The objective of these Golden Rules is to highlight over few pages the primary roles and responsibilities of the major stakeholders involved in chemical accident prevention, preparedness and response. It should be recognised that these points represent good practices and objectives to be achieved over time. They are not one-time actions but rather require ongoing vigilance.

OECD Guiding Principles for Chemical Accident Prevention, Preparedness and Response - Third Edition

Golden Rules

Abstract

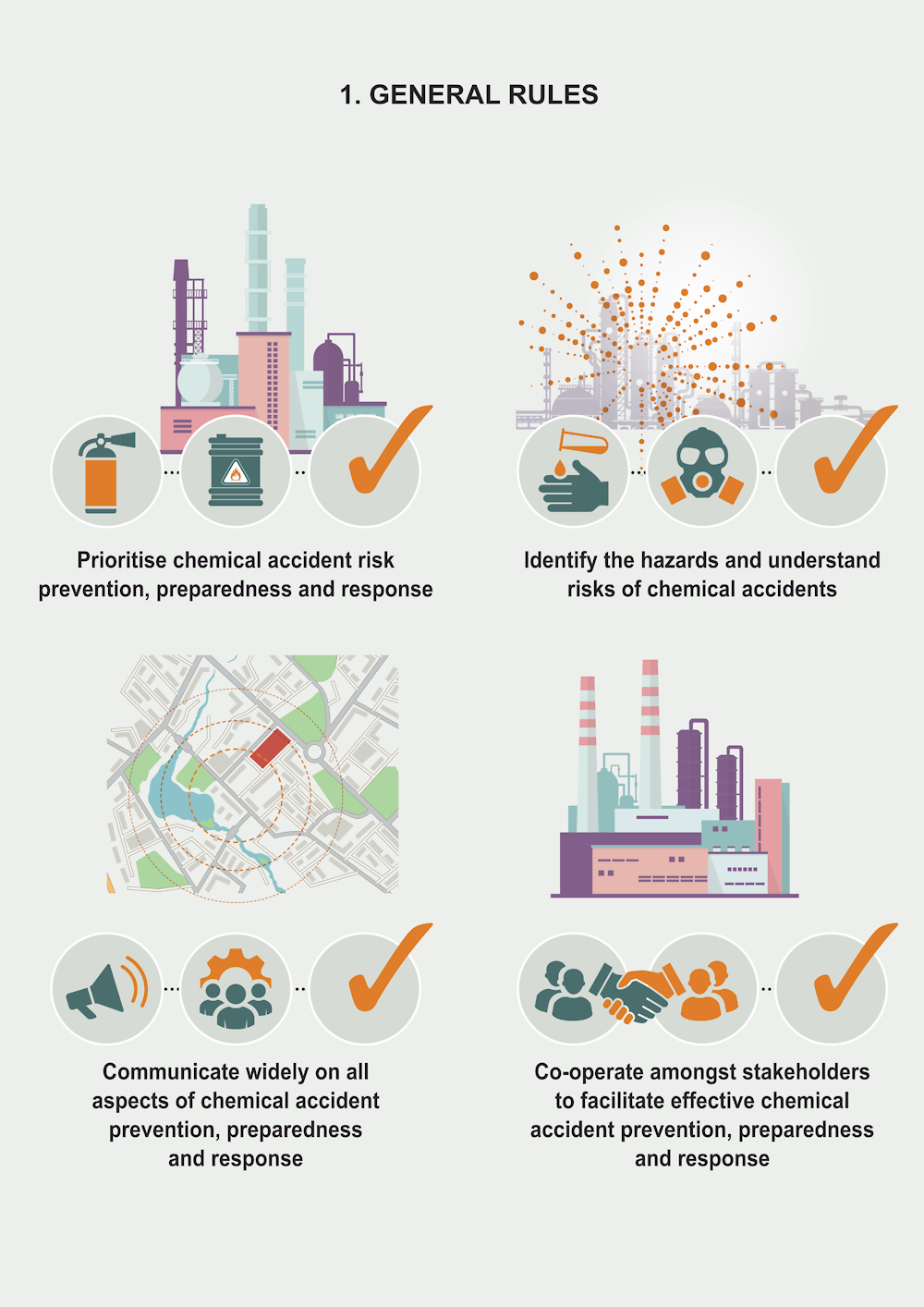

Infographic 0.1. General Rules for all stakeholders

General rules for all stakeholders

Prioritise chemical accident risk prevention, preparedness and response

Chemical accident prevention preparedness and response require efforts from all stakeholders within their own roles and responsibilities to ensure that hazardous installations and their risks are managed effectively. Beyond the local responsibilities, there are roles and activities that must be undertaken at the regional, national and international levels. Accidents may have a potential impact across borders, thus requiring the exchange of information and trans-frontier activities. Managing the risks of chemical accidents effectively requires leadership within industry and civil society. Leadership requires risk awareness, information from within the whole of the organisation, competency and decisive action to be effective.

Identify the hazards and understand the risks of chemical accidents

Industry must systematically identify the hazards associated with handling hazardous chemicals and understand the risks of chemical accidents associated with the operation of their installations. In doing so, they should take into account the potential impact of natural hazards. Hazard identification and risk assessment should be undertaken from the earliest stages of design and construction, throughout operation and maintenance, up until cessation of operations and closure. It should be recognised that temporary situations or any changes in operations require hazard identification and risk assessment to be reviewed, and appropriate measures to manage the changes in risk taken.

The measures taken by industry to address the risks of chemical accidents should be appropriate so as to reduce them as far as reasonably practicable. Considerations should be given to technological failures as well as to the influence of human factors on the safe operation of the facility. Measures should be taken to ensure as far as reasonably practicable that malicious acts (e.g. sabotage, cyberattack, terrorism, vandalism, theft) which may lead to a chemical accident are prevented, including cybersecurity.

Public authorities must understand the risks posed by chemical accidents from hazardous installations to people, the environment and property. This understanding should be used in developing the inspection and control measures for the oversight of the installations, the offsite emergency planning to be able to respond in the event of a chemical accident, and in ensuring that appropriate land-use planning is developed to minimise potential impacts to the community and the environment.

Members of the public and communities should be aware of the risk posed by chemical accidents in their vicinity and be involved in the planning and communication activities related to them.

Communicate widely on all aspects of chemical accident prevention, preparedness and response

Communication should be based on a policy of openness as well as the shared objective of reducing the likelihood of accidents and mitigating the adverse effects of any accidents that occur. One important aspect is that the potentially affected public should receive the information needed to support prevention and preparedness objectives. Communication mechanisms should be set up to ensure that trans-frontier communication is enabled.

Good communication is important within the facility in which the hazardous installations are sited so that everyone, at all levels of the organisation, understands the risks which are to be managed and their own role in ensuring that this is done. Effective communication is essential between the management of the facility and the local authorities, not only to co‑ordinate the measures and activities necessary to ensure that emergency plans are drawn up and acted upon in the event of a chemical accident, but also to allow the development of land use planning in the vicinity of the facility so as to avoid conflicts and manage risk effectively.

In the event of a chemical accident, effective communication must be activated immediately between the facility and the local authorities so that appropriate emergency measures are initiated and clear information is provided to the public regarding the behaviour to be adopted. This communication must be two-way, active, informed and continuous. This communication should take into account the existing crisis communication plan.

The public should participate in decision making relating to hazardous installations where this is possible. The laws in many communities require public authorities to provide opportunities for members of the public to participate in decision making related to hazardous installations, for example by commenting on proposed regulations or zoning decisions or providing input for procedures concerning licensing or siting of specific installations. Members of the public should take advantage of these opportunities to present the perspective of the community. They should work towards ensuring that such opportunities exist, whenever appropriate, and that the public has the information necessary for effective participation.

Co-operate amongst stakeholders to facilitate effective chemical accident prevention, preparedness and response

Management should co-operate with all employees and their representatives, public authorities, local communities and other members of the public in achieving the goals of chemical accident prevention, preparedness and response.

In addition, management should strive to assist other enterprises (including suppliers and customers) to meet appropriate safety standards. This may, for example, be through effective product stewardship programmes, the work of industry and trade associations, or chambers of industry and commerce.

Management should co‑operate with local authorities and emergency responders to ensure that emergency planning is appropriate to the risks presented by a chemical accident. This may include providing not only information on the chemicals handled, the processes operated and their location, but also specialised equipment, other resources or training to enable the delivery of an effective response.

Communities and the public should co‑operate with the management of the facilities in their area and with the local authorities so that, in the event of a chemical accident, the appropriate behaviours are followed and the impacts are minimised as far as possible. They should be aware of the risks in their community and know what to do in the event of an accident. This includes reading and taking note of the information provided with regard to the appropriate behaviours, sharing this information with others in their household and seeking additional information as appropriate.

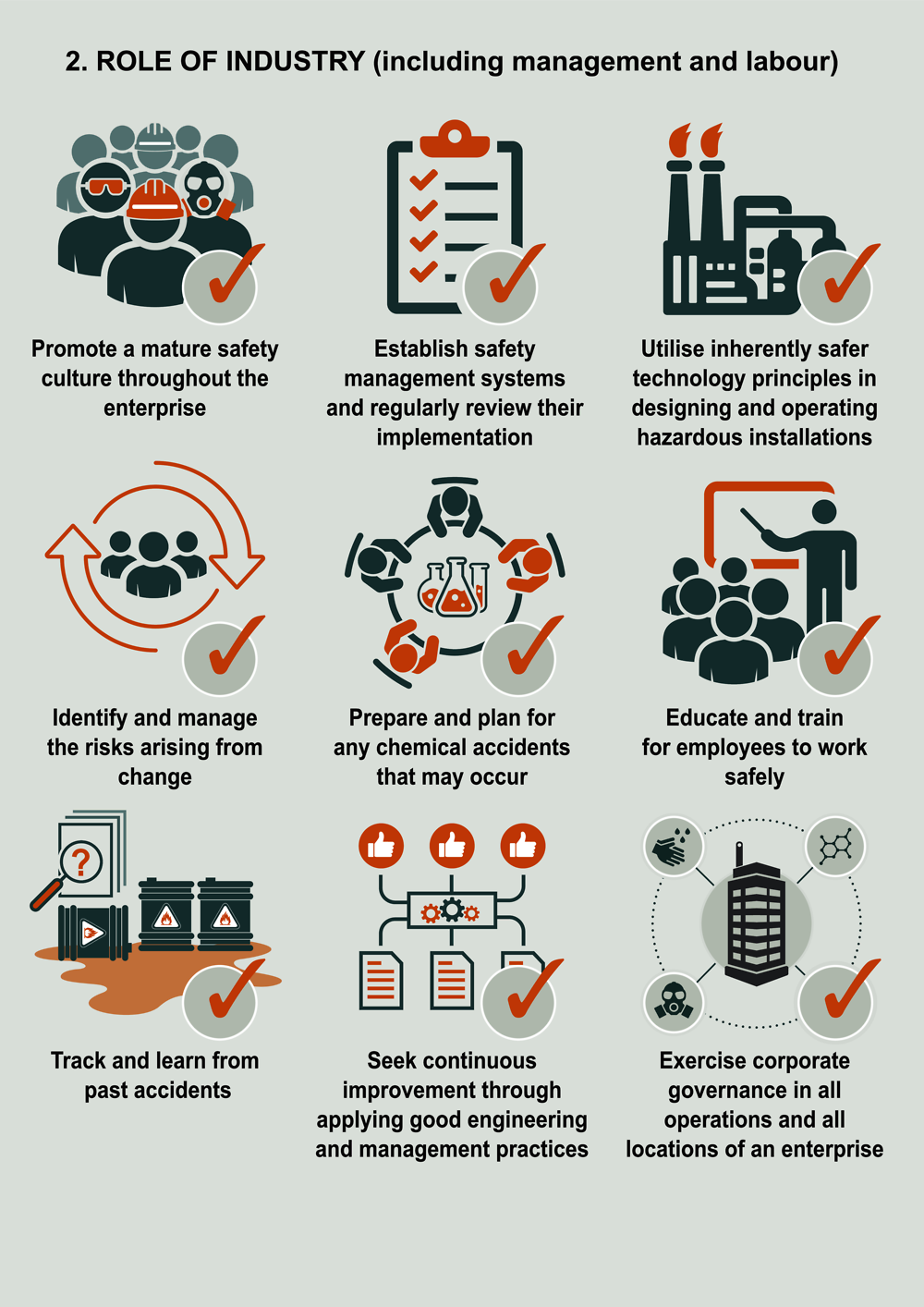

Infographic 0.2. Role of industry (including management and labour)

Role of industry (including management and labour)

Promote a mature safety culture throughout the enterprise

The safety culture, reflected in an enterprise’s safety policy, consists of both an attitude showing that safety is a priority and appropriate organisation. The safety culture is led from the top of the organisation. To be effective, a safety culture requires a visible top-level commitment to safety in the enterprise and the support and participation of all employees1 and their representatives. It should endeavour to improve the level of safety beyond legal requirements and guarantee a high level of safety where legal requirements are not available.

A mature safety culture involves everyone. It is open to receiving communication from all levels of the organisation and providing feedback, particularly to management, when appropriate. This should ensure that everyone is cared for and that no one is exposed to unacceptable risks. All employees of the facility and of contractors working for the facility should comply with all procedures and practices relating to accident prevention, preparedness and response in the discharge of their responsibilities. This should be in accordance with the training and instructions given by their employer, respectively organised by the facility management.

Establish safety management systems and regularly review their implementation

Safety management systems for hazardous installations include using appropriate technology and processes, as well as establishing an effective organisational structure (e.g. operational procedures and practices, effective education and training programmes, appropriate levels of well-trained employees and allocation of necessary resources). These all contribute to the reduction of hazards and risks. In order to ensure the adequacy of safety management systems, it is critical to have appropriate and effective review schemes to monitor the systems (including policies, procedures and practices). Senior management should take responsibility for regularly reviewing the performance of the safety management system and ensuring that corrective action is taken where deficiencies are identified.

Utilise inherently safer technology principles in designing and operating hazardous installations

This should help reduce the likelihood of accidents and minimise the consequences of accidents that occur. For example, installations should take into account the following, to the extent that they would reduce risks: minimising to the extent practicable the quantity of hazardous substances used; replacing hazardous substances with less hazardous ones; reducing operating pressures and/or temperatures; improving inventory control; and using simpler processes. This could be complemented by the use of backup systems.

Identify and manage the risks arising from change

Any significant changes (including changes in process technology, organisation, staffing and procedures) as well as maintenance/repairs, start-up and shut-down operations, increase the risk of an accident. It is therefore particularly important to be aware of this and take appropriate safety measures when significant changes are planned – before they are implemented. In particular, any change of ownership, that is mergers or acquisitions, should be considered for potential impacts on the safe operation of the facility. Care should be taken to address the ageing of plants, equipment, procedures and people as a continuous change process, which can have a significant impact on safety.

Prepare and plan for any chemical accidents that may occur

It is important to recognise that it is not possible to totally eliminate the risk of an accident. Therefore, it is critical to have appropriate preparedness planning in order to minimise the likelihood and extent of any adverse effects on health, the environment or property. This includes both onsite preparedness planning and contributing to offsite planning, as well as the provision of information to the potentially affected public.

Educate and train for employees to work safely

Management should ensure that all employees are suitably trained and qualified to carry out their tasks and understand the risks of chemical accidents associated with them. They should define the necessary qualifications for each job when recruiting new personnel or when appointing existing personnel to a new position. Training must be provided when carrying out tasks for the first time and regularly repeated to ensure that a high standard of compliance with expected operating procedures is achieved. Changes in operating procedures require new training. Training and instruction must be provided to contractors working on site.

Track and learn from past accidents

Industry must learn from past accidents. To do this, it must record and investigate all relevant accidents, report them, where required, to the appropriate authorities, develop lessons learnt from the accidents and disseminate not only the account of the accident but also those lessons learnt. Industry must actively follow up on accidents which are reported within their organisation, their business and beyond and adopt appropriate measures to ensure that lessons learnt are turned into measures to prevent the recurrence of similar accidents.

Seek continuous improvement through applying good engineering and management practices

Although it is not possible to eliminate all risks of accidents at hazardous installations, the goal should be to find improvements in technology, management systems and employees’ skills in order to move closer toward the ultimate objective of zero accidents. In this regard, management should seek to learn from past experiences of accidents and near misses, both within their own enterprises and at other enterprises. To this end, there should be an exchange of good practices within the organisation and across the industry.

Exercise corporate governance in all operations and all locations of an enterprise

Management should make sure that best practice is applied at all hazardous installations, independent of their location and age. The transfer of technology, that is the introduction of technology or hazardous substances to a location that does not have prior experience and knowledge, should be accompanied by the information and knowledge required for its safe operation. Local standards which are lower than the corporate standards, or the standards applied where the company has its headquarters, should not lead to lower standards in the operation of a facility.

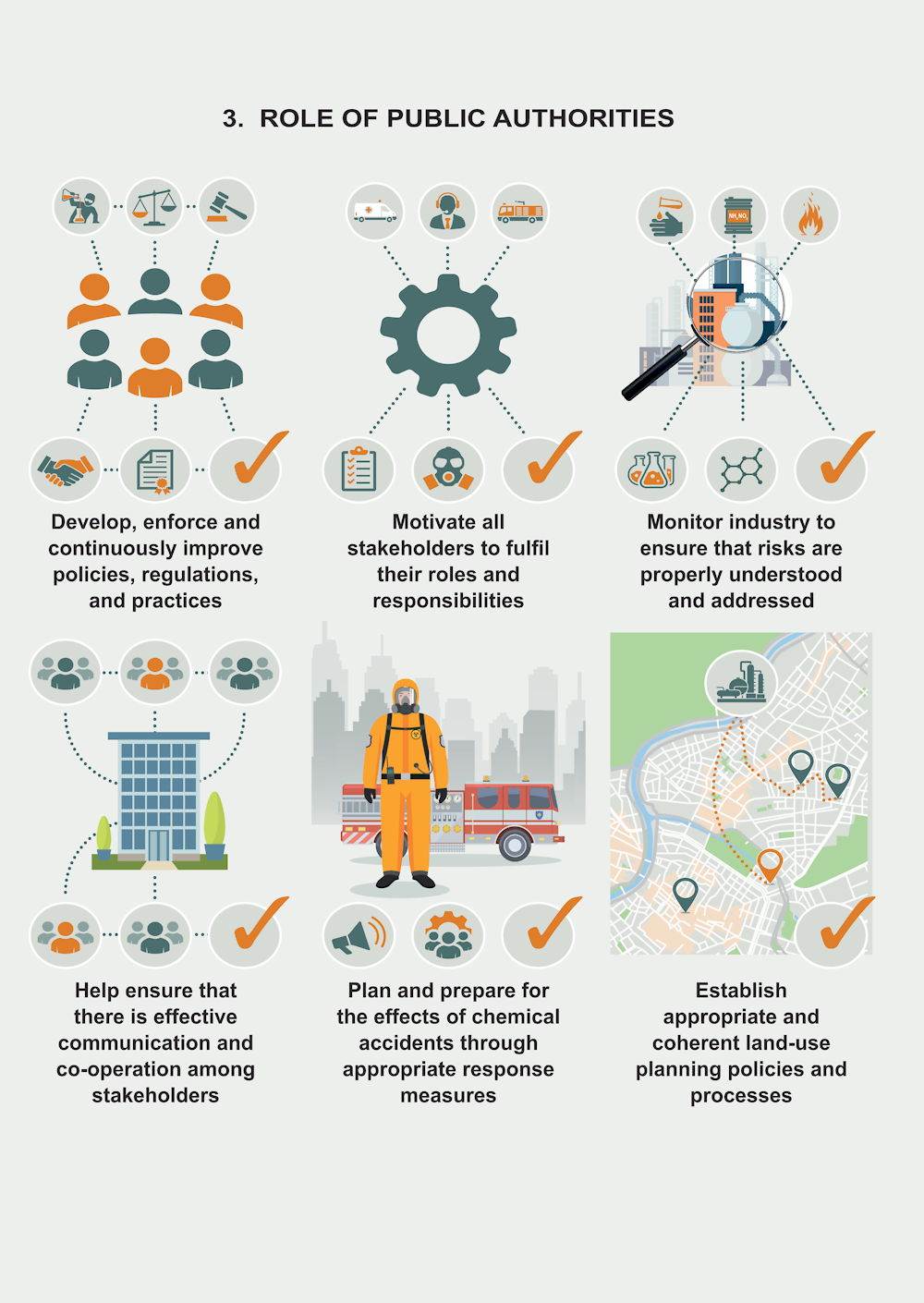

Infographic 0.3. Role of public authorities

Role of public authorities

Develop, enforce and continuously improve policies, regulations, and practices

It is important for public authorities at the national, regional and local levels to establish policies, regulations and practices and have mechanisms to ensure their enforcement. Public authorities should also regularly review and update, as appropriate, policies, regulations and practices. In this regard, public authorities should keep informed of and take into account relevant developments. These include changes in technology, business practices and levels of risks in their communities, as well as experience in implementing existing laws and accident case histories. Public authorities should involve other stakeholders in the review and updating process.

Motivate all stakeholders to fulfil their roles and responsibilities

Within their own sphere of responsibility and influence, all relevant public authorities should seek to motivate other stakeholders to recognise the importance of accident prevention, preparedness and response, and to take the appropriate steps to minimise the risks of accidents and mitigate the effects of any accidents that occur. In this regard, the authorities should establish and enforce appropriate regulatory regimes, promote voluntary initiatives and establish mechanisms to facilitate education and information exchange.

Monitor industry to ensure that risks are properly understood and addressed

Public authorities should establish mechanisms for monitoring hazardous installations to help ensure that all relevant laws and regulations are being followed and that the elements of a safety management system are in place and are functioning properly, taking into account the nature of the risks at the installations (including the possibilities of malicious acts or accidents triggered by natural hazards or disasters). Public authorities should engage in dialogue with management to ensure that lessons are learnt and that continuous improvement is achieved.

Help ensure that there is effective communication and co-operation among stakeholders

Information is a critical component of safety programmes. Public authorities have an important role in ensuring that appropriate information is provided to and received by all relevant stakeholders. Public authorities have a special role in facilitating the information to the public concerning chemical risks in their community so that members of the public are reassured that safety measures are in place, that they understand what to do in the event of an accident and that they can effectively participate in relevant decision-making processes. Public authorities are also in a position to facilitate the sharing of experience by providing public databases and publishing investigation reports.

Public authorities should publish information on natural hazards and communicate it to the management of hazardous installations that may be affected by them. Public authorities should make sure that there are early warning systems in case of chemical accidents or natural hazards.

Plan and prepare for the effects of chemical accidents through appropriate response measures

Public authorities (often at the local level) have primary responsibility for ensuring response to accidents that have offsite consequences, helping prevent deaths and injuries, and protecting the environment and property. They should make sure that the on- and offsite planning includes appropriate planning for monitoring and clean-up of releases, fires and explosions, including the definition of responsibilities for these activities.

Establish appropriate and coherent land-use planning policies and processes

Land-use planning can help to ensure that all installations are appropriately located, with respect to the protection of health, environment and property, in the event of an accident. It should establish and implement both general zoning as well as specific siting of hazardous installations and other developments. Land-use planning policies and processes can also prevent the inappropriate placement of new developments near hazardous installations. The construction of new residential, commercial or public buildings within certain distances of hazardous installations should be avoided. Land-use planning policies and arrangements should also control inappropriate changes to existing installations. They should also allow for the possibility of requiring changes to existing installations and buildings to meet current safety standards.

Effective land-use planning needs to involve public authorities from both the field of chemical accident prevention as well as urban and regional planning. In addition, stakeholders from industry and civil society should be actively engaged and consulted to provide balanced and acceptable management of chemical accident risks.

Note

← 1. For the purposes of this publication, “employee” is defined as any individual(s) working at or on behalf of a hazardous installation. This includes both management and labour, as well as (sub)contractors.