operations-during-covid-19 (accessed on 28 January 2021).

[11] Waltenburg, M. et al. (2020), “Update: COVID-19 Among Workers in Meat and Poultry Processing Facilities ― United States, April–May 2020”, MMWR Morbidity and Mortality Weekly Report, Vol. 69/27, http://dx.doi.org/10.15585/mmwr.mm6927e2.

[15] WHO and FAO (2020), COVID-19 and Food Safety: Guidance for competent authorities responsible for national food safety control systems, WHO and FAO, Rome, http://dx.doi.org/10.4060/ca8842en.

Notes

← 1. In the Sanitary and Phytosanitary Systems (SPS), e-certifications helped minimise the negative effects of social distancing arising from the COVID-19 pandemic. This has also helped reduce costs associated with physically handling certifications.

← 2. Source: OECD Secretariat interviews with food safety authorities from OECD Member countries.

← 3. See https://foodsafety.asn.au/topic/australias-food-safety-report-card-released-for-the-un-world-food-safety-day-7-june-2020/ and https://www.foodsafetynews.com/2021/02/covid-19-measures-accompany-decline-of-foodborne-infections/.

← 4. (OECD, 2018[33]) defines “inspection” as any type of visit or check conducted by authorised officials on products or business premises, activities, documents, etc.