This chapter investigates the effects of the COVID-19 pandemic and lockdown measures on the production, use and waste of plastics, focusing on the short-term effects in the year 2020, in order to shed light on the complex interactions between the effects of COVD-19 on economic activity and plastics use. It first looks at emerging evidence for the pandemic’s impact on specific uses and sectors, followed by an overview of the effects on waste and recycling. It then reports on the results of a detailed OECD modelling framework used to assess the consequences of COVID-induced changes in sectoral and regional economic activity on plastics use more broadly. It ends with a brief discussion of the possible longer-term implications of the pandemic on plastics use.

Global Plastics Outlook

3. The effects of the COVID‑19 pandemic on plastics use and waste

Abstract

KEY MESSAGES

In 2020, the COVID-19 pandemic and lockdown measures had a significant impact on plastics production, use and waste. In most sectors, plastics use declined in line with the reduction in demand and output, especially for large-scale plastics-using sectors such as motor vehicles, trade and construction. Global plastics use in 2020 is estimated to have declined in 2020 by around 10 million tonnes (Mt) or 2.2%, which is 4.5% below the pre-COVID projection for 2020.

This reduction is substantially smaller than the decline in overall economic activity, with the annual global gross domestic product (GDP) growth rate dropping from around +4% in 2019 to -3.5% in 2020. Consequently, the plastics intensity of the economy increased on average despite the pandemic.

In some sectors, especially healthcare, plastics use increased significantly – for instance for face masks and other personal protective equipment. Plastics use for face masks and other personal protective equipment is estimated to be around 300 kilotonnes, i.e. less than 0.1% of total plastics use in 2020, or a few percent of the overall impact of the pandemic on plastics use.

In other sectors, the nature of economic activity changed, for instance from eating in restaurants to take-away, and from in-store shopping to online retail (e-commerce). The net effects of such shifts are unclear at the time of writing of this report, but the boosted activities use significant amounts of single-use plastics. Plastics use declined in industrial sectors, with plastics use in construction and motor vehicles, respectively, estimated to have declined by 4.6 and 2.6 Mt from 2019 levels.

The pandemic has also resulted in significant disruptions to plastics recycling. This is due to the temporary halting of separate collection in some municipalities, a temporary shift to single-use plastics, disruptions to waste plastic trade, as well as a temporary loss of competitiveness of recycled plastics linked to the low price of oil and resulting low prices for primary plastics.

Plastics waste has been affected by the pandemic in the short run by a switch to single-use plastics and a switch from industrial and commercial waste to household waste. In 2020, while total plastic waste may have remained roughly stable, municipal plastic waste most likely increased, although robust information is not yet available. However, a significant portion of the effects on plastic waste will be delayed to future years due to the long lifespan of many plastics uses.

The increase in the use of protective personal equipment and single-use plastics has exacerbated plastic littering on land and in marine environments, with negative environmental consequences. While OECD countries are more likely to spend additional funds to collect litter from cities, non-OECD countries face the risk of plastic litter on land infiltrating the environment.

3.1. The Covid-19 pandemic has disrupted the economy and the use of plastics

The coronavirus that is the cause of an infectious disease known as COVID-19, first discovered in Wuhan in the People’s Republic of China in December 2019, spread to other countries and continents in less than a few months and triggered a global health pandemic. Governments responded to the emerging crisis with a range of measures to contain the spread, especially limiting the movement of people and goods and shutting down economic activity.

The COVID-19 pandemic and the associated lockdown measures have led to a significant contraction in the global economy (OECD, 2021[1]; IMF, 2020[2]). Around the world, economic activity shrank as supply, demand and trade were suddenly severely disrupted (Dellink et al., 2021[3]). Recovery will be a long-term process and economic activity will likely be affected even after the health crisis is over.1

The COVID-19 pandemic has also highlighted the importance of plastics in our daily lives. Given their properties, plastics are particularly well-suited for personal protective equipment (PPE) such as surgical face masks, single-use medical tools and packaging. Plastics are lightweight; can be resistant to external shocks, contamination and moisture; can be flexible; and offer various degrees of opacity. For instance, polyvinyl chloride (PVC) offers the durability required for surgical gloves (Hamann, Sullivan and Wright, 2014[4]). Another example is polypropylene (PP) which is largely used in food packaging as it is resistant to external influences and has a high melting point, making it suitable for microwavable containers (Marsh and Bugusu, 2007[5]). Plastics are also often less expensive to manufacture than alternatives, such as aluminium, and also cheaper to transport than heavier materials such as glass (Marsh and Bugusu, 2007[5]). Finally, single-use plastic items such as face masks and medical tools can reduce the potential spread of diseases and viruses effectively, as long as they are disposed of in a sanitary manner.

The use of plastics is also ubiquitous in sectors that were negatively affected by the pandemic, such as transport and construction – each accounting for more than 10% of annual plastic use before the COVID‑19 pandemic. Meanwhile, sectors such as retail and food services saw a significant shift away from in-store shopping and restaurants towards e-commerce, take-away and food delivery, with mixed effects on plastics use. Thus, because plastics are used in different applications by many sectors, the overall effect of the COVID-19 pandemic on plastics use in 2020 remains unclear. Effects should become clearer when new evidence and data on plastics use in the different applications and sectors becomes available over time. Annex B presents a summary of the main assumptions behind the modelling of the COVID-19 impacts in this report and the associated key economic impacts in 2020.

3.2. The pandemic’s impact on plastics production varies by use and sector

3.2.1. Plastics production was temporarily disrupted

Disruptions in supply chains due to lockdowns and border restrictions reduced plastics production overall. Plastics Europe (2021[6]) estimates that worldwide plastics production decreased by 0.3% in 2020 compared to 2019. However, low oil prices at the early stage of the pandemic may have boosted production – especially of primary plastics – by reducing the cost of raw materials (IEA, 2020[7]; US Bureau of Labor Statistics, 2020[8]). By contrast, low oil prices imply that the growth of secondary (recycled) plastics stalled in 2020, as the price of secondary plastics is linked to that of primary.

There are also big regional differences in the economic effects of the pandemic, and lockdown measures varied widely across countries. Thus, the changes in plastics production varied across countries. In the United States, production of plastic and rubber products fell drastically in March and April 2020, but almost returned to pre-COVID levels at the end of the year. The result was a 7.5% annual decline in production in 2020 compared to the previous year (US Board of Governors of the Federal Reserve System, 2021[9]). European plastics production declined the most during the months of April and May, leading to an annual production volume decline of 4.5% in 2020 compared to the previous year (Eurostat, 2021[10]). The Japan Plastics Industry Federation (2021[11]) reports that annual plastics production decreased by 4.1% in 2020 in Japan. By contrast, Plastics Europe (2021[6]) reports that on a yearly basis, China slightly increased its annual plastics production in 2020; this reflected both the active government response and the faster recovery of the Chinese economy in comparison to most other countries in the second half of 2020 (OECD, 2021[1]). Given the contractions in other countries, this implied an increase in China’s global market share.

The disruptions to economic activity in 2020 were widespread and covered all economic sectors, either directly or indirectly. Generally, reduced production also implied the reduced use of plastics as an input. In some sectors, plastics are a major share of production inputs, and thus the effects on plastics use were significant, and generally negative. This section briefly presents a few examples of uses and sectors that were significantly affected.

3.2.2. Plastics use for health purposes increased significantly

Plastics use for health purposes increased significantly

The health-related advantages of plastics were put under the spotlight as the COVID-19 pandemic unfolded (Box 3.1). They are used for a variety of sanitary and medical applications and have thus contributed immensely to the healthcare sector and public health safety. In order to limit the spread of the virus, governments across the world mandated the use of face masks in closed spaces, such as in transport, and often in open air spaces too (Patrício Silva et al., 2020[12]).

Box 3.1. Which polymers are used for personal protective equipment, medical devices and COVID-19 tests?

The production of PPE requires a number of polymers as feedstock. Face masks, which include N95 respirators and surgical masks, are commonly made from PP, while the masks’ nose wire is made out of polyethylene (PE) (Institute of Medicine, 2006[13]). Surgical gloves are commonly made from rubber or durable plastics such as PVC (Hamann, Sullivan and Wright, 2014[4]); face shields are often made up of polycarbonate (PC), propionate, acetate, PVC or polyethylene terephthalate glycol; and straps holding masks and goggles in place are made out of rubber or polyetherimide (Henneberry, 2021[14]).

Similarly, medical applications need a range of polymers; a number of medical instruments that were traditionally made of steel, ceramic or glass have gradually been replaced with plastics in recent decades (Joseph et al., 2021[15]). PVC is the most commonly used plastic polymer in medical devices, accounting for 25% of medical plastics use (McKeen, 2014[16]) In addition to face masks and surgical gloves, it is used for example, in intravenous bags, drug solutions, and for many medical produces that require tubing (e.g. infusion, injection, respiration) (Oral, Kurtz and Muratoglu, 2017[17]). Another 50% of medical plastics demand is covered by a mix of PE, PP and polystyrene (PS) (Basmage and Hashmi, 2020[18]). PE is typically used in containers, packaging films and joint replacements; PP in syringes, sutures and gowns; while PS is used for diagnostic instruments, disposable laboratory ware and pipettes, for example (Basmage and Hashmi, 2020[18]).

Finally, COVID-19 tests mostly require PP (around 90%), in addition to polyester (8%) and PE (2%) (Celis et al., 2021[19]).

Early on in the pandemic, the spike in demand for face masks was very sudden and caused a dramatic shortage in the supply of masks worldwide (OECD, 2020[20]). Prior to the pandemic, China was responsible for half of global face mask production. It increased its share in global production in the early months of 2020 due to a surge in global demand that could not be met by other countries (Subramanian, 2020[21]). Plastic manufacturers in China were reportedly producing 110 million surgical masks per day at the end of February – 12 times the volume in January (Ren, 2020[22]). By the end of April, 200 million surgical masks were being produced daily (SCIO, 2020[23]). This corresponds to a monthly production of approximately 33 to 42 kilotonnes (kt) of face masks for the first quarter of 2020.

In Thailand, it was reported in April 2020 that 1.5 million face masks were being used every day (National News Bureau of Thailand, 2020[24]). Japan secured the supply of 600 million face masks just for the month of April (METI, 2020[25]). In Bangladesh in March, which marked the first month of their lockdown, 455 million face masks and 1.2 billion gloves were used in total, corresponding to 1.6 and 3 kt of disposable plastics use respectively (ESDO, 2020[26]). To estimate the volume of face masks used in the European Union (EU), the European Environment Agency (EEA) uses data on the net import of PPE into the EU as a proxy for use in the early stage of the pandemic, when European production capacity was severely limited. Based on this, the EEA estimated that 170 kt of additional face masks and 105 kt of additional gloves (not only plastics but also synthetic rubber) were imported between April and September 2020 (compared to business-as-usual projections) (Graulich et al., 2021[27]).

Demand for PPE has been strong throughout the COVID-19 pandemic and although there has been some shift towards cloth masks, demand for plastic face masks remains much higher than before the pandemic. Aside from the regional and anecdotal evidence reported above, robust data on the number of face masks produced and discarded globally in 2020 are not yet available. An often-cited early estimate is presented by Prata et al. (2020[28]), who extrapolate from a local context in heavily hit Italy to a global use of 129 billion face masks per month. This would equate to more than one trillion masks for the year 2020. This reflects the hypothetical demand for face masks that would be needed for optimal protection, but does not consider whether supply could be increased rapidly enough to meet this demand. Using better data and taking into account supply restrictions, more recent estimates suggest more moderate numbers, such as global production of 52 billion face masks in 2020 (Arizton Advisory and Intelligence, 2020[29]). Box 3.2 uses a quick-and-dirty approximation to check the validity of this estimate.

Taking an average weight of 2.7 grams per surgical mask (Graulich et al., 2021[27]), this amounts to 140 kt of plastics use. However, this is a conservative estimate since other face masks such as N95 respirators weigh more. To account for this and for the fact that the estimate of 52 billion masks seems conservative, a reasonable approximation is to double that weight to 280 kt. Finally, it was estimated that 12 kt of plastic residues from PT-PCR diagnostic tests were generated by August 2020 worldwide (Celis et al., 2021[19]); a rough estimate for 2020 is 20 kt. Thus, plastics use for PPE has clearly increased in 2020 compared to earlier years: total additional plastics use for PPE purposes is estimated to equal around 300 kt.

Box 3.2. Tens of billions of face masks are likely to have been produced in 2020

China produced 9 million face masks per day in January, 110 million in February (Ren, 2020[22]) and 200 million by the end of April (SCIO, 2020[23]). Using the very bold assumption that production after April remained constant, total production for 2020 in China is estimated at 63 billion masks. In 2019, China represented around 50% of the global market (Bown, 2020[30]; Subramanian, 2020[21]), but it is clear that its market share went up considerably in 2020 (Section 3.2.1). Adopting a rough estimate of 75% global market share, global production would be estimated at 85 billion masks; at a constant 50% share the estimate becomes 126 billion masks. Thus, the estimate of 52 billion masks cited above seems conservative, but of the right order of magnitude.

Source: Own calculations based on data from Ren (2020[22]), SCIO (2020[23]) and Subramanian (2020[21]).

3.2.3. Plastics use for packaging shifted across sectors

In normal circumstances, almost one-third of global annual plastics use can be attributed to packaging (Chapter 2). The COVID-19 pandemic had mixed effects on the demand for packaging in the year 2020. On the one hand, the shift towards take-away, food delivery and e-commerce increased demand for plastic packaging. The demand for hygiene products, including disinfectant gel – which mostly comes in plastic packaging – also increased. On the other hand, the closure of shops and workplaces and other limitations to economic activity translated into reduced demand for packaging.

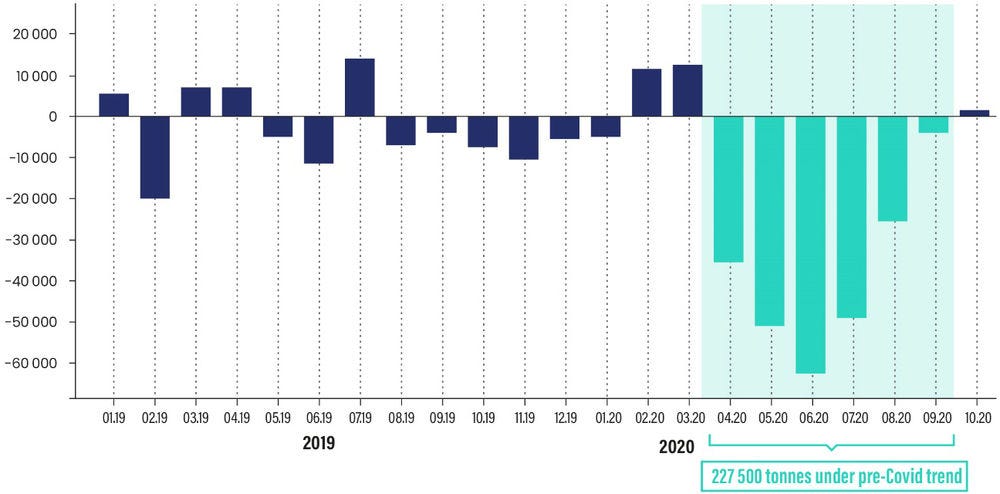

Graulich et al. (2021[27]) report that EU production of plastic packaging declined rapidly at the beginning of the pandemic, but picked up later in October as restrictions were lifted by many countries. The result was a reduction of 227 kt between April and October 2020 on the pre-COVID trend (Figure 3.1). This reflects roughly 1.5% of total use of packaging plastics in the European Union. Plastics Europe (2021[6]) suggests a somewhat larger drop in packaging plastics use, estimating that almost 500 kt fewer plastics were used in Europe’s packaging sector in 2020 – just over a 2.5% decrease. The reduction is attributed to lower production levels in sectors that demand packaging plastics, which significantly reduced the market of commercial and industrial packaging. The Italian National consortium for the Collection and Recycling of Plastic Packages (COREPLA) reports that in Italy plastic packaging use was 5% lower than 2019 levels in terms of weight (COREPLA, 2021[31]).2

Figure 3.1. Production of plastic packaging in the European Union temporarily dropped

Note: The deviations represent short-term fluctuations from a long-term trend. These fluctuations were exacerbated from April 2020 by COVID‑19 in Europe.

Source: Own elaboration based on Graulich et al. (2021[27]), “Impact of Covid-19 on single-use plastics and the environment in Europe”.

While plastic packaging production declined overall, the use of plastics for packaging in online sales (e‑commerce) increased substantially in 2020. Preliminary calculations by Graulich et al. (2021[27]) indicate that e-commerce used an additional 11.5 to 17.5 kt of plastics in the European Union compared to business-as-usual expectations. In China, where a relatively large share of consumer spending is conducted online, online sales of consumer goods increased by 14.8% in 2020 compared to 2019. By contrast, total retail sales of consumer goods decreased by 4.1% in 2020 (National Bureau of Statistics of China, 2021[32]).

Food packaging was a source of additional plastics use in 2020 as well, as take-away and e‑commerce use significantly more single-use plastics than restaurant visits. Indeed, an increase of around 15% has been estimated in the demand for food delivery services and in the associated plastics use and waste (Oliveira et al., 2021[33]). However, the decline in food packaging for shops and restaurants, which in normal years tends to reflect a substantially larger share of the total food market, mitigates this.

Finally, there were some incentives – and in some cases even regulations (Section 3.3.3) – to switch to single-use plastics as a perceived safer alternative to reusable bags that can be washed. For instance, the Governor of New Hampshire issued a health order requiring stores to use single-use bags (paper or plastic) (Tabuchi, 2020[34]). The evidence to support this push from a public health perspective is, however, weak (Laubinger and Varghese, 2020[35]).

This anecdotal evidence suggests that while there was a visible increase in some uses of packaging plastics, notably related to e-commerce and food delivery services, there were reductions in the use of packaging plastics throughout the economy in sectors whose production was disrupted. Thus, although the net effect of the COVID-19 pandemic and lockdown measures on plastics use for packaging in 2020 is unclear, it is unlikely to be large.

3.2.4. The temporary halt to construction had a large effect on plastics demand

The construction sector uses around one-sixth of all plastics globally (Chapter 2). In many countries, construction activities were shut down for several months to avoid health risks. There were important differences between countries: while for instance in Germany construction activities continued almost unhindered during the first wave of the pandemic, many other European countries severely limited construction activities, including France, Ireland, Italy and Spain, leading to a total reduction of more than 25% in construction activities in Europe during the second quarter of 2020 (de Vet, Nigohosyan and Nunez Ferrer, 2021[36]).

Quantitative information on the size of the effect of the pandemic on plastics use in construction is largely lacking, but the reduction in demand for all polymers that are commonly used in construction is estimated to be significant (Zhou Peng, 2021[37]; S&P Global, 2020[38]). Section 3.4.1 below quantifies the effect of the pandemic and lockdown measures on plastics demand in construction.

It is important to note that the effect on construction is likely to be short-lived: a large role is foreseen for the construction sector in the recovery from the pandemic, and it is likely that this will be accompanied by a corresponding surge in plastics use for construction (Section 3.5). This will be explored further in the projections of future plastics use in Volume 2 of the Global Plastics Outlook (OECD, forthcoming[39]).

3.2.5. Shrinking demand for vehicles also drove down plastics demand

The demand for plastics by the motor vehicles sector was directly impacted by lower demand for cars and supply chain disruptions. The European Automobile Manufacturers Association (2021[40]) reports that the number of cars sold globally fell by more than 15% in 2020, compared to 2019. The decline was more significant in Europe (-21%) than in Russia (-8%) or China (-7%) for example. North American car sales fell in the three first quarters of 2020, but rebounded slightly in the fourth quarter, resulting in an overall sales decline of 18% on 2019 levels. Car sales contracted the most in South America (-29%), primarily due to the large number of COVID-19 cases and severity of lockdowns.

More than ten different plastic polymers are used to make a vehicle on average. This adds up to more than 100 kilogrammes for an average vehicle, with PP accounting for more than one-quarter (Patil, Patel and Purohit, 2017[41]). Thus, the significant reduction in the sale of motor vehicles had a significant downward effect on global plastics use, as shown in Section 3.4.1 below.

3.2.6. The synthetic fibres and textiles sectors were disrupted

The clothing sector was heavily hit by the COVID-19 pandemic as many retail outlets were forced to close their doors when lockdowns were implemented in many countries. Moreover, there were multiple factory closures and supply chain disruptions in Asia, where the largest producers and exporters in the textile industry are located (Sabanoglu, 2020[42]). Martin et al. (2020[43]) report that global production of polyester fibres decreased by almost 9% in 2020 compared to the year before, whereas IHS Markit estimates that polyester fibre production contracted by 1.2% in 2020, corresponding to around 500-750 kt (Clark, 2021[44]; IHS Markit, 2020[45]).

Cloth masks and other uses of textiles and synthetic fibres for PPE have increased demand for plastics, specifically PP fibres. Nonetheless, the overall effect on the synthetic fibres and textiles sectors is estimated to have been negative in 2020 (Martin et al., 2020[43]).

3.3. Effects on plastic waste and recycling are not clear cut

Reductions in industrial and commercial plastic waste were compensated for by increases in household plastic waste. Even before the pandemic, 77 million tonnes (Mt) of plastic waste were being mismanaged annually (Chapter 2). COVID-19 contributed further to the challenge of managing municipal waste properly, especially in developing countries where resources and infrastructure are largely lacking (Das et al., 2021[46]; AIT/UNEP, 2021[47]). Many countries faced significantly increased physical and financial challenges in managing their solid waste. Rural regions were more affected than urban regions, as waste treatment facilities are not evenly distributed and tend to be located near populated areas (IGES, 2020[48]). New logistical considerations due to the shift in the origin and composition of waste, additional requirements for performing sanitation activities and increased spending on protective gear all contributed to these challenges (AIT/UNEP, 2021[47]). Furthermore, many waste treatment facilities were temporarily shut down (AIT/UNEP, 2021[47]). There was a significant increase in uncontrolled landfilling and local burning strategies, for example in India, which also reflected an attempt to prevent virus contagion (Patrício Silva et al., 2020[12]). Illegal dumping of municipal solid waste was also recorded in OECD countries, such as Australia, Belgium, Ireland, the Netherlands, and the United Kingdom (AIT/UNEP, 2021[47]). Many cities, however, continued to guarantee solid waste collection, even if not necessarily separated by type of waste (OECD, 2020[49]). Overall, a larger share than usual of plastic waste was incinerated or landfilled rather than recovered.

Anecdotal evidence presented below suggests that municipal plastic waste increased in 2020, due to changes in consumer behaviour. Moreover, there is evidence of an alteration of the composition of municipal solid waste, reflecting larger shares of single-use plastics and – unsurprisingly – PPE (Yousefi et al., 2021[50]). These increases are, however, mitigated by decreases in municipal plastic waste from commercial activities such as accommodation and food services, as many businesses were shut down at least temporarily. The net effect on municipal waste generation in 2020 is therefore not clear but likely relatively small (AIT/UNEP, 2021[47]).

In Bangkok, municipal solid waste declined by 12% during the lockdown while household plastic waste increased by 62% (Promchertoo, 2020[51]). Households in Singapore and Hong Kong, China, were also recorded to have increased their plastic waste generation, mainly due to takeaway and online food delivery, with single-use plastics from take-aways more than doubling in Hong Kong, China, in April 2020 compared to 2019, for example (CGTN, 2020[52]; NUS, 2020[53]). Although no specific data on plastics are available, households in New York and Ireland also increased their waste generation by 21% and 3.3% respectively (RWMO, 2020[54]; Staub, 2020[55]). Finally, in Kobe, a Japanese city, household plastic waste increased by 10.3% (AIT/UNEP, 2021[47]).

Reduced industrial activity is likely to have decreased industrial plastic waste generation in 2020 (Section 3.4.2). While there is no robust evidence yet that the combined decline in industrial and commercial waste outweighed the increase in household waste, if their waste streams declined in line with their production levels, the decrease could be substantial. The reported increase in municipal waste is not sufficient evidence, as many industrial waste streams are collected separately to municipal solid waste.

The nature of medical waste, including PPE waste, changed drastically: before 2020, most PPE was used in controlled medical facilities, which tend to have strict waste management protocols. But from 2020, a large volume of PPE, and especially face masks, was used by individuals in public settings and ended up as household waste. Some countries recommended double-bagging potentially infectious waste, which may also have led to additional plastics use (IGES, 2020[48]).

Most health facilities incinerate medical waste to ensure that pathogens do not spread further (Ghodrat, Rashidi and Samali, 2017[56]; Joseph et al., 2021[15]). This practice has been further strengthened during the pandemic (AIT/UNEP, 2021[47]; Peng et al., 2020[57]). Medical waste in Wuhan, China, amounted to 110 to 150 tonnes per day in mid-February, and increased to 247 tonnes as the number of cases worsened. The government of Wuhan was able to face the surge in medical plastic waste to some extent by building a waste management facility with a capacity of 30 tonnes per day in less than two weeks (Wei, 2020[58]). In a review of five hospitals in Iran, it was found that medical waste more than doubled compared to pre-COVID levels (Kalantary et al., 2021[59]). Medical waste generation in India averaged 163 tonnes in the second half of 2020, peaking in September (at 183 tonnes) when the number of cases significantly increased (Central Pollution Control Board, 2021[60]). In Manila, Jakarta, Bangkok, Ha Noi and Kuala Lumpur, medical waste was reported to be six times higher in the first quarter of 2020 than pre-COVID levels (ADB, 2020[61]). On the other hand, medical waste in New York was found to have declined in the first five months of 2020. This could have been partly due to the supply shortage of PPE and the halting of non-COVID related medical procedures; it could also reflect the fact that much of the used household and hospital PPE was not labelled as medical waste (Wei, 2020[58]).

3.3.1. Plastics littering worsened

Littering of disposable PPE items, particularly face masks, gloves and cleaning wipes, increased in many countries almost immediately after governments started recommending their use – around March 2020 in many countries (Prata et al., 2020[28]; Roberts et al., 2021[62]). It seems likely that this increased stream of littered PPE plastics continued in 2021 and will do so for much longer. This loss of plastics to the environment causes a number of environmental and economic problems, as discussed in Chapter 2.

Reports and news articles describing the littering of PPE in coastal environments began accumulating early on in the pandemic and increased throughout 2020 (e.g. (BBC News, 2020[63]; Bondaroff and Cooke, 2020[64]; Chapman and Bomford, 2020[65]). Bondaroff and Cooke (2020[64]) document the large numbers of face masks and gloves that have littered beaches across Asia, even those that are remote. For instance, on the small beach of Tai A Chau in the Soko Islands in Hong Kong, China, a marine conservation organisation found 70 masks spread along a short 100-metre stretch as early as February 2020. The composition of litter has also changed with the advent of health concerns. In two rivers in Indonesia, approximately 15% of littered items that were collected between March and April 2020 were PPE items (Cordova et al., 2021[66]).

Bondaroff and Cooke (2020[64]) estimate that in 2020 1.56 billion face masks entered the ocean (corresponding to a 3% leakage assumption except for masks used in controlled medical facilities which have lower leakage rates), resulting in 5 to 6 kt of marine plastic leakage. A higher value was reported by Chowdhury et al. (2021[67]) who find that 150 to 390 kt may enter global oceans by the end of 2021.3 While both values are small compared to the estimated 22 Mt of total leakage of plastics to the environment in 2019 in Chapter 2 of this report, littering as a direct result of the pandemic adds to the existing issues of environmental pollution.

Leakage does not only occur in marine environments – it also occurs on land. A recent analysis of land-based litter as reported by citizens of 11 OECD countries between September 2019 and October 2020 shows that face mask litter especially increased after the official onset of the pandemic. It amounted to less than 0.01% of total litter in October 2019, but made up 0.80% of total litter a year later (Roberts et al., 2021[62]). While this highlights that face mask littering increased significantly due to COVID-19, it also indicates that the share of PPE volumes in total littering remains small.

A number of reports highlight PPE littering in cities (BBC News, 2020[68]; Fazio, 2020[69]; Tesfaldet et al., 2021[70]). This was found to have harmed some urban drainage systems, which were clogged by face masks and gloves. This increased cleaning and replacement costs for equipment in affected areas and heightened the risk of flooding and water pollution (Geberemariam, 2021[71]). Face masks and other PPE litter can also be transported by drainage systems to the marine environment (Fadare and Okoffo, 2020[72]).

One study found that 170 face masks were littered on a 13-km stretch covering three streets in Bangkok over 42 days of 5 hours of observation per day (Tesfaldet et al., 2021[70]). Another study reported that more than one-third of 140 50-metre stretches of roads that were inspected in September and October 2020 in Essex (United Kingdom) contained at least one PPE item, mostly face masks (Chapman and Bomford, 2020[65]). A Canadian study conducted in Toronto reports that on average 1 010 PPE items were found for every squared kilometre of residential, commercial and hospital districts (Ammendolia et al., 2021[73]).4

While additional littering on land is aesthetically unpleasant, it is less likely to be environmentally harmful in OECD countries, which are likely to respond by spending more on litter collection, than in non-OECD countries. In Toronto, for instance, the cleaning costs for managing litter amounted to almost USD 113 500 (CAD 146 614) between March and the end of July 2020, most of which was directly due to the increased amount of litter (Solid Waste Management Services, 2020[74]).5 In developing countries, however, where litter may not be collected, this additional littering could lead to environmental degradation.

3.3.2. Plastics recycling was disrupted

Recycling of plastics was affected by the COVID-19 pandemic in various ways. First, disruptions to waste management, including the reduced collection of separated waste and the reduced trade in waste, lessened the supply of materials available for recycling (Laubinger and Varghese, 2020[35]).

Second, recycling companies were affected by the restrictions on economic activity. Recycling programmes were suspended in many regions and informal waste collectors reduced their activities (GMCA, 2020[75]; Martin et al., 2020[43]). Some cities in the United States suspended recycling programmes for fear that the virus would spread by the collected items (Zambrano-Monserrate, Ruano and Sanchez-Alcalde, 2020[76]; Staub, 2020[77]). A survey conducted in the United States indicates that 34% of recycling companies were partially or completely closed in April 2020 (Toto, 2020[78]). During the lockdown in Shanghai, centrally located neighbourhoods no longer had the option to separate recyclables (Bloomberg News, 2020[79]).

Third, the global oil price dropped significantly in the first quarter of 2020 (IEA, 2020[7]; US Bureau of Labor Statistics, 2020[8]). This reduced production costs for primary plastics, and thus the price of plastic products, while the production costs of secondary plastics were not reduced to the same extent. Although the price of secondary plastics has historically correlated with that of primary plastics, there is no spot market for secondary plastics (OECD, 2018[80]) and it is unclear how much the profitability of secondary production suffered. But it is likely that the competitiveness of the secondary plastics sector deteriorated (Brock, 2020[81]); see also Chapter 4. In Europe, many plastics recyclers temporarily shut down production in 2020 in response to government restrictions and deteriorating market conditions (PRE, 2020[82]).

The oil price picked up later in 2020, which pushed the price of primary plastics back up (IEA, 2020[7]; US Bureau of Labor Statistics, 2020[8]). At the same time, most governments began to manage lockdown measures better and in many countries municipalities ensured that separated waste collection was maintained or restored. This revived the recycling industry, although regional differences remained large. The overall effect on recycling volumes and the volumes of secondary plastics produced remain unclear, as there were no robust data available at the time of writing to identify which trend dominated over the course of the year.

Global recycling volumes have not only been influenced by the COVID-19 pandemic – the market has also been influenced by recent changes in national policies. These include mandatory minimum recycled content standards (Chapter 6), voluntary commitments by firms, and the broader international policy context, such as the recent amendments to the Basel Convention and China’s ban on the import of waste (Chapter 4).

3.3.3. Waste and recycling policies changed temporarily

The government response measures to the COVID-19 pandemic have also affected plastics use and waste, as well as recycling policies. In the wake of growing sanitary concerns, government actions to reduce single-use plastic items were delayed in numerous places (Murphy, 2020[83]; Tabuchi, 2020[84]; US State of Maine, 2020[85]). For instance, India, Portugal, Senegal and multiple states in the United States as well as certain states and territories in Australia delayed their bans on single-use plastics, while Scotland and the Netherlands delayed the implementation of deposit-refund schemes (da Costa, 2021[86]). Italy delayed the implementation of its tax on plastic packaging several times; it is currently planned to take effect in 2023 (Zecchini, 2021[87]). Several local and national governments have now proceeded to implement these policies. For instance, New York started enforcing its ban on plastic bags in October 2020, after a seven-month delay (Associated Press, 2020[88]). In 2021, Commonwealth, state and territory environment ministers identified eight single-use plastic products that have to be phased out nationally by 2025 (or sooner in some cases) under the National Waste Policy Action Plan (Government of Australia, 2021[89]; ACT Government, 2021[90]; Government of South Australia, 2021[91]). And despite pressure on the EU to delay the implementation of its plastics tax, it went ahead as scheduled in July 2021 (EC, 2021[92]; Simon, 2020[93]).

As a response to the increase in illegal dumping in the early months of the pandemic, the Irish Government provided EUR 1 million of additional funding to support efforts to tackle this issue (Government of Ireland, 2020[94]).

Recycling policies were also affected by the pandemic. For instance, Fort Collins, a municipality in Colorado, temporarily put on hold plans to start a “community recycling ordinance” which would require that recycling services be provided by trash haulers to most multi-family and commercial properties by the end of 2020; it finally entered into force in July 2021 (City of Fort Collins, 2021[95]; Staub, 2020[96]). Because of social distancing recommendations from local governments, some recycling centres reduced their activity or even temporarily closed in the early months of the pandemic (Staub, 2020[77]). Moreover, as some cities were experiencing collection delays due to the impacts of COVID-19 on the workforce, garbage collection was prioritised over recycling (Staub, 2020[77]). Finally, waste pickers and other informal waste workers were also affected by COVID-19 containment measures (Sarkodie and Owusu, 2020[97]).

Laubinger and Varghese (2020[35]) warned early on that the initially temporary reversal or halting of some of the policy measures to reduce plastics use and waste could become permanent. This would hold back the smooth transition towards a more resource-efficient, circular economy.

3.4. OECD modelling suggests COVID-19 on balance reduced plastics use in 2020

The anecdotal and partial evidence presented above is insufficient to assess the overall effect of the COVID-19 pandemic and associated government response measures on global plastics use. Beyond the selected plastics applications where a direct effect occurred, there are indirect effects on plastics use that are driven by changes in economic activity and household consumption and by linkages between sectors. Many sectors have reduced their production in response to a lockdown, trade barriers or falling demand, and these have generally scaled down their plastics use accordingly.

For a complete picture, an economy-wide assessment is needed that connects plastics use to specific economic activities, and that connects the different sectoral and regional economic activities to each other. As part of this Global Plastics Outlook, the ENV-Linkages modelling framework described in Chateau, Dellink and Lanzi (2014[98]) has been used for this broad assessment.6 This section presents the results of that modelling, while Annex B describes the economic impacts assessed in the modelling framework.

These modelling results need to be interpreted with care. First, estimates of economic activity and plastics use for 2020 are not final at the time of writing, and updates of official statistics can be expected. Second, the modelling assumes that plastics use by production sectors scales down roughly in proportion to output changes.7 This excludes shifts in production technology within the sector or shifts between different parts of the same sector, such as from eating in restaurants to take-away or from shop retail to e-commerce. Thus, these results are more indicative of the general implications of the economic effects of the pandemic on plastics use than of detailed use of specific polymers in specific subsectors. Nonetheless, the modelling assessment captures most of the major trends described in Section 3.2 and emphasises that indirect effects may be more important than the very visible direct effects for relatively small applications.

3.4.1. Plastics use declined in 2020, but less than economic activity

At the global level, the reduced scale of economic activity dominates the increased demand for specific plastic applications that were outlined above. Our modelling estimates that global plastics use declined by 2.2% from 2019 levels, or 4.5% below the pre-COVID projection for 2020 (Figure 3.2 and Figure 3.3). That is a drop of around 10 Mt from 2019 levels. Given that global GDP declined by almost 3.5% below 2019 levels (6.5% below the pre-COVID projection), the plastics intensity of the global economy actually increased. This contrasts with the recent declining trend in the plastics intensity of the economy: i.e. between 2015 and 2019 the growth in global plastics use was smaller than the growth in global GDP.

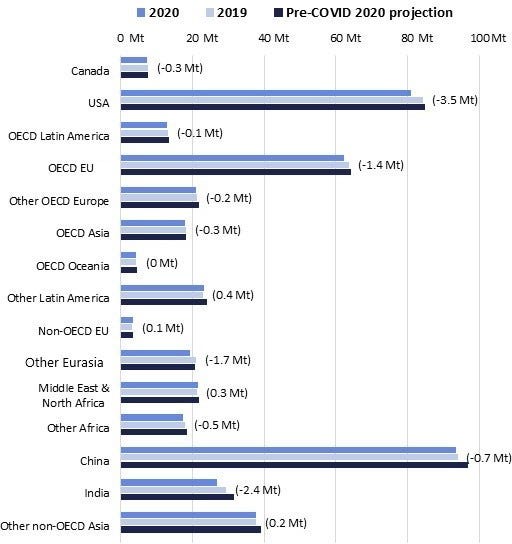

Some regions have seen a larger economic downturn than others, and this is reflected in their regional plastics use (Figure 3.2). For example, the Indian economy shrunk by 6% in 2020 (13% below the pre-COVID projection), leading to a reduction in plastics use of around 12.9% compared to the pre-COVID projection. This is equivalent to a 7% drop in 2020 compared to 2019, or 1.9 Mt.

Figure 3.2. Global plastics use declined by more than 10 Mt in 2020, affecting almost all regions

Regional changes in plastics use in 2020 are also determined by the structure of the economy, which varies significantly across regions. Countries that specialise in sectors that use large volumes of plastics, not least India and the Non-OECD Europe region, will have larger reductions in plastics use, just as countries that specialise in sectors that are most severely hit by the pandemic tend to have larger reductions in economic activity. Reductions in plastics use are smaller than GDP losses in many countries, especially those in the EU (-3% versus -8% when compared to the pre-COVID projection) and in the OECD Latin America region (-2% versus -9%). This reflects the fact that the substantial economic costs in these regions are largely caused by disruptions to sectors that do not use a lot of plastics.

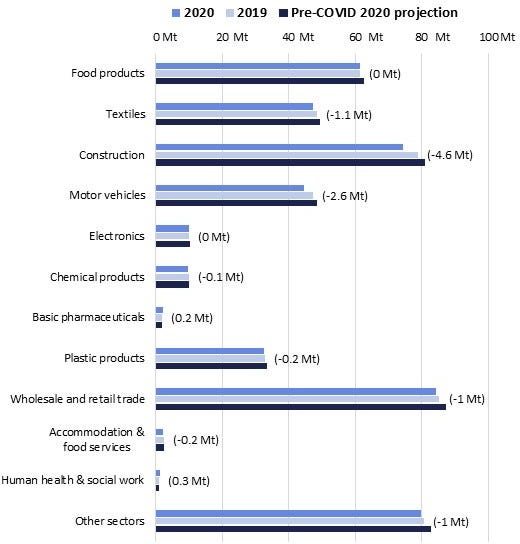

Figure 3.3. Global plastics use declined by more than 10 Mt in 2020, affecting almost all sectors

Note: Direct effects of consumption changes other than human health (including PPE) as discussed in Section 3.2.2 are not included in these calculations due to lack of robust global data. The change in plastics use between 2019 and 2020 is indicated in brackets.

Source: OECD Global Plastics Outlook Database , Dellink et al. (2021[3]).

Sectoral plastics use declined overall, except in health-related sectors

In line with the anecdotal evidence presented in Section 3.2, the impacts of the pandemic and lockdown measures on plastics use differ widely across sectors (Figure 3.3). Plastics use for food products is estimated to have remained roughly unchanged from 2019 (less than 200 kt) and declined by only a few percent below the pre-COVID projected levels for 2020. As explained above, the lockdown measures primarily affected the way in which food was consumed, rather than the overall volume of food consumption. Nonetheless, home delivery and take-away may have made this sector more intensive in its use of specific plastic polymers, something which could not be accounted for in this calculation as robust data are not (yet) available.

The big negative impact of the lockdown measures on construction activity and motor vehicles demand has led to a reduction in plastics use in these sectors by around 4.6 Mt and 2.6 Mt, respectively, according to the model simulations, compared to 2019 levels. This is driven by the substantial production declines in these sectors. Each of these sectors accounts for more than 10% of total plastics use, and together with food products, textiles and wholesale and retail trade, these reductions largely drive the total effects of the pandemic on plastics use.

Plastics use in the plastics and rubber production sector itself, and in the chemical sector, remain roughly unchanged from 2019 levels, which equates to a reduction of 3% from the pre-COVID projection. This is driven by the reduced demand for plastics products in other sectors.

Pharmaceuticals is the only sector for which the model simulates a significant increase in plastics use. The pandemic increased demand for pharmaceutical products, including vaccines and other medicaments. However, total plastics use in this sector remains below 2 Mt globally, and thus this increase is relatively minor in absolute terms (around 200 kt).

According to the simulations, plastics use in the human health and social work sector (which includes the medical sector) increased by 33% above the pre-COVID baseline projection for 2020 and 37% above 2019 levels. This can be almost completely attributed to the direct effect of PPE use in the health sector, such as face masks and gloves, roughly estimated at around 300 kilotonnes (Section 3.2.2). However, while this is large at the sectoral level, in absolute terms it is small in comparison to the changes in other sectors.

3.4.2. Plastic waste may have remained stable in the short run despite the switch to single-use plastics

The changes in plastics use discussed above will affect volumes of plastics waste for a long time. In the short run, much of the new or increased types of plastics use, such as for PPE, are single-use and have a short lifespan. Much of this additional plastic has already been discarded or will be very shortly. In contrast, the lifespans of plastics used in sectors seeing the most severely reduced demand, such as vehicle manufacture, is often significantly longer. Furthermore, packaging material used in e.g. wholesale and retail trade also declined, whereas packaging materials for take-away and e-commerce increased. Thus, although in 2020 total plastic waste may have remained roughly stable (although robust information is not yet available), the reduced plastics use in consumer products and motor vehicles, and especially in construction, is only likely to reduce plastics waste volumes years from now. This could change, however, if recovery from the pandemic implies a significant boost in construction and durable goods. These longer-term projections will be explored in more detail in Volume 2 of the Global Plastics Outlook (OECD, forthcoming[39]).

3.5. The longer-term implications of the COVID-19 pandemic remain unclear

Despite worries over the continued spread of COVID-19 for human health, and prolonged measures that restrict economic activity, economic activity in 2021 was significantly up from 2020 levels (OECD, 2021[1]). With a rebounding economy, plastics use is also projected to pick up again. But there are big variations in how fast different sectors and countries will recover (Dellink et al., 2021[3]), and there is considerable uncertainty around how the pandemic, economic activity and plastics use will evolve.

One major uncertainty that is directly relevant for plastics use and waste is the size of government recovery packages and the extent to which they are green. For instance, if there is large-scale investment in infrastructure boosted by these recovery packages, this will drive fast growth in construction activity, with an associated increase in plastics use as this sector accounts for more than 10% of total plastics use. If recovery packages are aimed at accelerating the transition towards a more resource-efficient and circular economy (OECD, 2021[99]), fast economic recovery does not need to imply a fast increase in plastics use. Instead, recycling and secondary use of plastics could be spearheaded, and the plastics intensity of the economy could be reduced.

Another key uncertainty is whether behavioural changes that emerged during the lockdown periods will become permanent, or whether things will “go back to normal”. It remains to be seen whether the fast growth in e-commerce will continue, and whether it increases short-lived plastics use for packaging. That face masks and other PPE will continue to be used in the coming years is perhaps a little less uncertain, but the amount of littered plastics resulting from this depends on how the pandemic evolves as well as on whether behavioural changes turn out to be permanent or temporary.

The backward-looking exercise in this chapter sheds light on how interactions in the economic system are crucial for a broad assessment of the implications of COVID-19 on plastics use. It has highlighted a widespread reduction in plastics use in 2020 in many economic sectors, but increases in selected applications and a shift towards more single-use plastics. Forward-looking analysis, as envisaged in Volume 2 of the Global Plastics Outlook (OECD, forthcoming[39]), will be able to shed light on the longer-term consequences.

References

[40] ACEA (2021), Economic and Market Report: EU Automotive Industry Full-year 2020, European Automobile Manufacturers Association, https://www.acea.auto/files/Economic_and_Market_Report_full-year_2020.pdf.

[90] ACT Government (2021), https://www.cityservices.act.gov.au/recycling-and-waste/single-use-plastics.

[61] ADB (2020), Managing Infectious Medical Waste during the COVID-19 Pandemic, https://www.adb.org/publications/managing-medical-waste-covid19.

[47] AIT/UNEP (2021), Covid-19 & Plastic Plight: a Reflection from One Year of the Pandemic, http://www.circular-economy.ait.ac.th/downloads/COVID-19%20&%20Plastic%20Plight%20Report.pdf.

[73] Ammendolia, J. et al. (2021), “An emerging source of plastic pollution: Environmental presence of plastic personal protective equipment (PPE) debris related to COVID-19 in a metropolitan city”, Environmental Pollution, Vol. 269, p. 116160, https://doi.org/10.1016/j.envpol.2020.116160.

[29] Arizton Advisory and Intelligence (2020), Medical Face Mask Market - Global Outlook and Forecast 2020-2025, Market Research.com, https://www.marketresearch.com/Arizton-v4150/Medical-Face-Mask-Global-Outlook-13345767/.

[88] Associated Press (2020), Plastic Bag Ban Starts in New York After Months of Delay, Associated Press, https://apnews.com/article/business-new-york-75d5e594b0090ae7263efc70f8a33f5b.

[18] Basmage, O. and M. Hashmi (2020), “Plastic Products in Hospitals and Healthcare Systems”, in Encyclopedia of Renewable and Sustainable Materials, Elsevier, https://doi.org/10.1016/b978-0-12-803581-8.11303-7.

[68] BBC News (2020), Coronavirus: Discarded disposable gloves on the street, BBC News, https://www.bbc.com/news/in-pictures-52188627.

[63] BBC News (2020), Coronavirus: French alarm at Covid-linked Med pollution, BBC News, https://www.bbc.com/news/world-europe-52807526.

[79] Bloomberg News (2020), China’s War on Garbage Faces a Major Coronavirus Setback, Bloomberg Quint, https://www.bloombergquint.com/business/china-s-war-on-garbage-faces-a-major-coronavirus-setback.

[64] Bondaroff, T. and S. Cooke (2020), Masks on the Beach: The Impact of COVID-19 on Marine Plastic Pollution, OceansAsia, https://oceansasia.org/wp-content/uploads/2020/12/Marine-Plastic-Pollution-FINAL.pdf.

[30] Bown, C. (2020), COVID-19: China’s exports of medical supplies provide a ray of hope, Peterson Institute for International Economics, https://www.piie.com/blogs/trade-and-investment-policy-watch/covid-19-chinas-exports-medical-supplies-provide-ray-hope.

[81] Brock, J. (2020), A Reuters Special Report: The Plastic Pandemic. Covid-19 trashed the recycling dream., Reuters, https://www.reuters.com/investigates/special-report/health-coronavirus-plastic-recycling/.

[19] Celis, J. et al. (2021), “Plastic residues produced with confirmatory testing for COVID-19: Classification, quantification, fate, and impacts on human health”, Science of The Total Environment, Vol. 760, p. 144167, https://doi.org/10.1016/j.scitotenv.2020.144167.

[60] Central Pollution Control Board (2021), COVID-19 Waste Management, Ministry of Environment, Forest and Climate Change. Government of India, https://cpcb.nic.in/covid-waste-management/.

[52] CGTN (2020), Hong Kong plastic waste: Food delivery and takeouts bring surge in plastic pollution, CGTN, https://news.cgtn.com/news/7a497a4d33514464776c6d636a4e6e62684a4856/index.html.

[65] Chapman, C. and K. Bomford (2020), Litter in lockdown: A study of litter in the time of coronavirus, CPRE, https://www.cpre.org.uk/wp-content/uploads/2020/12/Litter-in-lockdown-full-report-December-2020.pdf.

[98] Chateau, J., R. Dellink and E. Lanzi (2014), “An Overview of the OECD ENV-Linkages Model: Version 3”, OECD Environment Working Papers, No. 65, OECD Publishing, Paris, http://dx.doi.org/10.1787/5jz2qck2b2vd-en.

[67] Chowdhury, H., T. Chowdhury and S. Sait (2021), “Estimating marine plastic pollution from COVID-19 face masks in coastal regions”, Marine Pollution Bulletin, Vol. 168, p. 112419, https://doi.org/10.1016/j.marpolbul.2021.112419.

[95] City of Fort Collins (2021), Recycling: Recycling & Trash Ordinances, https://www.fcgov.com/recycling/ordinances.

[44] Clark, D. (2021), Recovery for the paraxylene industry or temporary reprieve?, IHS Markit, https://ihsmarkit.com/research-analysis/recovery-for-the-paraxylene-industry-or-temporary-reprieve.html?ite=997087&ito=1274&itq=3b1f1db2-19e0-4d34-b496-811584ab7ccb&itx%5Bidio%5D=771816356.

[66] Cordova, M. et al. (2021), “Unprecedented plastic-made personal protective equipment (PPE) debris in river outlets into Jakarta Bay during COVID-19 pandemic”, Chemosphere, Vol. 268, p. 129360, https://doi.org/10.1016/j.chemosphere.2020.129360.

[31] COREPLA (2021), I risultati 2020 di corepla: raccolta in aumento nonostante l’emergenza sanitaria (+4%) e dati più omogenei tra le regioni., Consorzio Nazionale Per La Raccolta, Il Riciclo E Il Recupero Degli Imballaggi In Plastica, https://www.corepla.it/news/i-risultati-2020-di-corepla-raccolta-aumento-nonostante-l-emergenza-sanitaria-4-e-dati-pi-omoge.

[86] da Costa, J. (2021), “The 2019 global pandemic and plastic pollution prevention measures: Playing catch-up”, Science of The Total Environment, Vol. 774, p. 145806, https://doi.org/10.1016/j.scitotenv.2021.145806.

[46] Das, A. et al. (2021), “COVID-19 and municipal solid waste (MSW) management: a review”, Environmental Science and Pollution Research 2021 28:23, Vol. 28/23, pp. 28993-29008, https://doi.org/10.1007/S11356-021-13914-6.

[36] de Vet, J., D. Nigohosyan and J. Nunez Ferrer (2021), Impacts of the Covid-19 pandemic on EU industries, European Parliament, https://www.europarl.europa.eu/RegData/etudes/STUD/2021/662903/IPOL_STU(2021)662903_EN.pdf.

[3] Dellink, R. et al. (2021), “The long-term environmental implications of COVID-19”, OECD Environment Working Papers, No. 176, OECD Publishing, Paris, https://doi.org/10.1787/123dfd4f-en.

[92] EC (2021), Single-use plastics, European Commission, https://ec.europa.eu/environment/topics/plastics/single-use-plastics_en.

[26] ESDO (2020), ESDO’s Online Press Briefing on COVID-19 Pandemic Outbreak 14,500 Tons of Hazardous Plastic Waste in a Month, Environment and Social Development Organization (ESDO), https://esdo.org/esdos-online-press-briefing-on-hazardous-plastic-waste-generation-in-a-month-during-covid-19-pandemic/.

[10] Eurostat (2021), Manufacture of rubber and plastic products, Calendar adjusted data, 2019-2020, Eurostat.

[72] Fadare, O. and E. Okoffo (2020), “Covid-19 face masks: A potential source of microplastic fibers in the environment”, Science of The Total Environment, Vol. 737, p. 140279, https://doi.org/10.1016/j.scitotenv.2020.140279.

[69] Fazio, M. (2020), Your Used Mask Needs to Make It to the Trash Can, The New York Times, https://www.nytimes.com/2020/07/25/climate/covid-masks-discarded.html.

[71] Geberemariam, T. (2021), “The Potential Indirect Impact of COVID-19 on Urban Drainage Systems”, Journal of Irrigation and Drainage Engineering, Vol. 147/10, p. 02521001, https://doi.org/10.1061/(asce)ir.1943-4774.0001606.

[56] Ghodrat, M., M. Rashidi and B. Samali (2017), “Life Cycle Assessments of Incineration Treatment for Sharp Medical Waste”, in The Minerals, Metals & Materials Series, Energy Technology 2017, Springer International Publishing, Cham, https://doi.org/10.1007/978-3-319-52192-3_14.

[75] GMCA (2020), All Household Waste Recycling Centres closed from today, Greater Manchester Combined Authority, https://www.greatermanchester-ca.gov.uk/news/all-household-waste-recycling-centres-closed-from-today/.

[89] Government of Australia (2021), Commonwealth%20Department%20of%20Agriculture,%20Water%20and%20the%20Environment.pdf.

[94] Government of Ireland (2020), Funding ringfenced to tackle illegal dumping during COVID-19, Department of the Environment, Climate and Communications, https://www.gov.ie/en/press-release/46f2f8-funding-ringfenced-to-tackle-illegal-dumping-during-covid-19/.

[91] Government of South Australia (2021), https://www.replacethewaste.sa.gov.au/.

[27] Graulich, K. et al. (2021), Impact of COVID-19 on single-use plastics and the environment in Europe, European Environment Agency.

[4] Hamann, C., K. Sullivan and P. Wright (2014), “Protective Gloves”, in Textbook of Hand Eczema, Springer Berlin Heidelberg, Berlin, https://doi.org/10.1007/978-3-642-39546-8_28.

[14] Henneberry, B. (2021), How to Make Personal Protective Equipment (PPE) for COVID-19 (Manufacturing and Sourcing Guide), THOMAS for Industry, https://www.thomasnet.com/articles/plant-facility-equipment/how-to-make-ppe/.

[7] IEA (2020), World Energy Outlook 2020, OECD Publishing, Paris, https://dx.doi.org/10.1787/557a761b-en.

[48] IGES (2020), Waste Management during the COVID19 Pandemic: From Response to Recovery, United Nations Environment Programme, https://www.iges.or.jp/jp/pub/waste-management-during-covid-19-pandemic-response-recovery/en.

[45] IHS Markit (2020), COVID-19 Has Impacted the Global Fibers Growth Trend, IHS Markit, https://cdn.ihsmarkit.com/www/pdf/1020/IHS-Markit-Annual-Global-Fibers-Infographic.pdf.

[2] IMF (2020), World Economic Outlook, October 2020: A Long and Difficult Ascent, International Monetary Fund, Washington, D.C., https://www.imf.org/en/Publications/WEO/Issues/2020/09/30/world-economic-outlook-october-2020 (accessed on 22 January 2021).

[13] Institute of Medicine (2006), Reusability of Facemasks During an Influenza Pandemic: Facing the Flu, The National Academies Press, Washington, D.C., https://doi.org/10.17226/11637.

[11] Japan Plastics Industry Federation (2021), Plastics production, 1999 to 2000, http://www.jpif.gr.jp/3toukei/conts/nenji/y_seihin_c.htm.

[15] Joseph, B. et al. (2021), “Recycling of medical plastics”, Advanced Industrial and Engineering Polymer Research, https://doi.org/10.1016/j.aiepr.2021.06.003.

[59] Kalantary, R. et al. (2021), “Effect of COVID-19 pandemic on medical waste management: a case study”, Journal of Environmental Health Science and Engineering, Vol. 19/1, pp. 831-836, https://doi.org/10.1007/s40201-021-00650-9.

[35] Laubinger, F. and N. Varghese (2020), COVID-19 and the looming plastics pandemic, OECD Environment Focus, https://oecd-environment-focus.blog/2020/07/07/covid-19-and-the-looming-plastics-pandemic/.

[5] Marsh, K. and B. Bugusu (2007), “Food Packaging? Roles, Materials, and Environmental Issues”, Journal of Food Science, Vol. 72/3, pp. R39-R55, https://doi.org/10.1111/j.1750-3841.2007.00301.x.

[43] Martin, P. et al. (2020), Can the polyester industry recover from Covid-19’s shockwaves?, Wood Mackenzie, https://www.woodmac.com/news/opinion/can-the-polyester-industry-recover-from-covid-19s-shockwaves/full-report/.

[16] McKeen, L. (2014), “Plastics Used in Medical Devices”, in Handbook of Polymer Applications in Medicine and Medical Devices, Elsevier, https://doi.org/10.1016/b978-0-323-22805-3.00003-7.

[25] METI (2020), METI to Convey Information on Menu of Support Measures for Businesses Affected by Novel Coronavirus Disease Utilizing LINE Application, Ministry of Economy, Trade and Industry (METI), Government of Japan, https://www.meti.go.jp/english/covid-19/mask.html.

[83] Murphy, H. (2020), California Lifts Ban on Plastic Bags Amid Virus Concerns, The New York Times, https://www.nytimes.com/2020/04/24/us/california-plastic-bag-ban-coronavirus.html.

[32] National Bureau of Statistics of China (2021), Total Retail Sales of Consumer Goods Went Up by 4.6 percent in December 2020, National Bureau of Statistics of China, http://www.stats.gov.cn/English/PressRelease/202101/t20210119_1812515.html.

[24] National News Bureau of Thailand (2020), Covid-19 has positive impact on ecosystem, National News Bureau of Thailand, https://thainews.prd.go.th/en/news/detail/TCATG200418155259223.

[53] NUS (2020), The poison of disposables, NUS, https://blog.nus.edu.sg/poisonofconsumerism/2020/07/16/the-poison-of-disposables/.

[1] OECD (2021), OECD Economic Outlook, Interim Report March 2021, OECD Publishing, Paris, https://dx.doi.org/10.1787/34bfd999-en.

[99] OECD (2021), The OECD Green Recovery Database : Examining the environmental implications of COVID-19 recovery policies, https://www.oecd.org/coronavirus/en/policy-responses.

[49] OECD (2020), Cities policy responses, https://www.oecd.org/coronavirus/policy-responses.

[20] OECD (2020), The face mask global value chain in the COVID-19 outbreak: Evidence and policy lessons, OECD Publishing, Paris, https://dx.doi.org/10.1787/a4df866d-en.

[80] OECD (2018), Improving Markets for Recycled Plastics: Trends, Prospects and Policy Responses, OECD Publishing, Paris, https://dx.doi.org/10.1787/9789264301016-en.

[39] OECD (forthcoming), Global Plastics Outlook, Volume 2, OECD.

[33] Oliveira, W. et al. (2021), “Food packaging wastes amid the COVID-19 pandemic: Trends and challenges”, Trends in Food Science & Technology, https://doi.org/10.1016/J.TIFS.2021.05.027.

[17] Oral, E., S. Kurtz and O. Muratoglu (2017), “7.3 Ultrahigh Molecular Weight Polyethylene Total Joint Implants”, in Comprehensive Biomaterials II, Materials Science and Materials Engineering, https://doi.org/10.1016/b978-0-12-803581-8.10219-x.

[41] Patil, A., A. Patel and R. Purohit (2017), “An overview of Polymeric Materials for Automotive Applications”, Materials Today: Proceedings, Vol. 4/2, pp. 3807-3815, https://doi.org/10.1016/j.matpr.2017.02.278.

[12] Patrício Silva, A. et al. (2020), “Rethinking and optimising plastic waste management under COVID-19 pandemic: Policy solutions based on redesign and reduction of single-use plastics and personal protective equipment”, Science of The Total Environment, Vol. 742, p. 140565, https://doi.org/10.1016/j.scitotenv.2020.140565.

[57] Peng, J. et al. (2020), “Medical waste management practice during the 2019-2020 novel coronavirus pandemic: Experience in a general hospital”, American Journal of Infection Control, Vol. 48/8, pp. 918-921, https://doi.org/10.1016/J.AJIC.2020.05.035.

[6] PlasticsEurope (2021), EU Plastics Production and Demand: First Estimates for 2020, PlasticsEurope Association of Plastics Manufacturers, https://www.plasticseurope.org/en/newsroom/news/eu-plastics-production-and-demand-first-estimates-2020.

[28] Prata, J. et al. (2020), “COVID-19 Pandemic Repercussions on the Use and Management of Plastics”, Environmental Science & Technology, Vol. 54/13, pp. 7760-7765, https://doi.org/10.1021/ACS.EST.0C02178.

[82] PRE (2020), Plastics recyclers cease production, Plastics Recyclers Europe, https://www.plasticsrecyclers.eu/post/plastics-recyclers-cease-production.

[51] Promchertoo, P. (2020), Food delivery services add tonnes of plastic to Thailand’s landfills during COVID-19 crisis, https://www.channelnewsasia.com/news/asia/food-delivery-increases-thailand-plastic-waste-during-COVID-19-12711692?cid.

[22] Ren, D. (2020), China boosts face mask production capacity by 450 per cent in a month, threatening a glut scenario, South China Morning Post, https://www.scmp.com/business/companies/article/3075289/china-boosts-face-mask-production-capacity-450-cent-month.

[62] Roberts, K. et al. (2021), “Increased personal protective equipment litter as a result of COVID-19 measures”, Nature Sustainability, https://doi.org/10.1038/s41893-021-00824-1.

[54] RWMO (2020), Interim Report: Performance of the Waste Sector in Ireland: Covid 19 - Initial Restrictions Phase 12th March - 18th May 2020, Regional Waste Management Offices, https://acrplus.org/images/project/Covid-19/RWMO_Ireland_Covid_19_Interim_Report_Waste.pdf.

[38] S&P Global (2020), Global petrochemical trends: H2 2020, S&P Global, https://www.spglobal.com/platts/en/market-insights/special-reports/petrochemicals/global-petrochemical-outlook-h2-2020.

[42] Sabanoglu, T. (2020), Top textile exporting countries worldwide 2019, Statista, https://www.statista.com/statistics/236397/value-of-the-leading-global-textile-exporters-by-country/.

[97] Sarkodie, S. and P. Owusu (2020), “Impact of COVID-19 pandemic on waste management”, Environment, Development and Sustainability 2020 23:5, Vol. 23/5, pp. 7951-7960, https://doi.org/10.1007/S10668-020-00956-Y.

[23] SCIO (2020), Fighting COVID-19: China in Action, The State Council, The People’s Republic of China, http://english.scio.gov.cn/whitepapers/2020-06/07/content_76135269.htm.

[93] Simon, F. (2020), EU dismisses industry calls to lift ban on single-use plastics, euractiv.com, https://www.euractiv.com/section/circular-economy/news/eu-dismisses-industry-calls-to-lift-ban-on-single-use-plastics/.

[74] Solid Waste Management Services (2020), Impact of Covid-19 on Waste Collection and LItter in Greenspaces and Parks, Solid Waste Management Services, Toronto, https://www.toronto.ca/legdocs/mmis/2020/ie/bgrd/backgroundfile-156330.pdf.

[55] Staub, C. (2020), City data shows COVID-19 impacts on recycling tonnages, Resource Recycling, https://resource-recycling.com/recycling/2020/04/28/city-data-shows-COVID-19-impacts-on-recycling-tonnages/#:~:text=Recycling%20programs%20are%20reporting%20greater.

[77] Staub, C. (2020), Coronavirus pandemic disrupts recycling sector, Resource Recycling, https://resource-recycling.com/recycling/2020/03/17/coronavirus-pandemic-disrupts-recycling-sector/.

[96] Staub, C. (2020), How programs in NY, Texas and Colorado are handling COVID-19, Resource Recycling, https://resource-recycling.com/recycling/2020/08/25/how-programs-in-ny-texas-and-colorado-are-handling-covid-19/.

[21] Subramanian, S. (2020), How the face mask became the world’s most coveted commodity, The Guardian, https://www.theguardian.com/world/2020/apr/28/face-masks-coveted-commodity-coronavirus-pandemic.

[84] Tabuchi, H. (2020), In Coronavirus, Industry Sees Chance to Undo Plastic Bag Bans, The New York Times, https://www.nytimes.com/2020/03/26/climate/plastic-bag-ban-virus.html.

[34] Tabuchi, H. (2020), In Coronavirus, Industry Sees Chance to Undo Plastic Bag Bans, The New York Times, https://www.nytimes.com/2020/03/26/climate/plastic-bag-ban-virus.html.

[70] Tesfaldet, Y. et al. (2021), “Assessing face mask littering in urban environments and policy implications: The case of Bangkok”, Science of The Total Environment, p. 150952, https://doi.org/10.1016/j.scitotenv.2021.150952.

[78] Toto, D. (2020), Challenges of the unknown, Waste Today, https://www.wastetodaymagazine.com/article/covid-19-recycling-industry-survey-responses/.

[9] US Board of Governors of the Federal Reserve System (2021), Industrial Production: Manufacturing: Non-Durable Goods: Plastics and Rubber Products (NAICS = 326) [IPG326S], Federal Reserve Bank of St. Louis, https://fred.stlouisfed.org/series/IPG326S.

[8] US Bureau of Labor Statistics (2020), From the barrel to the pump: the impact of the COVID-19 pandemic on prices for petroleum products, US Bureau of Labor Statistics, https://www.bls.gov/opub/mlr/2020/article/from-the-barrel-to-the-pump.htm.

[85] US State of Maine (2020), Governor Mills, Legislature Spearhead Emergency Legislative Package to Respond to COVID-19, State of Maine: Office of Governor Janet T. Mills, https://www.maine.gov/governor/mills/news/governor-mills-legislature-spearhead-emergency-legislative-package-respond-covid-19-2020-03-17.

[58] Wei, G. (2020), Medical Waste Management Experience and Lessons in COVID-19 Outbreak in Wuhan, https://www.waste360.com/medical-waste/medical-waste-management-experience-and-lessons-covid-19-outbreak-wuhan.

[50] Yousefi, M. et al. (2021), “Municipal solid waste management during COVID-19 pandemic: effects and repercussions”, Environmental Science and Pollution Research, Vol. 28/25, pp. 32200-32209, https://doi.org/10.1007/s11356-021-14214-9.

[76] Zambrano-Monserrate, M., M. Ruano and L. Sanchez-Alcalde (2020), “Indirect effects of COVID-19 on the environment”, Science of The Total Environment, Vol. 728, p. 138813, https://doi.org/10.1016/j.scitotenv.2020.138813.

[87] Zecchini, F. (2021), Italy delays contested new sugar and plastic taxes until 2023, Reuters, https://www.reuters.com/world/europe/italy-delays-contested-new-sugar-plastic-taxes-until-2023-2021-10-21/.

[37] Zhou Peng, T. (2021), Petrochemicals 2020: A year of resilence and the road to recovery, McKinsey & Company, https://www.mckinsey.com/~/media/mckinsey/industries/chemicals/our%20insights/petrochemicals%202020%20a%20year%20of%20resilience%20and%20the%20road%20to%20recovery/petrochemicals-2020-a-year-of-resilience-and-the-road-to-recovery-vf.pdf?shouldIndex=false.

Notes

← 1. This chapter focuses on the implications of the pandemic as they emerged in 2020. The longer-term consequences are included in the baseline projections presented in Volume 2 of the Global Plastics Outlook (OECD, forthcoming[39]).

← 2. Despite the lower input onto the market, separate collection of plastic packaging waste increased by 4% compared to 2019 levels, mostly reflecting improvements in waste management systems in parts of the country.

← 3. To reach these figures, they multiplied one face mask per day with the share of people who accept face masks in each region (a share varying widely across countries – from 5% in Sweden to 95% in Spain, with China at 84% and the USA at 73%). This leads to a global estimate of 140 billion face masks used per year. They then calculated the plastic pollution using the regional shares of mismanaged waste.

← 4. In comparison, 4 750 items of PPE were found for every km2 of grocery store parking lots and 1 330 items per km2 in hospital districts (Ammendolia et al., 2021[73]).

← 5. One quarter of the costs were attributed to the loss of labour due to COVID-19 related illness and medical recommendations for self-isolation (Solid Waste Management Services, 2020[74]).

← 6. The projections of plastics use to 2060 presented in Volume 2 of the Global Plastics Outlook (OECD, forthcoming[39]) build on these impacts in 2020 as well as on the recovery pathway laid out in Dellink et al. (2021[3]).

← 7. Changes in relative prices will affect production methods and lead to some substitution effects between various inputs in production, but the effect is relatively small compared to the effects of output changes.