This chapter defines “electrician” as assessed by PISA-VET and elaborates the framework for electrician that has been designed for the Development Phase of the project, including descriptions of the competencies and constructs to be assessed. It presents and explains the processes, content knowledge and contexts and provides several sample items with descriptions of task characteristics. The chapter also discusses how performance in the electrician area is measured and reported against proficiency levels and scales.

PISA Vocational Education and Training (VET)

3. Electrician

Copy link to 3. ElectricianAbstract

Introduction

Copy link to IntroductionThis chapter defines the role of the “electrician” for the purpose of assessment by the PISA-VET project. The chapter elaborates the assessment framework for an electrician that has been designed for the Development Phase of the project, including descriptions of the competencies and constructs to be assessed. It presents and explains the processes, knowledge, skills, competencies, and contexts reflected in PISA-VET’s electrician tasks and provides several sample items with descriptions of task characteristics. The chapter also discusses how performance in the occupational area of electrician can be measured and reported against proficiency levels and scales.

The rationale for the inclusion of the occupation of electrician in this Development Phase is strong because of its continued economic importance and international comparability. Electric power is responsible for running every aspect of society including industry, business, entertainment, and domestic life. The role is in global demand and is dynamic – it is constantly affected by advances in technology and the sustainability (UN Department of Economic and Social Affairs, 2022[1]). For example, there is increasing demand for efficient equipment and machinery plus renewable energy.

Another reason for selecting electrician for PISA-VET is that it is a highly regulated occupation with international standards that are universally recognised. In most countries, electrical installations comply with a set of regulations, issued by National Authorities or by recognised private bodies. The International Electrotechnical Commission (IEC) is the global organisation that prepares and publishes International Standards for all electrical, electronic, and related technologies which are often adopted by countries or regions to become national or regional standards. For example, approximately eighty per cent of European electrical and electronic standards are IEC International Standards. It should be noted that due consideration will be given to regional norms and standards in the design of the assessments to ensure recognition of differences and fairness.

This chapter represents the views of a group of global experts, including experienced electricians.

Defining the Electrician occupational area

Copy link to Defining the Electrician occupational areaOccupational definition and associated VET programmes

Copy link to Occupational definition and associated VET programmesThe purpose of the PISA-VET framework is to “encompass VET learners on a trajectory to become skilled professionals able to make well-rounded judgements and decisions”, as electricians in this instance (OECD, 2022a[2]). Therefore, the aim of this section of the chapter is to precisely define electrician for the purpose of PISA-VET by:

a) using the available global classifications to help define the electrician as an occupation

b) identifying the trajectory through which learners may become skilled professional electricians, together with their intermediate destinations and milestones, while

c) building on the lessons of recent years regarding the opportunities for and challenges of international comparative assessments and judgements.

While the classifications are occupational, as a minimum they indicate the extent of learning required to fulfil each role. The literature search and analysis that follows discusses electrician qualifications and their relationship with the necessary occupational requirements in the context of this project.

This chapter makes use of the International Standard Classification of Occupations (ISCO) to define the occupation of electrician.

Within ISCO-08, the sub-major Group 74” Electrical and Electronics Trades Workers” is the one most closely related to the electrician occupational area. Separate minor groups are provided for electrical (741) and for electronics (742) equipment installers and repairers. The unit groups, shown in Table 3.1, reflect the growing convergence between computer and telecommunications technologies and aim to provide a clear distinction between those working with high tension, and low tension, equipment. ESCO further details these ISCO occupations, including electrician roles in different environments, such as “domestic electrician” (7411.1.1.1) and “industrial electrician” (7411.1.1.2).1

Table 3.1. ISCO-08 Electrical and Electronics Trades Workers

Copy link to Table 3.1. ISCO-08 Electrical and Electronics Trades Workers|

ISCO-08 code |

ISCO-08 title |

||

|---|---|---|---|

|

74 |

Electrical and Electrical Trades Workers |

||

|

741 |

Electrical Equipment Installers and Repairers |

||

|

7411 |

Building and Related Electricians |

||

|

7412 |

Electrical Mechanics and Fitters |

||

|

7413 |

Electrical Line Installers and Repairers |

||

|

742 |

Electronics and Telecommunications Installers and Repairers |

||

|

7421 |

Electronics Mechanics and Servicers |

||

|

7422 |

Information and Communications Technology Installers and Servicers |

||

In accordance with the ISCO-08 classification, the occupation of electrician comprises skilled professionals, trained to install, fit, and maintain electrical wiring systems and machinery and other electrical apparatus, electrical transmission and supply lines and cables, and electronic and telecommunications equipment and systems. As such, the professionals select material, components, and tools regarding their appropriateness to meet applying regulations and standards. Electricians engage with activities ranging from the more abstract planning in accordance with customer requests to their repair and maintenance, including the diagnoses of malfunctioning electronic devices with adequate documentation. Often specialising in either craft or industrial sub-domains, electricians require a broad content knowledge to keep systems and equipment operating within (regulatory) requirements and to prevent potential issues or hazards. In summary electrician is a very responsible role which involves much complexity and requires the ability to transfer knowledge and skills across a wide variety of environments and situations some of which are emergencies. Whilst the Electrician is normally responsible for the management of their own workload, they may work within a team.

Discussions within the group have identified that, globally, individuals undertaking initial training to be an electrician embark on a three-to-four-year VET programme which is broadly based and provides a strong foundation. The programmes will be broadly aligned to Levels 3 and 4 of the European Qualifications Framework (EQF) and will have a wide range of titles including “electrician”, “electrical installer”, electrical maintenance technician”, electrical systems installer, “electrical installation technology”, “electronics technician”, “electrical engineering”, “electrical fitter”, “home appliance maintenance and repair technician”, “electronic worker”, and “industrial automation worker”, with or without the addition of either “trade/craft sector” or “industry sector”. After successful completion of the programmes individuals normally follow a particular career pathway, with “domestic/commercial (craft)” and “industrial” being very common. Thus, it has been agreed that in developing the PISA-VET framework the focus should be on both pathways referred to by the 2009 Feasibility Study as “craft” and “industry” electricians, particularly as the Study recommended that the two pathways should be included in subsequent research (Baethge and Arends, 2009, p. 91[3]).

Table 3.2. Examples of VET programmes for electricians

Copy link to Table 3.2. Examples of VET programmes for electriciansSelected programmes in data collection countries of PISA-VET

|

Australia |

Germany |

Portugal |

United Arab Emirates |

|

|---|---|---|---|---|

|

Title |

Apprenticeship: Systems Electrician Certificate Level 3 (Australian Qualification Framework) |

Apprenticeships: Electronics Technician- FR Energy and Building Technology (Craft) Electronics Technician for Building Technology (Craft) Electronics Technician for Industrial Engineering (Industry) |

Certificate 4 in Electrical Engineering Technology |

|

|

ISCED level |

4 |

3 |

3 |

|

|

EQF level |

5 |

4 |

3 |

|

|

Duration (years) |

3 - 4 |

3.5 |

2-3 |

International comparability of the occupational area

Copy link to International comparability of the occupational areaThe VET-LSA Feasibility Study (Baethge and Arends, 2009[3]) was designed to learn if there was a common basis for comparing four selected vocational programmes in each of eight participating European countries. The comparison was focused on a “medium level of proficiency, that is, initial VET programmes at ISCED level 3 and corresponding to occupations requiring medium or considerable vocational preparation” (Baethge and Arends, 2009, p. 7[3]). As one of the four programmes, the electrician occupation was divided into craft and industry, and both were analysed.

WorldSkills International (WSI, 2022[4]) similarly divides the area into electrical installation and industrial control and presents two occupational standards at mastery level. Since 2012 each WorldSkills competition has an associated WorldSkills Occupational Standard (WSOS). The WSOSs for “Electrical Installations” and “Industrial Control” have been updated biennially since that time (WorldSkills International, 2022). The WSOSs comprise the knowledge, skills, and competencies that represent occupational mastery, globally. As such, they draw competitors from diverse initial vocational education and training (IVET) programmes and qualifications across WSI’s global membership.

At the time of the Feasibility Study, ESCO V1 had not been published. Another limitation was the use of O*NET as a reference point, given the distinct nature of the North American labour market for the role of electricians. As can be seen from the table above, the European, Skills, Competences and Occupations (ESCO, 2020[5]) classifications presents “electrician” with a set of more specific roles including “domestic and “industrial”, while O*NET On-Line includes one occupation specification, noting that electricians can have a specific focus such as “industrial”.

As noted above, the electrician occupation is a highly regulated occupation with international standards that are universally recognised. This contributes to the international comparability of the occupation area.

Organising the domain of electrician for PISA-VET

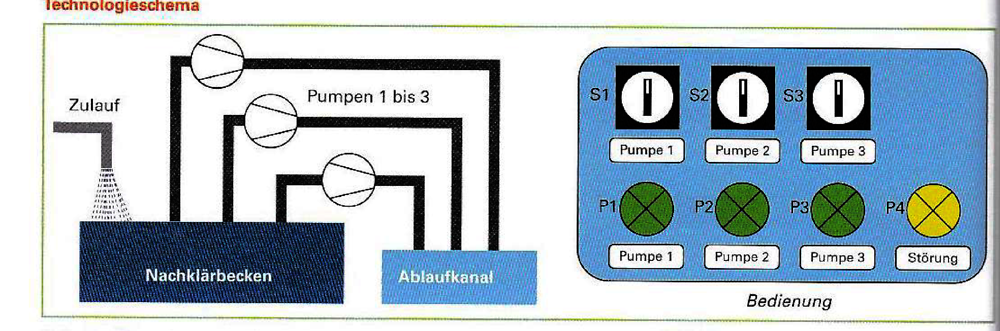

Copy link to Organising the domain of electrician for PISA-VETThis section sets out the contexts, processes, capabilities, and content knowledge required to perform the tasks of safely installing, maintaining and adjusting electrical systems and components in accordance with regulations and professional standards. This includes the reasoning and understanding necessary to select appropriate materials, components, and tools to achieve a desirable solution to a commercial or domestic challenge (e.g. based on a customer’s requirements). The domain consists of applying electrical theory and underlying fundamental concepts to electrical systems and applications. Professionals from this domain can use their expertise to implement programs for controlling motors, valves, and other devices used in industrial control. The professionals provide solutions by configuring systems and correcting detected faults.

Context

Copy link to ContextThe choice of appropriate Electrician strategies and representations is often dependent on the context in which a problem arises. For PISA-VET, it is important that a variety of contexts are used for each occupational area. This offers the possibility of connecting with the broadest possible range of individual interests and with the range of situations in which Electricians operate in the 21st century.

Electricians work broadly in three contexts: commercial and public sector, domestic, and industrial (see Table 3.3). The contexts have been selected in the light of the relevance to the demands that will be placed upon electrician students as they enter the world of work as skilled workers. The three context categories are equally demanding. The range of environments an electrician may work in, on successfully completing their initial training, is varied but there are two broad branches: “craft” and “industrial”. It should be noted that the following list of environments is not exhaustive as countries/regions will have additional specialisms (e.g., agriculture in Ireland).

Table 3.3. The environments in which Electricians work

Copy link to Table 3.3. The environments in which Electricians work|

Commercial and public sector |

Domestic (Residential) |

Industrial |

|---|---|---|

|

Education/libraries |

Houses |

Factories |

|

Museums/art galleries |

Flats/apartments |

Manufacturing plants |

|

Offices |

Bungalows |

Warehouses |

|

Hospitality establishments |

Shipyards |

|

|

Leisure/fitness |

Mines |

|

|

Shops |

Hospitals |

|

|

Entertainment venues |

Water treatment facilities |

|

|

Data centres |

Construction sites |

|

|

Server rooms |

Power generation stations |

|

|

Back-up generators |

Solar energy production |

|

|

Power Supplies |

Industrial control panels |

|

|

Government buildings |

||

|

Traffic and infrastructure systems |

Description of contexts

Copy link to Description of contextsCommercial and public sector

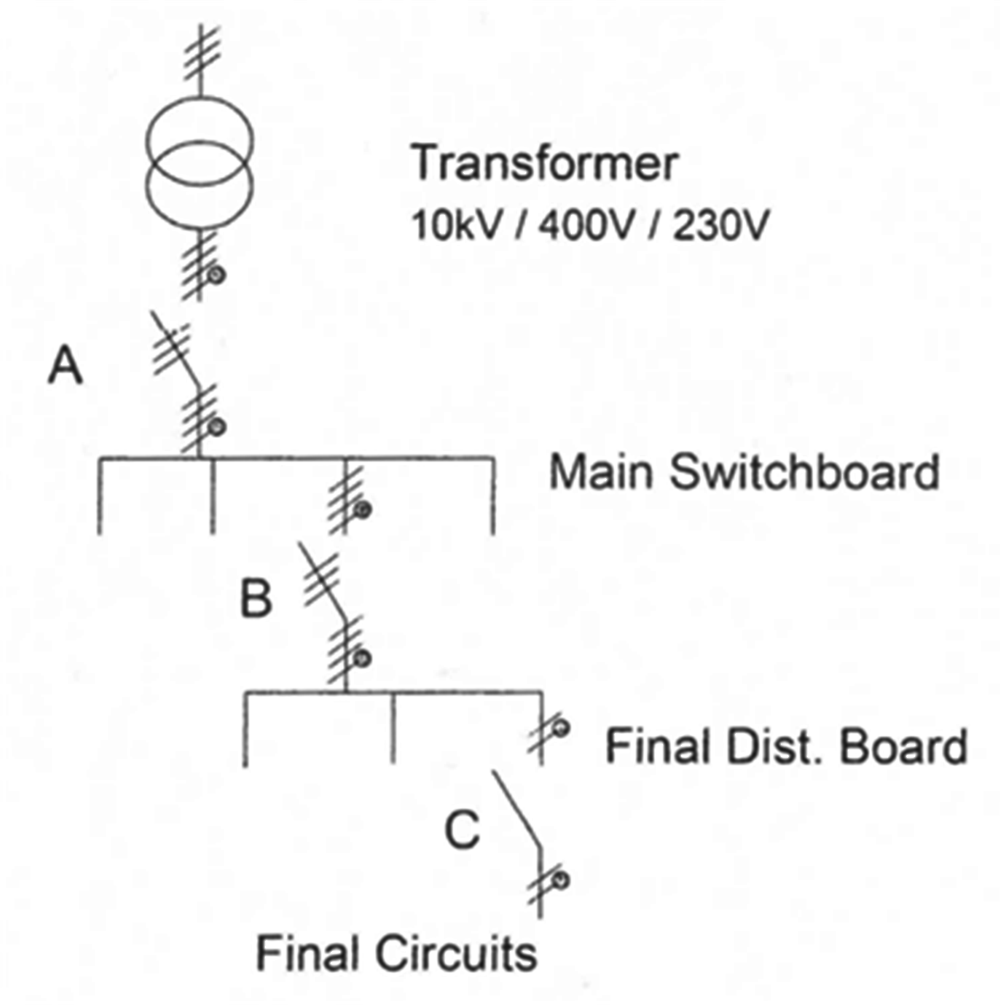

Copy link to Commercial and public sectorElectricians in the commercial sector often work in a busy public environment. They work with high voltage generators, electrical systems, appliances, traffic, transport, e.g. railway and infrastructure systems as well as heating and air conditioning units. Most Commercial Electricians work with three-phase systems, which use conductors having voltages between 120 volts and 480 volts. They also work with aerial lift operators, thus ‘working at heights’ is an integral part of the role.

There is a lot of pressure on the Commercial Electrician to be creative and quick to adapt to new challenges, in essence to work at speed. This is to prevent the client/organisation from suffering a reduction in customers/sales revenue due to ‘downtime’.

Domestic (Residential)

Copy link to Domestic (Residential)Domestic Electricians may work for small independent businesses or for providers of homes and residential services such as local authorities and housing associations, housing construction companies, care homes, electric utility companies and other companies providing electrotechnical services to the residential market. Domestic Electricians carry out electrical work mostly inside residential flats/apartments, houses and bungalows.

A Domestic Electrician will be responsible for completing their own work to specification, with minimal, if any, supervision, ensuring they meet set deadlines. The role is for people who like to work independently most of the time, but it also involves interacting with customers, colleagues, and others.

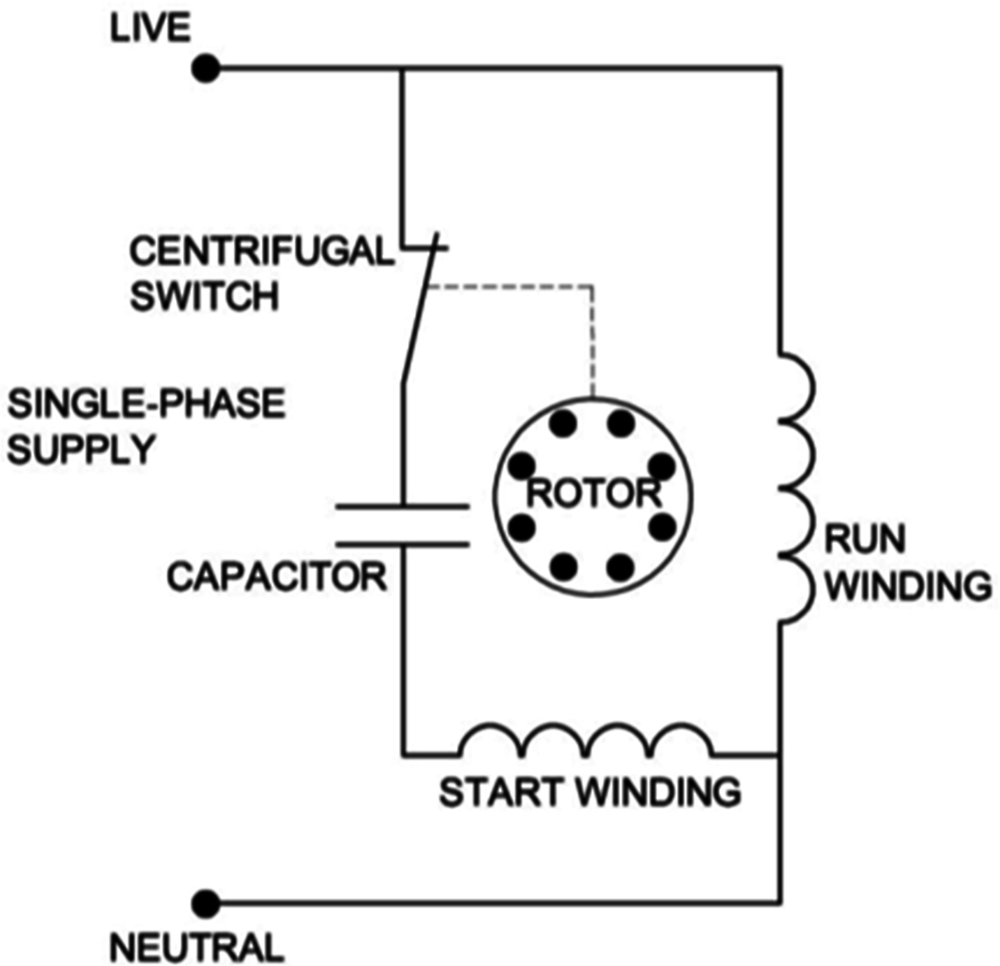

With the rising popularity of electric vehicles, the domestic electricians may install residential vehicle charging points as part of their service. Domestic Electricians typically work with single-phase voltage systems ranging from 120 volts to 240 volts.

Industrial

Copy link to IndustrialAn Industrial Electrician may work, for example, in steel production, manufacturing, and electrical power companies. Electricians in the industrial sector work in large organisations which are characterised by complex equipment and heavy machinery which requires specialist knowledge. For example, an Industrial Electrician working at a mine will need to be familiar with mining equipment, such as draglines and hydraulic shovels. Industrial projects will include large-scale plants, generators, and building environment systems.

Typical work includes installing electrical power and systems, telecommunications, fire, security systems, electronic controls, installing wires, servicing, and installing equipment. Alternative areas where an Electrician’s service is required are solar and wind power generation sites where installation work is continuously undertaken. They may be employed in one plant and install and maintain production equipment; or they may be employed by a sub-contractor and work in several industrial settings.

The working environment is likely to be one that is potentially very dangerous and hazardous. The industrial control practitioner proactively promotes best practices in health and safety and rigorously adheres to health and safety legislation. The individual is exposed to wires, conduits and other parts that carry live electricity. Some Industrial Electricians work outside in the cold or scorching heat, especially when the power is out due to inclement weather. Other Electricians work indoors in heated or air-conditioned buildings. Sometimes they stand, crouch or kneel for long periods. They also work at height if the job is inside a multi-story building.

Most Industrial Electricians work in factories and manufacturing plants, and their colleagues include building services engineers, electrical engineering technicians and security systems installers. They also work with electrical engineers, field engineers, technicians, and facility managers, as well as other specialists that could include project engineers, factory managers, project managers and cost estimators.

Companies never know when they will need an Industrial Electrician. Sometimes, they schedule an equipment repair or installation ahead of time, but if their system goes down, they need repairs immediately. For this reason, Industrial Electricians work nights, weekends and holidays. Since emergencies often occur, they frequently work longer than eight hours at a time. Most companies have part-time and short-term contracts for Industrial Electricians.

Desired distribution of items by context category

Copy link to Desired distribution of items by context categoryThis subsection provides the desired distribution of assessments selected for the Electrician domain across the context categories shown in Table 3.4. As commercial, public sector and domestic are normally clustered within “craft” no single context dominates and a balanced approach to item distribution is proposed.

Table 3.4. Percentage of items by context

Copy link to Table 3.4. Percentage of items by context|

Context category |

% of items in Assessment |

|---|---|

|

Commercial and public sector |

30 |

|

Domestic |

30 |

|

Industrial |

40 |

|

Total |

100 |

Electrician processes and the underlying occupational capabilities

Copy link to Electrician processes and the underlying occupational capabilitiesThe literature review and discussions with practising electricians and teachers/trainers of electricians have identified the following five internationally recognised processes which provide the framework within which the Electricians undertake their tasks:

assess and diagnose

plan and design

assemble and install

repair and maintain

inspect, commission, test and report.

The underlying capabilities for the electrician occupation that have been identified for PISA-VET include three of the employability skills presented in Chapter 7 of this framework document and five others. The details regarding each of these underlying capabilities are provided in a later section of this chapter. In summary, the nine underlying capabilities for Electrician:

Identifying and resolving electrical problems - the ability to identify, diagnose and resolve electrical problems in dynamic situations.

Responding to customers and colleagues - the ability to impart or exchange information with customers and colleagues, both verbally and “in writing”.

Collaborating on electrical tasks, problems, projects - the ability to work with other professionals on electrical projects and problems.

Using digital and communications technology for daily electrical tasks and problems - the ability to use digital technology, tools and networks within daily work routines.

Professional personal management skills for the electrician - the ability to regulate behaviours, thoughts, and emotions in the workplace in a productive way.

Critically assessing electrical situations – the ability to engage in reflection and independent reasoning, rigorously questioning ideas, and assumptions.

Safety consciousness in electrical situations – the ability to be constantly aware of hazards and to be alert to electrical dangers.

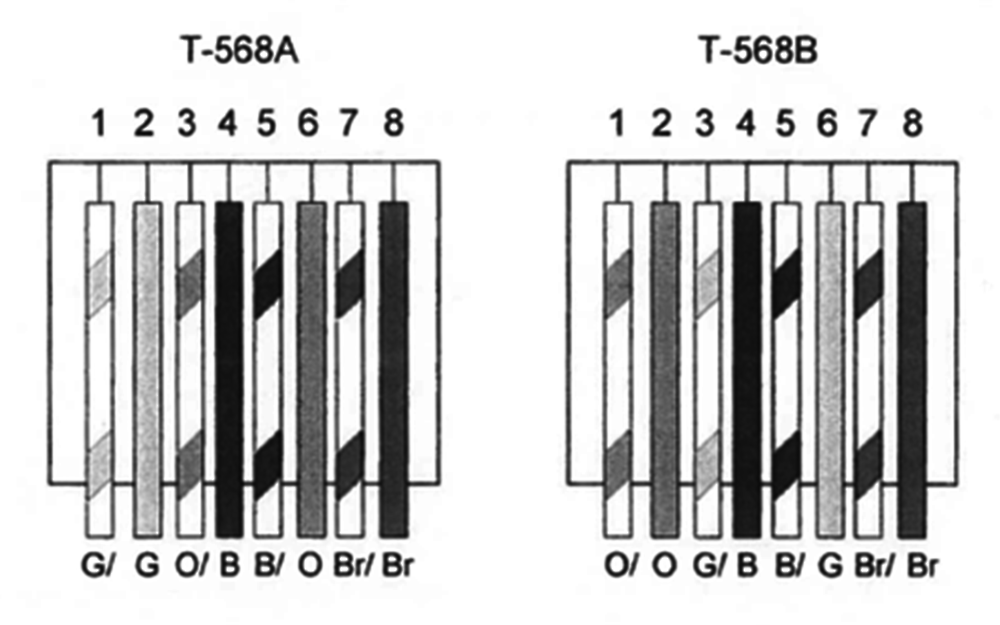

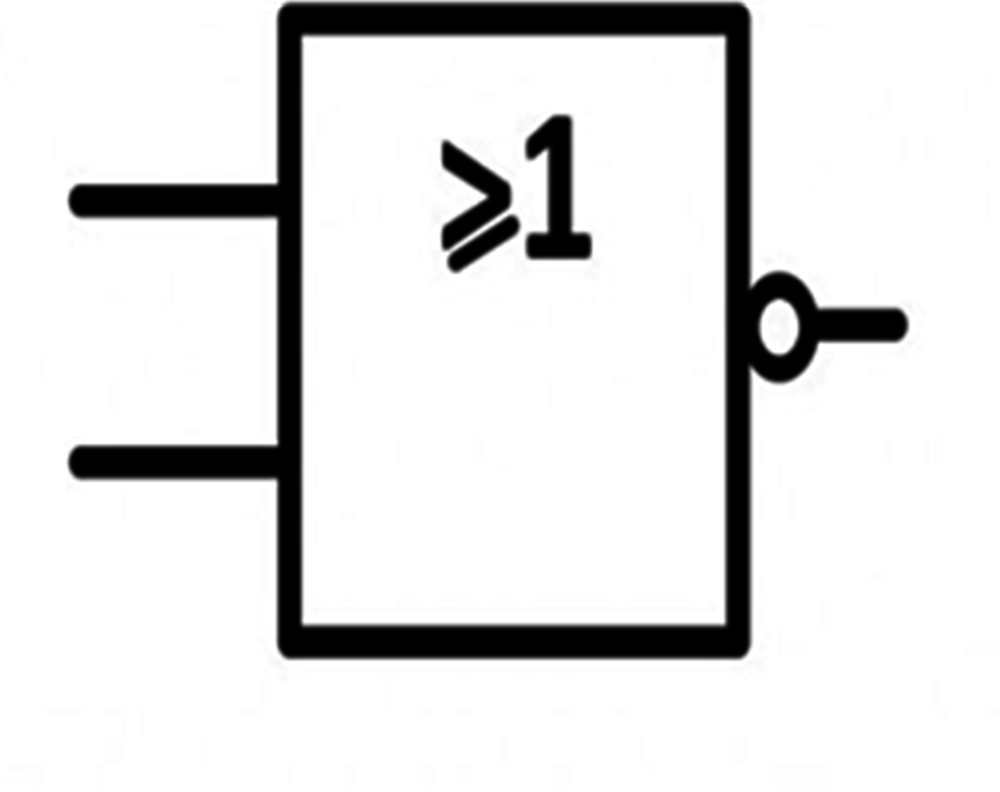

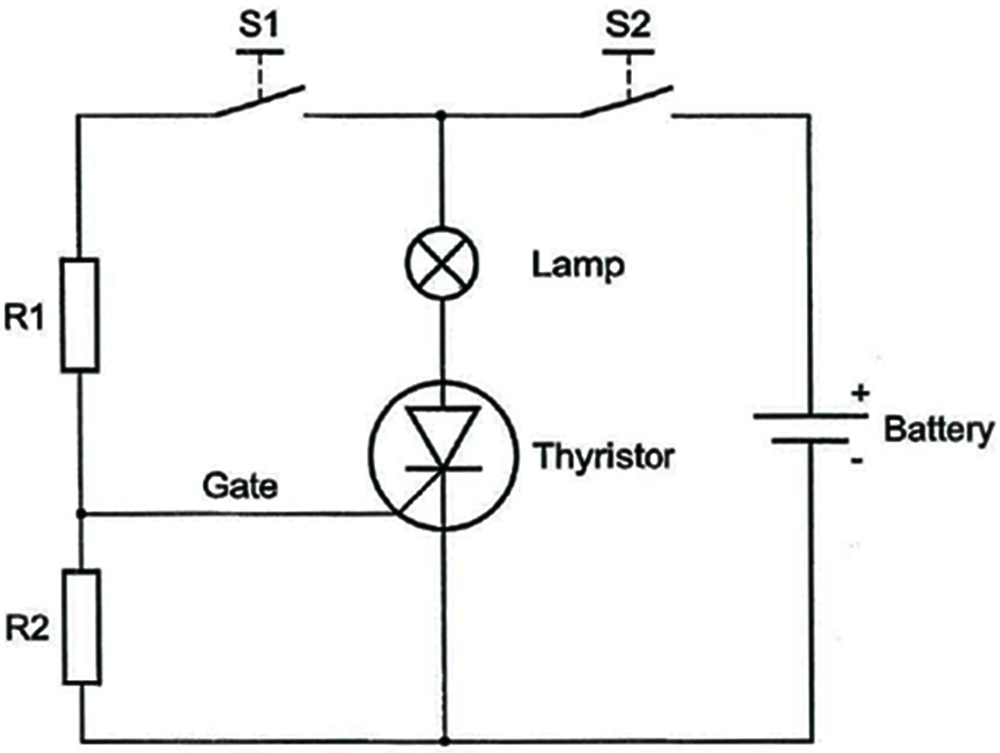

Reading electrical documentation and preparing reports - the ability to read manufacturer’s instructions, interpret electrical diagrams, write, speak and listen effectively.

Using mathematics and numeracy in daily electrical tasks and projects – the ability to deal with calculations and equations e.g. Ohm’s Law, and trigonometry.

Processes

Copy link to ProcessesProcess 1: Assess and diagnose

Copy link to Process 1: Assess and diagnoseOne of the most important processes that an Electrician engages in is to check customers/clients’ requests/requirements and identify problems in electrical systems. Before they begin any work, the electricians must review any documents used such as a customer order or a specification sheet, assess the situation generally and apply safety precautions. The diagnostic skills of electricians are critical for new tasks or for troubleshooting electrical and electronic systems. They use specialised instruments (e.g. multimeters, diagnostic devices, tools and software, and occasionally oscilloscopes) in the diagnostic process to measure, check and compare electrical quantities and further information. Often the electrical quantity does not directly correspond to the measuring device, so calculations must be performed and values checked for their plausibility. Electricians can analyse complex circuits and systems and identify and correct problems. They use their knowledge of electrical and electronic components and circuits to isolate the fault and find the exact source of the problem. They frequently disassemble the circuit or device into individual components to identify and correct the fault. Overall, the assessment and diagnostic activities of electricians are critical to the smooth operation of electrical and electronic systems. They are essential for identifying and resolving problems quickly and accurately to minimise downtime and costs.

Process 2: Plan and design

Copy link to Process 2: Plan and designThe Electrician will be involved in the process of planning and designing electrical projects (small to large, and straightforward to complex) independently, or as part of a team. This will involve in most cases the use of information technology. The overall electrical plan includes specifications, instructions, electrical layout drawings and wiring diagrams. The technical drawings and diagrams deliver visual representations of the requirements, and they consist of electrical symbols (global and national) and lines that outline the electrical design requirements. Furthermore, they detail the positions of the electrical apparatus. The specification describes in detail the overall requirements.

To plan and design a project effectively, electricians start by discussing and analysing customer/other professionals’ needs e.g. architects, engineers etc. Providing excellent ‘customer service’ is a very important part of this process and thus a high level of interpersonal skills is required. Communication and collaboration are fundamental integrated skills for an electrician when planning and designing. Communication, for example, may include providing technical and functional information about electrotechnical systems and equipment to a customer or colleague. Collaboration (teamwork) is important to maintain positive relations with other professions and minimise any potential conflict which may impact on the timing and ultimately the success of the project. Electricians may also lead a team and be responsible for manpower planning, work organisation and co-ordination, plus securing materials and tools and collaborating with other crafts during the work processes.

Planning and design processes are highly dependent on interpreting and understanding requirements, accessing information/facts from several sources (including the use of the internet), reading (e.g. manuals), understanding (e.g. recognising industry symbols), following safety requirements and instructions/procedures, international standards, national industry rules and regulations, calculating and quantifying requirements (numeracy and maths).

Process 3: Assemble and install

Copy link to Process 3: Assemble and installThe Electrician is responsible for the process of installation and assembly of containment systems (individually and as part of a team) to build cabling networks within an electrical installation. This involves following technical and manufacturers’ specifications. Using accessories and appropriate fixings, aligned and located in specified locations, is also part of this process.

Integral to the process is the installation and assembly of single phase and three phase distribution boards /enclosures, fittings, protective devices, isolation devices and associated electrical equipment. Distinguishing and selecting the correct equipment for a safe installation is very important.

The Electrician is also responsible for the termination of supply and load cables using organisation skills to mark and identify cabling and electrical equipment. In addition, Electricians are responsible for the installation and termination of circuits and sub-circuits, using various types of cables and accessories. Electricians install assemblies and electrical equipment located in specific locations, using appropriate fixings. In addition, Electricians select and install the cables and accessories required for an earthing system (main or local) to comply with wiring rules and standards.

Installation and assembly of light fittings, sockets and power outlets within manufacturers’ recommendations, incorporating overcurrent and residual current device (RCD) protection where necessary, is also undertaken by the Electrician. They install, wire and assemble motor control and power circuits utilising panel wiring accessories, protective devices and indicator devices. They also install, align, couple, connect, and test run electric motors.

Electricians also install, wire, assemble and program programmable logic controller (PLC) systems and smart/ automated systems, and interpret basic and advanced logical operations/functions. The installation and assembly of fire and intruder alarm control equipment, detecting devices, signalling devices and circuitry is also included in this process. The Electrician identifies efficiency savings in materials during the installation and assembly of equipment, minimising cost and waste to protect the environment.

The assembly and installation process are highly dependent on the Electrician understanding and checking requirements from reading plans/diagrams/sketches and collaborating and communicating with other professionals/the customer, to confirming the next steps. Following industry established safety procedures and manufacturers’ instructions, from memory and reading, are fundamental to the process.

Process 4: Repair and maintain

Copy link to Process 4: Repair and maintainThe Electrician undertakes the repair and maintenance of industrial electrical systems, complying with legislation, norms, standards and technical requirements for quality, health, safety and the environment. As part of this process, the Electricians identify:

the types of components, circuits and their positions in the updated design of the building electrical installation

preventive maintenance deadlines depending on the components of the building electrical system

the sequence of activities according to the type of maintenance to be performed on the building electrical system

the technical specifications of inputs, devices, machines, equipment and tools in the manufacturer's manuals and catalogues in accordance with building electrical maintenance

the technical maintenance procedures in a building electrical system depending on the component to be repaired or replaced

the causes and malfunctions of the building electrical system based on good maintenance practices

the technical and safety criteria applied to the maintenance of the building electrical system to be carried out based on the relevant standards.

In addition, the Electrician interprets the information provided by the customer regarding failures and the operating history of the building electrical system and selects the tools and equipment necessary for its maintenance. They apply verification tests and tests to ensure the functioning and safety of a building’s electrical system, and repair malfunctions based on good maintenance practices.

Repairing and maintaining electrical systems require the Electrician to gather information to solve operating problems and undertake preventative maintenance. The process involves communicating with customers/clients and other professionals to identify and confirm the work required. This can involve negotiation. Strong adherence to industry procedures and rules, particularly for safety, is very important.

Process 5: Inspect, commission, test, and report

Copy link to Process 5: Inspect, commission, test, and reportElectrical inspection, testing, reporting, and commissioning are critical processes in ensuring that electrical systems and equipment are safe, reliable, and functional. The inspection process involves a comprehensive examination of electrical systems and equipment to identify any potential issues or hazards. Testing is then carried out to verify that the systems and equipment are operating within acceptable parameters and meet regulatory requirements. Once the inspection and testing are complete, a detailed report is prepared, (using the appropriate documentation) that includes all findings, recommendations, and any necessary corrective actions. Finally, commissioning involves the final testing and verification of the electrical systems and equipment before they are put into service.

Effective communication and collaboration are essential during these processes, as they involve working closely with other professionals such as engineers, contractors, and project managers. Additionally, a high level of technical expertise, attention to detail, and adherence to safety regulations and industry standards are required to ensure that the inspection, testing, reporting, and commissioning processes are carried out successfully. The process is completed with the handover to the customer, with operating guidance and instructions.

Desired distribution of items by electrician process

Copy link to Desired distribution of items by electrician processThe goal in constructing the assessment is to achieve a balance in the weighting that reflects the primary focus of the processes described above. The following distribution of items is proposed:

Table 3.5. Desired distribution of electrician items, by process

Copy link to Table 3.5. Desired distribution of electrician items, by process|

Process category |

% of items in the assessment |

|---|---|

|

Assess and diagnose |

20 |

|

Plan and design |

20 |

|

Assemble and install |

20 |

|

Repair and maintain |

20 |

|

Inspect, commission, test, and report |

20 |

|

Total |

100 |

Fundamental electrician capabilities underlying the electrician processes

Copy link to Fundamental electrician capabilities underlying the electrician processesAs has been indicated in the review of the five key processes, electricians are dependent on a range of capabilities which enable them to undertake their role. These are as follows:

Identifying and resolving electrical problems

Copy link to Identifying and resolving electrical problemsA fundamental function of the Electrician is to identify, diagnose and resolve electrical problems for customers/clients in a domestic/commercial or industrial setting. The Electrician is responsible for identifying the root cause of issues and finding working solutions/offering guidance. For this reason, strong problem-solving skills are vital. When working individually they cannot rely on others for assistance, thus they must be confident in their abilities and self-reliant. Alternatively, the Electrician may be working as part of a professional team and will, therefore, be contributing to the problem-solving process. The possession of problem-solving abilities helps the Electrician to appraise diverse circumstances and develop solutions via the use of technical knowledge and critical thinking. As part of this process, the Electrician will require analytical abilities to compare potential solutions.

All five processes require problem solving skills. For example, when ‘assessing and diagnosing’ a boiler breakdown the Electrician will determine the facts through discussion with the customer/client and professional colleagues such as the plumbing and heating engineer, inspect the boiler and its connections, and work through potential solutions.

When reading ‘plans and designs’ produced, for example, by an architect, the Electrician is focussed on identifying and anticipating potential problems and making recommendations for amendments/alternatives to avoid difficulties at the implementation stage. During the ‘assembly and installation’ phase the Electrician may encounter problems linked to lack of equipment, incorrect materials, conditions, or the work of other professions; in this way they can respond quickly to changing circumstances and keep customers/clients informed as necessary. The situation is similar when the Electrician is involved in a ‘repair or maintenance’ activity because a task can unfold to reveal a more complex situation which can lead to problems such as securing parts for an old system. The ‘inspection, commissioning, testing and reporting’ process is the culmination of the work of the Electrician and this is the final opportunity to confirm there are no problems, or if need be, rectify them, and check that the system is fully operational.

Responding to customers and colleagues

Copy link to Responding to customers and colleaguesStrong verbal communication and interpersonal skills are core attributes for an Electrician because, before any electrical task is performed, they must understand how to respond to customer/client requests and concerns. Electricians must be patient as they are often dealing with people who do not have a working knowledge of electrical systems. They must be able to listen, ask the right questions, and then communicate with the customer/client and/or their professional colleagues, as necessary, to chart a course of action.

The Electrician must have a positive ‘can do’ attitude and be able to give the customer/client confidence that their electrical work will be undertaken to the right standard and be cost-effective. Building trust through effective communication is an important part of an Electrician’s job.

Clear and careful communication is a significant element of the ‘assess and diagnose’ process as the customer/client is likely to be anxious for a variety of reasons such as the time required to resolve an electrical breakdown and the impact that will have on the operation of their business. When interpreting ‘plans and designs’ the Electrician may need to raise queries and offer suggestions to professional colleagues either verbally or in writing e.g. emails and texts. As part of this process the Electrician must understand the needs/constraints of professional colleagues.

When ‘repairing and maintaining’ electrical systems the Electrician, as with the ‘assess and diagnose’ process, needs to discuss the situation with the customer/client and, as in the ‘installation’ process, research and check catalogues to order new parts and read instructions, and check rules and regulations. At the end of the ‘inspect, commission, test and report’ process the Electrician will give verbal or written feedback to the customer/client to advise of any issues that need further work and to outline the proposed solution.

Collaborating on electrical tasks, problems and projects

Copy link to Collaborating on electrical tasks, problems and projectsCollaboration will often be necessary during each of the five processes, depending on the type of electrical work required. When ‘assessing and diagnosing,’ the situation may require the Electrician to work closely with, for example, a heating and ventilation engineer to agree the work required and when it should be undertaken, together with an estimate of the time and cost.

For the ‘plan and design’ process an example would be a construction project where the client or building owner, general contractor and subcontractors, and design team, work together to make the project happen to everyone’s satisfaction. Electrical considerations may include everything from wiring for security systems installed in doorways or concealed in floors to speakers, fire alarms, and building management systems that enable heat, air conditioning, lighting and other building systems to be controlled from a central headquarters. Without effective project collaboration there may be many on-going changes, cost overruns, and deadlines missed. At worst, poor project collaboration may lead to the loss of a contract and repeat business.

When undertaking an ‘installation’, it may be necessary to discuss requirements with professional colleagues. For example, enabling smart power infrastructure is vital as we move into an increasingly all-electric era. This is only possible by propelling forward electrical innovation and efficiency – and this requires effective collaboration. Electrical contractors and panel builders must meet and exceed the growing levels of speed, reach and agility that the power industry requires. To achieve this, open partnerships must be created for digital transformation to happen. Since electrical contractors and panel builders often work together for low- and medium-voltage projects, it is vital for them to collaborate easily and respond to emerging customer demands for more digital and sustainable solutions. Deadlines are shrinking, and projects require multiple stakeholders, so connectivity and collaboration is simply good for business. Being able to think digitally and sustainably is now a requirement for success, and organisations need to have easy access to relevant expertise and shared resources to future-proof operations.

In a ‘repair/maintain’ situation the Electrician may need to collaborate with professional colleagues when the work they are planning will impact on several parts of the infrastructure/business operation. For example, an aircraft may experience an electrical failure resulting from a break in the connection between aircraft systems. A problem in one system may lead to a bus bar failure, causing a complete or partial failure of an airplane's avionics system. This could lead to the crew needing to turn off non-critical electrical items and/or diverting the aeroplane to the nearest suitable airport.

‘Commissioning’ within a large project is a collaborative, quality-driven, systematic process that focuses on verifying and documenting that a building and all its systems are planned, installed, inspected, tested, operated and managed as designed. Unforeseen issues develop during all projects. Early identification and prompt resolution may be the most important component of a successful commissioning process. From the moment commissioning begins through project completion, issues are identified, documented, communicated and tracked until they are officially resolved. The commissioning team participates in the resolution of most issue associated with their scope of work. They communicate with other team members, including the owner, designers and contractors, provide supporting documentation or research, and track the issues until they are resolved. The commissioning provider and the project management team strive for proactive issue resolution.

Using digital and communications technology for daily electrical tasks and problems

Copy link to Using digital and communications technology for daily electrical tasks and problemsDigital technology and communication tools are fully integrated into the five electrician processes. The Electrician is constantly adapting to the impact of new technology for the products and systems they install, e.g. retrofitting efficient smart lighting systems to support customers in controlling their energy consumption. Using digital tools and equipment is intrinsic to the Electrician’s role. For example, they use thermal imaging to detect infrared energy emitted from an electrical object and use a digital clamp meter to test a plant or piece of machinery. Problem solving in a technology-rich environment also involves the use of digital technology, communication tools and networks to acquire and evaluate information, communicate with others and perform practical tasks.

Electricians may use a range of analytical or scientific software, computer aided design (CAD), and industrial control procedures. They may also use customer and business management and administration applications and create information and digital content. Linked to this, the Electrician needs to understand and apply on-line security measures.

Professional personal management skills for the electrician

Copy link to Professional personal management skills for the electricianElectricians may work independently (self-employed) or be employed by an organisation/business. Whatever their employment status, Electricians often have sole responsibility for their tasks and are, therefore, self-reliant.

Self-management is the ability to regulate behaviours, thoughts, and emotions in a productive way. Aspects of self-management are adaptability, motivation, goal setting, decision-making, stress and time management, plus personal development. An Electrician with strong self-management skills knows what to do and how to act in different situations. For instance, they know how to control their frustration when suppliers change delivery dates.

Self-management has its roots in emotional intelligence where this capability may also be referred to as self-regulation. Self-regulation is supported by the capacity for self-awareness which helps individuals to create conscious access to thoughts, and feelings.

Critically assessing electrical situations

Copy link to Critically assessing electrical situationsCritical thinking is the ability to think clearly and rationally, understanding the logical connection between ideas. It is the ability to engage in reflective and independent thinking and to reason. For the Electrician it is about being an active listener rather than a passive recipient of information, for example, from a customer. The Electrician rigorously questions ideas and assumptions rather than accepting them at face value. They seek to determine the ideas, arguments and findings that represent the total situation and are open to finding that they do not. They will identify their own assumptions, beliefs and values. The skills the Electrician uses to think critically when undertaking each process include observation, analysis, interpretation, reflection, evaluation, inference, explanation, and decision making. For example, in assessing and diagnosing a malfunctioning piece of equipment in a factory, the Electrician will follow a sequence of questioning designed to identify the cause and the potential solution(s). The most important aspect of critical thinking is for the Electrician to know the purpose of their involvement, and to apply a consistent routine.

Safety consciousness in electrical situations

Copy link to Safety consciousness in electrical situationsSafety consciousness is critical for an Electrician, they must be committed to keeping the areas they work in and the equipment (powered and non-powered) they work with as safe as possible for themselves, colleagues and customers. They work in high-risk situations; thus, they need to undertake risk assessments as a regular part of their daily work. Where an area is not safe the electrician needs to know the action to take to remedy the situation. This requires a knowledge of specific electrical safety regulations.

It is important to understand the legal responsibilities of employers and employees and the role of enforcing authorities. Electricians also need to understand emergency and first aid arrangements, environmental requirements, safe storage and marking, waste control hierarchies and emergency planning. The Electrician also needs to understand the general personal health risks from workplace activities, including musculoskeletal problems and the effects of noise and stress.

Reading electrical documentation and preparing reports

Copy link to Reading electrical documentation and preparing reportsTrainee Electricians must be proficient readers to understand technical documents and technical terms, regulations and rules appropriate to the situations they may encounter. When ‘assembling and installing’ new products the Electrician must read and closely follow detailed written (technical) instructions produced by the manufacturer and check written industry rules and regulations, which may be in English. Electricians need to read and interpret wiring diagrams and operating instructions when assessing and diagnosing, assembling/installing, repairing/maintaining, inspecting, testing, commissioning, and reporting. Reading and understanding data generated by testing equipment and interpreting associated reports is also critical as is understanding inspection and commissioning procedures. Electricians must be able to read business related documentation such as invoices, accounts, emails from customers and suppliers etc.

Using mathematics and numeracy in daily electrical tasks and projects

Copy link to Using mathematics and numeracy in daily electrical tasks and projectsA certain level of numeracy (or mathematical literacy) is a necessary condition of being an Electrician. Mathematically related proficiencies such as number sense, familiarity with multiple representations of numbers, and skills in mental calculation, estimation, and the assessment of reasonableness of results are intrinsic to some aspects of the Electrician’s role. For example, Electricians need to perform routine measurements and calculations such as working out room dimensions, wiring lengths, converting watts to kilowatts, and calculating loads.

Mastering Ohm’s Law (an equation used to study electrical circuits, calculate voltage, current and resistance) is a fundamental capability for Electricians. Ohm's Law is a good example of the kind of logical thinking, problem solving, and practical mathematical skills an electrician needs. Trigonometry is used by Electricians when, for example, they are calculating the correct angle to bend a section of a conduit which is used to protect and route electrical wire when wiring a building or structure.

Table 3.6. Relationship between electrician processes and fundamental capabilities

Copy link to Table 3.6. Relationship between electrician processes and fundamental capabilities|

Processes |

|||||

|---|---|---|---|---|---|

|

Capabilities |

Assess/ diagnose |

Plan/ design |

Assemble/ install |

Repair/ maintain |

Inspect/commission/ test/report |

|

Identifying and resolving electrical problems |

√ |

√ |

√ |

√ |

√ |

|

Responding to customers and colleagues |

√ |

√ |

√ |

√ |

√ |

|

Collaborating on electrical tasks, problems and projects |

√ |

√ |

√ |

√ |

√ |

|

Using digital and communications technology for daily electrical tasks and problems |

√ |

√ |

√ |

√ |

√ |

|

Professional personal management skills for the electrician |

√ |

√ |

√ |

√ |

√ |

|

Critically assessing electrical situations |

√ |

√ |

√ |

√ |

√ |

|

Safety consciousness in electrical situations |

√ |

√ |

√ |

√ |

√ |

|

Reading electrical documentation and preparing reports |

√ |

√ |

√ |

√ |

√ |

|

Using mathematics and numeracy in daily electrical tasks and projects |

√ |

√ |

√ |

√ |

√ |

Electrician content knowledge

Copy link to Electrician content knowledgeIn addition to the capabilities needed to carry out the processes that are relevant for the electrician occupational area, electricians also need to build on content knowledge to effectively perform their tasks. The content knowledge for Electrician presented here is deemed to be relevant for trainees nearing the end of their IVET programme. For the structure of the corresponding content knowledge, common and shared areas have been placed in the centre of the five process areas. These are used here to reflect on how the curriculum is structured and to guide the item development at later stages of this project. While national VET programmes vary, the occupation of Electrician can be understood to consist of two large branches – the more domestically and commercially oriented application, often referred to as ‘craft’, and those employed in the more industrial-orientated activities, as outlined earlier.

In addition to national studies, WorldSkills Occupational Standards and occupational profiles in the classification of European Skills, Competences, Qualifications and Occupations (ESCO, 2020[5]) have been used to outline the required content knowledge. The five categories of knowledge are:

electrical theory and fundamentals (including mathematics and science)

norms, standards & regulations

materials, components, and tools

electrical systems and applications

configuration and control.

More details about the content topics underlying these knowledge categories are provided in the annex of this chapter.

Content knowledge categories

Copy link to Content knowledge categoriesElectrical theory and fundamentals

Copy link to Electrical theory and fundamentalsAt the end of their vocational training, trainees must have acquired the underlying principles of electrical theory and their fundamentals and apply them to calculate parameters in each equation. They recall the definitions and units (e.g. current, voltage and resistance). They understand technical drawings, layouts of installations and control panels, circuit diagrams, and flow charts. They can explain the mathematical relationships of voltage, current and resistance by using formulas. They apply their knowledge to design electrical circuits and systems, and to solve elementary problems involving electrical principles like Ohm’s and Kirchhoff’s laws. They identify and analyse equivalent circuits and determine the characteristics of complex AC circuits such as impedance and phase angle. The trainees use criteria such as cost, performance, reliability, safety, and environmental impact to compare different solutions for electrical problems. They assess the advantages and disadvantages of different types of electricity such as AC vs DC, single-phase vs three-phase, low-voltage vs high-voltage.

Underpinning a knowledge of electrical theory and fundamentals the trainee needs to have a deep understanding of arithmetic, algebra, geometry, calculus, statistics, and their applications (as also reflected in the capabilities which include numeracy and mathematics, see previous section).

Norms, standards, and regulations

Copy link to Norms, standards, and regulationsTrainees acquire factual knowledge related to norms that apply to their field of work. They gain knowledge of safety rules and precautions for working with electricity and which codes and standards apply to different electrical installations. They understand building codes and regulations specific to their region and trade. They understand the safety standards for working with electrical equipment and systems, such as lockout/tagout procedures, personal protective equipment (PPE), and hazard identification. Trainees can explain the meaning and purpose of norms, standards, and regulations for electrical work. They understand how safety rules and precautions protect them from electrical hazards. They evaluate given approaches regarding compliance and create solutions themselves that adhere to regulations and standards. Trainees can draw inferences from norms, standards and regulations regarding a given situation and identify inconsistencies.

Materials, components and tools

Copy link to Materials, components and toolsAt the end of their vocational training, trainees must have acquired in-depth understanding of the characteristics of materials, components, and tools used in electrical work. These include wire, conduit, boxes, connectors, switches, receptacles, circuit breakers, fuses, meters, as well as hand and power tools. Trainees can evaluate the appropriateness of selecting a given material or component based on its properties and/or in comparison to a given list of requirements. Trainees understand differences in requirements depending on the environment regarding electric lighting and heating systems. They have the required knowledge to understand the limitations and appropriateness of different materials and installation techniques in different environments. Trainees can evaluate the quality of electrical materials and components and suggest improvements under consideration of external factors (e.g. economic and/or ecological points of view).

Electrical systems and applications

Copy link to Electrical systems and applicationsTrainees understand the basic principles of electrical power generation and distribution. They are familiar with variable speed drive (VSD) technology and associated systems. They understand the difference between AC and DC systems, the characteristics of various types of electrical loads such as resistive, capacitive, and inductive. Trainees remember the terminology and symbols used in technical specifications and diagrams. They are familiar with the principles of technical drawings, circuit diagrams, layouts and function descriptions and remember different types of electric lighting, switchboards and wiring systems for usage in different fields of application and can create electrical schematics. Trainees understand structured cabling systems, remember different types of cabling, and can identify installations for specific environments. They can apply their knowledge to derive solutions that take interrelationships between different components into account.

Configuration and control

Copy link to Configuration and controlTrainees apply their knowledge to set up and configure systems to monitor different processes in buildings. They apply tools and software for parameterization and programming. They can implement programs for controlling motors, valves, and other devices used in industrial control. Trainees remember the different types of measuring instruments and understand their respective use. They understand the importance of delivering correct and proper documentation and can fill out existing forms. Trainees apply their knowledge to check parameters for electric and electronical devices, and interpreting results from fault finding procedures (e.g. using a multi-meter, PLC diagnostics). They analyse the outcome of given configurations (e.g. when monitoring systems) and develop suitable adjustments based on results of taken measurements. Trainees evaluate the functionality of a system compared to a given specification and use reports and records for verification purposes.

Desired distribution by content knowledge category

Copy link to Desired distribution by content knowledge categoryAll the content knowledge categories are deemed equally important for success thus there is a balanced distribution.

Table 3.7. Percentage of items by content knowledge category

Copy link to Table 3.7. Percentage of items by content knowledge category|

Content category |

% of items in Assessment |

|---|---|

|

Electrical theory and fundamentals (including mathematics and science) |

20 |

|

Norms, standards and regulations |

20 |

|

Materials, components and tools |

20 |

|

Electrical systems and application |

20 |

|

Configuration and control |

20 |

|

Total |

100 |

Assessing electrician learners

Copy link to Assessing electrician learnersIn this part of the chapter the focus is on the most appropriate methods to assess trainee electricians.

As described in Chapter 1, for the Development Phase of the Project the assessment will likely take the form of:

Scenario-based questions of technical and practical knowledge.

Digital simulations of professional problem solving at the workplace, and where possible.

Live or recorded demonstrations of professional skills with expert judges.

Based on a proposed 90-minute assessment of occupation-specific skills and knowledge, the first two methods of assessment are deemed most appropriate and feasible, with a suggested 60-minute allocation for the digital simulations - as they are the closest alternative to ‘a live practical test’. It was also noted that the trainees will need time to adjust to using the simulation technology.

However, if resources and testing time allows the inclusion of a live or recorded practical test would be recommended, as the best evidence of competence is gained from observing an individual undertaking task(s) in a live workplace situation. Performance tasks enable trainees to demonstrate their mastery of skills. Electricians normally undertake practical sessions as part of their learning programmes and as part of their formative and summative assessments. Generally, trainee Electricians, within their national systems, undergo a live practical ‘end test’, which is usually extensive/complex and therefore takes several hours to complete. The test is normally an important stage in the qualification/licensing process of electricians. For example, in Belgium ‘Electro Brain’ is the sectoral competence test. The trainee has six hours to complete the assembly of an electrical installation. In New Zealand trainee Electricians must undergo a practical assessment and a final computer-based examination. The practical assessment is undertaken in a decentralised way by different training providers, with results submitted to the Electrical Workers Registration Board for approval. The final examination for an electrician involves a multiple choice, computer-based test undertaken in an examination centre.

Assessment types

Copy link to Assessment typesDigital simulations of professional problem solving at the workplace

Copy link to Digital simulations of professional problem solving at the workplaceDigital simulations can be used for learning and assessment purposes. One example (for learning) is the USA skills training platform Transfr which has a package of simulations that harness the power of virtual reality (VR) and augmented reality to help educators and trainers create pathways to careers in electrical construction. Electrical Construction - Transfr Inc provides a video introduction to an electrical construction.

Simulations offer performance-based assessment which can be used to evaluate across all learning dimensions: cognitive, behavioural and affective depending upon the intended learning outcomes to be measured and the nature of the simulation developed. They lend themselves especially well to assessing professional competencies, application of knowledge, and decision-making.

The simulations will present the trainees with situations that replicate real-work challenges, giving them the same practical experiences, they face in the workplace (real, or simulated within an education and training organisation). Digital simulations are particularly suited to professions which work in high-risk/safety performance environments, such as those experienced by electricians.

The digital simulations will need to be realistic in terms of script and simulation environments and immersion will need to be high. Immersion refers to the extent to which the trainees lose their sense of being involved in a digital simulation and perceive the events in the situation as like their everyday work experience (Psotka, 1995[6]). The higher the immersion, the more likely the response from the trainee will be similar to that displayed in their usual work conditions (Psotka, 1995[6]). Hagiwara et al (2016[7]) state that the design of a digital simulation should consider the events and dynamics which could hinder immersion e.g. technology challenges.

The effectiveness of the digital simulation will be dependent on clear objectives and a strong understanding of the tasks usually performed in the workplace. The situation must be precisely defined with a tight script drawing on a team of expert practising Electricians, trainers, digital simulation designers and assessment experts. In discussing the format of the digital simulations, the group advised that visuals should be used as much as possible to aid communication across the global cohort of students, taking into consideration the sophistication/robustness of the technology available to the trainees. Finally, it was recommended that the text included should be as succinct as possible.

Below is one example of a digital simulation for proficiency level 1 (see below for further details about the proficiency levels), followed, in the annex, by more complex examples.

Table 3.8. Digital simulation example 1: Fault finding, testing, and reporting

Copy link to Table 3.8. Digital simulation example 1: Fault finding, testing, and reporting|

Proficiency level 1 At level 1 the trainee can work safely, apply basic knowledge and skills in the performance of a range of normally routine, simple and predictable tasks. They work under close supervision in structured work environments. This task requires the trainee to undertake the identification of basic faults, which is regular, standard practice. |

|---|

|

Time required for the task: 10 minutes |

|

The task: the trainee is required to:

The test circuit designs may include the following circuits:

Two of the following four installation testing faults must be included:

Additional types of installation testing faults that may also be included are:

|

|

The processes involved in this task are:

|

|

The capabilities involved in the task are:

|

|

The knowledge categories involved in the task are:

|

|

The context is: domestic. |

|

The assessment criteria for the task: the required number of faults are correctly identified following the correct process:

|

|

Note: the task must reflect the IEC standards Video: The video provides an example of what is included in electrical testing and fault finding Lecture 7: Electrical Testing and Fault Finding - YouTube |

Scenario-based questions of technical and practical knowledge

Copy link to Scenario-based questions of technical and practical knowledgeScenario-based assessments allow the trainees to apply their theoretical knowledge to the real-life workplace. They are powerful learning tools requiring students to draw from their own experiences and skills to analyse and respond to a situation. By using scenarios, teachers and trainers aim to develop student reasoning, problem solving and decision-making skills (Tunny, Papinczak and Young, 2010[8]; Bloomfield and Magney, 2009[9]). They can assess higher cognitive skills including application, analysis and evaluation.

In terms of structure, scenarios are typically short and could be described as mini-case studies which can be developed to provide different degrees of complexity. In designing the scenarios, consideration will need to be given to the level of the trainees, appropriateness of the content, and ability to gain engagement. They need to be easily understood and focused. Clearly written scenarios with a high level of visuals for the trainees are required. As part of PISA-VET in the electrician occupation area one or two scenarios could be provided (with more than one question allocated to each) to reduce the time for reading, thus maximising the time available to the trainee for answering the questions. The following is an example of a scenario question which was taken from the PISA science items released in December 2006.

Figure 3.1. Example item from PISA Science 2006

Copy link to Figure 3.1. Example item from PISA Science 2006Scenario: Wind Farms

Many people believe that wind should replace oil and coal as a source of energy for producing electricity. The structures in the picture are windmills with blades that are rotated by the wind. These rotations cause electricity to be produced by generators that are turned by the windmills.

Question 1 (selected response format)

The higher the altitude the more slowly windmills rotate at the same wind speed. Which one of the following is the best reason why the blades of windmills rotate more slowly in higher places at the same wind speed?

A. The air is less dense as altitude increases.

B. The temperature is lower as altitude increases.

C. Gravity becomes less as altitude increases.

D. It rains more often as altitude increases.

Question 2 (constructed response format)

Describe one specific advantage, and one specific disadvantage, of using wind to generate electricity compared with using fossil fuels like coal and oil.

Below is one example of a short scenario for proficiency level 1 (see below for more details about the proficiency levels), followed, in the annex, by a more complex scenario with sample questions spanning proficiency levels 1 to 5. Constructed response questions have been developed but some could be presented as selected responses, to provide a mix.

Table 3.9. Example of a potential scenario

Copy link to Table 3.9. Example of a potential scenario|

Scenario: Rewiring an office Hanna, the Electrician has visited a customer in their new offices. She assesses the electrical installation and advises the customer the wiring is not safe – it needs to be replaced, as it is very old. The office contains an entrance lobby, open plan office, private office and toilet. The customer has agreed the following details:

|

|

Proficiency level: Sample questions have been set for level 1 |

|

Time allowed: 10 minutes, but the number of questions would need to be decided |

|

Context: Commercial |

|

The knowledge categories included:

|

|

Sample questions: Q.1 List 3 points that need to be considered before any work should begin. Q.2 Briefly outline 4 problem(s) that could occur. Q.3 State the equipment and materials that will be required. Q.4 List the type of earth fault and overload protection that should be installed in the socket circuits. Q.5 List the tests (in order) that must take place on the completed installation. Q.6. Draw the circuit diagram of the electrical installation in the bathroom/toilet in coherent representation. |

Response format & item scoring

Copy link to Response format & item scoringFor both the digital simulations and the scenarios a combination of response formats is recommended. Selected-response items (questions) require trainees to select the correct answer from a list of options included in the item. Examples of selected response items include matching, true/false and multiple choice. Multiple-choice questions are common, but they do not suit all types of knowledge. They are often used to test factual recall, levels of understanding, and ability to apply learning (analysing and evaluating). For example, multiple-choice questions may be appropriate for assessing principles of electricity, basic electrical circuits, electromagnetism, basic mechanics, Star/Delta configurations, electrical equipment and A.C. circuits.

Constructed-response items ask trainees to write, or “construct,” the correct answer. Answer keys can be used to mark simple constructed-response items, such as “fill-in-the-blank”. The main challenge when setting constructed-response items is the marking process. It is more complex, requiring more time and effort from human markers. It is recommended that constructed-response items should only require the trainees to provide short answers. Technology is now supporting the process to provide automated marking. One factor to consider is the extent to which the assessment software allows for misspellings.

In summary there are many variations of question types which could be considered to support the scenarios and digital simulations. It is recommended that the assessment for the trainees includes both selected-response items and constructed-response items. This is to enable the most appropriate method to be selected for the content which is being assessed. A wider variety of item types is also potentially more engaging for the trainee. Whilst the number of female electricians in the industry is not high, as mentioned in the introduction, global efforts are being made to encourage females into the profession. This could have implications, going forward, for the item response format as research indicates that girls can be less engaged with multiple-choice questions as they tend to prefer questions which require more analysis and varied solutions (Griselda, 2020[10]).

Moreover, it is recommended that most of the items should be dichotomously marked (that is, answers should be awarded either credit or no credit), and the open constructed-response items should sometimes involve partial credit scoring, allowing answers to be assigned credit according to the differing degrees of “correctness” of the answers. The aim is to give the trainee as much opportunity as possible to demonstrate their skills and knowledge.

Reporting proficiency

Copy link to Reporting proficiencyDescriptions of the degree of Electrician competence typical of trainees for each proficiency level have been developed below. The lower score limits will be determined with data in the second stage of the Development Phase according to the standard PISA scaling procedure.

Table 3.10. Descriptors of learning outcomes

Copy link to Table 3.10. Descriptors of learning outcomes|

Level |

Lower score limit |

Descriptor |

|---|---|---|

|

6 |

To be confirmed with data |

At level 6 the trainee can work safely, has advanced knowledge and skills demonstrating the mastery and innovation required to solve challenging and significant unpredictable problems. They can deal with complex activities, organise work and make decisions in uncertain and changing situations. They can evaluate, introduce improvements, and take the initiative. They can lead others and collaborate with colleagues and teams. Key learning outcome verbs: assemble, compile, design, create, reorganise, articulate, synthesize, naturalise, value |

|

5 |

To be confirmed with data |

At level 5 the trainee can work safely. They have comprehensive, specialised, factual and theoretical knowledge. They can develop solutions to challenging problems and are able to work within an environment of uncertainty and change. They can develop their own work schedules, can manage others, and contribute to teams. Key learning outcome verbs: appraise, consider, critique, evaluate, rate, formulate, recommend, present, test, revise, redesign, estimate. |

|

4 |

To be confirmed with data |

At level 4 the trainee can work safely apply knowledge and skills in a broad range of complex, technical work activities, and problems which are mainly non-routine, adapting actions as required, and reflecting upon own performance. They can collaborate with colleagues and teams. Key learning outcome verbs: analyse, differentiate, classify, calculate, test, organise, examine, adjust, empathise, structure |

|

3 |

To be confirmed with data |

At level 3 the trainee can work safely and apply knowledge and skills in a broad range of varied routine and non-routine work activities, some of which may be complex. They can solve both routine and non-routine problems and take responsibility for the completion of tasks. They can collaborate with others through, for example, being a member of a team. Key learning outcome verbs: interpret, carry out, use, calculate, illustrate, complete, generalise, interpret, modify, predict. |

|

2 |

To be confirmed with data |

At level 2 the trainee can work safely and apply knowledge and skills in a range of normally varied work activities. They solve mainly routine problems although some tasks may be non-routine. They have some individual responsibility or autonomy. They work under supervision in a range of work environments. Key learning outcome verbs: arrange, associate, exemplify, compare, explain, predict, estimate, demonstrate, operate. |

|

1 |

To be confirmed with data |

At level 1 the trainee can work safely and apply basic knowledge and skills in the performance of a range of normally routine, simple, and predictable work tasks. They work under close supervision in structured work environments. Key learning outcome verbs: remember, understand, reproduce, outline, explain, identify, apply, discuss, review, report. |

References

[3] Baethge, M. and L. Arends (2009), “Feasibility study VET-LSA: A comparative analysis of occupational profiles and VET programmes in 8 European countries - international report”.

[9] Bloomfield, L. and A. Magney (2009), “Does Facilitator Expertise Matter?: A Perspective from Scenario-based Learning on an Old Problem-based Learning Question”, Focus on Health Professional Education: A Multi-disciplinary Journal, Vol. 10/3.

[12] Cairns, L. (1997), “Defining Capability for Education, Training and Industry, Discussion Paper No. 1”, Capable Organisations Research Project.

[5] ESCO (2020), European classification of Skills/Competences, Qualifications and Occupations, https://esco.ec.europa.eu (accessed on 16 December 2022).

[10] Griselda, S. (2020), “Different Questions, Different Gender Gap: Can the Format of Questions Explain the Gender Gap in Mathematics?”, 2020 Papers pgr710, Vol. Job Market Papers.

[7] Hagiwara, M. et al. (2016), “Measuring participants’ immersion in healthcare simulation: the development of an instrument”, Advances in Simulation, Vol. 1/1, https://doi.org/10.1186/s41077-016-0018-x.

[11] Miller, G. (1990), The assessment of clinical skills/competence/performance, https://doi.org/10.1097/00001888-199009000-00045.

[2] OECD (2022a), “International VET Assessment Framework”.

[6] Psotka, J. (1995), “Immersive training systems: Virtual reality and education and training”, Instructional Science, Vol. 23/5-6, https://doi.org/10.1007/BF00896880.

[8] Tunny, T., T. Papinczak and L. Young (2010), “Student perceptions of PBL tutor performance: A longitudinal cohort study”, Focus on Health Professional Education: A Multi-disciplinary Journal, Vol. 11/3, pp. 74-84.

[1] UN Department of Economic and Social Affairs (2022), United Nations Sustainable Development Goals Report 2022, Global Sustainable Development Report 2022.

[4] WSI (2022), Social and Personal Services, Health and Social Care, https://api.worldskills.org/resources/download/12384/14943/15871?l=en.

Further reading

Copy link to Further readingJones, K. (1995). Simulations: A Handbook for Teachers and Trainers. 3rd ed., Routledge, London, https://doi.org/10.4324/9780203761151.

ILO (2012), International Standard Classification of Occupations: ISCO-08. Vol. 1/Structure, Group Definitions and Correspondence Tables. International Labour Office, Geneva, https://www.ilo.org/wcmsp5/groups/public/---dgreports/---dcomm/---publ/documents/publication/wcms_172572.pdf.

Nyström, S. and S. Ahn (2020), “Simulation-based training in VET through the lens of a sociomaterial perspective”, Nordic Journal of Vocational Education and Training, Vol. 10/1, https://doi.org/10.3384/njvet.2242-458x.201011.

O*NET OnLine, National Center for O*NET Development, www.onetonline.org .

Annex 3.A. Content topics for guiding the assessment of electrician competence for VET learners