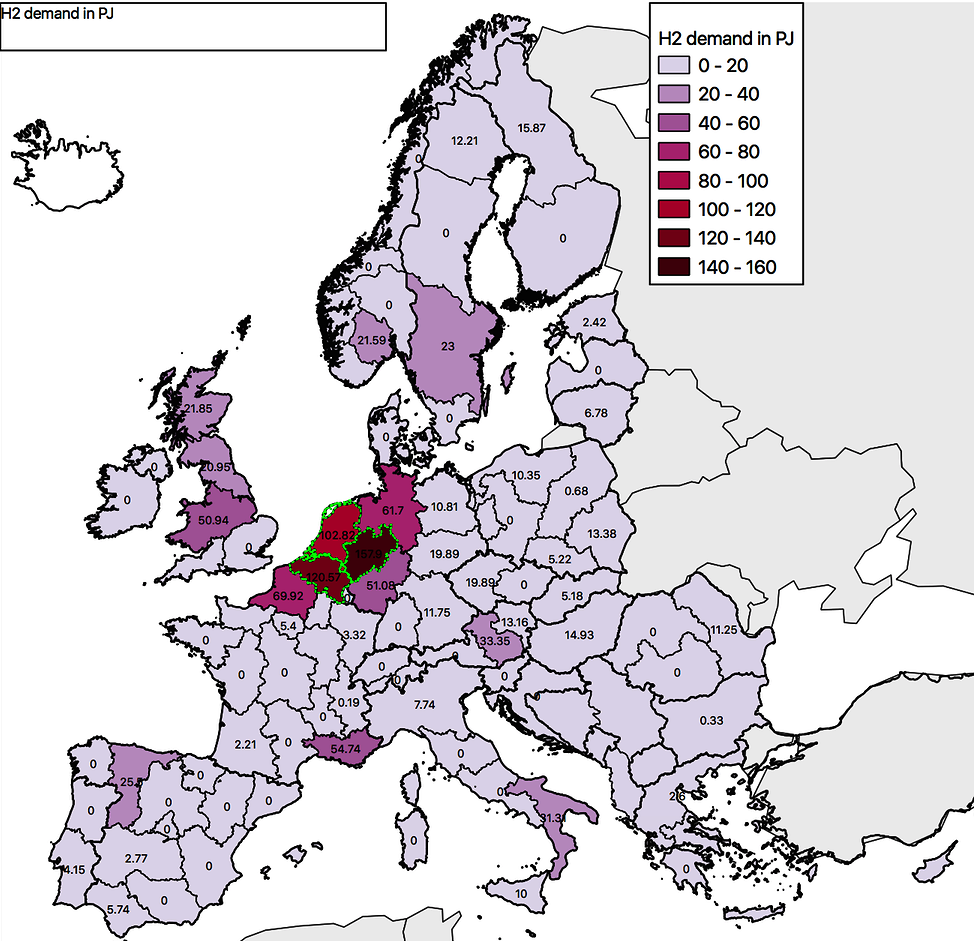

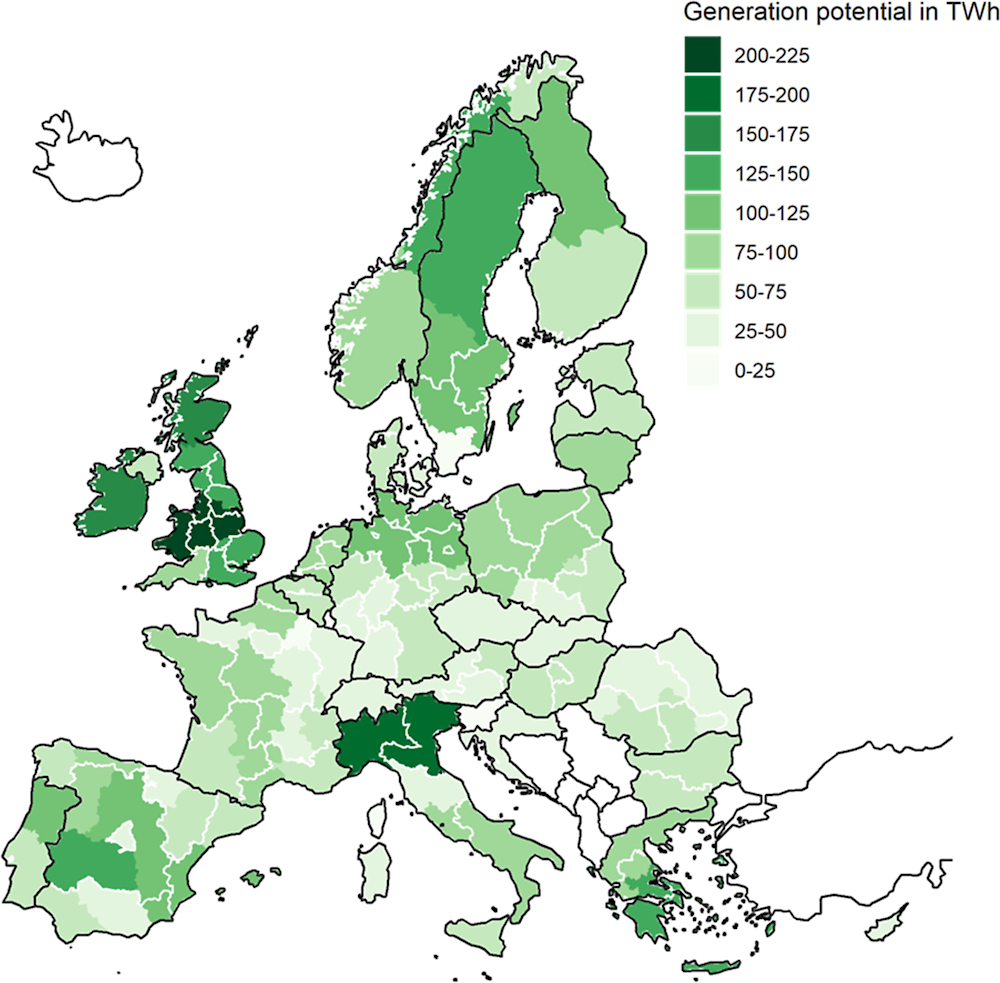

The port of Hamburg has taken a leading role in reaching climate neutrality by 2040. This chapter shows that Hamburg's strategic location can turn it into a major climate-neutral transport centre, building on its strong rail infrastructure. In this way Hamburg can deliver climate-neutral transport services client businesses need throughout Western and Central Europe quickly and at low cost. This includes harnessing its potential for a hydrogen hub. The transition to zero-emission fuels for international shipping therefore needs to be prepared now. This will raise costs by 2030 on account of initially higher fuel production cost and needed investment in zero-emission shipping, but an energy-saving fuel mix may help keep longer-term costs and trade flow impacts modest. Maximising the use of rail would deliver benefits beyond Hamburg. It requires addressing railway infrastructure bottlenecks and digitalization. Quick major steps towards electrified road transport are also needed, with electric charging infrastructure and continued efforts to improve logistics. Hamburg can play an important role in delivering imported green hydrogen and hydrogen-derived products, via pipelines or ships, to serve demand in local industry and shipping as well as in neighbouring industrial regions.

Reaching Climate Neutrality for the Hamburg Economy by 2040

3. Reaching climate neutrality in freight and industry

Abstract

Freight and logistics through ports play a critical role in trade flows. Goods handled in ports account for 46% of the value of goods traded between the EU and the rest of the world, and 75% of its volume (ERA, 2022[1]). Hamburg hosts one of the four largest ports in Europe. Transport and logistics activity in and around the port reflect its importance as a major economic hub. Hamburg is home to a large number of industrial, wholesale and retail businesses, including in e-commerce, which depend on the port and its transport and logistics services. Preparing the Hamburg port for climate-neutral international shipping is therefore central to the Hamburg economy, as well as beyond, providing much-needed zero-carbon transport services to business on the continent. The first section of this chapter is devoted to this issue.

Land-based transport connections from and to the port are of equal strategic importance. The vast cargo turnover in Hamburg has fostered a high-frequency supply chain in the hinterland. The influence of Hamburg and its port reaches deep into this hinterland down transport chains, shaping economic and environmental performance in the Hamburg region, Germany and many parts of Europe.

The major ports in Europe often serve overlapping hinterlands: as the distance between the port and the hinterland grows, competition between ports and between transport modes increases. Yet, land-based freight services are, alongside maritime shipping, particularly difficult to decarbonise. The second section therefore discusses the implications of Hamburg hinterland transport and logistics, providing insights into actions to successfully manage the transition to climate neutrality while harnessing Hamburg’s comparative advantage and its strategic position as one of Europe’s major ports.

The port is closely integrated with the manufacturing of basic materials that are also particularly challenging to make climate-neutral. This applies in particular to basic metals production and oil refining. These sectors depend strongly on fossil fuels, both as energy carriers and raw materials. They often require high temperatures in production processes which do not easily lend themselves to electrification. The decarbonisation of key manufacturing sectors in Hamburg is discussed in the third section.

Hydrogen and hydrogen-derived products are important for the climate-neutral operation of international maritime shipping as well as for some of Hamburg’s manufacturing activities. Some manufacturing might also require carbon capture and storage (CCS). The Hamburg port may also serve as a hub for the provision of hydrogen, CCS and related transport services. This is discussed in the fourth section of the chapter.

Anticipating the impact of decarbonising maritime transport

The Hamburg port has already adopted a strategy to reach climate neutrality for Scope 1 and 2 emissions in port operations by 2040. This includes all emissions in freight handling and transport. A consistent CO2 balance for the port will be used to monitor and control this process (Behörde für Wirtschaft und Innovation, 2023[2]). The first part of this chapter will therefore focus on the decarbonisation of international shipping. Preparing the Hamburg port for the major transformations this will bring is key for the Hamburg economy. This section will deploy transport and macroeconomic modelling for the port of Hamburg to provide insights about the implications, in terms of zero-emission fuel supply and impacts on trade (Halim et al., 2018[3]).

In July 2023 the International Maritime Organization (IMO, Box 3.1) adopted the revised 2023 IMO GHG strategy. This strategy sets objectives to reach net-zero GHG emissions by or around 2050 and reduce GHG emissions by at least 20% by 2030 while striving to reduce them by 30% and reduce GHG emissions by 70% by 2040, compared to 2008.

According to the revised 2023 IMO GHG Strategy, global shipping must lower its carbon intensity (CO2 emissions per transport service) by at least 40% by 2030.

Box 3.1. The role of the International Maritime Organization in decarbonising maritime freight

The International Maritime Organization (IMO) is a UN agency with 174 member countries. It is an intergovernmental consultative body which adopts policy measures to prevent and reduce environmental impacts as well as to improve the safety and security of international shipping. IMO has stated its aim to align with the 2015 Paris Agreement. It has revised the 2018 “Strategy on reduction of GHG emissions from ships” in 2023. A further review will be finalised when the IMO’s Marine Environment Protection Committee (MEPC) meets in the autumn of 2028 to adopt the 2028 IMO Strategy. The MEPC handles environmental concerns such as the management and prevention of ship-sourced pollution, or ship recycling. As a technical body to create, review, and revise the IMO strategy, the Intersessional Working Group on GHG Emissions (ISWG GHG) proposes policy measures to the MEPC.

Source: (IMO, 2023[4])

Economic measures to decarbonise international shipping are under ongoing discussion. To meet the agreed targets, IMO member countries have proposed baskets of economic and technical measures that will need to be adopted by 2025. These measures will have the broadest coverage, in terms of the number of countries as well as the range of ship types regulated under IMO policy. This section takes the latest IMO agreement as the starting point of the analysis, as well as the proposed basket of measures from the European Commission (EC).

For most businesses involved with the trade of goods from and to the port, the emissions from international shipping are Scope 3 emissions. Climate neutrality for international shipping by 2050 may therefore be consistent with the 2040 HCC climate neutrality target, provided there is no strong reliance on international offsets to reach it. However, businesses operating vessels in international shipping headquartered in Hamburg should move ships to largely zero-emissions fuels by 2040.

Preparing the port for zero-carbon fuels

The availability and the use of zero-emission fuels will be key to decarbonising international shipping according to the timeline that the revised IMO targets. Ports could play a strategic role as a logistics node in their supply, serving as bunkering stations for ships.

To estimate cost-minimising zero-carbon fuels, this section draws on the results of a modelling exercise carried out with the NavigaTE model (Mærsk Mc-Kinney Møller Center, 2021[5]). NavigaTe is a techno‑economic shipping model developed by the Mærsk Mc-Kinney Møller Center for Zero Carbon Shipping to assess the most cost-effective decarbonisation pathways, taking comprehensive account of costs from adopting different fuel measures. It captures the entire energy value chain for powering the maritime vessel from raw materials and primary energy used in fuel production to the fuel combustion in the vessel. A description of this model can be found in the Annex. The model uses a cost-minimising approach to estimate the projected uptake of different fuel types in line with the 2023 IMO strategy. Figure 3.1 presents the results. Assuming the adoption of a carbon levy, discussed in detail below, which is expected to close the price gap to current fossil fuel types, proposed by the EU Commission, demand for ammonia is expected to increase from 2027. From 2035 onwards, ammonia may be the dominant zero‑carbon fuel type. It may drive the decarbonisation of the sector thanks to its cost efficiency, higher volumetric energy density, simplified production, and existing well-developed infrastructure compared to other alternatives (Hoang et al., 2022[6]). Ammonia is emission-free in combustion and can also be produced emission-free with green hydrogen (Box 3.2).

Figure 3.1. Estimated fuel mix for decarbonising international shipping

Estimation based on the revised 2023 IMO strategy and proposed measures by the European Commission

Note: Ammonia includes blue ammonia produced from natural gas with carbon capture and storage as well as green ammonia from green hydrogen.

Box 3.2. Ammonia may be the most promising zero-emission shipping fuels

Ammonia is a cost-effective zero-carbon bunker fuel that is easier to produce and store in large quantities than other zero-carbon fuels. “Green” ammonia is produced from hydrogen made by hydrolysis of water with renewable electricity. Research and development efforts are required to address potential air pollution of nitrogen oxides and nitrous oxide from ammonia combustion. Since ammonia is toxic to humans and aquatic life it needs to be stored and managed safely.

Green methane and methanol can also be produced and used emission-free. They require carbon, which can be sourced emission-free in two ways (World Bank, 2021[8]):

from sustainable biofuels, in biofuel synthesis (biomethane, biomethanol),

as a synthetic fuel, through recovering CO2 from carbon capture and combining it with hydrogen, in hydrogenation for alcohol synthesis (synthetic methane, synthetic methanol).

Their advantage is that they are similar to conventional fossil fuels and therefore require relatively minor changes in conventional fossil bunkers and engines. However, the production of synthetic fuels is energy-intensive. The climate-neutral sourcing of captured CO2 may also be a concern. In particular, sourcing it from CO2 emissions in industrial processes would not be fully climate-neutral. Sourcing it from direct air capture would be climate-neutral but would increase energy needs. Biofuels should also be sourced sustainably to ensure their use is emission-free. Another limitation is the high demand for biofuels in multiple sectors to reach climate neutrality, as well as competing land use for agriculture or biodiversity protection.

Next to ammonia bio and synthetic methane and methanol, as well as advanced biofuels are also expected to see some uptake to reach the 20%-30% GHG reduction target by 2030. Safety is another important aspect of zero-carbon fuels (Box 3.3).

Box 3.3. Safety of zero-carbon fuels: The role of the Clean Marine Fuels Working Group

The Clean Marine Fuels Working Group (CMF) plays a crucial role in facilitating and regulating the supply of new marine fuels by providing expertise and guidance. CMF has taken significant strides in ensuring bunkering safety and broader system safety. Initially, a bunkering safety toolkit for liquefied natural gas (LNG) was introduced, and subsequently, it has been adapted to encompass all low- and zero-carbon fuels. On the operational safety front, comprehensive safety bunkering checklists for liquid gases were released in 2022, followed by one for methanol in 2023. Ongoing investigations are developing safety protocols for ammonia. Regarding system safety, CMF is currently in the process of transforming the existing "audit tool for bunker facility operators" and "bunker-ready terminal tool" into universally applicable tools suitable for all existing and emerging marine fuels.

The port can provide incentives for shippers’ voluntary emission reduction

Ports can voluntarily offer incentives to promote and reward shipping companies for surpassing legal emission standards. To facilitate this effort, the International Association of Ports and Harbors (IAPH) established the Environmental Ship Index (ESI), which quantifies environmental performance in terms of air pollutants, CO2 emissions and noise. This index has been universally adopted by ports worldwide as a tool to incentivise ships to lower emissions below the IMO emission standard. Currently, the ESI database includes around 7,000 commercial ships and more than 60 organisations, primarily consisting of port authorities. The Hamburg Chamber of Commerce could encourage shipping carriers to make use of the Environmental Ship Index (ESI) and monitor emission reductions in line with its 2040 climate neutrality target.

Measures by ports to schedule the arrival and mooring of ships (port call optimisation) lead to GHG emission reduction through lower energy use. Effective cooperation is vital. To that end, the International Taskforce on Port Call Optimization (ITPCO) aims to achieve optimised port calls through collaboration among relevant agents (international shipping, ports, terminals, and cargo owners) thanks to timely high‑quality data sharing and standardisation.

Establishing green shipping corridors involves identifying specific trade routes between major hubs that support zero-emission solutions. This initiative depends on voluntary cooperation among ports, shipping entities, and other stakeholders. Successful implementation will require the participation of ports from developing countries. The Clean Energy Marine Hubs (CEM-Hubs) platform, a cross-sectoral public‑private initiative involving energy, ports, finance, and shipping sectors, aims to accelerate the production and maritime transport of low-carbon-emission fuels, including those directly used for shipping.

Modelling the cost impact of potential decarbonisation measures

This subsection discusses the scenario design and the modelling method used to assess the economic impacts of measures proposed by the European Commission to reach the 2023 IMO emission reduction and climate neutrality targets. The assessed impacts include trade costs and on the value of trade flows in Hamburg. They include a global fuel standard (GFS) and a carbon levy on ships with a capacity above 5 000 gigatons (GT).

In the proposed GFS emissions are assessed “well-to-wake” (WTW) across the whole value chain of fuels. WTW refers to emissions in the entire process of fuel production, delivery and use on ships, so comprises Scope 1, 2 and 3 emissions in fuel use. A 16% reduction in the carbon intensity of ship fuel is applied in 2030. According to the EC proposal, the GHG reduction from the GFS is raised to 80% and 95% by 2040 and 2050, respectively. In addition, a carbon tax of 150 USD per ton is applied by 2030, to be increased to 200 USD by 2050.

Scenario design

The economic impacts are assessed comparing a policy scenario with the proposed measures against a business-as-usual (BAU) scenario, which includes climate action on international shipping only up to the measures introduced by IMO in 2021. Both policy and baseline scenarios assume that global climate action more generally will limit global warming to 2 degrees (Box 3.4).

Box 3.4. The Business-As-Usual (BAU) scenario

The Business-As-Usual (BAU) scenario applies the Shared Socio-Economic Pathway (SSP) 2 and Representative Concentration Pathway (RCP) 2.6 to reflect global socio-economic development and climate actions expected to be taken by countries worldwide. SSPs are pathways that describe how global society, demographics and economic developments might change over the next century and are used as a backdrop to model climate action. In SSP2 trends broadly continue historical patterns. RCPs refer to atmospheric GHG concentrations and other forces acting on climate, resulting from climate action. RCP 2.6 is consistent with 2-degree global warming. The economic projections rely upon DG-ECFIN for the European Union, while the IMF and OECD long-term projections inform the outlook for non-EU economies.

Furthermore, the BAU scenario takes into account the International Maritime Organization's (IMO) short-term measures in 2021 —including the Energy Efficiency Design Index (EEDI), Energy Efficiency Existing Ship Index (EEXI), and Carbon Intensity Indicator (CII)— to curtail shipping carbon intensity (IMO, 2021).

EEDI gauges the ship designs energy efficiency, with lower EEDI values as an indication of increased ship efficiency. This index, introduced in 2013, applies to new ships. EEXI applies to ships’ operating emissions. These two indices oblige ship owners to adhere to specific energy efficiency standards. CII quantifies CO2 emitted by ships during transport activity on an annual basis. It is specified in grams of CO2 emitted per cargo-carrying capacity and nautical mile. The IMO has introduced a rating system ranging from A to E with an increasing stringency towards 2030. Ships with a D rating for three consecutive years are required to apply a corrective action plan.

Methodology

There will be a direct and an indirect impact of the GFS and of the carbon tax on transport costs, given the strong interdependencies between transport and trade systems (Halim, Smith and Englert, 2019[9]).

First, a direct impact will be on ship running costs on account of fuel and capital costs, as well as on account of the carbon levy on remaining emissions. This will increase transport costs. The increase in these costs impacts global trade. In turn, transport costs are sensitive to the change in trade volume, as unit transport costs could respond to the loss or gain in economies of scale in shipping. Scale economies can reinforce trade-cost-induced shifts in trade flows.

To assess the economic impacts on trade through Hamburg, this study focuses on the following indicators:

1. Change in transport costs by commodity for imports and exports (measured in percentage change), based on a comparison between BAU and policy scenario;

2. Change in trade values by commodity for import and export (measured in USD and percentage change) based on a comparison between BAU and policy scenario;

3. Change in trade values for the top 20 import/export countries (measured in percentage change).

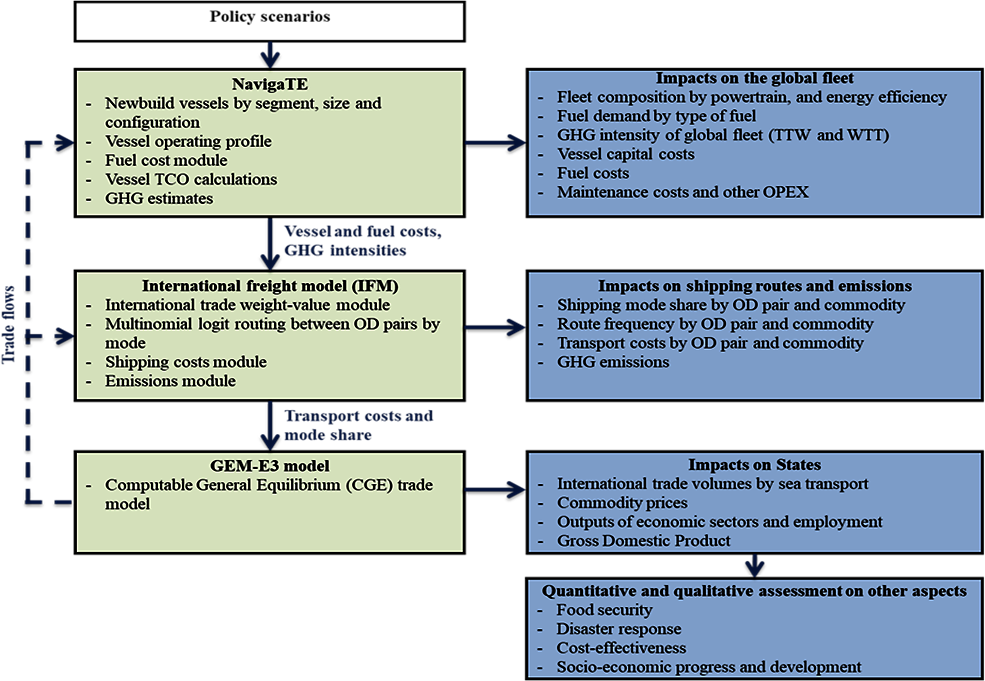

To assess these impacts, the analysis is carried out using the output of NavigaTE, described above and in the Annex. The approach also deploys Equitable Maritime Company’s (EMC) International Freight Model (IFM) to model cost-minimizing international freight transport choices, including transport mode choices, taking into account the quality of infrastructure and shipping services at a detailed network level (Halim et al., 2018[3]) This analysis is complemented by the output of the GEM-E3 model, a global computable general equilibrium economic model designed to project worldwide commodity trade under different scenarios (E3modelling). The modelling approach follows three steps, illustrated in Figure 3.2. A description of the 3 models and the 3-step modelling approach is in the Annex. This analysis is complemented by the output of the GEM-E3 model, a global computable general equilibrium economic model designed to predict worldwide commodity trade volumes under different scenarios (E3modelling). A detailed explanation of these three models can be found in the Annex and the cited references. The modelling approach follows three steps, illustrated in Figure 3.2. A description of the 3 models and the 3‑step modelling approach is in the Annex.

Figure 3.2. Methodology Diagram

The impact of potential mid- and long-term decarbonisation measures: Modelling results

Impact on import and export costs by commodity

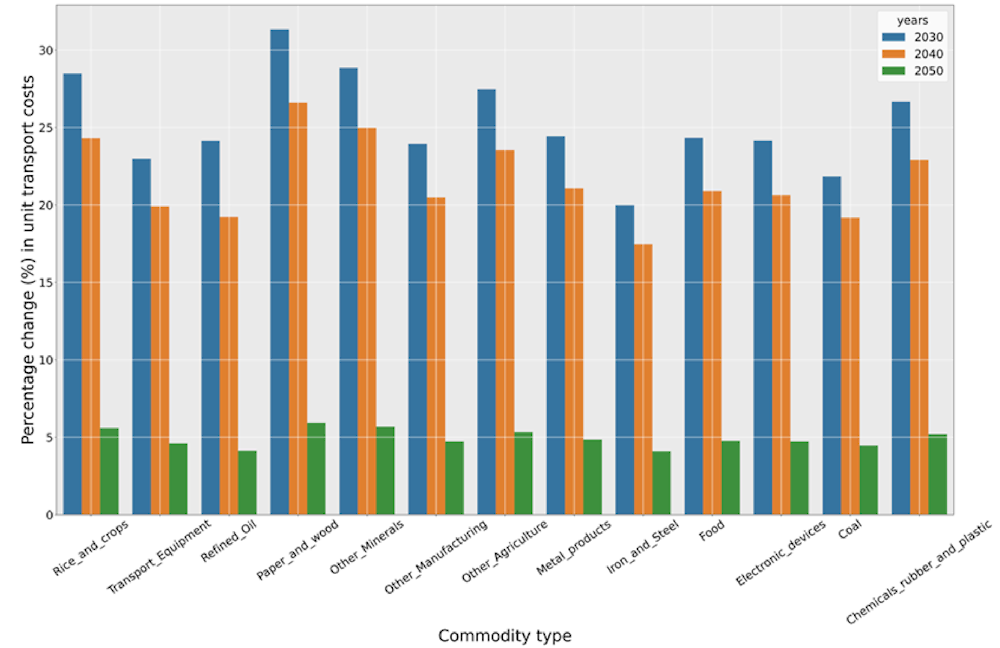

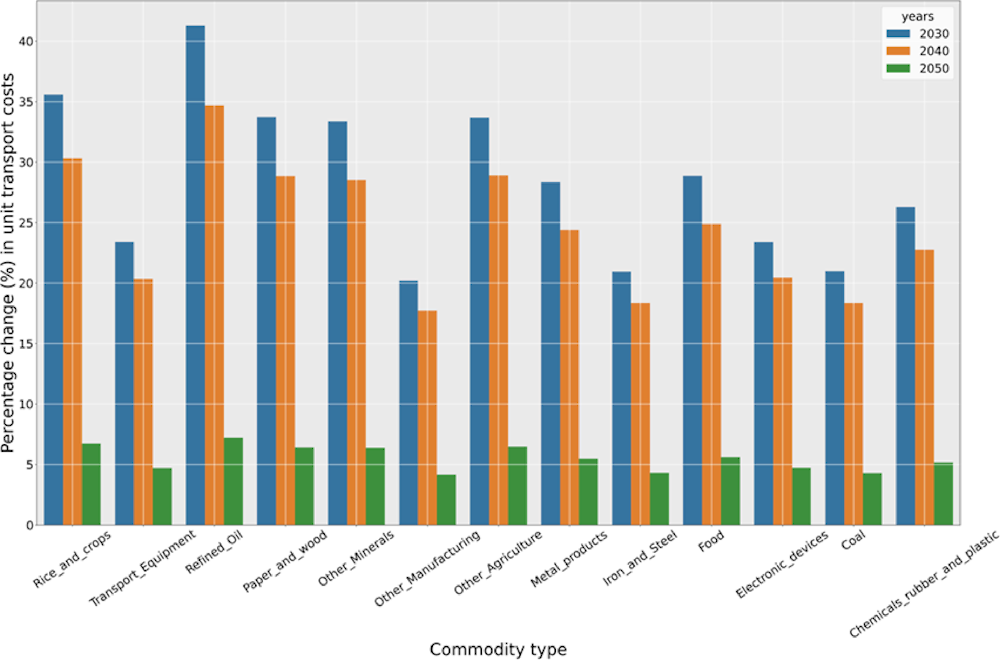

The GHG mitigation measures proposed by the EC may lead to higher ship running costs through higher fuel prices and higher capital costs. Users and producers of zero-emission fuels invest in new technologies and vessels, including advanced propulsion systems. Based on the assessment using NavigaTE, ship running costs are estimated to increase up to 20.37%, 17.78%, and 4.13% in 2030, 2040, and 2050 respectively, relative to BAU.

The estimations with the NavigaTe model suggest that the resulting increase in fuel costs due to the adoption of more expensive cleaner fuels is significantly higher than in vessel capital costs. However, this increase varies across ship types, routes, and commodities (Halim, Smith and Englert, 2019[9]). Even so, the measures will trigger a substantial increase in shipping company CAPEX around 2030 due to ship retrofitting and the purchases of ships with zero-carbon fuel capabilities.

While fuel costs may rise significantly initially, fuel costs are then projected to decrease gradually with the assumed improvement in the productivity of zero-carbon fuel production. Concurrently, lower emissions reduce costs on account of the carbon tax. Improvements in energy efficiency following regulation and technological progress, such as in hull shapes or propulsion systems, may also reduce costs. However, whether this benign long-term cost assumption materialises depends on many uncertain factors, including on the availability of renewable energy and green hydrogen world-wide, energy and hydrogen demand trends, as well as the choice of a cost minimising fuel mix, taking into account the needed energy inputs.

Table 3.1 presents the average impact on import unit transport costs of all commodities over time. By 2050, the increase in import transport costs across commodities may be relatively small. The changes in the top three commodities by import value for Hamburg are displayed in Figure 3.3 with broadly similar impacts. Across a broader range of commodity types (Annex Figure 3.A.1), import costs are estimated to increase between 20% and 32% in 2030. The highest costs concern raw materials which are mostly imported from developing countries.

Table 3.1. Projected average increase in unit transport costs across commodities imported in Hamburg

Impact of proposed IMO policy measures, relative to business-as-usual scenario

Figure 3.3. Projected increase in unit transport costs for top 3 commodities imported in Hamburg

Percent change in import unit transport costs (USD/ton-km), relative to business-as-usual scenario

Note: Estimation based on the revised 2023 IMO strategy and proposed measures by the European Commission

A similar pattern over time emerges for export unit transport costs (Table 3.2). Among the top 3 export goods for Hamburg increases in unit transport costs are bigger in the export of metal products and food than in transport equipment (Figure 3.4). They may also be somewhat bigger than in the case of unit import costs.

Table 3.2. Projected average increase in unit transport costs across commodities exported in Hamburg

Impact of proposed IMO policy measures, relative to business-as-usual scenario

Figure 3.4. Projected increase in unit transport costs for top 3 commodities exported in Hamburg

Percentage change in export unit transport costs (USD/ton-km), relative to business-as-usual scenario

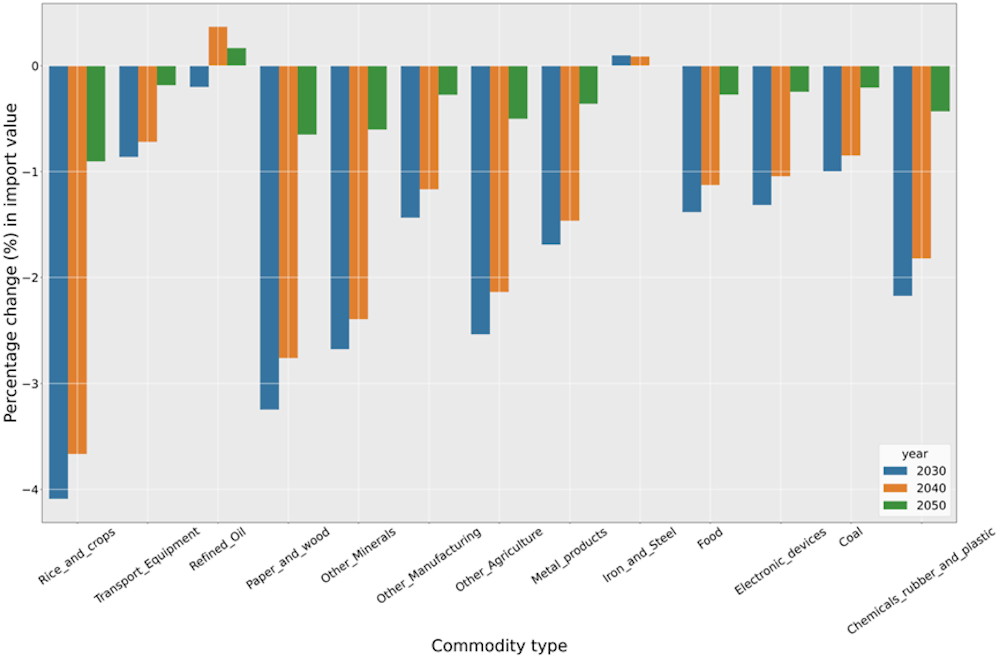

Impact on import and exports by commodity

Higher transport costs could lower trade flows, for example as a result of firms relocating production. The projected impact on Hamburg trade flows is small (Tables 3 and 4). With its diversity of trading partners, Hamburg may have more potential to accommodate and adjust to changes in origins and destinations than other ports. Indeed, the port serves as a major hub in the maritime network, supporting this flexibility.

Table 3.3. Projected total Hamburg import values

Billion USD

|

Import value |

Baseline |

Policy scenario |

Difference (%) |

|---|---|---|---|

|

2030 |

63.4 |

62.8 |

-0.9 |

|

2040 |

67.4 |

66.9 |

-0.7 |

|

2050 |

71.7 |

71.6 |

-0.2 |

Table 3.4. Projected total Hamburg export values

Billion USD

|

Import value |

Baseline |

Policy scenario |

Difference (%) |

|---|---|---|---|

|

2030 |

54,9 |

54 |

-1,7 |

|

2040 |

59,6 |

58,8 |

-1,4 |

|

2050 |

66 |

65,7 |

-0,4 |

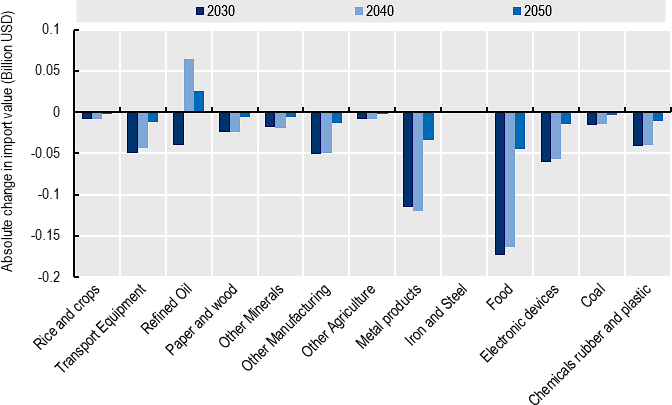

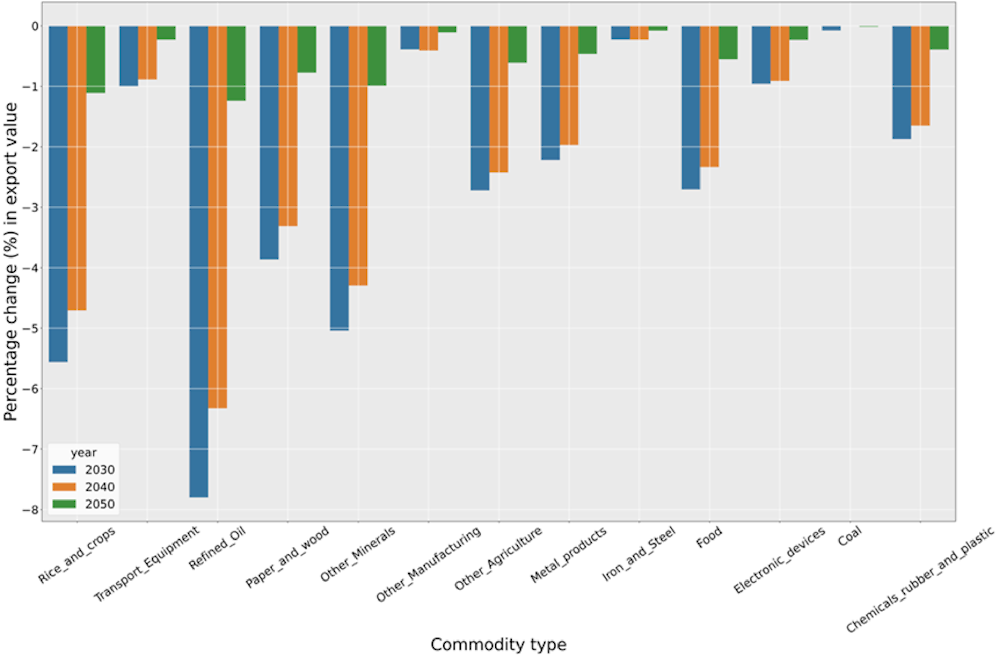

Food commodities may be subject to the most substantial decrease in both import and export values in absolute terms (Figure 3.5, Figure 3.6). Figures in the Annex present the percentage change in import and export values by commodity.

Figure 3.5. Projected change in import value of each commodity in Hamburg

Absolute change in import value (Billion USD), relative to business-as-usual scenario

Figure 3.6. Projected change in export value of each commodity in Hamburg

Absolute change in export value (Billion USD), relative to business-as-usual scenario

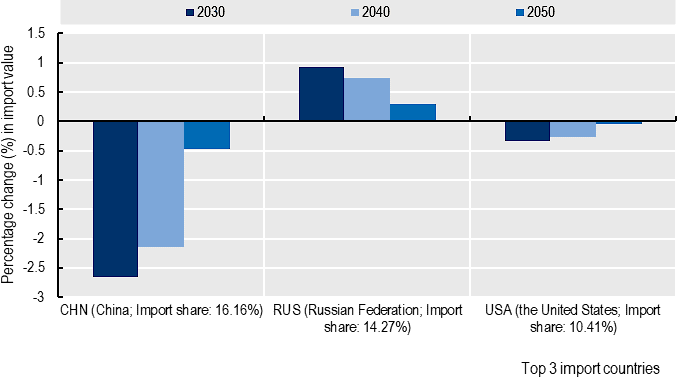

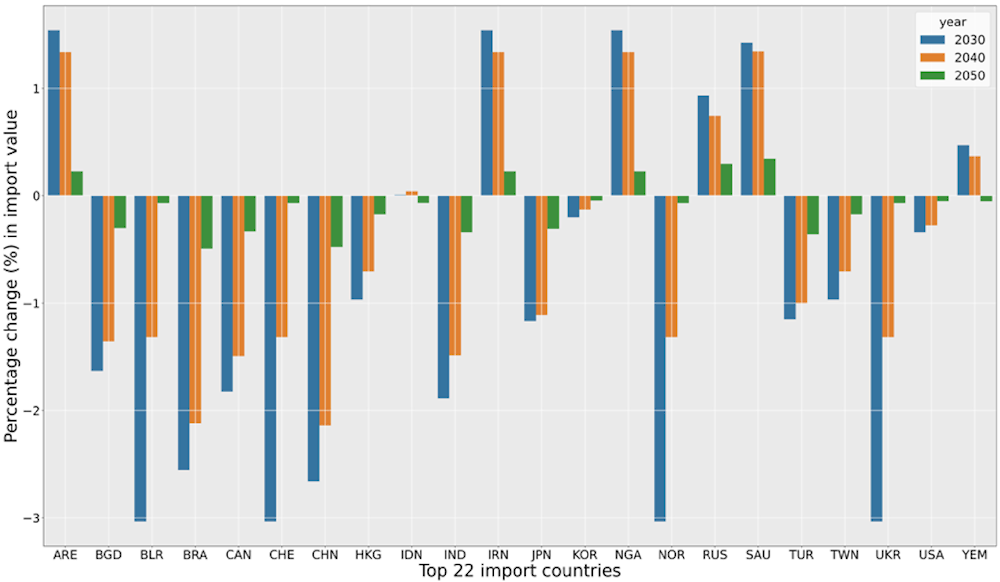

Impact on import and export value by country

Figure 3.7 displays the projected differences for the top three Hamburg trading partner countries in terms of import values, along with their respective shares in total import value in the base year (2022). The results suggest China may experience a relatively substantial decline. Figure 3 in the Annex shows the impact for the 22 countries from which Hamburg consistently imports the highest values of commodities.

Figure 3.7. Projected change in imports to Hamburg from the top 3 trading countries

Percent change in import from the top 3 countries, relative to business-as-usual scenario

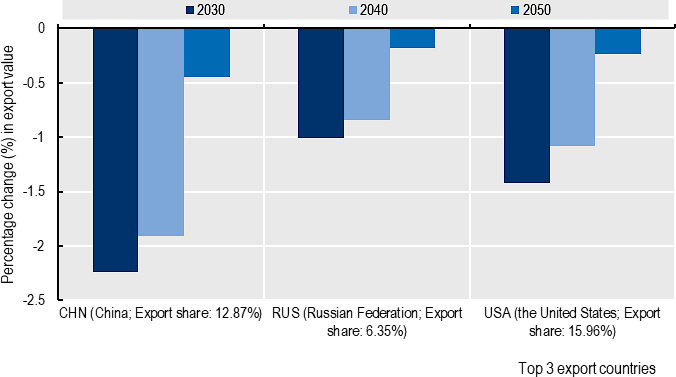

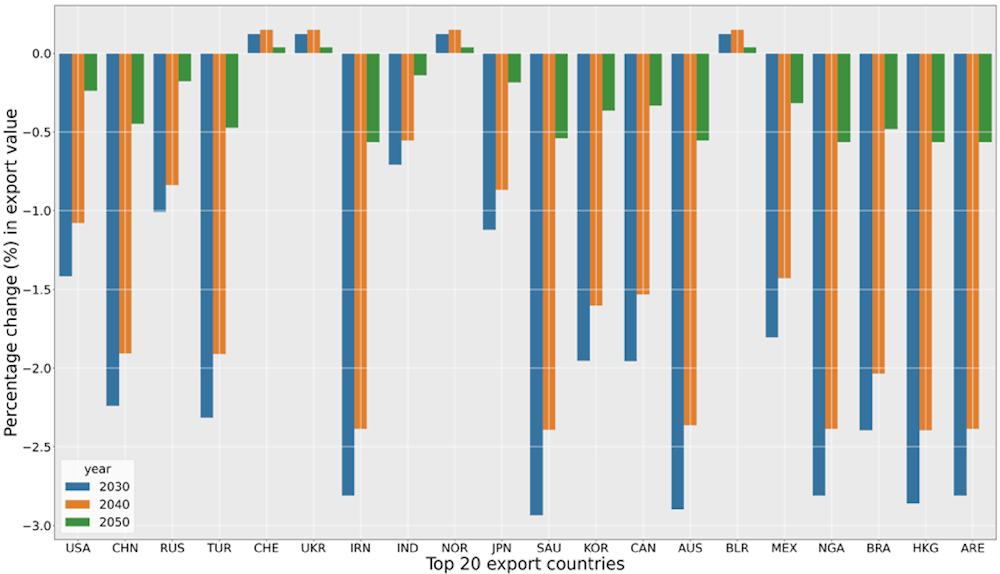

Figure 3.8 displays the changes in export value for the top three countries in the base year. The results suggest all of them experience a decline, notably China. Figure 4 in the Annex presents the analysis for the top 20 countries.

Figure 3.8. Projected change in exports from Hamburg to the top 3 trading countries

Percentage change in export of Hamburg to top 3 countries, relative to business-as-usual scenario

Key actions

Immediately

The Hamburg Chamber of Commerce could, together with the port authority, key shippers in Hamburg, as well as researchers, and in coordination with other major ports, assess advances in the deployment of zero-emission fuel and ships, with a view to promoting fuels likely to do best in terms of system-wide low cost and resilience.

The Hamburg Chamber of Commerce could encourage shipping carriers to make use of the Environmental Ship Index (ESI). It could provide incentives for shippers’ voluntary emission reduction, by rewarding companies that surpass legal emission standards.

All new ships should run on, or be able to run on, zero emission fuels, ideally anticipating a long‑term system-wide low-cost fuel mix.

By 2030

Shipping companies could augment zero-carbon fuel use, such as ammonia. Ensuring safe production, transport and delivery of zero-carbon fuel will be key to that end.

The Hamburg port could cooperate with other major ports and shipping entities to establish green shipping corridors to identify specific trade routes between major hubs that support zero-emission solutions.

The Hamburg Chamber of Commerce could continue assessing the impacts of transport costs on trade flows through Hamburg.

By 2040

Broadly complete the replacement of fossil fuels with zero-emission fuels in international maritime shipping.

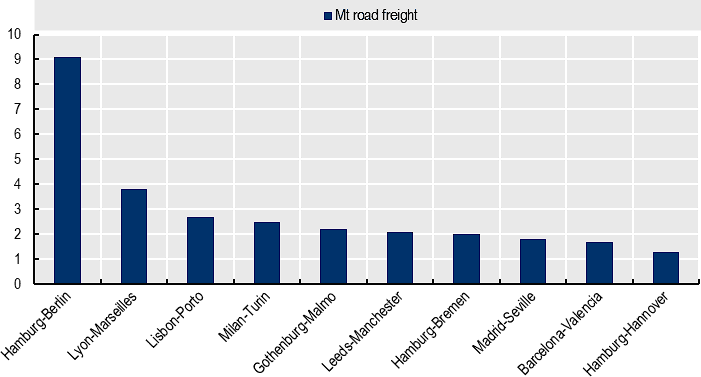

Climate neutrality in transport logistics and transport from and to the port

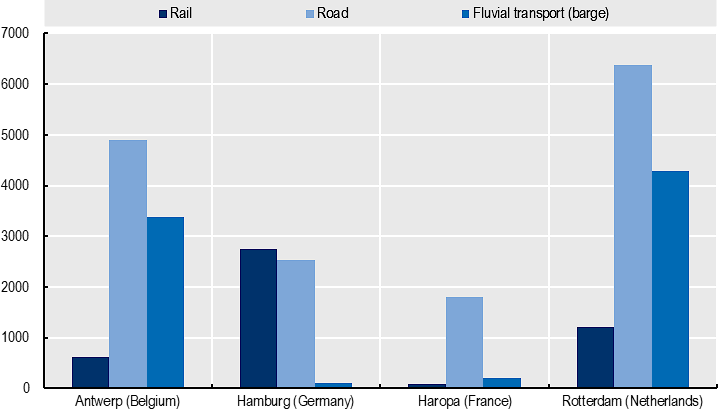

Hamburg is the largest rail port and the busiest road freight transport node in Europe, and the third largest inland water transport (IWT) port in Germany. One in seven of all rail freight journeys in Germany start or finish in Hamburg, carrying 15% of Germany’s rail freight. Some 200 freight trains use the port daily. Hamburg is the largest rail container transhipment centre in Europe. Three out of nine major European road freight transport routes – the TEN-T corridors, which account for 80% of EU road freight transport – intersect in Hamburg, which is by far the busiest node, with the Hamburg-Berlin route alone accounting for over 9 Mt annually (Figure 3.9). Hamburg is one of the largest road freight loading regions in Europe (OECD, 2021), with 40 000 trucks driving into the port daily. With good connections to the pan-European canal and river network, the port also attracts 11 000 calls annually from inland vessels travelling essentially to Berlin, Hannover and the Czech Republic.

Just over half of containers were transported by rail (50.5%), road accounting for 47.3%, and inland water transport for 2.2%. Some 53.9% of freight tonnage was by rail, 37.6% by road and 8.5% by inland water transport (Port of Hamburg Marketing, 2023[10]). In other large ports, the share of rail ranges from 7% (Le Havre and Antwerp) to 11% (Rotterdam) (Figure 3.10). Only two smaller ports reach a higher share. Inland water transport covers 9% of hinterland freight transport (mainly bulk cargo) and 2% of container transport out of Hamburg, whereas in the ports of Rotterdam or Antwerp, inland water transport accounts for half of freight tonnage and 40% of container transport.

The Port of Hamburg stands out among European ports because of the large share of rail in hinterland transport, which has almost doubled over the last 20 years, largely at the expense of road. Four main factors have helped this increase:

Hamburg has been able to leverage its position as a gateway for long-distance trade thanks to good rail connections (2 000 offered daily out of the port) and a hinterland network that could handle a large number of trains with segments with third tracks and sidings for longer trains.

An extensive railway system within the port gives rail a head start from the moment of unloading. Ports that have high shares of rail for hinterland transport, such as Gothenburg, Trieste and Koper, share this characteristic. Over half the HPA rail track is electrified, a higher share than other major ports in Europe (for instance Antwerp and Rotterdam).

There have been major investments to remove infrastructure bottlenecks within and through the port, such as the Kattwyk railway bridge, one of the largest in the world.

The governance structure of the port and a high degree of vertical integration have supported rail choices, for instance opening up HPA tracks to all 57 railway operators.

Figure 3.9. Road freight traffic over the main Ten-T corridors (2020)

Figure 3.10. Hinterland container transport from European ports by modal share

Thousand twenty-foot-equivalent container units (TEU), 2022 or the latest available date

The high share of rail in hinterland transport places Hamburg in a favourable position to work towards climate neutrality since much of its freight transport is already zero-emission. This share is concentrated in long-haul transport (up to 80% of long-haul freight is transported by rail) so that much of road transport takes place on shorter trips, a segment more amenable to electrification.

Hamburg is also a major logistics hub, combining short, medium and long-range transport with warehousing and storage services. The logistics industry occupies a significant part of Hamburg’s commercial real estate, covering one-third of its total warehousing and storage area. Urban freight logistics are a growing segment of the logistics business, bolstered by Hamburg’s high population and value-added density. In 2019, the average number of courier, express and parcel items per inhabitant in Hamburg was a third above the national average, with related traffic already accounting for about 10% of inner-city traffic.

Acting on Hamburg’s competitive advantage: governance, vertical integration and interlinkages in hinterland transport and logistics

The Port of Hamburg is an intermodal hub serving shippers and freight forwarders who are clients of a multitude of hinterland transport and logistics companies. Transport choices are often part of multimodal supply chain strategies, especially as containerisation has reduced the time and cost of transferring cargo.

The port, city transport and logistics businesses are closely interlinked through cross ownerships, partnerships and long-term commercial relationships that support the use of rail for hinterland transport:

The City of Hamburg is the majority shareholder of the HPA and of the largest port terminal operator HHLA.

Both terminal operators (HHLA and Eurogate) hold substantial equity shares in railway operators (Metrans and EUROKOMBI respectively) and rail terminals in the hinterland. EUROKOMBI is Germany’s largest intermodal railway terminal. Metrans links its port terminals to inland rail terminals in Germany, Poland, Hungary, Slovakia and the Czech Republic.

The Port of Hamburg is one of Deutsche Bahn's largest customers. In addition to Transfracht International (TFG), companies such as Railion, Intermodal, HHCE, Interconainer-Interfrigo or Kombiverkehr also transport goods straight from the port to the hinterland by rail.

Some rail freight operators, such as DB Cargo, are also active as third-party logistics companies and freight forwarders.

The actors in road hinterland transport are more dispersed, with 1 700 road haulage companies operating 45 000 trucks registered with the Hamburg Chamber of Commerce. Over 120 courier services are available in Hamburg for the transport of small and urgent consignments across Germany and beyond. Some are also active in the urban logistics business in Hamburg.

In addition to these specialised trucking and freight rail operators, combined transport operators offer intermodal services. For instance, the Hamburg-based Zippel Group has a fleet of 200 trucks and operated 2 000 block trains in 2019. Third-party logistics service providers offer storage, packaging and customs brokerage, and a range of door-to-door hinterland transport services. Container lines such as Maersk, CMA CGM, Cosco and NYK, have their own freight forwarding subsidiaries. Some freight forwarders (such as Kühne+Nagel) hold shares in shipping companies (in this example, Hapag Lloyd). DB Schenker, a division of Deutsche Bahn, is a global logistics provider.

Altogether, about 12 600 companies employ 400 000 people in the local logistics industry. Shippers range from small businesses to huge multinationals. Retail contributes to a large part of containerised shipping and procures considerable amounts of freight transport services directly or via freight forwarders. Larger retailers can own warehouses, vehicles for last-mile transport, or even their own freight forwarding companies, such as Hermes, which belongs to the Hamburg-based retailer the Otto Group, one of the world’s largest e-commerce businesses.

Breaking the link between growing freight activity and CO2 emissions

At 3 602 Mt and 417.2 billion tonne-kilometres, German freight transport is by far the largest in Europe, accounting for almost one-quarter of total EU tonnage, and twice as much as the next largest (France and Spain). The share of rail has grown from 16% to 19% over the last twenty years because the fall in traditional bulk cargo has been more than compensated by an increase in container transport, thanks to substantial investment at key connection points such as ports (BALM, 2023[12]). By contrast, in Europe, the share of freight transported by rail has halved to about 15% in the last 40 years, prompting a downward cycle of increasing fixed costs, loss of competitiveness and loss of volume.

Road freight transport in Germany reached 303.50 billion tonne-kilometres in 2022, 89% of which was national transport. Over half of road tonnage is transported less than 50 km. The German fleet of trucks numbers about 2.7 million, with close to one million vehicles over 3.5 tonnes. Some 85 000 heavy-goods vehicles (HGVs) are newly registered every year.

At 5.1% of total freight transport, Germany has one of the largest modal shares of inland water transport in Europe. Some 182.45 Mt of goods were transported on German inland waterways in 2022, of which over 75% was international transport. Around 80 % is transported on the Rhine for at least part of its journey.

Projections of the effect of current policies agree that inland freight transport will grow by at least 30% into the 2040s, and that road transport will grow more strongly, reinforcing its dominant position in the modal mix:

EU forecasts show an increase of 31% in inland freight transport by 2030 compared with 2015, and of 55% by 2050, with road freight transport growing by 35% by 2030 (ITF, 2021[13])

In Germany, a recent forecasting exercise for the Federal Ministry of Digital Affairs and Transport (BMDV) sees freight transport grow by 30% and road freight transport by 34% by 2051 compared with 2019 (Intraplan Trimode, 2023[14]).

In 2019, transport accounted for 23% of Germany’s greenhouse gas (GHG) emissions. Road transport represents 80% of total transport emissions (196 MT of CO2 equivalent), of which around 28% are from heavy-goods vehicles (UBA, 2023[15]) If projections for freight activity turn into reality, without decarbonisation, freight transport would continue to contribute substantially to CO2 emissions. EU and national emission reduction objectives therefore appear relatively ambitious:

The EU aims for a 55% reduction in GHG emissions by 2030 compared with 1990 and climate neutrality by 2050, with a 90% reduction in CO2 emissions from transport, and a 50% increase in the share of rail in freight transport by 2030 and a doubling by 2050.

Germany aims to reduce its GHG emissions by at least 65% by 2030 compared with 1990 levels, reach net-zero emissions by 2045, electrify 30% of HGV vehicle-kilometres and increase the share of rail in freight transport to 25% by 2030.

The HPA is aligned with the Hamburg Chamber of Commerce’s objective of climate neutrality by 2040. The ports of Antwerp and Rotterdam have set this objective for 2050. The HPA has also set a target of 65% for hinterland freight transport by rail by 2040, as well as a target for train container capacity utilisation of 80 TEU in 2025 (BWI, 2023[16]). HHLA has signed up for climate neutrality by 2040 concerning its operations (scope 1 and 2) and aims to reduce its emissions by 50% by 2030, compared with 2018 (HHLA, 2023[17]). Some larger transport operators have formulated emission reduction targets. For example, Deutsche Post DHL Group has set itself a 2050 climate neutrality objective, with a 2025 target to increase carbon efficiency by 50% compared with 2007. Several large shippers have carbon emission reduction targets that cover both their own operations and those of their transport and logistics service providers. For instance, the Otto Group aims to be carbon-neutral by 2030 for its transport and logistics, and IKEA aims to reduce its carbon footprint from freight transport by 70% and from logistics by 80% by 2030.

Opportunities and barriers on the way to climate neutrality

Reconciling the projected growth of freight transport with ambitious climate neutrality targets will require a major effort to decarbonise and improve energy efficiency in freight transport and logistics. Options relevant to Hamburg and its hinterland include the following:

Modal shift from road to rail

Modal shift from road to decarbonised inland water transport

Options for the decarbonisation of road transport

Energy efficiency improvements in hinterland transport and logistics

Their potential contribution to making Hamburg’s economy climate-neutral by 2040 is evaluated in this section, in terms of their costs, their effectiveness and their timeframes.

The potential for further modal shift to rail

Shifting freight from road to rail depends on two factors: making rail more attractive on the one hand and securing additional rail capacity to handle the increased demand on the other.

Distance is one of the main differentiators in mode choice: longer distances bring economies of scale and flow bundling opportunities, and reduce intermodal handling cost relative to total cost. Weight and volume are also key factors, with small volume and low-weight goods such as textiles and food products frequently shipped by road, but over 80% of coal and crude oil transported by rail or inland water transport. Rail is the most competitive transport mode for high volumes and weight, long shelf life and low sensitivity to transport conditions, over longer distances, the sweet spot being generally beyond 300 km to 500 km. Ports such as Hamburg have the advantage that they can generate the critical mass of cargo needed to operate high-frequency large-capacity shuttle trains to the hinterland.

A recent ITF study found that because rail is already very cost-effective for long-distance freight transport, when it already accounts for a large share of freight transport as is the case for hinterland transport out of Hamburg, generating modal shift is difficult (ITF, 2022[18]). The main factor blocking change is inelastic demand for road transport: the reach, speed, and flexibility of road transport are generally superior to rail, so price changes do not always alter the mode-choice decisions of shippers. Modal shift efforts therefore need to focus on increasing attractiveness beyond cost considerations, notably by encouraging multimodal transport and reducing intermodal dwell time. The modal shift requires better information so users can make the appropriate choices. Digital technology is critically important in this respect, starting in ports. The Port of Hamburg’s EVITA/TransPORT Rail digital platform includes rail information and plays an important part in supporting rail hinterland transport.

If demand for rail shifts from road transport, rail capacity will need to grow. Resolving rail bottlenecks around Hamburg involves substantial investment with long lead times. For instance, the Hamburg to Hannover corridor is at full capacity and in need of renovation, and the Hamburg to Bremen connection needs upgrading and a third track. Dry ports or extended gates have reduced bottlenecks and increased rail use in ports such as Gothenburg and Antwerp, but are not an option for Hamburg due to spatial constraints and lead times beyond 2040 (Merk and Notteboom, 2015[19]). A further issue is that in Europe, passenger rail transport is prioritised over freight, restricting access to daytime slots, especially close to critical nodes. Increasing freight capacity would require dedicated freight lines, many of which have been dismantled to cut costs. Recreating such redundancies would be a lengthy and, in some cases, an impossible task, since land has long been sold off.

It is generally considered that the most realistic solution to capacity constraints is to focus on making the best of currently available routes through large-scale digitalisation: advanced train control and signalling systems using wireless communication to supervise trains could increase capacity by more than 20% on many network lines without additional tracks (ITF, 2022[20]). The 2000 European Rail Traffic Management System legislation has led to technological improvements, but progress has been slow, partly because digitalisation requires transformation rather than a step-by-step change. Except for a few countries, the pace of digitalisation has been slow, including in Germany. The Digitaler Bedienplatz should update a portion of the system, though completion is only scheduled for 2033 to 2035.

Modal shift to decarbonised inland water transport

Cargo transport by barge emits up to ten times less CO2 per tonne than by road (and up to 5 times less than rail). However, reaching climate neutrality requires switching from barge diesel engines to zero-emission propulsion, which is a big challenge. Inland water transport shares structural characteristics with rail in terms of cost, time and flexibility. It also suffers from infrastructure restrictions, notably the bottleneck in the Scharnebeck ship lift south of Hamburg, as the new lock will not be completed until the early 2030s. The Elbe and the Rhine regularly struggle with low water levels, which are affected by climate change. In addition, within the port itself, access to barges will need to be expanded to increase capacity.

Zero-emission barges are being tested in Hamburg. A hydrogen fuel cell-powered pusher boat and a battery electric powered workboat are being tested in the port (Port of Hamburg Marketing, 2023[10]). A feasibility study for the City of Hamburg of an electrified barge for last-mile transport did not show significant energy use and emission reductions compared with electric trucks for loads under its maximum tonnage (108 tonnes), thereby reducing its usefulness for urban short-range transport of small loads (Fraunhofer Institute, 2022[21]).

The inland water transport industry is small and fragmented. The technological leap needed to move to zero-emission inland water transport is likely to require progress made with electric propulsion in sea shipping and road haulage. The uptake of new technologies will be slowed by the large variety and long lifespan of vessel hulls and engines, which exceeds 30 years. Options for totally decarbonising inland water transport therefore appear currently limited.

Decarbonising road freight transport and logistics

According to the BMDV, reducing transport CO2 emissions by up to 48% by 2030 will entail one-third of the mileage of road freight transport being zero-emission, and one-third of semi-trailer trucks (about 145 000 vehicles) being zero-emission vehicles. These are transformative challenges. The main options for decarbonising road freight transport in the 2020s and 2030 are generally considered to be:

Battery electric vehicles (BEVs)

Electric road systems (ERSs)

Hydrogen-powered fuel cell electric vehicles (FCEVs)

Though these options have been extensively analysed, major uncertainties remain as to their potential, if only because scaling up involves overcoming many technological, market and policy barriers.

Battery electric vehicles

With over one million electric cars on the road, the German electric passenger vehicle market has matured. BEVs are now also progressing in the light commercial vehicles (LCV) segment: according to the German Association of Automotive Industry, there were over 180 000 battery electric light commercial vehicles in Germany in 2021, up 6% from 2020 (VDA, 2022[22]). Much of this increase is attributable to last-mile delivery vehicles and short-haul trucks, which have predictable daily range and payload, return-to-base operations and charging.

Trips over 400 km make up around 5% of all trips in Europe but represent 40% of the EU truck activity (in tonne-km) and 20% of truck emissions, with similar figures for German road freight. BEVs with up to a 500 km range are entering the market. Charging during the driver's mandatory rest period (generally 45 minutes every 4 and a half hours) can extend the range to cover over 90% of road freight activity in Germany (T&E, 2021[11]).

The electrification of vehicles above 7.5 tonnes will require a high-power charging infrastructure. Battery electric trucks that use high-power fast charging need smaller batteries, shifting the economics of battery electric heavy-goods vehicles (ITF, 2022[23]). The numbers for the infrastructure needed are large: the European Automobile Manufacturers Association (ACEA) has estimated that heavy-goods vehicles would require up to 279 000 charging points across Europe by 2030, of which 84% would be in fleet hubs and the rest mostly public high-power points along highways and in overnight charging points (ACEA, 2022[24]).

As part of the EU “Fit for 55” package of regulation, the 2023 revision of the Alternative Fuels Infrastructure Directive mandates that 15% of the entire TEN-T be equipped with fast-charging stations at least every 120 km by 2025, increasing to 50% by 2027, and 100% by 2030, when the maximum distance between stations will be 60 km in the core TEN-T and 100 km in the comprehensive TEN-T (ICCT, 2023[25]). In Germany, the 2022 Federal Master Plan for Charging Infrastructure II proposes 10 measures to accelerate the expansion of HGV charging infrastructure, primarily information-sharing for mapping demand and grid requirements, but also tendering for a HGV fast-charging network along main transport axes (BMDV, 2022[26]). Business initiatives include a partnership of 20 research institutions and businesses, including MAN and ABB, which is working on the publicly funded “HoLa” megawatt high‑performance charging system. Daimler Truck, the Traton Group (Volkswagen) and the Volvo Group have also come together for the Milence project, which is building two-megawatt charging systems along the A2 highway.

Electric road systems

An alternative to static charging is an electric road system (ERS) with an overhead catenary line which can also recharge a truck’s battery, storing enough power to drive short distances. In Germany, Electric road systems (ERSs) are being tested with Federal funding on two short highway sections and a national road, with results expected at the end of 2024. Siemens, which is testing the concept in Germany and Sweden, estimates that 4 000 kilometres of ERS could accommodate about 60% of German truck traffic on the busiest routes.

Despite high energy efficiency, the high upfront cost of overhead cables (about EURO 10 billion for 4 000 km) appears to be a major barrier to adoption (Fraunhofer Institute et al., 2022[27]). The risk is that uptake might be limited by market inertia, or that ERS technology be rendered obsolete by BEV improvements. There are also major organisational obstacles to be overcome, such as reaching a Europe-wide agreement on technical standards.

Hydrogen-powered fuel cell electric vehicles

Hydrogen-powered FCEVs are less energy efficient than BEVs, but for heavy-goods vehicles driving long distances, weight is a game-changer: hydrogen is significantly more energy-dense. For an 800 km range truck, the weight difference can reach 2 tonnes. FCEVs can travel further with heavier payloads with shorter layover time since refuelling is generally faster than recharging. The range advantage means FCEVs would be suited for trips over 1 200 km, though such trips make up less than 9% of tonne-kilometres in Germany.

There is considerable interest in Hamburg around the hydrogen economy. A 100 MW electrolysis plant is being built on the site of the former Moorburg coal-fired power station. By 2026, it will provide green hydrogen for industrial processes, and transport and logistics (REH, 2023[28]). Ultimately it could be scaled up to 800 MW. A study for the logistics company Dachser identified Hamburg as one of 4 strategic locations where FCEVs could initially operate due to the availability of hydrogen and favourable location (Dachser, 2022[29]). The regions of Hamburg and Lower Saxony have launched an EUR 32 million project to replace diesel trucks with FCEVs. The Clean Cargo Connect project will build five hydrogen refuelling stations and two mobile refuelling facilities, as well as an electrolyser close to Oldenburg.

According to a recent ITF study, the key challenges are energy conversion losses, high vehicle cost (over EUR 400 000 compared with around EURO 250 000 for battery electric trucks and EUR 130 000 for diesel trucks), refuelling infrastructure and the price of hydrogen (ITF, 2023[30]). Fuel cells and hydrogen will likely not see substantial cost reductions from scaling up this decade. Other fuel cell markets such as maritime shipping might not start growing significantly before the 2030s.

Improving energy efficiency in hinterland transport and logistics

Energy efficiency improvements will be essential during the transition to climate neutrality and beyond, since demand for sustainable electricity will increase for a broad range of energy uses. For instance, charging the 40 000 heavy-goods vehicles that arrive in the Port of Hamburg daily would require as much as 16 GWh (for 40-tonne trucks with a battery capacity of 400 kWh). While they would not be charging simultaneously, this would require careful capacity planning. The upper-bound estimate of fuel efficiency improvements expected from the recent revision of European standards would reduce truck fuel consumption by 21% by 2030 compared with 2020. This level of efficiency would require an optimised aerodynamic tractor design, which would also reduce the electricity consumption of electric heavy-goods vehicles.

Reducing the energy intensity of freight transport also relies on route optimisation and reducing empty runs. In 2022 in Europe, 20% of all road freight kilometres were travelled by empty vehicles, with a higher share for national transport (24%) than for international transport (13%). About 20% of trucks had suboptimal loads (European Commission, 2022[31]). In Germany, the LKW Maut highway toll is estimated to have reduced empty runs by 2% (T&E, 2017). There remains scope for optimisation, especially for smaller transporters and for light commercial vehicles that will start paying the LKW Maut in 2024.

The Port of Hamburg is positioning itself as a major hub for e-commerce freight flows. E-commerce brings the challenge of managing urban logistics, with consignments in Hamburg expected to grow by 71% to 163 million by 2030. Hamburg’s 2020 Sustainable Mobility Plan includes a strategy for decarbonising urban logistics, with a 40% emission reduction target for the last mile by 2030 compared with 2017. Hamburg is a testbed for innovative solutions to handle the sharp increase in deliveries with decarbonisation and efficiency improvements. Initiated by Logistics Initiative Hamburg (LIHH), efficient delivery networks include micro-depots instead of large storage centres, floating depots on unused canal sections and shared depots, vehicles and lockers (LIHH, 2023[32]). A trial with UPS found that 100 micro-hubs in the city centre could shift 40% of last-mile deliveries to cargo bikes. Other initiatives include Digital Hub Logistics Hamburg (one of 12 digital hubs chosen by the Federal Ministry of Economics and Energy to support digitalisation), which connects companies, startups, investors and researchers. The Hamburg Ministry of Economic Affairs and Innovation is assessing the feasibility of shifting courier traffic to urban waterways with support from the EU DECARBOMILE project. LIHH and nine partners are also testing inland water transport as part of the European sustainable urban freight AVATAR project.

Logistics is more than mobility: it includes warehousing and storage, where the main measures to improve energy efficiency and reduce emissions are equipment electrification, LED lighting and adapting the layout to reduce forklift and truck movement. For instance, all the forklifts operated in Kühne+Nagel warehouses are now electrified, and 75% of lighting is LED. With the growth of e-commerce, logistics real estate is expanding, providing opportunities to build sustainably, as for a new 53 300 m2 logistics centre in Hamburg Wilhelmsburg, with geothermal heating, 6 000 m2 of solar panels to power BEVs, and state-of-the-art insulation, heating and air exchange systems to minimise energy use.

Moving faster towards climate neutrality: The effect of policy measures

“Peak internal combustion engine” for passenger cars is in sight and the electrification of road freight is underway: battery electric light commercial vehicles produced at scale can already be cost-competitive with diesel vehicles, given current battery prices (ITF, 2020[33]). The electrification of larger vehicles, because they are heavier and travel longer distances, requires expensive high-power chargers. According to ITF analysis, battery electric heavy-goods vehicles are not likely to reach total cost of ownership parity with diesel trucks until 2037. As for FCEVs, they would only be cost-competitive with hydrogen priced below EUR 2.5/kgH2 (at the pump), down from the current EUR 11/kgH2, which represents a major challenge (ITF, 2022[18]).

The cost-competitiveness of zero-emission technologies depends largely on economies of scale over the coming decade. Batteries are experiencing a self-reinforcing dynamic driving down costs in the passenger car market. This dynamic is spilling over into the urban and regional delivery truck segment. If it takes another 15 years to do so into long-haul trucking, it would be too late. Competitiveness parity should be reached before 2030 because of slow fleet turnover: in Germany, the average age of light commercial vehicles is 8 years, and 9.5 years for heavy-goods vehicles (Eurostat, 2023[34]). According to ITF’s 2023 Outlook, assuming battery electric light commercial vehicles are already competitive with diesel vehicles and that battery electric heavy-goods vehicles become so in 2030, their share of the fleet by 2040 would only be 30% to 60% for light commercial vehicles and 15% to 30% for heavy-goods vehicles (ITF, 2023[35]).

Germany has introduced one of the highest purchase subsidies for zero-emission trucks in Europe, covering up to 80% of additional vehicle costs and/or charging infrastructure, with an EUR 500 000 cap, but take-up has been small. The 2023 revision of the European HGV CO2 standards raises targets for manufacturers of zero-emission trucks to 45% of their sales from 2030, 65% from 2035 and 90% from 2040, in line with the EU Green Deal objective to decarbonise by 2050. They are designed to incentivise manufacturers to ramp up production to avoid supply bottlenecks in the zero-emission vehicle market.

The 2022 amendment to the EU Eurovignette introduces a tax of EURO 200 per tonne of CO2 for HDVs in Member Countries with public distance-based tolling, with an optional higher external-cost charge for CO2 emissions limited to 16 cents/km in all or part of their highway network. Germany’s highway toll system, the LKW Maut, introduced in 2005, applies to all vehicles over 7.5 tonnes (extended to vehicles over 3.5 tonnes in 2024), except zero-emission vehicles. Its rate ranges from 9.8 cents/km to 35.4 cents/km, depending on vehicle weight, axle number and EURO emission category (Toll Collect, 2023[36]).

Taking action for the Hamburg economy in the lead-up to climate neutrality

Achieving climate neutrality by 2040 requires a proactive attitude on the part of all stakeholders in the Hamburg economy. This calls for a dedicated plan of action by the Chamber of Commerce and by businesses active in hinterland transport and logistics.

Actions for the Hamburg Chamber of Commerce

The first step towards climate neutrality is to shift from an emission reduction strategy based largely on transition fuels, with an energy mix centred on LNG and CNG, biofuels, and grey or blue hydrogen, to one focused on zero-emission solutions relying on renewable electricity. Renewable electricity generation has long been a major feature of the city-state: 28 offshore wind farms now dot the North Sea and Baltic Sea, several of which are managed from Hamburg. The city already prioritises deep geothermal and waste heat for thermal uses so that valuable renewable electricity can be directed to transport and other hard-to-abate uses. All stakeholders should integrate the need to manage this electricity efficiently into their climate neutrality strategies.

The Port of Hamburg has been remarkably successful in promoting rail for hinterland freight transport, contributing to a virtuous circle that helped preserve the overall share of rail in Germany’s freight transport: according to a study by McKinsey, targeted rail infrastructure investment such as that by the Port of Hamburg have triggered larger shifts to rail than investments dispersed across European rail networks (McKinsey & Company, 2022[37]). The City of Hamburg has voiced support for the Federal goal of increasing the share of rail freight transport from 18% to 25% by 2030 and is keen to address the bottlenecks on railways out of Hamburg. This will require coordination with different tiers of government, including in non-transport policy areas such as spatial planning.

The city and the port benefit from a major competitive advantage in the transition to climate neutrality, since so much of hinterland freight transport is already zero-emission thanks to rail. The large share of rail, especially for long-haul trips, will provide a further advantage in decarbonising road freight transport: battery electric trucks are moving fast to cost parity with diesel in the short to medium-distance segment; for long haul trucks, this might not happen before the 2030s. In the case of Hamburg, with rail well established on long-haul routes, decarbonisation will concentrate on routes up to 300 km to 500 km where battery electric trucks are currently entering the market. This presents Hamburg with an early opportunity to position itself as a climate-neutral transport hub within the timeframe of its 2040 objective.

All zero-emission technologies require new infrastructure and investment. Now is the time for stakeholders to lay the ground, given that achieving the 2040 climate neutrality objective will require 10 to 20 years of infrastructure development. Uncertainty is amplified for long-distance freight transport since different jurisdictions could make diverging choices, making it essential to coordinate infrastructure planning along major routes out of ports into the hinterland well ahead of final technological choices.

A 2021 ITF study on zero carbon supply chains in Hamburg recommended that the HPA play a more proactive role in driving the decarbonisation of transporters by leveraging its position as a key transport node (ITF, 2021[38]). The Chamber of Commerce is well placed to encourage hinterland transport and logistics businesses to develop targets in line with the 2040 neutrality objective and support them in developing relevant strategies. This should include setting up networks and thematic committees within the Chamber so that all stakeholders coordinate and share knowledge as well as resources.

The challenge of reaching zero emissions over global supply chains is daunting: encouraging route-specific cooperation among transporters and jurisdictions makes it more manageable. Such efforts can reduce uncertainty and mobilise infrastructure investment, giving Hamburg a head start. This could involve promoting hinterland freight transport “green corridors”, similar to the zero-emission maritime green corridor route agreed in 2022 between Hamburg and Halifax (Port of Halifax, 2023[39]).

Businesses could also benefit from immediate practical help in choosing zero-emission solutions for trips using tools such as the Port of Barcelona’s “eCOcalculator” to evaluate CO2 emissions generated by transporting a container into the hinterland (Port of Barcelona, 2019[40]). This service could be extended to in-depth analysis, assessing more complex transport chains and exploring emission reduction solutions.

Hamburg is, like many other ports, deeply embedded in a metropolitan area with a densely populated hinterland. While zero-emission vehicles will eliminate CO2 emissions and tailpipe pollutants, and halve traffic noise, other impacts such as braking emissions and traffic congestion will remain and indeed grow along with the projected rise in freight transport. The future importance of BEVs also points to the need to associate decarbonisation efforts with energy and transport demand management.

Experience shows that businesses benefit from information exchange and networking to make transformations and reach financial decisions - they help find cost-effective solutions and lower transaction costs. Generally, business-based energy-intensive solutions are more readily considered than changing habits or processes to reduce energy inputs, even though energy savings are in fact the first “zero-emission fuel” (IEA, 2021[41]) and are of critical importance in view of the difficulties to expand renewable energy production to the required scale. Coordinated logistics harness such savings.

The ITF Hamburg case study also recommended stronger involvement of the city administration in zero carbon freight by initiating a coordination group for port cities in Europe and across the world to develop common policies. Coordination with jurisdictions that could be considered freight transport competitors is particularly relevant for the Chamber of Commerce to avoid carbon leakage. The city and its port are ideal backdrops to test and demonstrate zero-emission solutions. Effective policy advocacy requires a technological and policy watch of the issues involved should be formally established as soon as possible, so that relevant information can be shared in a timely fashion.

Actions for Businesses

The main obstacle for shippers is the lack of zero-emission transport solutions offered by transport operators. The large share of rail in freight transport out of the port of Hamburg provides carriers and forwarders with a head start in working towards zero-emission supply chains, compared with many other large ports. At the moment, the only zero-emission freight transport chain possible would combine rail transport with last-mile transport by BEVs, though in practice there are still unavoidable CO2 emissions because road transport has not been entirely decarbonised.

Businesses can accelerate the climate neutrality transition by investing early in zero-emission solutions, even if they initially come at a “green" cost premium which some customers are willing to pay. To succeed in these new markets, companies should design market strategies that target green segments of their business.

Many stakeholders in freight transport are interrelated. Strategic partnerships between shippers, logistics providers and their transport partners can provide a collaborative environment supportive of supply chain decarbonisation. Long-term shipping contracts that include climate neutrality criteria in contract bidding can also provide an opportunity to decarbonise transport and logistics operations.

Transport and logistics businesses with large fleets could pilot zero-emission truck adoption in clusters or along transport lanes, as a first step towards decarbonisation. Networking could help deploy private depot chargers which will be central to fleet charging needs, with access encouraged through collaboration between fleet owners, truck manufacturers, utilities and infrastructure providers.

Financing and leasing companies should turn their attention to innovative business models to overcome the upfront costs associated with zero-emission trucking, particularly for smaller operators. Solutions such as trucking-as-a-service and charging-as-a-service can facilitate the transition to zero-emission trucking for fleet owners, as they are less capital-intensive (ICCT and ECTA, 2022[42]).

The larger businesses have dedicated research and innovation centres focused on preparing for the logistics of the next decade and beyond. Hamburg, as a major industrial and transport hub, has the critical mass of knowledge and resources to support these efforts. The Chamber could work towards linking small businesses with these efforts and combining them with local scientific advice.

Key actions

Immediately

The Hamburg Chamber of Commerce could prepare hinterland freight transport green corridors through cooperation among transporters, vehicle manufacturers and infrastructure providers.

The Hamburg Chamber of Commerce could provide "ecocalculator" tools to evaluate CO2 emissions generated by transporting goods, considering emission options for individual trips and routes.

The Hamburg Chamber of Commerce could establish a technological and policy watch for monitoring and sharing information related to zero-emission options in freight transport and logistics.

Shippers should introduce decarbonisation and energy efficiency criteria in bidding processes for shipping contracts to incentivize carriers to adopt greener practices.

Transport and logistics businesses should pilot the adoption of zero-emission trucks in clusters or specific transport lanes as a step toward full decarbonisation.

Transport and logistics businesses should design a green/climate-neutral service proposition, identify target markets and create a pricing strategy for zero-emission services.

By 2030

The Hamburg Chamber of Commerce could promote leveraging Hamburg’s position as a clean energy hub, taking into account the shift from transition fuels to decarbonisation.

The Hamburg Chamber of Commerce could promote coordinated energy-saving logistics by providing information and networking.

Shippers should form strategic partnerships with logistics providers and transport partners to collaboratively work toward supply chain decarbonisation.

Transport and logistics businesses should collaborate to deploy private depot chargers for electrified heavy-goods vehicles, especially where public infrastructure is lacking.

By 2040

The Hamburg Chamber of Commerce could monitor and coordinate with other jurisdictions, notably on railway renovation and other infrastructure improvements.

The Hamburg Chamber of Commerce could continue taking account of the urban environmental impacts of freight transport, including PM emissions, traffic congestion and noise.

The transition to climate neutrality in key manufacturing sectors

As discussed in Chapter 1, manufacturing employs more than 100 thousand people in Hamburg and generates around 12% of value added. It is the most productive economic sector in the Hamburg economy. Some manufacturing sectors will be particularly hard to make climate-neutral (OECD, 2023[43]), mostly those producing basic materials, including basic metals and oil refining. They employ around 8000 workers in Hamburg. In addition, cement is produced close to Hamburg.

These sectors have depended particularly strongly on fossil fuels as inputs, both as energy carriers and as raw materials. They require high temperatures in production processes which do not easily lend themselves to electrification. Long-lived fixed capital assets characterize production in the sectors. Replacement of existing equipment may therefore need to be net-zero consistent starting in 2025 even to reach climate neutrality in 2050 (Material Economics, 2019[44]).

The manufacturing activities producing basic materials are located within the port. The port helps better integrate production in global value chains. Indeed, the production of basic materials permeates the value chains of a wide range of manufacturing products. It also depends on imports of materials and energy inputs. For example, in the EU the manufacture of basic iron and steel alone employs 375.000 workers. Upstream and downstream jobs could be 5 times as many (Oxford Economics, 2019[45]). Aluminium production employs about 230.000 workers and about 1 million workers when including indirect employment (European Aluminium, 2015[46]). Successful decarbonisation of basic materials production is therefore important beyond Hamburg on a European scale.

Transformations towards the circular economy are particularly important in manufacturing industries producing basic materials. Reducing demand for raw materials saves energy and other resources and avoids process emissions. (Sun, Lettow and Neuhoff, 2021[47]). Circular economy approaches, for example, could reduce CO2 emissions in plastics, steel, aluminium, and cement by 56% in developed economies by 2050 relative to a baseline with no further climate action and no major shift in materials intensity or industry structure (Johnson et al., 2021[48]; Sharmina et al., 2021[49]; Material Economics, 2019[44]).

Beyond climate, raw materials extraction and processing also account for substantial water, soil and air pollution and ecosystem destruction worldwide. These environmental impacts are particularly severe in basic metals production, notably steel and copper. Most global environmental impacts of extraction and processing of these key materials are projected to at least double between 2017 and 2060 if recent materials use and policy trends continue (OECD, 2019[50]). These trends need to be reversed to address the global interrelated challenges from climate change, biodiversity loss and the degradation of land.

The circular economy requires exchanging and reprocessing materials or shared-use assets among manufacturing plants or their customers. It also requires moving towards producing goods that can be used for longer, be reused, or be available for shared use. Reducing transaction costs is therefore important, for example, to ensure the precise composition of materials or the repairability of components is known. Digitalisation and industrial symbiosis can contribute:

Digitalisation can support the circular economy practices in the industry through improved tracking of product and materials composition. Major opportunities include marking technologies, low-cost sensors, and real-time tracking to provide better information on materials composition as well as automation, for example in sorting (Material Economics, 2018[51]). Other opportunities are geolocation technologies to indicate asset locations or blockchain to store information (OECD, 2020[52]). Digital technologies also reduce transaction costs in innovative circular economy business models, such as in the provision of capital goods as a service (Barteková and Börkey, 2022[53]).

Industrial symbiosis, or closed-loop recycling as it is sometimes called, involves the use of by‑products from one firm as inputs for another. Industrial symbiosis reduces intermediaries and is most common in industries that produce pure and homogeneous materials, such as the chemicals industry. Some of these relationships may develop organically or are the result of carefully planned industrial parks (OECD, 2019[54]). The partnership of industrial establishments across sectors, sharing infrastructures and their material inputs and outputs (including waste) can also optimise resource use.

Decarbonising manufacturing is a particular challenge in view of global competition and different climate policy ambitions across countries. In principle, the pricing of environmental footprints in value chains could address this challenge. The EU carbon border adjustment for steel, aluminium and cement products addresses this challenge to some extent but may expose domestic producers to deteriorated competitiveness in third markets, where such rules do not exist. Broad international alliances for the taxation of environmental footprints would therefore be useful.

The remainder of this section will take a closer look at manufacturing activities in Hamburg that are difficult to decarbonise, in particular, steel, copper, aluminium and oil refining.

Steel manufacturing

Steel is essential in the global economy for its wide manufacturing and construction applications such as automobiles, industrial machinery, buildings, railways, and bridges. Steel is also vital for capital goods and infrastructure in the net-zero transition, such as for electric vehicles and wind power. The demand may overall remain stable or slightly increase in Europe, while global demand may increase by more than a third (IEA, 2020[55]). Among heavy industries producing basic materials, iron and steel production is particularly dependent on freight services, relative to value-added, alongside non-metallic minerals (OECD, 2023[43]).

Hamburg has three installations in steel manufacturing in the EU ETS, all owned by ArcelorMittal. In 2019, emissions of the three installations summed up to 346 thousand MtCO2. ArcelorMittal is one of the world’s leading integrated steel and mining companies. Globally, they produce 69.1 million tonnes of crude steel, of which 0.9 million tonnes in Hamburg. In Hamburg, the company also produces billet and high-quality wire rods, and its production is mainly sold to automotive and engineering customers in the European market.

In the long term, decarbonisation will require the adoption of new technologies for steel production on the basis of mined raw iron (primary production). The main option without relying on Carbon Capture and Storage (CCS) is hydrogen-based direct reduction with “green” hydrogen (H-DR) (IEA, 2020[55]; Material Economics, 2019[44]). The H-DR route for making steel may be more attractive in regions with access to low-cost green hydrogen. Green hydrogen produced with renewable electricity replaces coal or natural gas as the reducing agent. Steel production in Hamburg could therefore benefit from a hydrogen hub in Hamburg to obtain access to hydrogen at the lowest possible cost, an issue taken up below. Hydrogen needs can also be avoided by outsourcing the production of iron pellets to locations with cheap hydrogen production. Iron pellets are easily transported.

Currently, most steel worldwide is produced with a combination of blast furnaces and basic oxygen furnaces (BF-BOF). Another method to produce steel is through direct reduction and electric arc furnaces (DRI-EAF). DRI-EAFs have the potential to be fully decarbonised, in terms of Scope 1 and Scope 2 emissions, using green hydrogen and climate-neutral electricity sources (Wang et al., 2021[56]; Bataille, 2020[57]) without large-scale replacement of production equipment (Box 3.5).

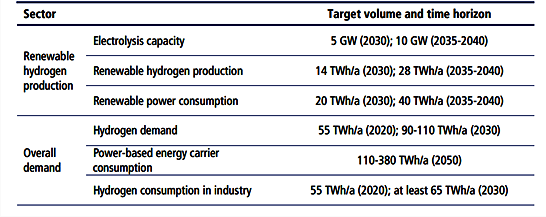

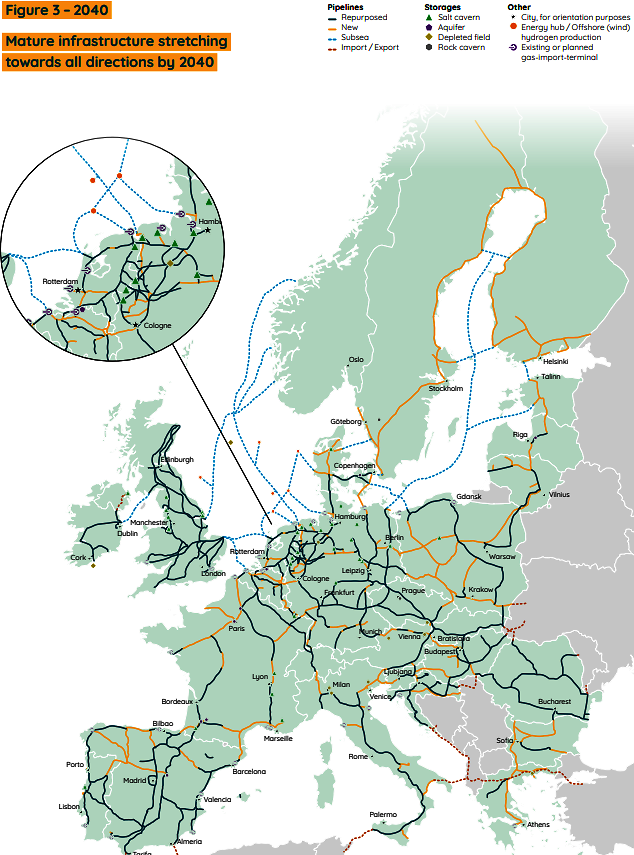

Steel in Hamburg is produced using Europe’s only DRI-EAF furnace (Eurofer, 2022[58]). Hamburg steel production is therefore relatively well-placed for decarbonisation. Even so, the new production processes will have wide implications for infrastructure such as raw materials storage and processing, transport and supply of energy, power and steam distribution and generation (Material Economics, 2019[44]). As elsewhere, steel manufacturing in Hamburg is particularly energy-intensive.