This chapter outlines the manufacturing landscape of OECD rural regions looking at trends in the manufacturing sector and the forces shaping these trends through regional data analysis spanning two decades. While many regions have experienced large falls in manufacturing employment over the last two decades, the sector remains a significant employer and supports upstream service sector jobs and jobs in other sectors. Manufacturing is also an important driver of gross value added across the OECD, yet rural manufacturing trends come in different forms across OECD countries and amongst regions, reflecting different local conditions, amenities, and areas of comparative advantage.

The Future of Rural Manufacturing

2. The manufacturing landscape of OECD rural regions

Abstract

This chapter examines the manufacturing landscape across OECD rural regions. The analysis makes use of the data available in the OECD Regional Database for TL3 regions. This also applies to the extended OECD typology based on a five-category classification breaking down metropolitan and non-metropolitan regions (see Box 2.1); in this context, rural regions are referred to as non-metropolitan TL3 regions.

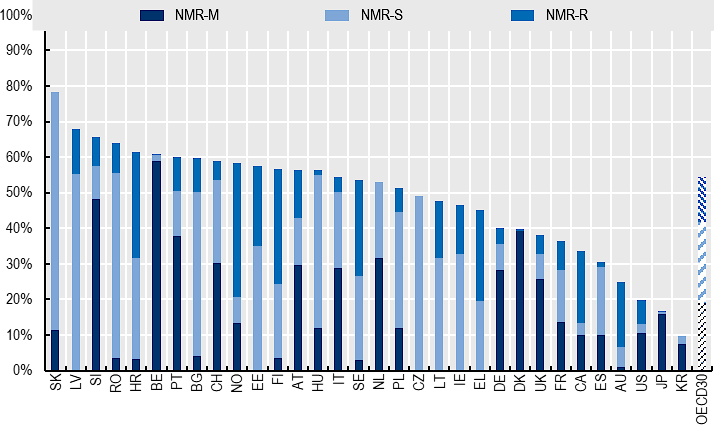

The long-term process of deindustrialisation in OECD countries has resulted in decreasing employment in manufacturing and a declining share of manufacturing in overall economic activity in OECD economies. Despite the overall decline, manufacturing in rural regions remains an important driver. On average, 46% of manufacturing workers across the OECD were working in rural regions in 2019 (Figure 2.1), significantly higher than the share of the OECE population living in rural regions (30%). The contribution is higher in Nordic countries and vast countries such as Australia and Canada, and even reaches eight out of ten employees in the Slovak Republic.

Figure 2.1. Share of employment manufacturing to national manufacturing by TL3 regions, 2019

Note: The OECD average includes only countries for which regional typology or employment data are available at the TL3 level. Geographical typology refers to OECD TL3 typology defining metropolitan (large MR-L and medium MR-M) and non-metropolitan regions (near a large city NMR-M, near a small city NMR-S and rural region NMR-R), for further details see Box 2.1. The year for which information is available is 2017 for most of the countries, except Canada, France, Japan, Poland and Switzerland (2016), Belgium, Estonia, Denmark, Hungary, Slovenia, the United Kingdom and the United States (2018), Australia and South Korea (2019).

Source: Based on the OECD Regional Statistics (database), https://www.oecd.org/regional/regional-statistics/

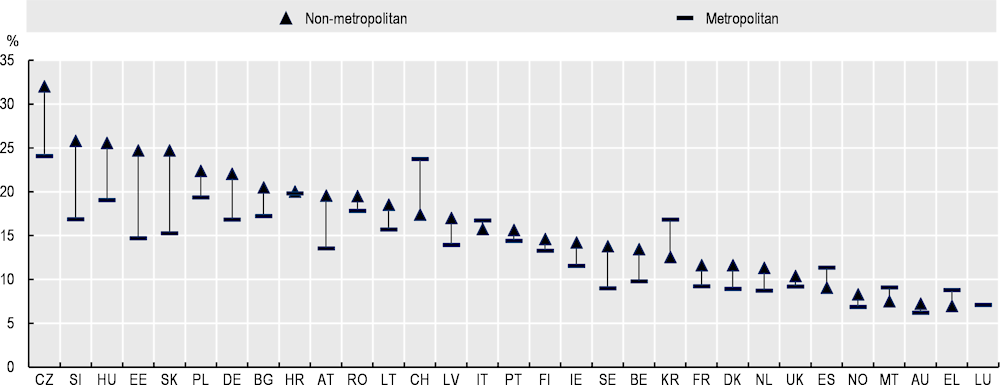

At the same time, across the OECD, 1 in 7 jobs in rural areas are manufacturing jobs and 1 in 5 in European Union countries. Indeed, the manufacturing employment share is higher in non-metropolitan regions than in metropolitan regions in 80% (or 25 out of 31) of OECD countries, (Figure 2.2). The overall share differs quite a lot between countries. Regional manufacturing employment in Central European countries is, on average, larger than in the rest of the OECD and the European Union and thus has a higher value when considering these non-OECD countries in the European Union. In the Czech Republic, for example, the average share of manufacturing employment amounts to 30%, followed by Hungary and Slovenia (around 24%), the Slovak Republic (23.1%) and Bulgaria, Estonia, Poland and Romania (between 20% and 23%). In contrast, some of the lowest shares in manufacturing employment in rural regions are present in Norway (7.6%) and Australia (6.7%). Overall, across the OECD, manufacturing employment, on average, is 14.2% in rural regions against 12.9% in metropolitan regions (16.7% vs. 14.0% in the European Union). Notable exceptions are Japan and Korea, where metropolitan areas are often home to large industrial complexes (Ulsan, in Korea, for example, hosts some of the largest automotive and petrochemical plants in the world).

Figure 2.2. Manufacturing employment to total regional employment in TL3 regions, 2020

Note: Countries are included based on data availability. Geographical typology refers to OECD TL3 typology defining metropolitan (large MR-L and medium MR-M) and non-metropolitan regions (near a large city NMR-M, near a small city NMR-S and rural region NMR-R), for further details see Box 2.1.

Source: Based on the OECD Regional Statistics (database), https://www.oecd.org/regional/regional-statistics/

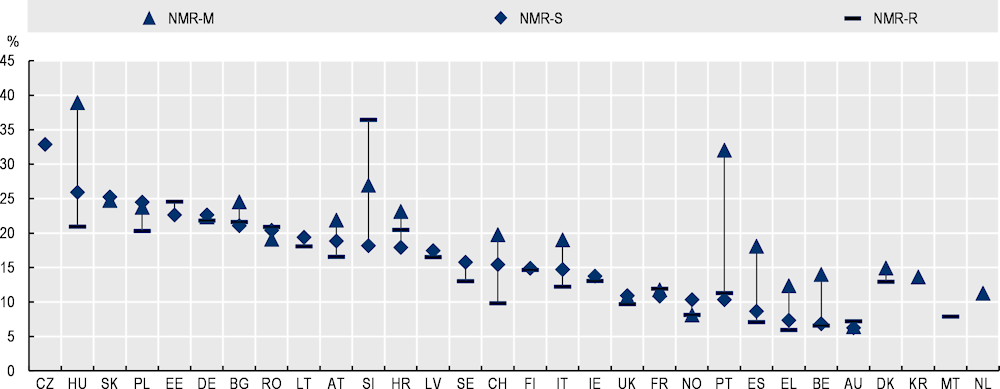

Non-metropolitan regions near a mid-size city have an average manufacturing employment share of 18.3%; this decreases to 16% for those close to small cities and is lowest in remote rural regions (10.9%), as seen in Figure 2.3. In Canada and Portugal, the gap between nonmetropolitan regions close to cities and remote regions is amongst the largest, at 15 and 10 percentage points respectively, likely highlighting strong firm preferences for locating close to large markets and transport networks in these countries. Although manufacturing plays an important role in remote rural regions of Slovenia (average 28.3%, highest region: Carinthia 35.4%), Estonia (23.3%) and Germany (average 21.9%, Sonneberg and Freudenstadt 37.3% and 33.7%), this could also be driven by border effects given that the OECD typology (Box 2.1) is based on an accessibility criteria inside countries, but it does not capture proximity to neighbouring functional urban areas or markets.

Figure 2.3. Manufacturing employment to total employment, non-metropolitan TL3 regions, 2020

Note: Countries are sorted by average rural manufacturing employment; in most cases NMR-Ms have the highest shares. Geographical typology refers to OECD TL3 typology defining metropolitan (large MR-L and medium MR-M) and non-metropolitan regions (near a large city NMR-M, near a small city NMR-S and rural region NMR-R), for further details see Box 2.1.

Source: Based on the OECD Regional Statistics (database), https://www.oecd.org/regional/regional-statistics/

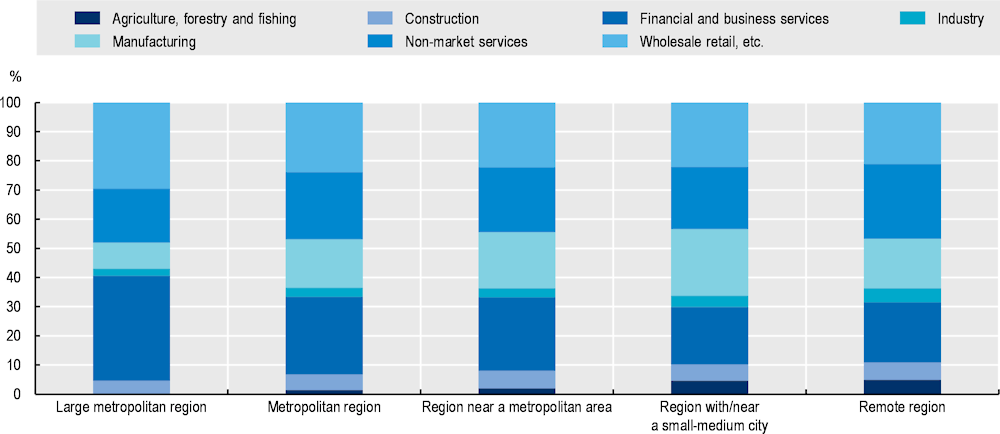

In 2018, EUR 1 in every EUR 5 came from manufacturing; in rural areas near metropolitan cities, this increases to EUR 1 in every EUR 4. Manufacturing contributes notably to the gross value added (GVA) of each type of region, as illustrated in Figure 2.4. Using data from European OECD countries, the value that industry1 contributes to the economy of each type of region in 2018 is, on average, 21%. This rises to 25% in rural areas near mid-size metropolitan cities, indicating industry prominence despite the service sector’s rise. At the same time, it can be seen that, whilst financial services are more prominent in metropolitan regions, non-financial services play a clear and increasing role in non-metropolitan regions, pointing towards the trend of increased interconnectivity between this sector and the manufacturing sector.

Figure 2.4. Share of value-added across types of OECD TL3 regions

Note: Geographical typology refers to OECD TL3 typology defining metropolitan (large MR-L and medium MR-M) and non-metropolitan regions (near a large city NMR-M, near a small city NMR-S and rural region NMR-R), for further details see Box 2.1.

Source: Based on EC (2019[1]), ARDECO Database, https://knowledge4policy.ec.europa.eu/territorial/ardeco-database_en.

Box 2.1. Territorial classification and typology of OECD regions

Regions within the 38 OECD countries are classified at 2 territorial levels reflecting the administrative organisation of countries. The 433 OECD large (TL2) regions represent the first administrative tier of subnational government. The smaller (TL3) units comprise 2 414 regions, with each TL3 being contained in a TL2 region (except for the United States). TL3 regions correspond to administrative regions, with the exception of Australia, Canada, Germany and the United States. All the regions are defined within national borders. This classification – which, for European countries, is largely consistent with the Eurostat NUTS 2021 classification – facilitates greater comparability of geographic units at the same territorial level. These two levels, which are officially established and relatively stable in all member countries, are used as a framework for implementing regional policies in most countries.

This OECD methodology classifies TL3 regions into metropolitan and non-metropolitan according to the following criteria:

Metropolitan regions if more than 50% of its population live in a functional urban area (FUA) of at least 250 000 inhabitants. Metropolitan regions are further classified into:

Metropolitan large regions (MR-L), if more than 50% of its population live in an FUA of at least 1.5 million inhabitants.

Metropolitan mid-size regions (MR-M), if the TL3 region is not a large metropolitan region and 50% of its population live in an FUA of at least 250 000 inhabitants.

Non-metropolitan regions, if less than 50% of its population live in an FUA. These regions are further classified according to their level of access to FUAs of different sizes:

Near a mid-size/large FUA region (NMR-M), if more than 50% of its population live within a 60‑minute drive from a metropolitan area (an FUA with more than 250 000 people); or if the TL3 region contains more than 80% of the area of an FUA of at least 250 000 inhabitants.

Near a small FUA region/medium city TL3 region (NMR-S), if the TL3 region does not have access to a metropolitan area and 50% of its population have access to a small or medium city (an FUA of more than 50 000 and less than 250 000 inhabitants) within a 60-minute drive; or if the TL3 region contains more than 80% of the area of a small or medium city.

Remote region, if the TL3 region is not classified as NMR-M or NMR-S, i.e. if 50% of its population does not have access to any FUA within a 60-minute drive.

We use the TL3 classification in our analysis which provides more granularity, however the analysis also needs to consider the higher degree of asymmetry present in the distribution of TL3 regions across OECD countries. For example, Germany contains 400 TL3 regions followed by Canada with 282. All things equal there will be more variability in these countries. It also carries implications on the methodology to derive OECD average figures. The analysis therefore assigns to each country the same weight to ensure that the large sample of rural regions in a given country does not bias the OECD average figures.

Source: Fadic, M., et al. (2019[2]), “Classifying small (TL3) regions based on metropolitan population, low density and remoteness”, https://doi.org/10.1787/b902cc00-en.

Aggregate values mask subnational variations

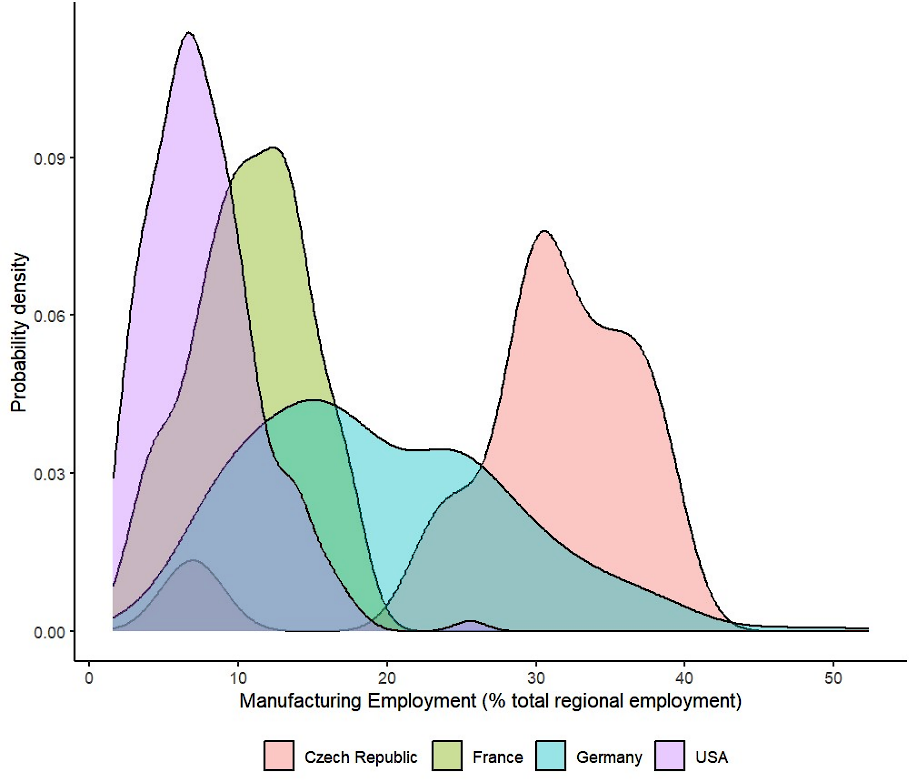

Manufacturing activities tend to concentrate in certain geographies and have important multiplier effects in other economic activities. It is no surprise that strong variation is present at the subnational level across regions in manufacturing activities. Figure 2.5 indicates the distribution of TL3 regions according to their share of manufacturing employment to total employment in France, Germany, the United States, and the Czech Republic. In France, TL3 regions have a share of manufacturing employment between 2-18%. Germany in contrast, as one would expect due its higher number of TL3 regions, depicts much more variation across regions with manufacturing employment ranging from 2% to 52%. Given the size differences in the number of TL3 regions, considerable care is warranted when drawing comparing across countries.

Figure 2.5. Distribution of manufacturing employment in TL3 regions, 2018

Note: Geographical typology refers to OECD TL3 typology defining metropolitan (large MR-L and medium MR-M) and non-metropolitan regions (near a large city NMR-M, near a small city NMR-S and rural region NMR-R), for further details see Box 2.1.

Source: Based on European Commission (2019[1]), ARDECO Database, https://knowledge4policy.ec.europa.eu/territorial/ardeco-database_en.

Table 2.1 depicts the top 10 regions with the highest employment share of manufacturing and Table 2.2 the top 10 regions with the highest GVA share in manufacturing. It is interesting to note that 6 of the top 10 regions with the highest employment share of manufacturing and 4 out of 10 with the highest GVA2 share of manufacturing are non-metropolitan regions. Amongst the non-metropolitan regions, the majority were near a large city and none where remote also suggesting the important role that cities and by extension markets play in manufacturing activities in non-metropolitan regions. In Germany the variation of manufacturing employment to the total workforce in TL3 regions ranges from 2.9% in Landshut, Bavaria to 47.5% Tuttlingen, Baden-Württemberg. In Canada, the values also vary considerably due to its high number of TL3 non-metropolitan regions (222) from less than 1% in Keewatin, Northwest Territories to 42% in Bellechasse, Quebec.

Table 2.1. German TL3 regions with the highest employment share of manufacturing

Top German TL3 regions by share of manufacturing in total employment, 2019

|

Country |

Region (TL3) |

Region type |

Manufacturing employment (% total employment in the region) |

Manufacturing employment (% total manufacturing in the country) |

|---|---|---|---|---|

|

Germany |

Wolfsburg, Kreisfreie Stadt |

MR-M |

52.6 |

0.9 |

|

Germany |

Tuttlingen |

NMR-M |

49.3 |

0.6 |

|

Germany |

Dingolfing-Landau |

NMR-S |

46.1 |

0.4 |

|

Germany |

Salzgitter, Kreisfreie Stadt |

MR-M |

42.1 |

0.3 |

|

Germany |

Ingolstadt, Kreisfreie Stadt |

MR-M |

40.3 |

0.7 |

|

Germany |

Enzkreis |

MR-M |

40.2 |

0.4 |

|

Germany |

Olpe |

NMR-M |

39.8 |

0.4 |

|

Germany |

Kronach |

NMR-M |

39.4 |

0.2 |

|

Germany |

Biberach |

NMR-M |

39.3 |

0.6 |

|

Germany |

Rottweil |

NMR-S |

38.4 |

0.4 |

Note: Geographical typology refers to OECD TL3 typology defining metropolitan (large MR-L and medium MR-M) and non-metropolitan regions (near a large city NMR-M, near a small city NMR-S and rural region NMR-R), for further details see Box 2.1.

Source: Based on the OECD Regional Statistics (database), https://www.oecd.org/regional/regional-statistics/Source: Based on the OECD Regional Statistics (database), https://www.oecd.org/regional/regional-statistics/

The case of Germany also shows that manufacturing in some non-metropolitan regions play a role in the regional and local economy. In the non-metropolitan region of Dingolfing-Landau, almost two—thirds of the regions’ output was derived from manufacturing activity. In Wolfsburg, Kreisfreie Stadt, this was 82%.

Table 2.2. German TL3 regions with the highest GVA share of manufacturing

Top German TL3 regions by share of manufacturing in local total gross value added, 2017

|

Country |

Region (TL3) |

Region type |

Manufacturing GVA (% total GVA in the region) |

Manufacturing GVA (% total manufacturing in the country) |

|---|---|---|---|---|

|

Germany |

Wolfsburg, Kreisfreie Stadt |

MR-M |

82.6 |

2.6 |

|

Germany |

Ingolstadt, Kreisfreie Stadt |

MR-M |

76.0 |

1.8 |

|

Germany |

Dingolfing-Landau |

NMR-S |

65.4 |

0.5 |

|

Germany |

Salzgitter, Kreisfreie Stadt |

MR-M |

65.1 |

0.5 |

|

Germany |

Ludwigshafen am Rhein, Kreisfreie Stadt |

MR-M |

61.1 |

7.7 |

|

Germany |

Tuttlingen |

NMR-M |

57.1 |

3.5 |

|

Germany |

Schweinfurt, Kreisfreie Stadt |

MR-M |

56.3 |

0.5 |

|

Germany |

Böblingen |

MR-L |

53.4 |

0.4 |

|

Germany |

Emden, Kreisfreie Stadt |

NMR-M |

52.8 |

10.9 |

|

Germany |

Erlangen, Kreisfreie Stadt |

MR-M |

51.1 |

0.3 |

|

Germany |

Biberach |

NMR-M |

49.9 |

14.3 |

Note: Geographical typology refers to OECD TL3 typology defining metropolitan (large MR-L and medium MR-M) and non-metropolitan regions (near a large city NMR-M, near a small city NMR-S and rural region NMR-R), for further details see Box 2.1

Source: Based on the OECD Regional Statistics (database), https://www.oecd.org/regional/regional-statistics/

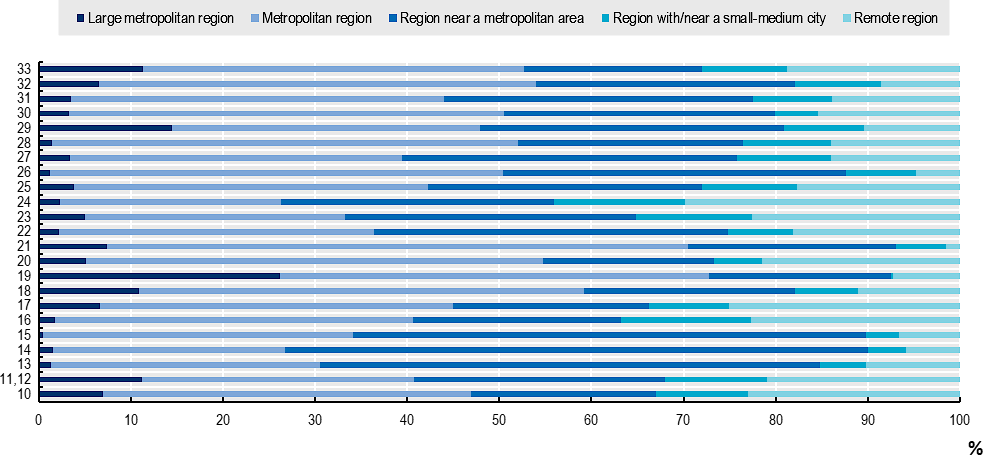

Within manufacturing, there are a wide range of subsectors and their distribution among OECD countries is also largely varied. Utilising microdata from five OECD countries, Figure 2.6 shows the distribution of employment across the European Community Statistical Classification of Economic Activities (NACE) two-‑digit subsectors for manufacturing across TL3 regions. There is a total of 32 two-digit manufacturing subsectors that range from 10 (manufacture of food products) to 33 (repair and installation of machinery equipment). The full list of sub-sectors is described in Anne 4.A2. Large metropolitan regions show greater shares in the manufacture of tobacco and beverages (11 and 12) and the manufacture of coke products (19, where 1 in 7 jobs lie). Non-metropolitan regions close to a city show the largest shares in manufacturing basic pharmaceutical products and preparations (21). At the same time, 63% of non-metallic minerals, except fuels (14) can be found in these non-metropolitan regions close to a city.

Figure 2.6. Manufacturing employment across types of TL3 regions and two-digit industry, 2020

Note: Geographical typology refers to OECD TL3 typology defining metropolitan (large MR-L and medium MR-M) and non-metropolitan regions (near a large city NMR-M, near a small city NMR-S and rural region NMR-R), for further details see Box 2.1. 10 to 33 refer to the two-digit industrial activities within the manufacturing sector (see Annex 4A2).

Source: Based on national statistics agencies data from Finland, Norway, Portugal, Slovenia and Switzerland.

Manufacturing activity over time

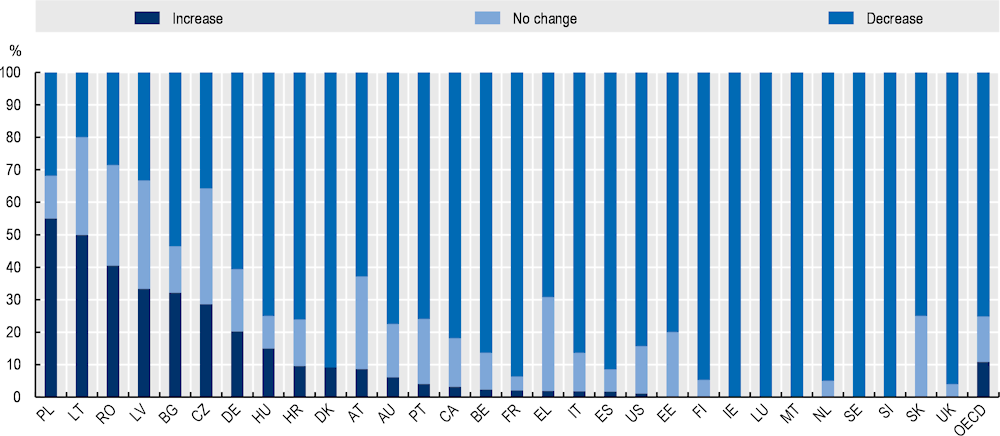

The importance of OECD countries in global manufacturing has consistently dropped over past decades. Manufacturing employment in the OECD decreased by 14% since 2000. Figure 2.7 shows that between the years 2000 and 2019, more than 80% of OECD regions saw manufacturing employment as a share of total employment decrease, including all regions in Finland, Ireland, Slovenia, Sweden and the United Kingdom. The decrease was particularly pronounced in Ireland, where the average share dropped by 7 percentage points, whilst in the other 4 countries, it decreased by an average of 5.5 percentage points. At the same time, 20% of regions saw an increase in the share of jobs. Manufacturing employment has increased in more than half of the regions in Poland and Romania. In Poland, in particular, the sectoral contribution to local labour markets increased on average by 1.1 percentage points, suggesting that some rural regions in the European Union benefitted from cross-border reallocations.

Figure 2.7. Changes in manufacturing jobs to total regional employment in TL3 regions, 2000-19

Note: Only OECD countries for which data was available for 2000 and 2001, and 2016 and beyond were considered. Within the legend, increase/decrease” is defined as a growth of regional manufacturing share of 1%/-1% or more and “no change” is defined as anything in between.

Source: Based on the OECD Regional Statistics (database), https://www.oecd.org/regional/regional-statistics/

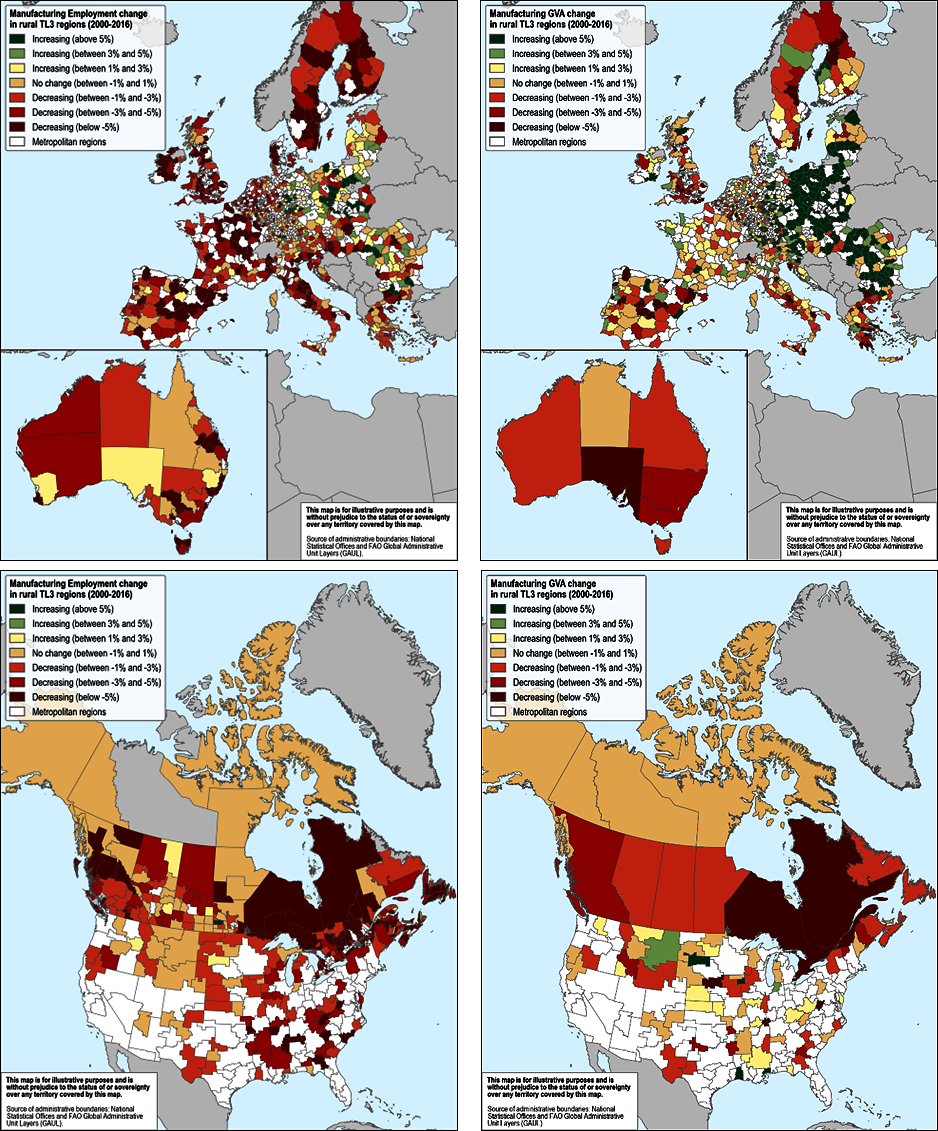

Geographical trends highlight manufacturing clusters and indicate employment reductions outweighed GVA changes. Figure 2.8 highlights the declines in GVA in some regions were outweighed by significant increases in others across the OECD. A clear cluster of regions in the eastern side can be observed in European countries. Some regions, such as in Finland, Norway and the United Kingdom, saw losses of employment shares of over 5%, yet corresponding increases in GVA shares in many of these places.

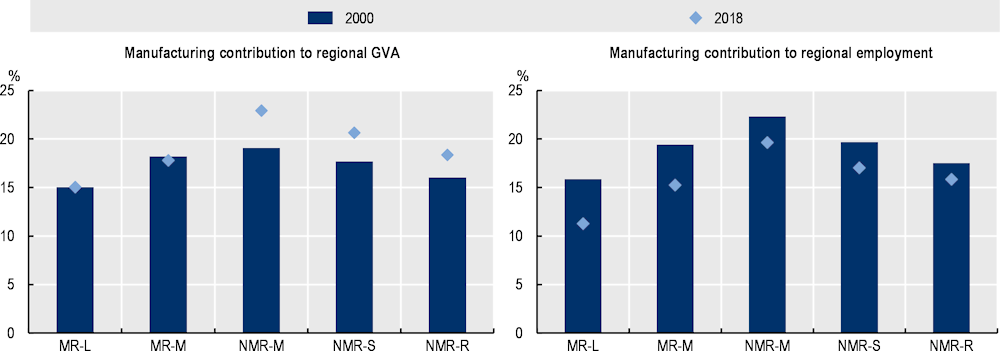

These trends are summarised below by regional type. Allowing for aggregations enables the analysis to cover more recent years. Yet the trends are still the same; on the one hand, the share of employment in manufacturing as a share of total regional employment decreased in both rural and urban areas between 2000 and 2018. Regions close to medium cities continued to hold the most manufacturing jobs (moving from 21% to 18% of regional jobs on average). On the other hand, the patterns in GVA of manufacturing shares as contributions to total regional GVA have been increasing during the same period. What is more, the increase in non-metropolitan regions (an average of 2.2%) was significantly higher than the increase in metropolitan regions (an average increase of 0.1%) across (26) European OECD countries.

Figure 2.8. Change in shares of manufacturing employment and GVA for non-metropolitan regions, 2000-16

Note: Increases and decreases in manufacturing are relative to total values of employment and GVA in the regions.

Source: Based on the OECD Regional Statistics (database), https://www.oecd.org/regional/regional-statistics/ Data for GVA is provided at TL2 level for Canada and Australia based on data availability.

Figure 2.9. Manufacturing employment and GVA over time by type of TL3 region across OECD countries

Note: The sample includes 1317 TL3 regions from 26 OECD countries that include: Austria, Belgium, Bulgaria, Croatia, the Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, the Netherlands, Poland, Portugal, Romania, Spain, the Slovak Republic, Slovenia and the United Kingdom. Geographical typology refers to OECD TL3 typology defining metropolitan (large MR-L and medium MR-M) and non-metropolitan regions (near a large city NMR-M, near a small city NMR-S and rural region NMR-R), for further details see Box 2.1. To derive the OECD average figures across regional types, the analysis assigns the same weight to each region.

Source: Based on the OECD Regional Statistics (database), https://www.oecd.org/regional/regional-statistics/

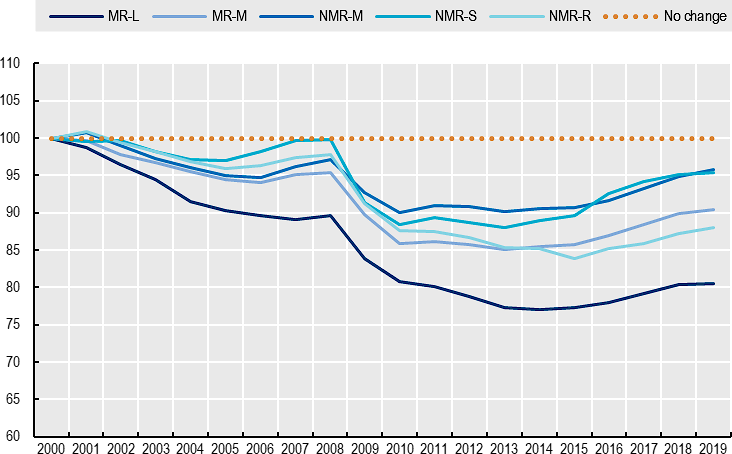

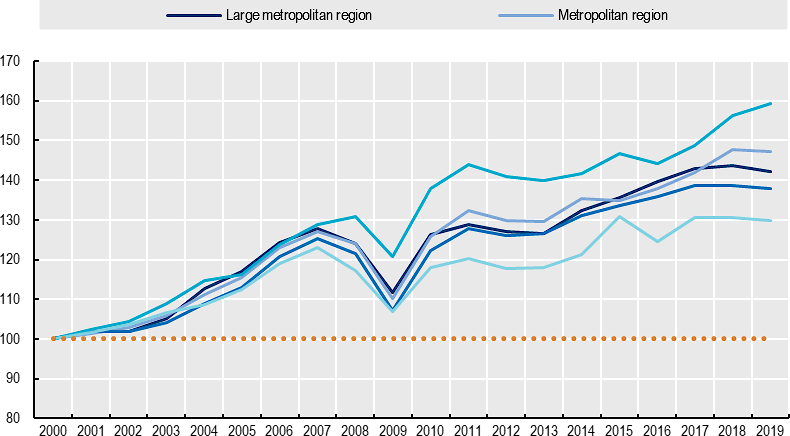

Figure 2.10 provides more detail, showing the development of manufacturing employment over time by regional type. It displays the total number of employed in manufacturing relative to 2000 and covers 26 OECD countries. It shows the decline of importance of OECD countries in global manufacturing over that past decades. Manufacturing employment decreased across all types of TL3 regions, especially during the years of the global financial crisis from 2008 to 2010. The drop however was more pronounced in large metropolitan regions, non-metropolitan remote regions, and medium metropolitan regions with percentage point declines of 21.7, 14.3, and 12 respectively. The regions with the least decline were non-metropolitan regions near a small city and near a large city with percentage points declines of 6.3 and 8.2 respectively. This overall decline appears to stabilise and even slightly increase over the last five years.

Figure 2.10. Evolution of manufacturing employment across types of TL3 regions, 2000-19

Note: The data includes regions from 26 OECD countries. Geographical typology refers to OECD TL3 typology defining metropolitan (large MR-L and medium MR-M) and non-metropolitan regions (near a large city NMR-M, near a small city NMR-S and rural region NMR-R), for further details see Box 2.1

Source: Based on the OECD Regional Statistics (database), https://www.oecd.org/regional/regional-statistics/

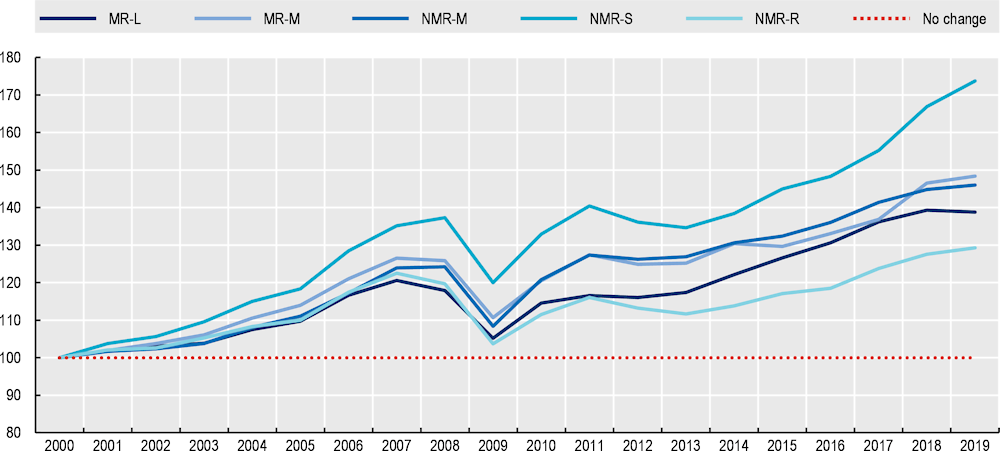

When considering the similar trend for output (Figure 2.11), the differences in trends from employment patterns are stark. Manufacturing GVA increased in all region types over the observed period, with a sharp decline in 2008 reflecting the repercussions of the financial crisis. Declines in 2020 across all region types reflect the effects of the pandemic. Overall, regions near a small city saw the largest increases, almost 60 percentage points from 2000 values. Whilst remote rural regions witness the smallest increases, these were still 20 percentage points higher than two decades prior.

Figure 2.11. Evolution of manufacturing GVA across types of TL3 regions, 2000-19

Note: The analysis covers 28 OECD countries from 2000 to 2020, underlying values are based on USD millions, constant prices, constant purchasing power parity (PPP), base year 2015. Geographical typology refers to OECD TL3 typology defining metropolitan (large MR-L and medium MR-M) and non-metropolitan regions (near a large city NMR-M, near a small city NMR-S and rural region NMR-R), for further details see Box 2.1

Source: Based on the OECD Regional Statistics (database), https://www.oecd.org/regional/regional-statistics/

Of the top ten regions with of the largest employment decline, seven were non-metropolitan regions. Despite this, manufacturing as a source of employment remained prominent in many regions (Table 2.3). For example, Arr. Oudenaarde in Belgium saw manufacturing employment decline by almost 15% from 2000 figures. However, this still meant that in 2019 almost 1 in 5 jobs in the region relied on the manufacturing sector. Similarly, Biella (in the northern region of Piemonte, Italy), which suffered the most from the relative job losses in the manufacturing sector of 15.2%, saw employment in manufacturing account for 23.7% of total regional employment by 2019.

Table 2.3. TL3 regions with the highest reduction in employment manufacturing

Top 10 regions with respect to declines in manufacturing employment as a fraction of total regional employment, 2000-19

|

Country |

Region name |

Region type |

Manufacturing employment share (%, 2000) |

Manufacturing employment change (2000-19) |

Manufacturing employment share change (p.p, 2000-19) |

|---|---|---|---|---|---|

|

Italy |

Biella |

NMR-S |

39 |

-10 900 |

-15.2 |

|

Belgium |

Arr. Oudenaarde |

NMR-M |

32 |

-5 700 |

-14.7 |

|

Spain |

Barcelona |

MR-L |

27 |

-247 200 |

-13.6 |

|

Croatia |

Međimurska županija |

NMR-R |

39 |

-6 920 |

-13.5 |

|

Belgium |

Arr. Hasselt |

NMR-M |

25 |

-16 900 |

-12.8 |

|

Malta |

Malta |

MR-M |

22 |

-7 980 |

-12.8 |

|

Germany |

Leverkusen, Kreisfreie Stadt |

MR-L |

32 |

-8 370 |

-12.0 |

|

Germany |

Frankenthal (Pfalz), Kreisfreie Stadt |

MR-M |

31 |

-2 020 |

-11.9 |

|

United Kingdom |

East Lancashire |

NMR-M |

28 |

-14 000 |

-11.9 |

|

Germany |

Groß-Gerau |

MR-L |

31 |

-13 780 |

-11.9 |

Note: The analysis covers OECD EU countries plus 3 non-OECD non-EU countries. Geographical typology refers to OECD TL3 typology defining metropolitan (large MR-L and medium MR-M) and non-metropolitan regions (near a large city NMR-M, near a small city NMR-S and rural region NMR-R), for further details see Box 2.1. p.p.: percentage points.

Source: Based on the OECD Regional Statistics (database), https://www.oecd.org/regional/regional-statistics/

A handful of OECD countries experienced the largest increase in manufacturing employment, notably former Eastern European countries. Amongst the 10 TL3 regions with the highest increases in employment one third of them are non-metropolitan remote regions (Table 2.4). For example, the number of workers in the manufacturing sectors in Ostrołęka County – a remote region in the Mazovian Voivodeship, east-central Poland – increased from 8,200 in 2000 to 27,700 in 2019 more than tripling its total manufacturing employment. On the western side of the same voivodeship,3 in Płock County, a rural region near a small metropolitan city, the number of manufacturing workers increased by 17,100 (the fifth largest across 28 OECD countries).

Table 2.4. TL3 regions with the highest increases in employment manufacturing

Top 10 regions by increase in manufacturing employment in both absolute and relative terms, 2000-19 (or latest year available)

|

Country |

Region name |

Region type |

Manufacturing employment share (%, 2000) |

Manufacturing employment change (2000-19) |

Manufacturing employment share change (p.p, 2000-19) |

|---|---|---|---|---|---|

|

Poland |

Wrocławski |

NMR-M |

18 |

55 800 |

14.7 |

|

Romania |

Arad |

NMR-S |

32 |

14 640 |

13.9 |

|

Bulgaria |

Смолян |

NMR-R |

14 |

4 450 |

13.7 |

|

Poland |

Ostrołęcki |

NMR-R |

7 |

19 500 |

12.5 |

|

Poland |

Ciechanowski |

NMR-R |

9 |

16 300 |

12.0 |

|

Poland |

Krakowski |

MR-M |

13 |

35 200 |

11.4 |

|

Poland |

Radomski |

MR-M |

10 |

25 500 |

10.9 |

|

Poland |

Płocki |

NMR-S |

11 |

17 100 |

10.5 |

|

Germany |

Sömmerda |

MR-M |

19 |

3 390 |

10.1 |

|

Poland |

Legnicko-głogowski |

NMR-S |

12 |

19 800 |

9.6 |

Note: The analysis covers OECD EU countries plus 3 non-OECD non-EU countries. Geographical typology refers to OECD TL3 typology defining metropolitan (large MR-L and medium MR-M) and non-metropolitan regions (near a large city NMR-M, near a small city NMR-S and rural region NMR-R), for further details see Box 2.1 . p.p.: percentage points.

Source: Based on the OECD Regional Statistics (database), https://www.oecd.org/regional/regional-statistics/

When considering the top regions with respect to changes in GVA, Table 2.5 illustrates the analysis, which finds that the highest reduction in manufacturing GVA was largely in Belgium, with four out of ten of the most affected regions. The biggest decrease by far was in Arr. Soignies (Belgium), with a decrease of 42% in manufacturing contribution to GVA. Despite this, in 2019, one-fifth of regional GVA was derived from the manufacturing sector.

Table 2.5. TL3 regions with the highest reduction in GVA manufacturing

Top 10 regions by decrease in manufacturing GVA in both absolute and relative terms, 2000-19

|

Country |

Region name |

Region type |

Manufacturing GVA share (%, 2000) |

Manufacturing GVA change (2000-19) |

Manufacturing GVA share change (p.p, 2000-19) |

|---|---|---|---|---|---|

|

Belgium |

Arr. Soignies |

MR-L |

64 |

-1 252.19 |

-42.0 |

|

Belgium |

Arr. Charleroi |

MR-M |

34 |

-2 106.6 |

-21.7 |

|

Greece |

Boeotia |

NMR-R |

55 |

-1 035.61 |

-20.8 |

|

Bulgaria |

Burgas |

MR-M |

35 |

-681.24 |

-20.1 |

|

Germany |

Leverkusen, Kreisfreie Stadt |

MR-L |

56 |

-1 889 |

-18.3 |

|

United Kingdom |

Mid and East Antrim |

NMR-M |

38 |

-1 002.21 |

-18.2 |

|

Greece |

Euboea |

NMR-R |

40 |

-1 054.66 |

-17.8 |

|

Belgium |

Arr. Virton |

NMR-M |

36 |

-224.9 |

-16.5 |

|

Belgium |

Arr. La Louvière |

NMR-M |

18 |

-371.84 |

-16.0 |

|

Germany |

Offenbach am Main, Kreisfreie Stadt |

MR-L |

22 |

-845.95 |

-13.6 |

Note: The analysis covers OECD EU countries plus 3 non-OECD non-EU countries. GVA is calculated based on USD millions, constant prices, constant PPP, base year 2015. Geographical typology refers to OECD TL3 typology defining metropolitan (large MR-L and medium MR-M) and non-metropolitan regions (near a large city NMR-M, near a small city NMR-S and rural region NMR-R), for further details see Box 2.1. p.p.: percentage points.

Source: Based on the OECD Regional Statistics (database), https://www.oecd.org/regional/regional-statistics/

Similar to the growth in employment, growth in output is most stark amongst East European regions. Five out of ten of the highest growth rates were found in Polish regions. For the largest increasing region, Płocki, over half of regional GVA was derived from the manufacturing sector by 2019. For the more remote regions, this is even greater; for example, in Ingolstadt, Germany, 76% of all value generated in the region was driven by the manufacturing sector in 2019.

Table 2.6. TL3 regions with the largest increases in GVA manufacturing

Top 10 regions by decrease in manufacturing GVA in both absolute and relative terms, 2000-19

|

Country |

Region name |

Region type |

Manufacturing GVA share (%, 2000) |

Manufacturing GVA change (2000-19) |

Manufacturing GVA share change (p.p, 2000-19) |

|---|---|---|---|---|---|

|

Poland |

Płocki |

MR-L |

26 |

6 912.3 |

31.6 |

|

Ireland |

South-East |

MR-M |

19 |

10 637.25 |

28.1 |

|

Germany |

Ingolstadt, Kreisfreie Stadt |

NMR-R |

48 |

11 499.55 |

27.7 |

|

Poland |

Świecki |

MR-M |

24 |

1 446.74 |

23.5 |

|

Poland |

Kaliski |

MR-L |

14 |

5 044.79 |

22.3 |

|

Poland |

Wrocławski |

NMR-M |

17 |

5 626.29 |

22.3 |

|

Ireland |

South-West |

NMR-R |

44 |

50 102.1 |

21.7 |

|

Bulgaria |

Gabrvao |

NMR-M |

12 |

664.85 |

20.0 |

|

Poland |

Koniński |

NMR-M |

10 |

3 636.69 |

19.6 |

|

Czech Republic |

Zlínský kraj |

MR-L |

27 |

5 182.95 |

19.4 |

Note: The analysis covers OECD EU countries plus 3 non-OECD non-EU countries. GVA is calculated based on USD millions, constant prices, constant PPP, base year 2015. Geographical typology refers to OECD TL3 typology defining metropolitan (large MR-L and medium MR-M) and non-metropolitan regions (near a large city NMR-M, near a small city NMR-S and rural region NMR-R), for further details see Box 2.1. p.p.: percentage points.

Source: Based on the OECD Regional Statistics (database), https://www.oecd.org/regional/regional-statistics/

In sum, whilst global trends might have facilitated the emergence of new manufacturing powerhouses, they may not have dented some of the traditional ones. In general, the contribution of manufacturing to local employment decreased the most in regions that had a large share of the manufacturing workforce back in 2000, but not the largest. A few regions that used to be manufacturing hubs in 2000 – by relative workforce – have not been so for almost 20 years and they are mostly rural: Carinthia in Slovenia, Coburg in Germany, Vas in Hungary and Vicenza in Italy.

A better contextualisation of changes in local manufacturing is needed. For example, the significant drop in the manufacturing workforce in Biella, Italy, signals that the sector in the region may be in particular distress. However, the share of manufacturing employment in Biella remains one of the highest in the country.

Box 2.2. Substantial changes in the statistical classification of manufacturing may be artificially overemphasising the decline of the sector

A firm is defined as a manufacturer in the International Standard Industrial Classification (ISIC) (UN, 2008[3]) if the majority of its activity, related to output or employment, comes from the production of goods and vice versa for a service provider.

Considerable outsourcing of previously in-house services by manufacturing firms overstates the overall number of jobs lost in manufacturing in recent decades. In addition, the distinction between a manufacturing firm and a services firm, particularly with regards to factory-less producers also creates significant measurement and comparability challenges, see for example UNECE guide to measuring global production (United Nations, 2015[4]).

Changes in labour productivity

Measuring employment changes and GVA changes independently provides only a partial picture. As such, considering labour productivity (output per worker) can shed light on the forms of growth and decline. Figure 2.12 illustrates how labour productivity in the manufacturing sector evolved over time across the different region types. Overall, the manufacturing labour productivity in every region type increased over the observed period. There are some slight differences, however. For instance, non-metropolitan regions near a small-medium city display the highest increase in labour productivity, while remote regions display the smallest gains.

Figure 2.12. Evolution of manufacturing productivity across types of regions

Note: The data include 27 OECD countries, values are based on USD millions, constant prices, constant PPP, base year 2015. Geographical typology refers to OECD TL3 typology defining metropolitan (large MR-L and medium MR-M) and non-metropolitan regions (near a large city NMR-M, near a small city NMR-S and rural region NMR-R), for further details see Box 2.1

Source: Based on the OECD Regional Statistics (database), https://www.oecd.org/regional/regional-statistics/

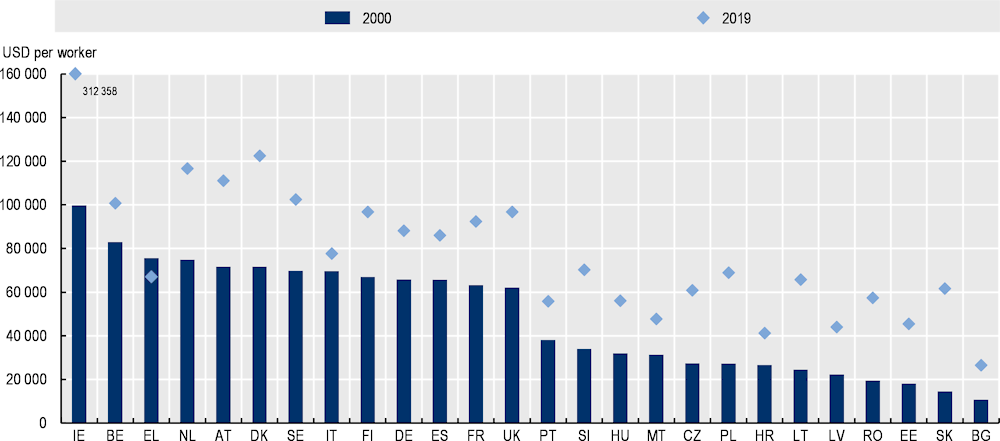

When considering changes in productivity in manufacturing across countries over the last two decades, it can be seen (Figure 2.13) that with the exception of Greece, manufacturing productivity increased in all countries during the years 2000-2019. The increase in manufacturing productivity ranged from an annual increase on average of 0.6% in Italy and Belgium to an annual increase on average of 10.5% and 7.9% in the Slovak Republic and Estonia respectively.

Figure 2.13. Manufacturing productivity by OECD country

Note: The data include 27 OECD countries, values are based on USD millions, constant prices, constant PPP, base year 2015.

Source: Based on the OECD Regional Statistics (database), https://www.oecd.org/regional/regional-statistics/

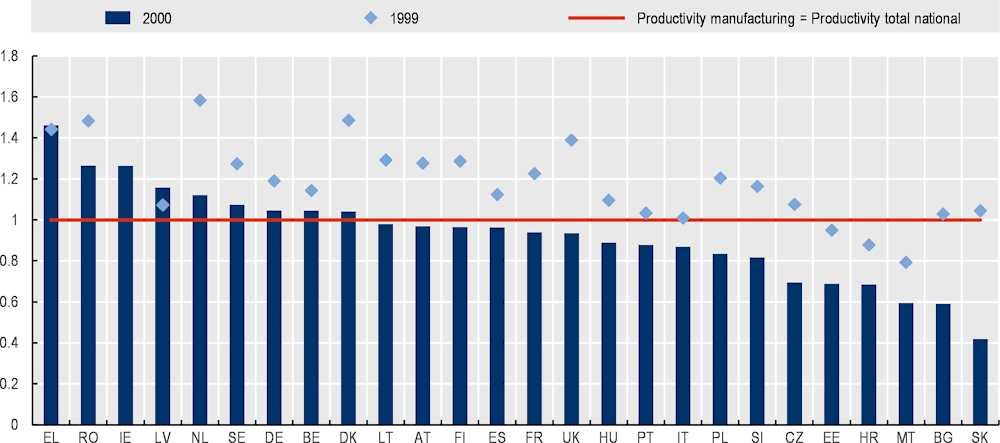

Figure 2.14 considers the productivity growth in manufacturing relative to national total productivity growth in the country. Here it can be observed that in the year 2000, the manufacturing sector of ten countries was performing below the average productivity of the nation. By 2019, however, this had reduced to only 4 countries. In 2019, countries such as Denmark, Romania and the United Kingdom had productivity in manufacturing that was 1.5 times greater than the average for the economy.

As productivity is a construct of both employment changes and output changes, the analysis breaks this down by its components and presents six cases. Table 2.7then shows whether the characteristics of each of these groups are particularly different to the other. The analysis covers 1 327 TL3 regions across 27 countries, including 769 non-metropolitan regions. In the non-metropolitan regions, 87% experienced an increase in manufacturing productivity between 2000 and 2019. However, this increase was accompanied by a decrease in manufacturing employment in most of these non-metropolitan regions.

These results are broken down by type of non-metropolitan region. In the case where both employment and GVA declined but productivity grew, these regions had (on average) lower GVA compared to employment. These regions were therefore less productive than the regions in the other two cases (especially non‑metropolitan regions near a small city and more remote rural regions). In other words, this means that the less-productive regions were more likely to experience productivity growth due to GVA and employment increases. They show that non-metropolitan regions near a large/mid-size city, due to their greater share of the total number of regions, make up the largest share of change. Amongst non-metropolitan regions that saw a productivity increase, almost half experienced an increase in GVA but deceases in employment. At the same time, these regions had a higher mean regional employment and mean regional GVA in 2000 than those in the same region type that saw productivity increase through increases in employment and GVA combined. In more rural regions, more regions were able to combine manufacturing productivity growth with increasing manufacturing employment. For regions that saw a productivity decrease (13% of all regions), this was driven by a decline in GVA that was greater than the decline in employment (64% of declining regions).

Figure 2.14. Manufacturing productivity relative to national productivity, 2000 and 2019

Note: The data include 27 OECD countries, values are based on USD millions, constant prices, constant PPP, base year 2015.

Source: Based on the OECD Regional Statistics (database), https://www.oecd.org/regional/regional-statistics/

Table 2.7. Productivity changes in employment and GVA by type of TL3 region

Productivity growth in manufacturing relative to national productivity, 2000 and 2019

|

Number of regions |

As a share of case (%) |

As a share of region type (%) |

Mean regional GVA 2000 |

Mean regional employment |

|

|---|---|---|---|---|---|

|

Prod increase: GVA increase, EMP decrease |

|||||

|

Share of total regions: 38%; Share of productivity increasing regions: 43% |

|||||

|

NMR-M |

132 |

46 |

47.7 |

6 937 |

103 816 |

|

NMR-S |

81 |

28 |

36.5 |

6 837 |

132 529 |

|

NMR-R |

76 |

26 |

44.4 |

4 779 |

83 131 |

|

Prod increase: GVA increase, EMP increase |

|||||

|

Share of total regions: 21%; Share of productivity increasing regions: 24% |

|||||

|

NMR-M |

52 |

33 |

18.8 |

4 081 |

82 158 |

|

NMR-S |

71 |

44 |

32.0 |

4 566 |

148 789 |

|

NMR-R |

37 |

23 |

21.6 |

2 348 |

60 372 |

|

Prod increase: GVA decrease, EMP decrease |

|||||

|

Share of total regions: 29%; Share of productivity increasing regions: 33% |

|||||

|

NMR-M |

93 |

42 |

33.6 |

8 423 |

120 151 |

|

NMR-S |

70 |

32 |

31.5 |

7 978 |

123 068 |

|

NMR-R |

58 |

26 |

33.9 |

4 766 |

76 919 |

|

Prod decrease: GVA decrease, EMP increase |

|||||

|

Share of total regions: 2%; Share of productivity decreasing regions: 15% |

|||||

|

NMR-M |

4 |

27 |

13.3 |

3 109 |

45 770 |

|

NMR-S |

4 |

27 |

13.8 |

2 614 |

57 577 |

|

NMR-R |

7 |

47 |

17.5 |

1 936 |

45 011 |

|

Prod decrease: GVA decrease, EMP decrease |

|||||

|

Share of total regions: 8%; Share of productivity decreasing regions: 64% |

|||||

|

NMR-M |

19 |

30 |

63.3 |

4 796 |

68 232 |

|

NMR-S |

20 |

32 |

69.0 |

5 583 |

132 696 |

|

NMR-R |

24 |

38 |

60.0 |

3 743 |

61 619 |

|

Prod decrease: GVA increase, EMP increase |

|||||

|

Share of total regions: 3%; Share of productivity decreasing regions: 21% |

|||||

|

NMR-M |

7 |

33 |

23.3 |

3 920 |

72 228 |

|

NMR-S |

5 |

24 |

17.2 |

3 843 |

105 786 |

|

NMR-R |

9 |

43 |

22.5 |

3 240 |

145 900 |

Note: The data include 27 OECD countries, values are based on USD millions, constant prices, constant PPP, base year 2015. Geographical typology refers to OECD TL3 typology defining metropolitan (large MR-L and medium MR-M) and non-metropolitan regions (near a large city NMR-M, near a small city NMR-S and rural region NMR-R), for further details see Box 2.1

Source: Based on the OECD Regional Statistics (database), https://www.oecd.org/regional/regional-statistics/

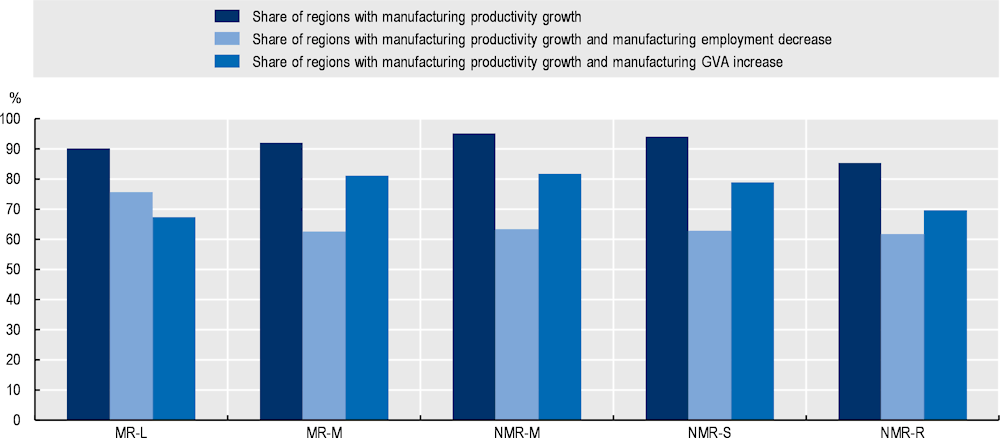

Focusing on changes in employment in the cases of productivity growth, as illustrated in Figure 2.15. below, highlights the differences across region types:

It can thus be clearly seen that for metropolitan regions, increases in manufacturing GVA were accompanied much more readily by declines in employment (labour replacing productivity growth) than in non-metropolitan regions.

For example, 86% of rural remote regions saw an increase in manufacturing productivity from 2000 to 2019; however, 14% of these regions also increased employment in manufacturing.

Conversely, it can also be seen that, across all region types, the increase in manufacturing productivity has largely been accompanied by a corresponding increase in manufacturing GVA (58% of productivity increasing regions), so that only a small part is attributable to combined declines in manufacturing employment and manufacturing GVA. This points to increased capital intensity of manufacturing over time.

Figure 2.15. Manufacturing productivity and output growth and employment declines by region type

Note: The data include 27 OECD countries, productivity values are based on USD millions, constant prices, constant PPP, base year 2015. Geographical typology refers to OECD TL3 typology defining metropolitan (large MR-L and medium MR-M) and non-metropolitan regions (near a large city NMR-M, near a small city NMR-S and rural region NMR-R), for further details see Box 2.1

Source: Based on the OECD Regional Statistics (database), https://www.oecd.org/regional/regional-statistics/

Within-country relevance of manufacturing in rural regions over time

While the above sections focused on absolute changes, which are relevant in an increasingly globalised world, it may also be interesting for national policy makers to identify patterns of change within their own countries. This section develops a typology to better understand the degree and direction of growth and declines in manufacturing within OECD countries.

Therefore, for each country, the distributions of the shares of manufacturing employees in rural regions in 2000 and 2017 are divided into quintiles.4 Second, the ex-poste probabilities of regions moving or remaining in any quintile are calculated. The probability of remaining in any particular quintile i is the ratio of the number of regions in quintile i in 2000 to the number of regions in quintile i in 2017. Conversely, the probability of moving from status i to status k is the ratio of the number of regions that used to be in quintile i in 2000 and moved to quintile k in 2017 to the number of regions in quintile i in 2000. The result is a matrix for each country in which each element is the probability of moving across the five quintiles between 2000 and 2017.

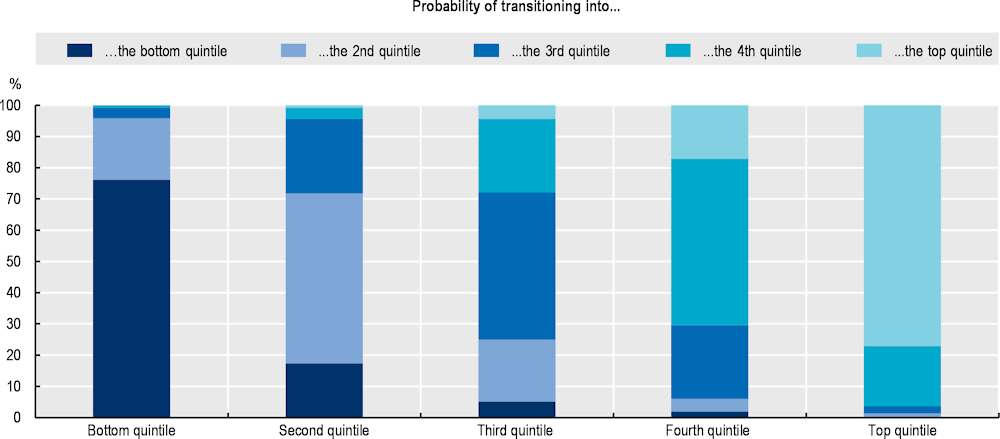

Our analysis finds that despite the overall decline of manufacturing across the OECD, the probability of change in the position of each individual region relative to other regions is relatively stable. By considering all OECD regions and calculating their probability of increasing or decreasing their manufacturing importance relative to the national level, little change can be seen. That is to say, if a region was a manufacturing-intensive region in 2000, it is most likely to have remained so by 2017. About 75% of the rural regions that used to be in the top quintile in 2000 did not change status by 2017; at the same time, around 77% of the bottom quintile regions did not move up the distribution 18 years later (Figure 2.16). The probability of moving out of the quintile in 2000 is, in general, low throughout the distribution, as summarised by a standard mobility index normally used to measure income and employment dynamics (Ward-Warmedinger and Macchiarelli, 2013[5]).

Figure 2.16. Probability distributions for changes in regional employment shares of manufacturing

Source: Based on the OECD Regional Statistics (database), https://www.oecd.org/regional/regional-statistics/

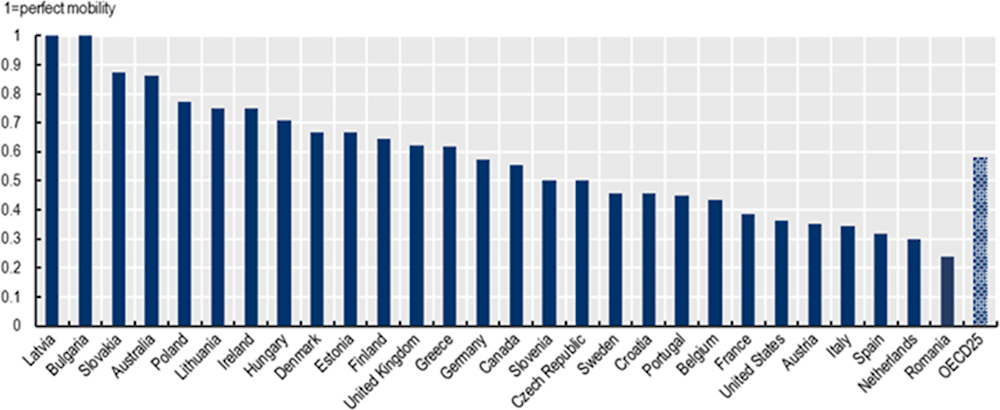

Looking at this across countries, there are variations within the OECD. Figure 2.17 indicates that the lower the index of mobility value (y-axis), the lower the overall probability of leaving any quintile. In other words, very few regions in the Netherlands or Romania have moved their ranking within their countries in relation to its share of manufacturing in their region against the share of manufacturing in the other regions. On the contrary, over the last two decades, every region in Bulgaria and Latvia has seen a shift in their manufacturing activity internal rankings.

Based on the transition probabilities, six categories of regions can be identified (Table 2.8). These are: i) traditional manufacturing hubs (16.6% of the rural regions); ii) new entrants in top quintile regions (5.9%); iii) vanishing from top quintile regions (3.8%); iv) moving up regions (17.3%); v) moving down regions (13% of the regions); and vi) static regions outside of the top quintile (48.8%).

Figure 2.17. Changes in the relative position of manufacturing across OECD TL3 regions

Note: The index of mobility is defined as the number of regions that increase or decrease their position of manufacturing employment

Source: Based on the OECD Regional Statistics (database), https://www.oecd.org/regional/regional-statistics/

Table 2.8. Typology of regions based on transition probabilities

|

Type of regions |

Description |

Number of regions |

Share of regions (%) |

|---|---|---|---|

|

Traditional manufacturing hubs |

Regions that occupied the top quintile of the distribution in both 2000 and 2017 |

372 |

16.05 |

|

New entrants in top quintile regions |

Regions that joined the top quintile in 2017 |

138 |

5.95 |

|

Vanishing from top quintile regions |

Regions that used to belong to the top quintile in 2000 and occupied a lower quintile in 2017 |

88 |

3.8 |

|

Moving up regions |

Regions that moved to a higher quintile in 2017, outside of the top quintile |

402 |

17.34 |

|

Moving down regions |

Regions that moved to a lower quintile in 2017 but that were not in the top quintile in 2000 |

302 |

13.03 |

|

Static/ no change regions |

Regions that have not changed quintile between 2000 and 2017 |

1 016 |

48.83 |

Source: Based on the OECD Regional Statistics (database), https://www.oecd.org/regional/regional-statistics/

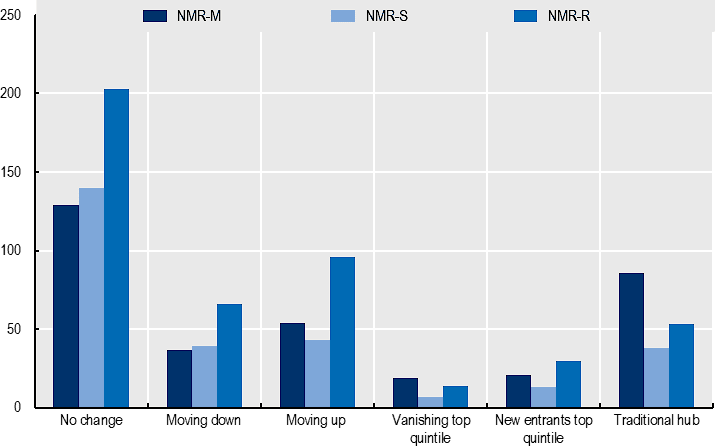

Considering these positional changes by degree of rurality can help identify patterns amongst rural regions which may differ from more metropolitan regions. Figure 2.18 finds that rural, remote regions make up the largest share of moving up rural regions (48.7%). It shows that rural regions close to metropolitan areas make up the largest share of traditional hubs (46.7%). Movement of regions across quintiles is the lowest among remote regions: close to half of them (41.3%) have not experienced any change of quintile in the past two decades, while a lower share of them has moved up or down the distribution. To reiterate, these are regions that had manufacturing activity in the 2000s and continue to do so today. Remote rural regions saw greater increases in relative manufacturing activity over the past two decades.

Figure 2.18. Relative movement in manufacturing by type of TL3 regions

Note: Geographical typology refers to OECD TL3 typology defining metropolitan (large MR-L and medium MR-M) and non-metropolitan regions (near a large city NMR-M, near a small city NMR-S and rural region NMR-R), for further details see Box 2.1

Source: Based on the OECD Regional Statistics (database), https://www.oecd.org/regional/regional-statistics/

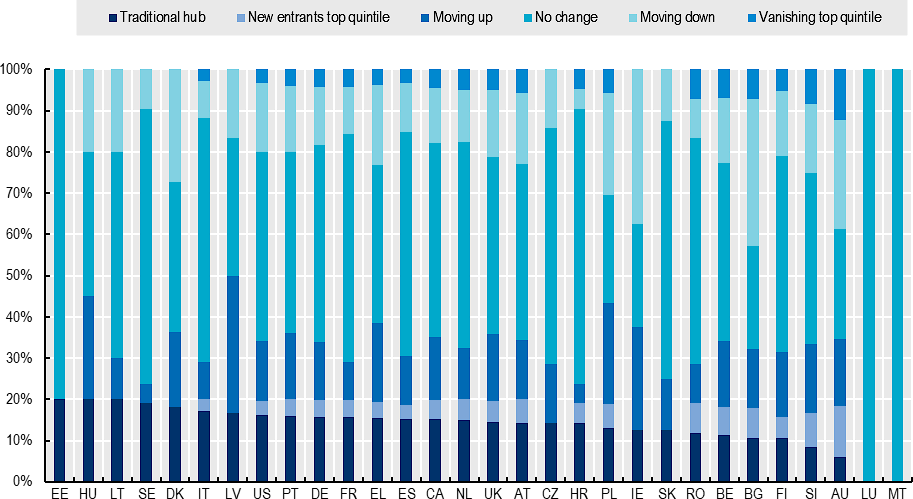

Breaking this down by country, Figure 2.19 shows some subtle variations among them. As illustrated previously, most countries see no change in many regions in their relative positions. Countries such as Estonia, Hungary and Lithuania hold the highest shares of traditional hubs. In comparison, Austria and Slovenia see a larger share of vanishing hubs compared to other countries.

Figure 2.19. OECD countries in relative manufacturing position typology

Source: Based on the OECD Regional Statistics (database), https://www.oecd.org/regional/regional-statistics/

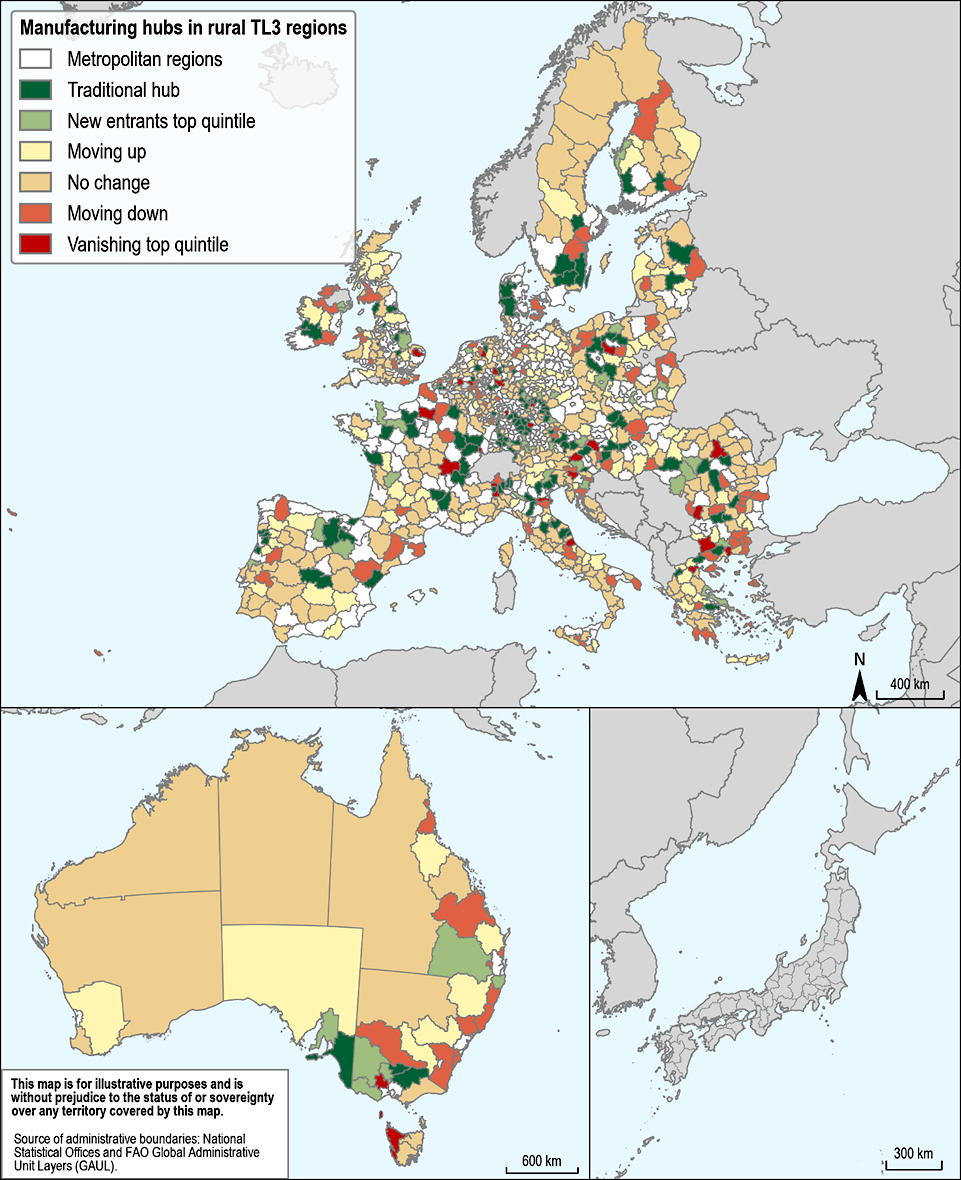

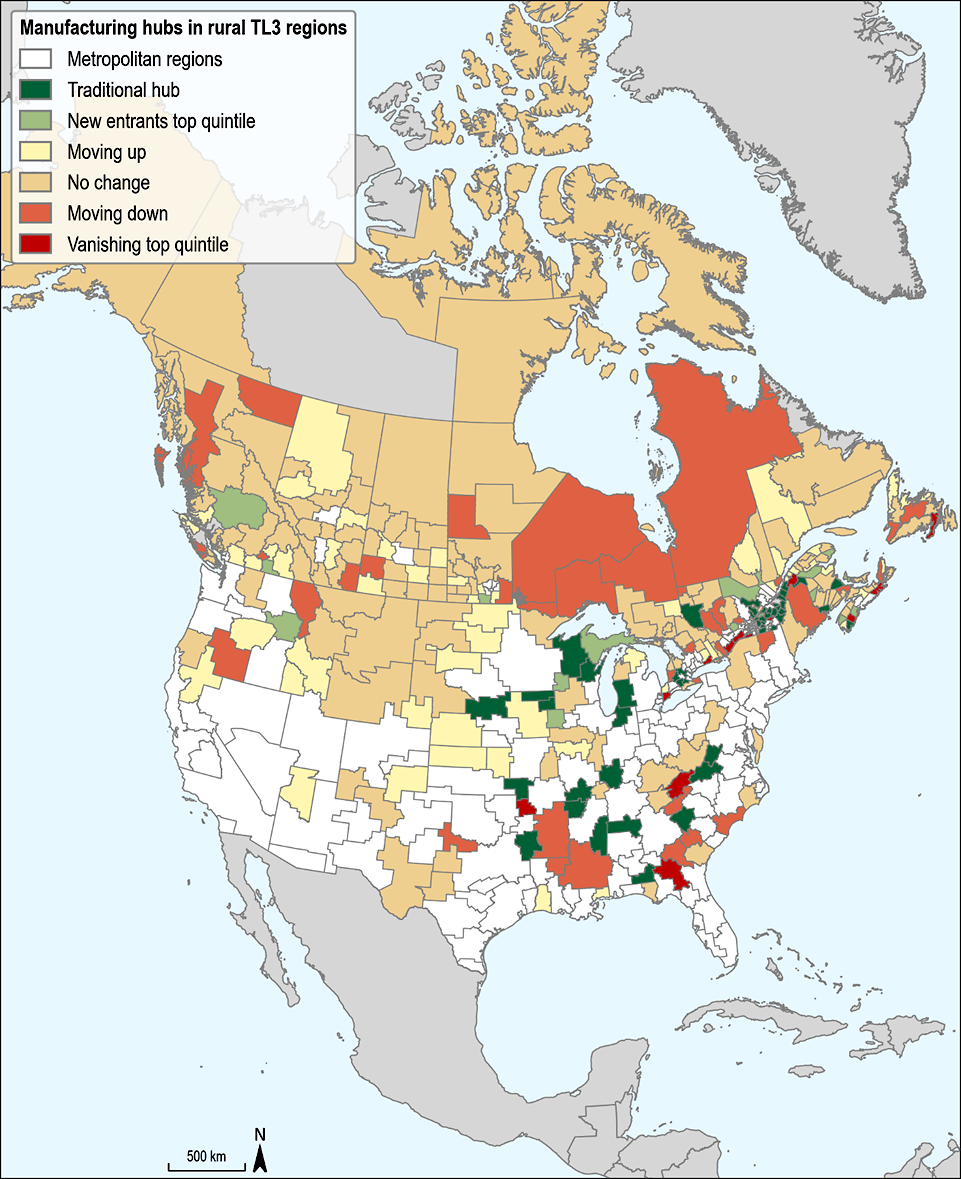

This is also illustrated in the maps of Figure 2.20 and Figure 2.21. For non-European countries in the analysis, manufacturing accounts for 25.8% in Canada and 13.9% in the United States. Rural regions in North America are mostly stable or moving up manufacturing hubs. Vanishing manufacturing hubs are less prevalent in Canada and the United States, which have more traditional and upcoming hubs in their centres. This indicates that whilst overall employment may have decreased, sometimes drastically, in these regions and countries, these regions have maintained their positions relatively within their countries. A similar exercise across Australia reveals some clustered patterns of change over the last decades.

Figure 2.20. Manufacturing hubs and relative positions in rural TL3 regions, Europe and Australia

Source: Based on the OECD Regional Statistics (database), https://www.oecd.org/regional/regional-statistics/

Figure 2.21. Manufacturing hubs and relative positions in rural TL3 regions, USA and Canada

Source: Based on the OECD Regional Statistics (database), https://www.oecd.org/regional/regional-statistics/

Rural remote regions are more likely to fall to the lowest quintile for manufacturing employment and GVA – 26.7% of remote regions were in the lowest quintile of manufacturing employment regions in 2000 (Table 2.9). This share decreased to 24.5% in 2017. This is the most common form of change for remote regions – an increase in manufacturing from not very much to slightly more. On the other hand, regions close to metropolitan areas are most likely to move up into the highest quintiles for manufacturing and GVA – 30.4% in 2000 and 31.2% in 2017, and 27.4% in 2000 and 26.4% in 2017 respectively.

Table 2.9. Distribution of OECD TL3 regions across manufacturing employment and GVA

Distribution of rural regions by quintile of origin/destination in employment and metropolitan/non-metropolitan typology

|

TL3 type |

Quintile at time of origin (around 2000) |

Quintile at time of destination (around 2017) |

||||||||

|---|---|---|---|---|---|---|---|---|---|---|

|

1 |

2 |

3 |

4 |

5 |

1 |

2 |

3 |

4 |

5 |

|

|

NMR-M (%) |

35 (9.94) |

43 (12.22) |

77 (21.88) |

90 (25.57) |

107 (30.40) |

23 (6.53) |

46 (13.07) |

80 (22.73) |

93 (26.42) |

110 (31.25) |

|

NMR-R (%) |

130 (26.75) |

110 (22.63) |

89 (18.31) |

83 (17.08) |

74 (15.23) |

119 (24.49) |

104 (21.40) |

90 (18.52) |

82 (16.87) |

91 (18.72) |

|

NMR-S (%) |

57 (17.54) |

70 (21.54) |

72 (22.15) |

73 (22.46) |

53 (16.31) |

56 (17.23) |

69 (21.23) |

70 (21.54) |

69 (21.23) |

61 (18.77) |

|

Total (%) |

222 (19.09) |

223 (19.17) |

238 (20.46) |

246 (21.15) |

234 (20.12) |

198 (17.02) |

219 (18.83) |

240 (20.64) |

244 (20.98) |

262 (22.53) |

While movements in and out of the top quintile usually involve the fourth quartile, in a small handful of regions, the manufacturing sector changed from being a secondary provider of jobs to becoming one of the main pillars of the local economy. Smoylan (Bulgaria) and Wrocławski (Poland), for example, jumped from the first and second quintiles respectively to the top quintile within their countries – their shares of manufacturing employment increased on average by 15 percentage points (Table 2.10). However, not all fast-rising hubs are based on positive experiences: the regions identified as fast-rising in some rural regions of Australia and the United Kingdom were simply experiencing a fall at a relatively slower rate than the other regions in their country. As such, in these cases, manufacturing has become more important to the local economy with respect to other regions.

Table 2.10. OECD rural regions with new entrants in the top quintile

Rural regions that have moved into the top quintile by starting from the lowest quintiles

|

Country |

Region |

Region type |

Manufacturing employment (% total local employment), 2000 |

Growth of manufacturing employment (p.p., 2000-17) |

Quintile of origin |

|---|---|---|---|---|---|

|

Poland |

Wrocławski |

NMR-M |

18.5 |

15.38 |

2 |

|

Bulgaria |

Smolyan |

NMR-R |

14.5 |

14.17 |

1 |

|

Romania |

Hunedoara |

NMR-R |

21.9 |

7.6 |

3 |

|

Poland |

Oswiecimski |

NMR-M |

21.1 |

6.86 |

3 |

|

Lithuania |

Utena |

NMR-R |

14.5 |

4.5 |

1 |

|

Canada |

Le Rocher Percé (Quebec) |

NMR-R |

14.3 |

3.4 |

3 |

|

Latvia |

Pieriga |

NMR-S |

15.9 |

3.06 |

3 |

|

United States |

Lewiston (Idaho) |

NMR-R |

8.7 |

1.8 |

2 |

|

Australia |

Bendigo |

NMR-S |

9.9 |

0.49 |

3 |

|

Australia |

North West |

NMR-R |

9.7 |

0.02 |

3 |

|

Australia |

Richmond- Tweed |

NMR-R |

9.1 |

-0.3 |

2 |

|

Australia |

Darling Downs – Maranoa |

NMR-R |

10.1 |

-0.9 |

3 |

|

United Kingdom |

Newry, Mourne and Down |

NMR-R |

14.0 |

-1.13 |

3 |

Note: Geographical typology refers to OECD TL3 typology defining metropolitan (large MR-L and medium MR-M) and non-metropolitan regions (near a large city NMR-M, near a small city NMR-S and rural region NMR-R), for further details see Box 2.1.

Source: Based on the OECD Regional Statistics (database), https://www.oecd.org/regional/regional-statistics/

Some of these regions are in Bulgaria and Poland, in line with the overall relatively higher mobility patterns that these countries showcase. Many regions from these countries in earlier sections that saw a rise in their manufacturing employment and GVA are not represented below, as the growth of their peer regions was at a faster pace than their own. In Queens, Canada, the manufacturing sector in 2001 was small in absolute terms (1 140 of 4 020 total jobs) but large in relative terms (28.3% of the local labour force), placing it among the top quintile of the distribution; almost 16 years after, 305 manufacturing had vanished and the population of total employed in the region had declined to 3 140. While in absolute terms, these are small numbers, locally, these global trends have reshaped the economy as well as the local social fabric.

Table 2.11. OECD rural regions with fast-vanishing traditional hubs

Rural regions that have moved out of the top quintile and ended in the lower quintiles

|

Region |

Region type |

Manufacturing employment (% total local employment), 2000 |

Growth of manufacturing employment, 2000-latest year |

Quintile of destination |

|

|---|---|---|---|---|---|

|

Bulgaria |

Montana |

NMR-S |

25.2 |

-4.3 |

3 |

|

Poland |

Inowroclawski |

NMR-S |

26.7 |

-4.4 |

3 |

|

Australia |

Ballarat |

NMR-S |

13.8 |

-6.9 |

3 |

|

Greece |

Xanthi |

NMR-S |

14.0 |

-7.3 |

3 |

|

Belgium |

Hasselt |

NMR-M |

24.9 |

-13.1 |

3 |

|

Canada |

Queens (Nova Scotia) |

NMR-R |

28.3 |

-18.7 |

3 |

Note: The latest years are as follows: Australia 2019, Belgium 2019, Bulgaria 2018, Canada 2001-16, Greece 2018, Poland 2018. Geographical typology refers to OECD TL3 typology defining metropolitan (large MR-L and medium MR-M) and non-metropolitan regions (near a large city NMR-M, near a small city NMR-S and rural region NMR-R), for further details see Box 2.1

Source: Based on the OECD Regional Statistics (database), https://www.oecd.org/regional/regional-statistics/

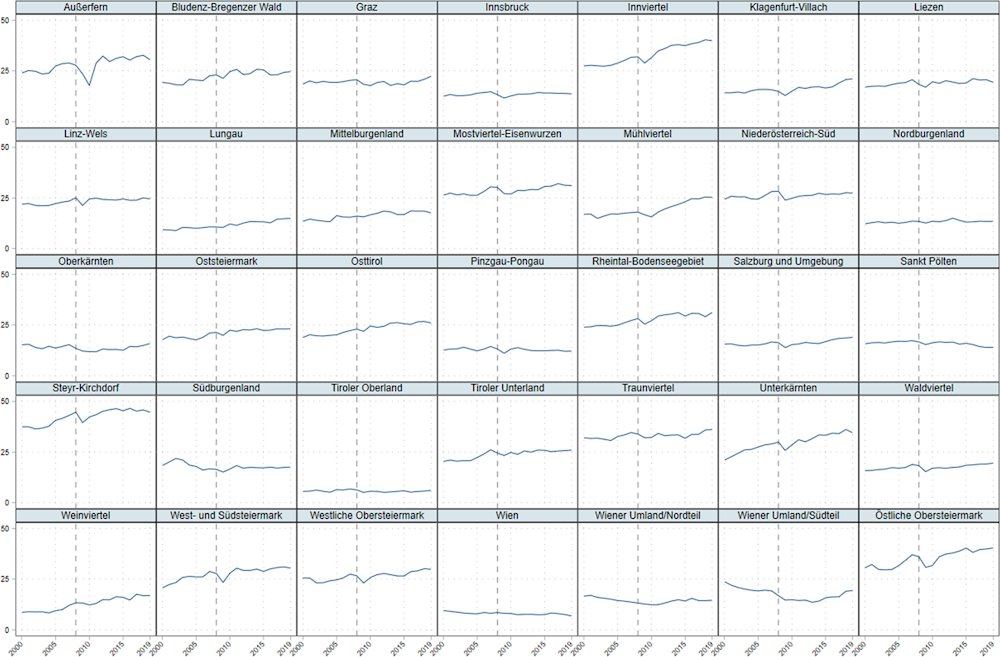

On many occasions, the trajectory of a region is not linear. As highlighted by the fluctuations over time of aggregate employment and output, the granular data highlight a similar trend. It is not necessarily the case that a region that moved from the 2nd quintile in 2000 to the 5th quintile in 2017 has moved across quintiles 3 and 4 steadily and consistently in the in-between years. Figure 2.22 takes the example of Austria, depicting changes across the time series. Across the analysis amongst other countries, the most prominent instability was around remote rural regions. For example, Slovak rural regions witnessed unstable patterns in output growth, many years seeing no change followed by both rises and falls. Similarly, when considered from a manufacturing employment development perspective, Baltic countries (Estonia, Latvia and Lithuania) show unstable patterns in more than half of their rural regions.

Figure 2.22. Manufacturing GVA of non-metropolitan regions across Austria 2000 to 2019

Note: Includes 2008 line to highlight the financial crisis impacts. Austria is used as an example for illustrative purposes.

Source: Based on the OECD Regional Statistics (database), https://www.oecd.org/regional/regional-statistics/

Characteristics of regions that move quintile groups

Do regions that moved up in their manufacturing quintile have something that regions that moved down do not have and do manufacturing regions in the top quintile show different traits to manufacturing regions in the bottom quintile? Correlation analysis indicates limited results. On average, regions with high levels of employment in manufacturing tend to have high levels of regional employment more broadly. They are also more likely to have higher levels of digital connectivity (defined as downloadable kilobytes per second for mobile telephones). Factors such as proximity to the ports or being a border town seem to have limited bearing on the likelihood of relative success. Proximity to other manufacturing hubs is likely to be more of a driver; more granular data to specify these are required for a more in-depth analysis.

Overall, mean differences between non-movers and movers in the first and fifth quintiles are not very important in the distribution of unemployment, labour force, birth and death rates of firms, airports, ports as well as universities. However, they remain high in the distributions of GVA per worker and mobile connectivity in both the agriculture and services sectors.

Path dependency explains most of the development of manufacturing in OECD countries. Capabilities inherited throughout centuries of history as well as the social and economic fabric, determine the role that manufacturing still has in some rural regions today (Hidalgo and Hausman, 2009[6]). The evolution of Tuttlingen, Germany, from the centre of shoe production into a hub of manufacturing of medical technologies is an example of how regions can leverage their past to reinvent themselves and weather global megatrends. When transformation is not endogenous and pulled by existing characteristics, it can be induced by external forces, such as foreign direct investment or targeted industrial policies. While push factors may lead to leapfrogging, it is crucial to understand what drivers can make fast manufacturing development long-lasting.

Summary

In sum, this chapter shows that although there is an overall decline in manufacturing deindustrialisation across OECD economies, this decline has been less severe across rural regions, and manufacturing still plays an important role in rural economies, especially in rural areas near large cities and near small cities. The trends confirm an overall loss of employment across all regional types including in rural regions. In terms of the manufacturing contribution to regional GVA, it has increased over the last two decades in all three types of rural regions, thus showing the importance to better understand the enabling factors and bottleneck driving trends in rural manufacturing. Taking stock of the typology developed in Chapter 1 showing diverse forms of manufacturing activities that can take place in rural regions, this chapter shows a diverse picture in terms of the distribution of manufacturing activities across OECD rural regions. This diverse picture is driven by a hybrid of factors that include industrial legacy, geographic proximity to markets, access to natural resources and innovation intensity. The distributions show high concentrations of rural manufacturing activities in certain geographies, notably the former Eastern European countries and in Germany. Some factors driving manufacturing activity in these countries include their lower relative labour costs within the EU block and good skilled labour.

The chapter also examines trends in labour productivity and reveals that amongst those rural regions with positive gains in manufacturing productivity, 60% of them experienced declines in manufacturing employment over the past two decades. Furthermore, amongst those rural regions that increased manufacturing productivity, 77% of them also increased GVA in manufacturing. This partly suggests a steady transformation towards more capital-intensive forms of manufacturing activities. Thus innovation, skills development, and adoption of technology will be important drivers for the future of rural manufacturing.

The chapter finally examined movements within countries over the past decades using a typology based on relative movements in the manufacturing importance of regions to the national average. This typology shows a relatively stable picture, meaning if a region was a manufacturing-intensive region in 2000, it is most likely to have remained so by 2017. This relative picture also points that the importance of regions-specific factors and assets for rural manufacturing highlighted in the previous chapter, including heritage, presence of natural resources, geographic location to markets or innovation ecosystem. Finally, amongst the regions that occupied the top quintile of the distribution in both periods, the majority of them are rural close the cities, thus confirming to importance of proximity to markets to sustain rural manufacturing.

References

[8] ADB (2019), Services and Manufacturing in Global Value Chains: Is the Distinction Obsolete?, Asian Development Bank, https://www.adb.org/publications/services-and-manufacturing-global-value-chains (accessed on 8 November 2022).

[7] Christensen, J. (2013), “The ability of current statistical classifications to separate services and manufacturing”, Structural Change and Economic Dynamics, Vol. 26, pp. 47-60, https://doi.org/10.1016/j.strueco.2013.06.002.

[9] Delgado, M. and K. Mills (2020), “The supply chain economy: A new industry categorization for understanding innovation in services”, Research Policy, Vol. 49/8, p. 104039, https://doi.org/10.1016/j.respol.2020.104039.

[1] EC (2019), ARDECO Database, Directorate General for Regional and Urban Policy, European Commission, https://knowledge4policy.ec.europa.eu/territorial/ardeco-database_en (accessed on 10 November 2022).

[2] Fadic, M. et al. (2019), “Classifying small (TL3) regions based on metropolitan population, low density and remoteness”, OECD Regional Development Working Papers, No. 2019/06, OECD Publishing, Paris, https://doi.org/10.1787/b902cc00-en.

[6] Hidalgo, C. and R. Hausman (2009), “The building blocks of economic complexity”, Proceedings of the National Academy of Sciences, Vol. 106/26, pp. 10570-10575.

[3] UN (2008), System of National Accounts 2008 - 2008 SNA, United Nations, https://unstats.un.org/unsd/nationalaccount/sna2008.asp (accessed on 8 November 2022).

[4] United Nations (2015), United Nations Economic Commission for Euorpe Guide to Measuring Global Production.

[5] Ward-Warmedinger, M. and C. Macchiarelli (2013), “Transitions in labour market status in the EU”, IZA Discussion Paper, No. 7814, https://www.oecd.org/els/emp/Macchiarelli_11Februray2014_paper.pdf.

Notes

← 1. Industry is defined as all activities in the NACE categories B-E, i.e. mining and quarrying, energy production and water “production” including supply processing and remediation as well as the broader forms of manufacturing.

← 2. It is also important to note that GVA numbers may be affected by headquarters effects that will be discussed further in Chapter 4 (Box 4.1).

← 3. A voivodeship or voivodate is the area administered by a voivode in several countries of central and eastern Europe.

← 4. The manufacturing employment as a share of total regional employment in a top quintile region is higher than in 80% of all other regions in the country. Shares in second quintile regions are higher than 60% of all other regions in the country and so on and so forth.