This chapter develops policy recommendations to support the transition to circularity in Hungary’s construction priority area, with a specific focus on buildings along all stages of their life cycle. It provides an overview of the current situation and policy framework in the country and identifies potential areas for improvement, putting forward a set of concrete policy recommendations. These recommendations are enriched with findings from international good practices.

Towards a National Circular Economy Strategy for Hungary

6. A circular transition for construction

Abstract

6.1. Circular economy opportunities in the construction industry

Construction covers economic activities related to creating, renovating, repairing and extending buildings, infrastructure and industrial facilities (OECD, 2013[1]). Construction activities play a significant role in the economy, with the performance of the industry indicating a country’s level of economic development (OECD, 2019[2]).

6.1.1. Construction is one of the largest consumers of raw materials and energy

The construction industry is one of the world’s largest consumers of raw materials and producers of waste. Close to half of all raw materials extracted globally are used for the built environment, with about 3 billion tonnes used in buildings construction every year (World Economic Forum, 2016[3]). At the same time, the industry is responsible for nearly one-third of all waste generated globally, more than two-thirds of which is discarded without further recovery and reuse (World Economic Forum, 2016[3]).

Construction is also the largest energy-consuming sector and an important emitter of carbon dioxide (CO2). In 2020, the share of buildings accounts for nearly 40% of global final energy consumption and a similar share of energy-related CO2 emissions (UNEP, 2021[4]).1 Additionally, processes related to production, transport and the use of building materials, in particular, cement, concrete and steel, account for an ever-growing CO2 footprint of buildings (IRP, 2020[5]; Material Economics, 2018[6]).

Driven by population growth and urbanisation, the construction industry will continue to significantly influence the demand for raw materials globally, further exacerbating its environmental impact. The industry therefore needs to enact transformational changes and move towards new ways of sourcing, consuming and managing end-of-life resources within its operations.

6.1.2. The circular economy offers opportunities to reduce the ecological footprint of construction

The circular economy offers several opportunities for transforming construction into a more sustainable industry. Applying the concept of circular economy to construction, and to buildings in particular, leads to a new understanding. A “circular building” is one that is developed, managed, used and reused without the unnecessary depletion of resources, environmental pollution and the degradation of ecosystems. A circular building is built in an economically responsible manner, contributes to the well-being of humans and the biosphere, and allows for the disassembly and reuse of technical elements, as well as bringing elements back into biological cycles at the end of its (extended) lifespan (adapted from ARUP (2016[7]) and Circle Economy, DGBC and Metabolic (2018[8])).

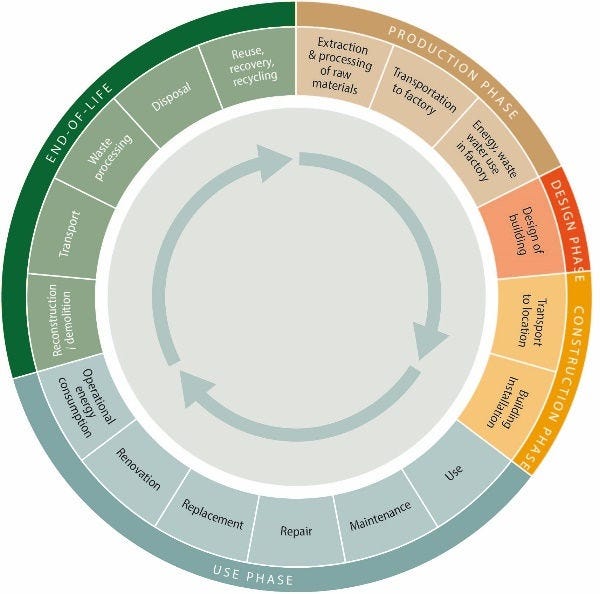

Although buildings are by definition not circular, reshaped approaches along life cycle stages can lead to their circular transformation. The life cycle stages of circular buildings (illustrated in Figure 6.1) pertain to the following circular economy principles (ARUP, 2016[7]; Circle Economy, DGBC and Metabolic, 2018[8]):

Production of construction materials. The sourcing of virgin materials for the production of building materials is reduced to a minimum and substituted with secondary raw materials (such as reused materials or components, recycled materials and bio/renewable materials), with priority given to local sourcing. Production includes material extraction and domestic material consumption of construction materials.

Design of buildings. The design of buildings is conceived within a long-term perspective, which considers both modularity and adaptability criteria as well as energy-efficient principles that minimise externalities. Operation and performance are embedded in the design and its processes, while open-source architectural design techniques allow designers, architects and engineers to distribute design ideas and build on each other’s work.

Manufacturing of construction components and construction of buildings. The process of construction accommodates more flexibility, enabling easy remodelling of buildings during renovation and easier disassembly at the end-of-life stage. Off-site manufacturing and prefabrication help eliminate waste from construction sites. Transportation of construction materials prioritises distance over price. Novel techniques, such as 3D printing, allow for the production of construction materials, components or even entire buildings at high accuracy and flexibility in design, time efficiency, lower cost and material waste production, with use of resins and substrates made from renewable or reusable materials.

Use of buildings. The life of the building is prolonged through the use of internal circular resource cycles, such as waste capture and filtering, or net-energy production. Users of circular buildings lease components and services instead of owning them. Through regular maintenance, optimal resource operation in buildings is ensured, while the premature destruction of building components is prevented through repair or small renovations. Flexible use and sharing of buildings optimise use and occupancy rates.

End-of-life of buildings and new lifetime of components and materials. The demolition of buildings is minimised and mostly limited to old and inefficient building stock. New design approaches allow easy access to building services and include demountable and reconfigurable systems. Systems or models, such as Building Information Modelling (BIM) supported by Digital Product Passports (DPPs), helps to expand, contract or redesign buildings as well as to reconstruct and deconstruct them. Cloud-based BIM models offer an opportunity to collaborate remotely and with more stakeholders. The lifetime extension of construction materials, products, components and even whole buildings is achieved through reuse, repurposing, refurbishment, recovery and recycling. These approaches maximise the value of elements in use, thereby minimising the demand for virgin raw materials.

Figure 6.1. Construction life cycle phases and the circular economy

To help increase the circularity of buildings, several circular economy strategies can be rolled out along the construction life cycle. Strategies based on using renewable and secondary raw materials during production, design for disassembly, extension of a building’s life through renovation, and the reuse of materials and components at buildings’ end-of-life contribute to unlocking the potential in materials as well as cost and resource savings throughout the entire life cycle of a building. Circular economy strategies also contribute towards mitigating environmental pollution and the degradation of ecosystems, while achieving the goal of net zero emissions.2 For circular strategies to be effective in disrupting linear practices, new innovative business models and enabling policies are required.

6.2. Role of construction in Hungary’s economy

6.2.1. Construction plays a significant role in the Hungarian economy

Construction is an important industry in the Hungarian economy. It represented almost 6% of the country’s GVA in 2020 (up from just above 4% in 2010) (Hungarian Central Statistical Office, 2022[9]). The industry’s output grew by 13% between 2020 and 2021, with growth rates in buildings at 17% and civil engineering at 9% (Hungarian Central Statistical Office, 2022[10]). Although employment within the broader industry3 has also grown since 2010, and is currently at about 5% (European Construction Sector Observatory, 2021[11]), the industry has been facing severe shortages in skilled labour (Institute for Economic and Enterprise Research, 2019[12]). SMEs employed almost 92% of total persons employed in the broader industry in 2018, highlighting the prominence of SMEs in the industry (European Commission, 2021[13]). The Hungarian housing market has also seen a continuous increase in prices for almost a decade, reflecting a surge in demand for self-owned apartments and houses. This trend has been driven by rising disposable incomes, urbanisation, falling interest rates as well as certain government measures (European Construction Sector Observatory, 2021[11]).

6.2.2. Hungary’s domestic material use is expanding and is dominated by construction minerals

Hungary’s economic growth over the past decade has been accompanied by a huge expansion in the use of materials. Of the construction materials used, non-energy minerals extracted domestically include aggregates (such as sand, gravel, building and dimension stone) and industrial minerals (such as raw materials for cement, lime and the ceramic industry, as well as silica sand, gypsum, perlite, zeolite, diatomite and bentonite). In contrast, Hungary’s metal mining has been in decline for decades, with only bauxite and manganese ores currently mined in the country (MinPol, 2017[14]). To satisfy domestic demand, Hungary relies heavily on materials imports (as discussed in chapter 2). In 2016, about one-third of materials used domestically were imported (OECD, 2018[15]).

Hungary’s domestic materials consumption per capita (30 kg per person per day) ranked below the OECD Europe average (35 kg per person per day) in 2016 (Eurostat, 2022[16]). Following a downturn between 2008 and 2012 due to the economic crisis, the growth in the country’s domestic materials consumption has resumed, as has the consumption of construction minerals (OECD, 2020[17]). At 96 000 tonnes, construction minerals represent almost 43% of materials consumed by the Hungarian economy – a share comparable to the OECD average (OECD, 2020[17]).

6.2.3. Construction output has been increasing, yet the country’s residential building stock remains outdated

The value of production in construction in Hungary has been growing year on year.4 This value in 2020 was approximately EUR 8 720 million, having more than doubled in the course of a decade (with EUR 4 270 million in 2010).5 The split between buildings and civil engineering has remained roughly equal over time (with respective shares of 57% and 43% in 2020 compared to 50% and 50% in 2010) (Hungarian Central Statistical Office, 2022[18]).

However, the country has an ageing stock of residential buildings. There were more than 3.7 million residential dwellings in Hungary in 2021, with a total floor area of approximately 274 million square metres (m2). The country’s residential building stock (a 96% share) is dominated by single-occupancy or terraced houses (with 1 to 3 apartments). However, nearly one-quarter of housing stock was built before 1945. One-half was built between 1946 and 1980. Houses built after 2001 represent only about 8% of the total stock (Ministry for Innovation and Technology, 2021[19]). The housing stock is therefore in urgent need of renovation. Although the renewal rate of residential building stock is increasing, it remains low at around 1% (compared to the annual renovation target of 3% of total housing stock by 2030 (Ministry for Innovation and Technology, 2021[19])).

Public buildings are owned by the Hungarian State and local governments (and managed by the Hungarian National Asset Management Company), as well as by churches and private owners. Between 2011 and 2019, 780 new properties were built, most of which were office and commercial buildings (Ministry for Innovation and Technology, 2021[19]).

6.2.4. Growth in the construction industry is fuelling the surge in Hungary’s waste generation

The construction industry was responsible for about one-third of Hungary’s total waste generation (Eurostat, 2020[20]).6 Driven by expansion of the construction industry, by nearly 30% in 2017 (Hungarian Central Statistical Office, 2022[9]), the growing amount of construction and demolition waste (CDW) has been the main contributor of total waste generated in Hungary. CDW grew by nearly 70% in 2018, its highest growth rate) (Eurostat, 2020[20]).7 As the development of the construction industry remains a priority for the national economy, it is expected to have a continued significant impact on CDW generation in the near future (Ministry for Innovation and Technology, 2021[21]). The materials composition of Hungarian CDW reveals that the largest waste category (by weight) is composed of concrete, bricks and ceramics (around 55%), followed by metals and their alloys (around 35%) (BRE et al., 2017[22]).

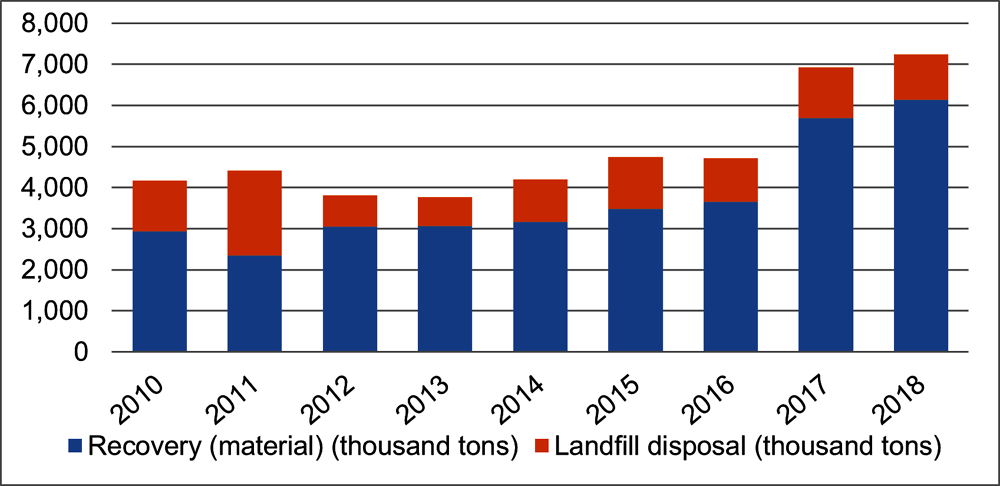

In terms of treatment, the amount of landfilled CDW has decreased over time, while the recovery rate has increased over the same period (see Figure 6.2).8 The recovery rate for CDW, in line with the calculation methods of the Waste Framework Directive (WFD), reached 68.5% in 2018 (Ministry for Innovation and Technology, 2021[21]).9 By December 2020, the combined rate of preparation for reuse, recycling and other materials recovery of non-hazardous CDW increased to at least 70% by weight of the amount generated, thereby fulfilling the EU target under the WFD. However, the materials reported as recovered also includes a considerable amount of backfilling.10

Figure 6.2. CDW treatment in Hungary between 2010-2018 (based on EWC codes)

6.3. Hungarian construction-related policy and legal framework

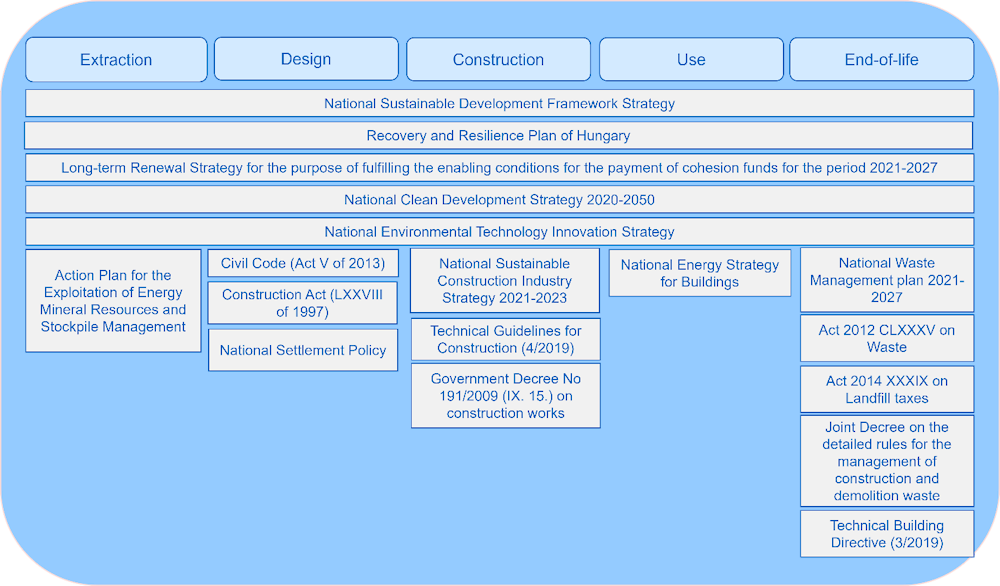

6.3.1. Several strategies address the sustainability of buildings in Hungary, yet only a few target greater efficiency in material uses

Hungary’s policy reform ambitions for more sustainable buildings are reflected across several cross-cutting and sector-specific policies and legislations (see Figure 6.3). However, only a few directly target circular economy principles. The majority of policy documents address circular economy indirectly, targeting various related topics, such as energy modernisation during renovations, energy efficiency in buildings use, renewable energy, and smart technology uses in buildings, with the ultimate goal of reducing energy imports and strengthening decarbonisation potentials.11 As energy performance is the key environmental concern in the construction of buildings, materials life cycle considerations remain largely underrepresented in the cross-cutting flagship policy documents, including in the National Recovery and Resilience Plan (RRP) (Government of Hungary, 2021[23]), the National Clean Development Strategy 2020-2050 (Ministry for Innovation and Technology, 2021[24]), and the Long-term Renovation Strategy (LTRS) (Ministry for Innovation and Technology, 2021[19]). A comprehensive sectoral strategy, integrating material and energy efficiency, is therefore missing in Hungary.

Figure 6.3. Overview of Hungarian construction-related strategies and policies

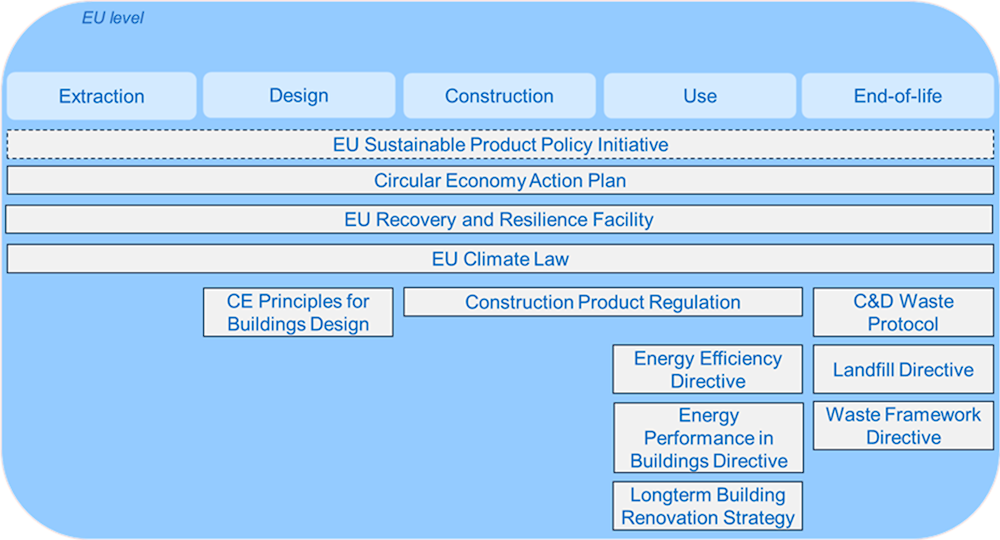

Hungary’s construction-related policy framework and related objectives align with the obligations set out in the EU legislation (see Annex Box 6.A.1 for an outline of relevant EU policies and legislation). However, its national goals and targets do not go beyond any of these obligations. The rate of preparation for reuse, recycling and other materials recovery of non-hazardous CDW remains Hungary’s only quantitative target, directly supporting the transition to a circular building construction sector.12 Although its legislative framework on CDW is currently under revision, the government has no plans for setting any sector-specific targets to drive the transition further.

6.3.2. The construction policy framework has a strong focus on the end-of-life phase

From a life cycle perspective, the Hungarian construction policy framework has a strong focus on the end-of-life phase (see Figure 6.3). Yet, no specific national strategy on CDW has been developed thus far. The management of CDW in Hungary is regulated by the Act 2012 CLXXXV on Waste (Parliament of Hungary, 2012[25]), with the NWMP 2021-2027 and its Waste Prevention Plan guiding the implementation of strategic objectives for CDW (Ministry for Innovation and Technology, 2021[21]). These documents outline the strategic objectives for a more sustainable management of CDW, including a higher rate of preparation for reuse and recycling, the promotion of selective demolition and on-site recovery, a reduction in the amount of waste landfilled, a greater number of drop-off opportunities for the public, and improved control, monitoring and quality control. The documents also put forward specific courses of action, including a number of measures to reach the 70% target rate of preparation for the reuse and recycling of non-hazardous CDW (as outlined in Annex Box 6.A.2).13

Hungary also has regulations in place detailing specific rules for the management of CDW. For buildings, these set out the obligations for builders after the completion of construction and demolition activities, and regulate the classification and certification of some CDW streams for their reuse (45/2004. [VII. 26.] BM-KvVM Joint Decree and Technical Building Directive [3/2019]). For road construction, legal provisions and technical guidelines regulate the procurement and use of secondary construction raw materials (Government Decree No. 93/2012 [V. 10.], Article 5(5) of Act CXXVIII of 2003, e-UT 05.02.31, e-UT 05.02.15, e-UT 05.02.41).

6.3.3. Concrete measures for circular construction are largely absent from Hungary’s upstream policies except for the construction phase of the life cycle

Principles for the circular use of raw materials are so far missing from Hungary’s upstream policy framework. No comprehensive strategy or policy exists for the use of either primary or secondary raw materials in the production of construction materials.14 For the design of buildings, the provisions regulating the design and implementation of building projects (Civil Code [Act V of 2013]) and the protection of the built environment (Construction Act [Act LXXVIII of 1997]) lack focus with regard to the use of secondary raw materials, circular design principles, and the recovery of building materials or CDW. The country is also missing an all-encompassing national urban policy document.

In the construction phase, the recent National Sustainable Construction Industry Strategy addresses some of the principles of a circular construction sector (Ministry for Innovation and Tehcnology, 2021[26]). While the strategy lists some objectives that are directly or indirectly related to a circular transition (including green building materials and technologies, use of innovative technologies and efficient manufacturing processes), it falls short of outlining concrete measures for their implementation or metrics for evaluating their progress. Requirements and conditions for the use of recycled construction materials and products, their incorporation into construction works, production control requirements, as well as the classification of the CDW generated, based on its material quality, are regulated by the Technical Guideline for Construction as well as by Government Decree No 191/2009 (IX. 15.).

6.4. Life cycle gap analysis and policy recommendations for a transition towards a circular building construction sector

Although the government is committed to advancing environmental sustainability perspectives, as shown in the overview of Hungarian policies in the previous section, applying circular economy principles in the building construction sector is not yet a political priority for the country. Hungary has no comprehensive national strategy in place for the transition to a circular building construction sector. Moreover, Hungary’s strategic goals and quantitative targets, spelled out in policies and strategies supporting the circular economy transition, remain at a high level (in contrast to the indirectly related targets for energy consumption, efficiency and decarbonisation).

The implementation of circular economy principles within this priority area in Hungary will require a “whole of life cycle” approach with the involvement of stakeholders from across the entire value chain and different parts of the government. Hungary will need to implement the planned revisions in its legislative framework on CDW and to strengthen the focus on the remaining parts of the construction life cycle.15 This will require introducing new policies in the production of materials and in the design of buildings, as well as strengthening existing measures targeting construction, renovation and the end-of-life of buildings. Dedicated horizontal tools to improve collaboration among stakeholders, strengthening capacity, knowledge transfer and education, and enhancing data availability must also be established to facilitate the transition towards a circular building construction sector.

This section identifies areas for improvement to further the circularity of construction in Hungary with a focus on the life cycle of buildings. The advancement of horizontal measures facilitating the circular transition of buildings is also discussed. Additionally, some perspectives on the end-of-life of road construction are considered.

6.4.1. To make the production of construction materials more circular requires policies to further the uptake of secondary materials and to curb the extraction of their virgin alternatives

The economic growth and the continuous expansion of the country’s construction output have been putting pressure on Hungary’s domestic extraction of virgin raw materials and their imports. These have been further exacerbated by the fact that Hungary does not have a secondary raw materials policy in place nor a functioning market for secondary construction materials.

To make the production of raw materials more circular and less dependent on imports, and to ensure a stable material input flow, Hungary will need to optimise the extraction of virgin construction materials and support the development of a secondary construction materials market.

Stimulating use of secondary construction materials

As noted by interviewed stakeholders, Hungary has considerable resources that can be used as secondary construction materials (including blast furnace slag and raw materials from road construction and renovations) to replace their virgin alternatives (mainly sand or gravel). However, instead of maximising their exploitation, the government's response to increasing global prices of construction raw materials has been to open new mines and expand the extraction of virgin natural resources. This comes at both a considerable environmental and monetary cost.

The creation of a secondary construction materials market in Hungary will require a mix of economic and regulatory policy instruments. This could start by eliminating administrative and economic barriers that hinder the uptake of secondary construction materials in the country, which will require revisions to some of Hungary’s existing regulations. First, simplifying the authorisation procedure for incorporating secondary raw materials into construction projects would help reduce the heavy administrative burden on contractors. This, in turn, could encourage greater use of recovered materials in the planning of new construction projects. Second, adapting the Act on National Property (Act CXCVI of 2011) to better reflect market needs could stimulate a higher degree of recoverability and the reuse of secondary raw materials. As noted by the interviewed stakeholders, dismantled materials originating from public investment projects are treated as national assets, so their sales prices are set by the State. The higher price of these secondary materials relative to their virgin alternatives makes contractors reluctant to use recovered materials in construction projects. The current regulation would therefore benefit from allowing CDW, originating from public investments, to be managed by market operators.

Among the new policy instruments, Hungary will need to adopt a secondary raw materials policy, implement new quality standards for secondary raw materials and consider introducing a tax on selected virgin construction materials.

Secondary raw materials policy to improve self-sufficiency in construction materials

Secondary raw materials are recycled materials or by-products that can be reused in construction processes instead of, or alongside, virgin raw materials (European Commission, n.d.[27]). Their use presents several advantages, including increased security of supply, less primary materials extraction and related energy use, less adverse impacts on climate and the environment and, ultimately, lower production costs.

The use of secondary raw materials, i.e. circular materials use rate, in Hungary remains low and well below the EU average (as discussed in chapter 2). This is largely due to the absence of a policy encouraging secondary material uses. Hungary remains one of the few EU Member States that does not have such a policy in place.16 Developing a secondary raw materials policy could not only help set framework conditions for promoting the recovery and reprocessing of raw materials from used construction products and waste (not least by setting an ambitious recycling target for recyclable construction materials), it could also contribute to strengthening the local economy and help reduce Hungary’s import dependence on construction minerals and metals. Moreover, given that some of the infrastructure necessary for secondary raw materials recovery is readily available in Hungary (including stone crushing equipment as well as mobile and processing units), the policy could provide guidance on the recovery of materials while taking advantage of existing structures.

Several EU Member States have already adopted secondary raw materials policies. The secondary raw materials policy of the Czech Republic, which also covers raw materials from construction, could inspire Hungary (see Annex Box 6.A.3). Hungary’s future policy could also consider promoting industrial symbiosis in keeping with the economic structure of regions.

Quality standards to enhance confidence in the quality and performance of secondary construction materials

To further strengthen the uptake of secondary raw materials, it is important to create a system to assess and certify the quality of the recycled construction materials for their reuse. Standards that define and certify the quality and safety of recycled construction materials place secondary construction materials on par with their virgin alternatives, thereby enhancing market confidence in their quality and performance (Nadazdi, Naunovic and Ivanisevic, 2022[28]). Moreover, prioritising high-quality durable secondary raw materials can help extend the lifetime of buildings, postpone the need for renovation or premature demolition, and eliminate the need to extract virgin raw materials with the related environmental challenges this poses.

A number of the interviewed stakeholders believed that the lack of guidance on technical specifications and standards in Hungary on the use of recycled materials for structural applications appeared to be a major obstacle for the marketing and use of secondary raw materials. To overcome this obstacle would require a revision of the existing quality standards and the development of a new standard for secondary construction materials. This new standard with technical requirements would guarantee the technical performance of the final products with clear procedures on how to incorporate secondary raw materials. The standard should be accompanied by metrics to measure performance, and tests and calculation procedures to help ascertain impurity levels and suitability for high-grade recycling. The information obtained from complying with such quality standards could be fed into a voluntary national quality scheme for recycled construction materials. Moreover, the introduction of a new quality label for secondary construction materials could enable alternative materials to quickly access the construction market. Hungary will also need to develop structures for implementing this new standard, which may involve the National Association of Hungarian Building Contractors or the Hungary Green Building Council.

National standards for recycled aggregates have been widely implemented across countries. An international comparison is outlined by Tam, Soomro and Evangelista (2018[29]). More specifically, the Austrian Construction Materials Recycling Association has developed a voluntary quality label for recycled construction materials, which could serve as an example for implementing such an instrument in Hungary. Other examples of quality standards include the quality scheme for recycled CDW in the Netherlands, the example for recycled wood classification in France, and the standards (EN 50625 and EN 50614) for recycled waste electrical and electronic equipment (WEEE) at the EU level (see Annex Box 6.A.4).

Taxes on construction aggregates discourage extraction and use of virgin raw materials

To further promote the shift towards recycled construction materials, it is also important to disincentivise the extraction and use of their virgin alternatives. Environmental taxes, including taxes on construction aggregates, can act as a key element in achieving better sustainability in the production of construction materials (EEA, 2008[30]). Evidence shows that such taxes contribute to a reduction in the use of virgin materials and encourages the use of recycled materials and by-products from other industrial processes (Söderholm, 2011[31]; European Commission, 2011[32]).

Reducing virgin raw materials use in the production of construction materials is one of the strategic objectives of Hungary’s National Waste Prevention Programme. One of the ways to achieve this objective would be to introduce a tax on selected virgin construction materials.17 Through a tax on aggregates, such as stones, gravel or sand, the government could send a strong price signal by making the sourcing and the use of virgin materials for construction less attractive. Moreover, aggregates are not traded internationally and would therefore not threaten the competitiveness of domestic producers. However, the timing of the measure will require a careful evaluation of the market conditions in the building construction sector.18 Once implemented, Hungary may also consider earmarking the revenues generated from taxes for funding R&D on the circular economy and related pilot projects.

Taxes and levies on virgin construction aggregates have been introduced in several countries, which Hungary could draw upon for inspiration. For instance, Denmark and Sweden tax on an ad quantum (physical) basis, while other countries apply ad valorem (monetary) taxes. In the United Kingdom, a levy is applied to the commercial exploitation of rock, sand and gravel, which has led to the country having one of the highest shares of secondary aggregates use across Europe (see Annex Box 6.A.5).

6.4.2. To steer designers and contractors towards implementing circular economy principles in building design and construction requires better guidance at the national level

In the design phase, Hungary’s policy and legal framework is well aligned with the relevant requirements of EU legislation, which mainly consider energy efficiency. Yet, there is an absence of common design principles that push for circularity in materials. In the construction phase, the recently developed National Sustainable Construction Industry Strategy falls short of outlining concrete implementation measures. In turn, the lack of circularity considerations in the design and construction of buildings has an amplifying effect on the required production of raw materials in the country. This is compounded by the strong demand in residential construction and renovation activities.

To encourage the consideration of circularity in building design and construction in practice, Hungary will need to translate circular economy principles into concrete strategies and actions at the different levels of implementation in terms of materials, buildings and urban environments.

Prioritising circularity in the design of buildings and urban environments

On micro and meso levels, early design decisions influence the circularity potential of buildings and their embedded materials. On the macro level, urban planning that considers circular design principles can help boost circularity at larger scales (Dokter, Thuvander and Rahe, 2021[33]).

Mainstreaming circular economy principles into design will require a revision of existing Hungarian legislation relevant to design and material choices in buildings, including the Civil Code (Act V of 2013), the Act LXXVIII of 1997 on the development and protection of the built environment, and the Government Decree 191/2009 (IX.15) on Construction Work Activities. These documents need to integrate language in support of the circular economy. They need to make a link to the minimum recycled content requirement for certain construction products, as put forward by the revised European Construction Products Regulation (CPR) (European Commission, 2022[34]), and mandate the development of performance-based criteria for construction materials and components in line with the EU’s Circular Economy Principles for Buildings Design (European Commission, 2020[35]).

Hungary will also need to steer designers, architects and engineers towards a more circular design of buildings and urban environments by developing a new strategy for circular construction design and by adapting its urban planning strategies.

Design guidelines to mainstream circular construction principles in buildings

A circular designed building is environmentally sustainable thanks to its resource efficiency and smart design. A circular building takes into consideration the effective use of space and efficient energy consumption during the use phase, efficient resource use during its construction, and materials reuse and recovery during renovation and its end-of-life (Window of circular opportunity, n.d.[36]).

Currently there is no legally binding regulation guiding the planning and design of the built environment in Hungary.19 Circular economy principles are only considered within sectoral recommendations and standards (see the section “Hungarian construction-related policy and legal framework”). The lack of guidance poses a challenge for the uptake of circular designed buildings in Hungary. Specific challenges mentioned by the interviewed stakeholders relate to the modularity and longevity of buildings and to the composition of their materials. For instance, less than 5% of buildings in Hungary are currently constructed with modularity in mind, i.e. with modules built off-site. Neglecting concerns for longevity during design has reduced the life expectancy of commercial and prefabricated residential buildings from a typical life span of 50-80 years to 30-50 years. The use of composite materials also hampers their disassembly, with only energy or chemical recovery possible.

Hungary should develop guidance on designing buildings with circular economy principles in mind to help reduce the pressure on raw materials and their environmental impact, as well as help designers, architects and engineers adopt a life cycle approach to the structures and systems they create. This will need to address design for modularity, flexibility, durability, adaptability and disassembly, and provide guidelines on how to incorporate secondary construction materials into buildings and their components. The measures put forward should also encourage digitalisation of construction and promote the application of BIM and digital product passports (DPP). In developing such guidance, Hungary should draw on the Circular Economy Principles for Buildings Design recently developed by the European Commission (see Annex Box 6.A.6). The country will also need to reflect on the future legislative measures proposed within the Sustainable Products Initiative (SPI) (European Commission, n.d.[37]).20

Urban planning strategies to support the development of smart, sustainable and circular cities

Urban planning and design are a channel to stimulate the uptake of circular construction and infrastructure within cities. Cities account for 85% of global GDP generation and 75% of natural resource consumption. They also produce 50% of global waste and 60-80% of GHG emissions (Ellen MacArthur Foundation, n.d.[38]). The pursuit of future-proof urban environments therefore needs to focus on regulating resource use and waste management, target self-sufficiency in energy and material production, and consider community involvement (Andreea Cutieru, 2022[39]). Approaches such as planning for walkability, high-quality buildings and resource efficiency in infrastructure have proven to contribute to smarter, more environmentally sustainable and circular neighbourhoods (Krisch and Suitner, 2020[40]). Moreover, nature-based solutions (NBS) applied to the built environment can counter the negative impacts of urbanisation and contribute to the circular economy through the provision of ecosystem services. Some of the solutions include green building materials (such as use of biocomposite materials, the production of which requires lower energy, carbon and water consumption) and green building systems (such as the application of green roofs, façade greenery and living walls, which helps improve air quality and stormwater management, as well as reduce pollution levels, temperatures inside and outside of buildings, and their energy usage). Other solutions for green building sites include establishing nature in cities, enhancing biodiversity through blue-green infrastructure components and providing opportunities for biophilic design, with positive impacts on human health (Pearlmutter et al., 2019[41]).

Hungary currently does not have a single national urban policy document in place. Instead, principles for urban policy are incorporated across various strategies and plans, including the National Development Strategy 2030, the Hungarian spatial planning system, and the integrated urban development strategies on the municipality level. However, these strategies are missing a unified approach to sustainability. In particular, Hungary faces limitations and challenges in green infrastructure planning and development, and in restoring degraded ecosystems and developing ecological networks. It also lacks a harmonised development and land use approach as well as related tools (Krisztina Filepné Kovács, 2019[42]). To address these challenges, Hungary should promote more integrated spatial planning that prioritises environmental sustainability and circularity.

Copenhagen’s urban planning strategy and Vienna’s urban development project are examples of how urban planning and design can drive the creation of sustainable and circular spaces (see Annex Box 6.A.7). They adopt a sustainable approach to the liveability of neighbourhoods through the integration of public transport, the use of natural materials in construction, the restoration of the natural environment, and the introduction of sustainable services. The EU Urban Agenda Partnership on Circular Economy – a joint effort between the EC, the EU Member States and the European Cities Networks – has identified several actions and recommendations for cities in their circular transition (Håkon Jentoft, 2018[43]). These best practices and concrete actions can be used to source inspiration for adapting the Hungarian urban planning approach and related strategies, such as the Integrated Urban Development Strategy – Budapest 2020 (Municipality of Budapest, 2015[44]).

Encouraging a circular building construction sector

With the continuous increase in construction activities, a growing potential for integrating sustainability and circular economy principles into future construction projects emerges. Moving away from the current linear and cost-efficiency-driven construction towards greener and more circular projects requires a clear vision, a set of shared goals, and guidance on the national level.

In Hungary, the absence of a strong legislative basis for the construction phase,21 results in a scattered policy landscape locked into outdated architecture principles. The only overarching policy document currently in place is the National Sustainable Construction Industry Strategy. While this lays out the priorities, areas of intervention and proposals for action in the industry, it lacks concrete recommendations that focus on the circular economy. The strategy needs to be revised to include specific targets on the circular economy (beyond a building’s energy performance) as well as guidance for addressing construction activities from a more systemic perspective.22 It will also need to reflect the revision of CPR (European Commission, 2022[34]).

Besides revising the policy in place, Hungary will also need to adapt its Public Procurement Act to include Green Public Procurement (GPP) criteria and possibly integrate minimum content requirements into these.

GPP to incentivise the supply of and investment into more circular construction products and building services

The GPP tool is used by authorities to procure goods, services and works with a reduced environmental impact throughout their life cycle. Circular public procurement takes the GPP a step further by targeting closed energy and material loops in purchasing decisions within supply chains, while minimising and, in the best case, preventing negative environmental impacts and waste creation across the whole life cycle (European Commission, 2017[45]).

As noted during the stakeholder interviews, the current Public Procurement Act and the procurement process in Hungary do not take on board the principles related to sustainability and circularity. Elements of green procurement have only been integrated in projects procuring secondary raw materials. To gradually increase the use of GPP criteria when awarding contracts and to incentivise service providers to supply and invest in more circular construction products and building services, a revision of the Public Procurement Act or the development of a stand-alone Green/Circular Public Procurement policy, extending the use of GPP criteria for construction works, will be required. The scope of such revisions could be examined by the Sustainability Working Group established under the Sustainable Hungary Programme.23

The recent publication of the Environmental Public Procurement Ethics Code (Green Code) by the Hungarian Public Procurement Authority is a step in the right direction (Hungarian Public Procurement Authority, 2021[46]).24 The code identifies the environmental objectives and areas that the participating contracting authorities commit to prioritise in their public procurement, one of which is the circular economy approach. While currently a voluntary initiative, this guidance should be made mandatory in the future. In the long term, Hungary should also consider integrating minimum “recycled content requirements” into GPP to encourage the further use of recycled materials in construction works.25 Doing so will first require a revision of the current legislation on design and materials choices in buildings (as discussed in the section “Prioritising circularity in the design of buildings and urban environments”).

The EU’s voluntary GPP criteria for construction led many European countries to develop guidance in this area in the form of national GPP criteria embedded in their national regulation. Examples of implementation include in the Netherlands where the regulatory environment and effective cooperation between public and market actors enabled a successful integration of sustainability criteria into the public procurement of infrastructure projects (see Annex Box 6.A.8).

6.4.3. Extending a building’s life and promoting more intensive and flexible uses calls for strengthened incentives

Buildings are responsible for a large share of energy consumption and CO2 emissions.26 While more sustainable and circular design (as discussed in the section “Prioritising circularity in the design of buildings and urban environments”) can produce highly efficient new buildings, improvements in the way buildings are used and maintained are also necessary. In Hungary, the incentives in place are weak and favour neither the extension of a building’s lifetime nor an improvement in how they are used. Despite the ageing residential building stock, Hungary’s annual renewal rate remains around 1% for residential buildings, which is far below the 3% rate set in the LTRS as a part of the EU renovation wave.27 Hungary also lacks effective space-sharing strategies to promote a more intensive use of buildings as well as zoning regulations to enhance flexibility in a building’s uses while advancing circularity in cities.

Improvements in the way buildings are used and maintained also contribute to a prolonged life cycle of construction products (one of the objectives of Hungary’s National Waste Prevention Programme). To help achieve this objective, Hungary will need to promote a systematic renovation of buildings and a more efficient use of their spaces.28

Extending the lifetime of buildings through renovations

The use phase of buildings in Hungary has a significant potential for more circularity. Promoting the extended lifetime of structures and materials will require a greater number of renovation support schemes specifically tailored to promote circular economy principles and to introduce other economic instruments to make renovations of public and residential buildings more economically attractive.

Renovation support schemes to incentivise renovation of public and residential buildings

Renovation of the building stock has been singled out as a key initiative to drive energy efficiency within the European Green Deal (European Commission, n.d.[47]). Besides energy-related considerations, the EU Renovation Wave strategy counts circularity, use of organic materials and environmental standards among its key principles. Adopting circular economy principles during building renovations reduces the use of materials in existing structures, thereby delaying their demolition and forgoing the use of new materials in the construction of new buildings. Renovation support programmes are an important way to incentivise the renovation of public and residential buildings.

As pointed out by the interviewed stakeholders, the Hungarian construction industry prefers investments in the construction of new buildings rather than the renovation of old housing stock. This is due to the insufficient financial incentives available for renovation projects in Hungary. Current renovation support schemes and grants are limited both in their scope and coverage. Aside from the “home improvement grant”, which is set to expire by the end of 2022 (Hungarian State Treasury, 2021[48]), there is currently only one scheme subsidising home renovations. However, the Housing Subsidy for Families (CSOK) scheme is limited to households with at least one child. Additionally, this scheme seems to prioritise newly built homes over the renovation of existing residential buildings, thereby contributing to urban sprawl and an increase in demand for materials for buildings and related infrastructure in new residential areas.29 Moreover, the latest draft of the Cohesion Fund Environmental and Energy Efficiency Operational Programme Plus (EEEOP Plus) plans to allocate support for improving buildings renovation for only about 32 000 homes in the coming 7 years (representing less than 1% of total homes in Hungary). Those funds are likely to be used exclusively for energy efficiency schemes (Cashawards, 2021[49]).

In order to better target the actual demand for renovations of the housing stock and to meet the country’s renovation targets, Hungary will need to extend its renovation support schemes both in scope and coverage.30 These schemes will also need to better reflect circular economy principles at building and product levels when considering options for renovation (ECOS, 2020[50]). For instance, it is important to prioritise innovative materials with high circularity potential, such as the use of mineral wool for its excellent recycling potential, and stone wool for insulation, which are produced as by-products from other industries (Olympia Dolla, 2022[51]). The Czech Republic is an international example of a successful wide-scale implementation of renovation financing and it has now extended its financial support programmes for both renovation and new efficient construction to all categories of buildings and across all regions (BPIE, 2017[52]).

Reduce value added tax on renovation works to make them more affordable

Renovations offer opportunities to deploy circular strategies beyond energy efficiency improvements. However, the transition towards circularity and the sustainable renovation of the building stock currently faces economic obstacles, which is coupled with political barriers and a lack of awareness (Giorgi, Lavagna and Campioli, 2018[53]). To make renovation works more affordable and boost their uptake, various financial incentives could be implemented. These include value added tax (VAT) rebates, green taxes and tax refunds.

Hungary could investigate the potential of using targeted VAT reductions for renovations to improve materials use in buildings, and possibly to target the use of secondary and renewable materials in renovation projects. Alternatively, VAT reductions could also target the uptake of deep energy renovation projects, but they entail significant costs for owners and are carried out at much lower frequency. For example, improvements in energy performance of a building by at least 60% occurs only in 0.2% of the building stock annually (BPIE, 2021[54]). To design effective schemes, it is important to first evaluate the scope and relevance of introducing VAT reductions that target specific activities.

The VAT reduction for housing renovations has been implemented in the United Kingdom (Government of the United Kingdom, n.d.[55]). The reduced tax rate of 5% (compared to 20% for domestic building works) can be obtained for any works of repair, maintenance or improvement to a property, with only a few exemptions. In France, a tax rate of 10% (down from 20%) applies to works related to improvements, conversion and repair of residential property, while a rate of 5.5% applies to building works related to energy conservation (French-Property.com, n.d.[56]).

Promoting a more intensive use of buildings

To encourage a more efficient use of the building stock, both in terms of using the building space and reducing the need for new buildings, Hungary will need to evaluate the future implementation of space-sharing strategies and reform the current zoning regulations in cities.

Shared and mixed-use concepts for buildings to enhance their use and advance the overall circularity of cities

The rapid growth in urbanisation and the urgent need to make cities smarter, more sustainable and resilient have spurred urban planners to look for new solutions. For instance, the concept of mixed-use buildings allow planners to flexibly adapt how buildings are used as times change (TKE, 2018[57]). It also contributes to the sustainable use of resources and space, and provides inhabitants with neighbourhoods that integrate work, home, shopping, transportation and green spaces. On a larger scale, zoning regulations establish the rules governing different types of activities permitted or prohibited on a designated piece of land or within a “zone”, thereby controlling the development of properties and their uses. Allowing mixed uses of land within higher density zones can enhance a building’s uses and introduce more flexibility into urban planning, thereby advancing the overall circularity of cities (Deloitte, 2021[58]).

In Hungary, the largest category of new buildings built between 2011 and 2019 are offices. However, during the COVID-19 pandemic, offices have been severely underutilised. Moreover, the shift towards teleworking is driving a more permanent decline in office space. To repurpose unused office and public administration buildings (representing 23% of the total stock of public buildings by number) and thus make the most of the space in educational buildings (representing 40%) (Ministry for Innovation and Technology, 2021[19]), Hungary could consider developing space-sharing strategies targeting multi-use and mixed-used concepts.

At the same time, as the population in Hungarian cities continues to grow, the higher density of residential areas presents an alternative to the many problems of urban sprawl, but requires solutions for more flexibility and space efficiency. To allow for higher density residential development with a mix of uses and housing types, Hungary should consider rezoning parts of districts or cities where space distribution and utilisation are most critical, and include affordable housing, while putting forward measures to repurpose the existing buildings for new types of uses.

A prior feasibility study, carried out in collaboration with policy makers, urban planners, academia and civil organisations, will be necessary to examine the applicability of the different concepts targeting some of the building stock across cities, as well as the willingness of the residents to adjust to new concepts. Examples of mixed-used developments, upon which Hungary can draw, include projects in Toronto (Canada) of co-location of schools, libraries, recreation centres and childcare into community hubs, and the development of a standardised approach for shared use facilities in Western Australia (see Annex Box 6.A.9). In terms of zoning regulations, Seattle’s Housing Affordability and Livability agenda provides an example of amended zoning codes to allow for higher density in residential areas (City of Seattle, n.d.[59]). Flexible zoning has also been introduced in some European cities with mixed uses of land. For instance, the strategy by the city of Prato (Italy) foresees opportunities for repurposing empty buildings to reduce the use of raw materials for new builds and to extend the life of existing buildings (OECD, 2020[60]).

6.4.4. To close the loop at the end-of-life, measures are needed to divert CDW from landfills and encourage more appropriate treatment and reuse

As construction activities have expanded, so too has the amount of CDW produced, which represents a significant part of Hungary’s total waste generation. Despite decreasing landfilling and increasing materials recovery rates, the existing Hungarian policy measures have not succeeded in achieving a more significant shift from landfilling to CDW reduction and its recycling and reuse (an objective set within Hungary’s NWMP 2021-2027 and its Waste Prevention Plan). The slow progress has been exacerbated by the absence of both a regulation on mandatory selective demolition and an extended producer responsibility (EPR) scheme for certain construction products.

To close the loop at the end-of-life phase, Hungary will need to accelerate the diversion of CDW from landfills, and prioritise recycling and high-value reuse over backfilling operations and low-grade recovery.

Diverting CDW from landfilling

Decreasing landfilling is one of the strategic objectives of Hungary’s NWMP 2021-2027. This objective can be achieved through an increased landfill tax and improved enforcement measures.

Higher landfill tax rate coupled with better enforcement measures to reduce CDW landfilling

A gradual increase in landfill taxes, in combination with better enforcement of waste management regulations, will help divert CDW away from landfills and prevent any uptick in illegal dumping (European Commission, 2012[61]).

Hungary’s current system of landfill taxes incentivises the unsustainable treatment of CDW and possibly acts as an impediment to CDW recycling. Hungary’s landfill tax has been in place for almost a decade. Despite the planned incremental increase that was originally foreseen, the current tax rates have been frozen at their 2014 levels, and are currently lower than in other EU Member States (Cewep, 2021[62]). Plans to implement further increases were reversed in 2016 over fears of a possible uptake of illegal dumping (OECD, 2018[15]). Although the landfilling rate of CDW is decreasing, more CDW ends up in municipal landfills as part of municipal solid waste (MSW) because there are more landfill locations, reducing transportation costs. Moreover, a large amount of CDW is sent to landfills as backfilling material (Deloitte, 2015[63]).31 As these quantities are reported as recovered, they are exempt from the landfill tax. To correct these inefficiencies, which is also acknowledged by the government (Ministry for Innovation and Technology, 2021[21]), Hungary will need to revise its landfill tax system by raising taxes to at least compensate for the operating and capital costs of landfills, but preferably to include environmental externality costs (OECD, 2021[64]). Coupled with the tax increase, Hungary will also need to enforce its waste regulation by strengthening the control of waste arriving at landfills and penalising non-compliance and illegal dumping.

The Danish weight-based landfill tax can provide insights into how effective taxes can be in diverting waste from landfills and influencing how it is handled (see Annex Box 6.A.10). In terms of enforcement, several EU Member States have implemented regulatory responses to illegal dumping following increases in landfill taxes. For instance, Austria has organised huge awareness and information campaigns, increased monitoring and enforcement activities, and improved the electronic recording of waste streams and waste management (European Commission, 2012[61]). The Czech Republic aims to enhance cooperation among environmental law enforcement agencies and strengthen their capacity to improve the overall regulatory environment and create public awareness of waste-related matters through a short-term national strategy (Ministry of the Interior of the Czech Republic, 2019[65]).

Improving quality and increasing recycling and the safe reuse of recovered CDW

Strengthening the recycling and reuse of CDW requires its safe use and the recovery of high-quality materials from it. However, Hungary will have to work on removing existing legal obstacles to the use of recycled materials. According to the current definition in the Joint Decree 45/2004 (VII. 26.), CDW represents waste from the construction of buildings listed in Annex 1, including excavated soil, concrete debris, asphalt debris, wood waste, scrap metal, plastic waste, mixed CDW, and waste building materials of mineral origin. Although this definition includes the most important construction materials, clarifying the status of waste and end-of-waste (EoW) criteria for other waste streams could encourage the safe reuse of additional raw materials from CDW.32 Further waste streams to be targeted by EoW criteria could possibly include bricks, tiles and ceramics, which together with concrete represent the largest category of CDW in Hungary. The obtained aggregates could then be considered for use in building and construction works, especially for road construction, bound surfaces or concrete and asphalt mixes.33

To further encourage the recycling and subsequent reuse of CDW, Hungary will also need to implement new policy instruments, including: i) adopting a strategy for CDW; ii) establishing a mandatory selective demolition scheme, which is also one of the objectives of the NWMP 2021-2027; and iii) consider developing an EPR scheme for construction materials.

The CDW strategy would move away from extensive backfilling to higher-value recovery and reuse of CDW

The development of a CDW strategy can help in identifying sustainable treatment options for the management of CDW arising along the building’s life cycle (from excavation to construction to demolition activities). The strategy would contribute to increasing the supply of secondary construction materials and promote an improvement in the quality of materials recovered and reused from CDW (ERA, 2021[66]).

Hungary, as in many other countries, does not yet have a strategy in place that lays out the management and treatment of CDW in a harmonised way. Developing a dedicated national strategy could help the country establish a system for the management of CDW as well as better connect national targets with specific measures and activities. In particular, a CDW strategy could help Hungary move away from excessive backfilling towards a more circular and higher-value recovery and reuse of CDW. The backfilling activity in Hungary has significantly contributed towards meeting the 70% of CDW preparation for reuse, recycling and recovery. However, in the future, the country should aim to achieve higher rates of CDW preparation for reuse and recycling while reducing its high reliance on backfilling. The strategy should also have quality standards in place and promote education and awareness raising as well as improvements in data collection (discussed in the sections “Stimulating use of secondary construction materials” and “Horizontal tools and cross-cutting measures”, respectively).

Malta’s recent strategy provides an example of a good practice in developing such a CDW management strategy. Like Hungary, Malta is considered to have reached a very high recovery rate of CDW driven by its high backfilling activity (see Annex Box 6.A.11).

Mandatory selective demolition scheme to facilitate high-quality recycling and reuse of CDW

Selective demolition enables the removal and safe handling of hazardous substances, facilitates reuse and high-quality recycling, and contributes to the establishment of sorting systems for several materials such as wood, mineral fractions, metal, glass, plastics and plaster (European Commission, 2016[67]). When successfully applied, selective demolition can drive the recovery of high-quality materials for recycling and reuse such that only a small fraction of rejects and hazardous waste would have to be disposed.34

Selective demolition, although one of the strategic objectives of the NWMP 2021-2027, is not carried out systematically in Hungary, with only a few individual projects emerging. According to evidence collected from the interviewed stakeholders, the recycling and recovery of CDW in Hungary is hampered by the complexity of demolitions of modern building structures, the high proportion of plastic elements and foams contained within these, as well as the presence of hazardous materials, such as asbestos, tar and bitumen. The situation is similar for CDW from road infrastructure.35 In order to ensure an easier identification and to enable separate collection and sorting of CDW from buildings and road infrastructures, as well as facilitate their on-site reuse in high-grade applications, Hungary should establish a mandatory selective demolition scheme for specific waste streams, including inert waste.36 Mandating material specific separation of CDW requires a prior understanding of potential environmental impacts along the life cycle, as well as consultations with relevant stakeholders. Such a scheme should include a system of inspection/audit (before and after demolition) that is aligned with the national classification/definition of waste and CDW. Once established, selective demolition will need to be embedded within the National Sustainable Construction Industry Strategy and should also be linked to a CDW database (see the section “Horizontal tools and cross-cutting measures”).

In the EU, the revised WFD has recommended the promotion of selective demolition (European Parliament, 2018[68]). Several countries, including Belgium, Denmark, Finland and Sweden, have already established legal requirements for the materials-specific separation of CDW at demolition sites (European Environmental Agency, 2020[69]). The Austrian technical standards for the design and execution of selective demolitions demonstrate the successful implementation of such requirements within national legislation (see Annex Box 6.A.4). An example of an online traceability system providing quality assurance for the selective demolition process is the database developed in Flanders (Belgium) (Hradil et al., 2019[70]). Guidelines for waste audits before demolition and renovation works have also been laid out by the EC (European Commission, 2018[71]).

Extended producer responsibility (EPR) scheme to encourage recovery activities and incentivise design changes that facilitate the reuse or better recycling of CDW

The EPR schemes for construction products and materials help shift some of the costs of managing the high volume of CDW from operators to producers. They also incentivise changes in the actual design of products and materials, thereby facilitating the reuse and recycling of waste (OECD, 2016[72]). In construction, the introduction of EPR schemes could encourage modular building designs, easier disassembly, the introduction of digital product passports, as well as the use of secondary construction materials.

Despite the substantial share of recovery in Hungary, a large portion of the CDW (including concrete and tile waste, mainly used for embankment construction) suffers from poor quality recycling and low-grade recovery. The CDW from plastics and insulation materials, as well as the recovery of glass from windows and doors. currently does not exist in Hungary (as confirmed by the interviewed stakeholders). On the positive side, Hungary has been successful in metal scrap recovery, for which a recovery strategy is available going back several decades. To improve the recovery of certain construction and renovation products and materials, including concrete and tile waste, plastics and insulation materials, doors and window glass, Hungary could consider developing an EPR scheme specifically targeting these materials. Such a scheme would require producers of construction materials to establish the necessary infrastructure that would enable the take-back of their products and improve recovery activities. In its first years, such a scheme could be voluntary, becoming mandatory in the longer term.

Currently, there are only a few examples of EPR schemes for construction materials, not least because of the challenges posed by implementing such schemes related to the long lifetime of buildings, their multiple ownership and purposes during their lifetimes, and the large scale of materials streams compared to other products for which EPR has been typically applied (Pomponi and Moncaster, 2017[73]). France has recently introduced an EPR scheme for marketers of building construction products and materials, including windows, carpets and concrete, which expands the existing collection points for free take-back of building materials waste from professionals, and establishes schemes for waste recovery from craftspeople and private individuals (Ministry of Ecological Transition, 2020[74]) (see Annex Box 6.A.12). The Netherlands has in place a general binding agreement for flat (insulation) glass. Initially started on a voluntary basis, the programme is now a binding financial contribution for post-consumer collection, sorting and treatment (Dimitropoulos, Tijm and in ’t Veld, 2021[75]). Outside of Europe, Japan’s EPR law requires contractors to sort and recycle wood, concrete and asphalt (Ogushi and Kandlikar, 2007[76]). In the United States a number of states have introduced mandatory EPR programmes for architectural waste paints (PaintCare, n.d.[77]).

6.4.5. Horizontal tools and cross-cutting measures need to be put in place to support a more circular building construction sector

Various horizontal tools can be used to support and further accelerate the uptake of circular construction activities in Hungary. Enhancing coordination and facilitating collaboration between all relevant stakeholders could help address cross-cutting issues in the industry and contribute to more coherent circular economy-related policy actions. Improving capacity-building, knowledge transfer and education is essential for mainstreaming circular economy principles across all life cycle stages of construction. Improving data availability on CDW generation would facilitate sustainable waste flow management, while large-scale digitalisation would contribute towards increasing resource efficiency and productivity in the industry and support the adoption of circular business models. Finally, tailoring government support helps stimulate the innovation potential of the circular transformation of SMEs.

Enhancing coordination and facilitating collaboration between stakeholders to address cross-cutting issues in construction

Better coordination and increased collaboration are essential for mitigating fragmentation in the construction industry, breaking down silos, increasing the pace and dissemination of innovation and making the entire industry more circular.

Hungary is currently one of the few EU Member States that does not have a dedicated Ministry of Environment in place. The coordination of the transition to a circular economy is carried out at the state secretary level, specifically by the State Secretariat for Environmental Policy and Circular Economy of the Ministry of Energy. According to the interviewed stakeholders, the lack of inter-sectoral and cross-agency collaborative mechanisms has led to coordination issues and made it more challenging to meet the targets and objectives related to the circular economy. Improving the coordination between the different ministries, relevant agencies and stakeholders, would help tackle some of the industry’s cross-cutting issues, such as innovative circular business models, new technologies, and recovery and reuse of materials across different sectors, thereby contributing to more coherent policy actions. To steer the transition to a circular construction, Hungary should consider establishing a coordination mechanism, possibly at the level of a state actor, for example, a newly created ministry or an agency, a government commissioner or a public-private-partnership. The creation of a formal coordination body will need to be preceded by the establishment of a working group in order to build on the momentum created by the adoption of the NCES as well as to leverage synergies and bring about common actions within the industry. The working group could be composed of construction industry stakeholders in the newly created Circular Economy Technology Platform and be led by the State Secretary for the Environmental Policy and Circular Economy of the Ministry of Energy.

Several examples of successful inter-sectoral collaborations and partnerships have emerged over the past years, including “green deals” and public-private discussion platforms in the Netherlands (see Annex Box 6.A.13). In Hungary, two collaboration platforms were established to accelerate the transition to a circular economy: the Circular Economy Platform (BCSDH, n.d.[78]) and the Circular Economy Technology Platform (EGOV.HU, 2022[79]) (see Box 2.2° in chapter 2).

Improving capacity building, knowledge transfer and education to mainstream circular economy principles within the construction industry

Effective education, capacity building and knowledge sharing are essential for awareness raising about circular economy principles, and further accelerating the circular transition in the construction industry.

The application of circular economy principles within the Hungarian construction industry is poor and predominantly focused on waste management aspects. As noted during the stakeholder interviews, the lack of innovative approaches and knowledge transfer continues to determine conservative attitudes in Hungarian design, architecture and engineering practices. Many contractors do not know what to do with recovered materials, while good practices from abroad are rarely disseminated to domestic stakeholders. The uptake of circular approaches in Hungary’s construction industry would therefore benefit from stronger capacity building, knowledge transfer and education.

Training programmes, such as the Circularity Thinking Programme, developed by EIT Climate-KIC for stakeholders and practitioners of the Deep Demonstration project in Slovenia, could inspire greater capacity building in Hungary (see Annex Box 6.A.14). More specifically, this could be achieved by developing a national training programme targeted to industry stakeholders and policy makers, which could be run by the Hungary Green Building Council. Better knowledge transfer could be achieved through dedicated private-public platforms that bring together relevant stakeholders. The Holland Circular Hotspot provides an example of such a platform where knowledge on advanced, innovative and circular construction practices are disseminated. On another level, mainstreaming circular economy into curricula of higher education programmes would help prepare the next generation of policy makers, designers, architects and constructors for more circular thinking (see Annex Box 6.A.14).

Better monitoring of uses of construction materials and CDW generation will accelerate the uptake of more circular practices across the industry

Besides the life cycle specific measures discussed in the previous sub-sections, accelerating the uptake of circular practices in the construction industry requires consistent data on and monitoring of construction material flows across the entire construction value chain.

In Hungary, data collection on material uses and their flows and CDW in construction is either completely missing or is not carried out systematically.37 The building sector has currently no database in place that would ensure a harmonised approach for reporting CDW streams. In road construction, although a database for monitoring waste streams is already underway, this currently only covers asphalt. Hungary therefore needs to reform its national database or put in place a new inventory, which would register the volumes of CDW generated across the entire economy as well as their quality specifications. The precondition for such a revised data inventory is improved data reporting on EWC codes, lifetimes, prices and usability of different waste streams by construction companies. Moreover, laboratory tests to determine the quality of secondary raw materials recovered from CDW will need to be specified. This information could, in turn, be used to inform the quality standards and labels for secondary construction materials (discussed in the section “Quality standards to enhance confidence in the quality and performance of secondary construction materials”). Moreover, it could serve as an outlet for matching suppliers with users of recycled construction materials, which would spur the creation and uptake of a marketplace for secondary raw materials. Ultimately, improved data availability would also contribute to evidence-based policy making.

When reforming the existing database for the building sector, Hungary could draw on the experience from existing initiatives in the country and abroad. For instance, the CLEAN-WAY database and map (CLEAN-WAY Kft, n.d.[80]), which was established with the aim of enhancing the reuse of secondary raw materials, might have a future potential to be used on a larger scale and be inter-connected with other databases. The National Buildings Database in France [Base de Données Nationale des Bâtiments] is an international example of an open-data project cross-sourcing information from about twenty different datasets covering more than 21.4 million buildings (see Annex Box 6.A.15).

Promoting digitalisation of the construction industry to support the adoption of new circular business models

Digitalisation drives innovation and helps tackle the industry’s challenges related to labour shortage, competitiveness, resource and energy efficiency, and productivity. Digital tools are considered especially important in the planning, authorisation and design phases of construction (European Commission, 2019[81]). They are also an important enabler for the adoption of new circular business models (OECD, 2019[82]), such as the industrial symbiosis and digital marketplace for infrastructure (World Economic Forum, 2021[83]).38

To ensure a systematic digital circular transition of the construction industry in the country, it needs to become one of key themes of Hungary’s National Digitalisation Strategy. More specifically, it will need to indicate the links and inter-dependencies between the different technologies, the national context and the industry’s structure. In terms of specific technologies, Hungary could possibly focus on BIM (helping to improve decision making in buildings and public infrastructure projects for renovation, refurbishment and maintenance),39 digital twins (enabling easier maintenance, repair, reuse, safe dismantling and disposal of constructions, products and materials),40 and open-source design (facilitating collaboration on designs of buildings, neighbourhoods or cities)41. To facilitate a stronger uptake of digital solutions, policy measures targeting digitalisation need to be accompanied by financial support in the form of grants, loans or equity, but also by technical assistance.

The Danish Strategy for Digital Construction and Bulgaria’s Digital Transformation Strategy are examples of cross-sectoral digitalisation agendas, with measures targeting the digitalisation of the construction industry. On a different level, the Estonian Digital Construction Cluster (EDCC) aims to develop an innovative digital environment targeting the entire construction life cycle and value chain (see Annex Box 6.A.16). Moreover, several national governments have embedded BIM requirements into their public procurement processes (European Commission, 2021[84]). National and local governments have also facilitated the uptake of digital technologies by providing e-services, such as digital building permit systems, digital logbooks and registries of properties (in some cases enriched by the inclusion of Geographic Information System [GIS] and 3D models for digital registry of properties) (European Commission, 2021[84]).

Tailoring government support to stimulate the innovation potential of the circular transformation of SMEs