This chapter outlines the circular economy potential of North Macedonia’s mining and metallurgy sectors, examining key aspects such as mining and metal processing value chains, material flows, research and innovation, and industrial symbiosis. It identifies crucial levers to make the sectors more circular. The analysis reviews the existing circular economy-related policy landscape, pinpoints areas for improvement and presents specific policy recommendations, enriched with insights from international best practices.

A Roadmap towards Circular Economy of North Macedonia

8. Circular potential in mining and metallurgy in North Macedonia

Abstract

The circular economy in the mining and metallurgy sectors

Minerals and metals are central to the circular economy transition. They are key material inputs into other sectors of the economy, including manufacturing, construction and energy, driving the green transition. The mining and metallurgy sectors in this chapter are defined as including:

mining operations (extraction, aggregating, hauling, etc.)

processing operations (concentration, separation, dewatering, etc.)

material production (smelting, refining, cutting, etc.).

To date, primary resource sectors, such as mining and metals production, and how to improve circularity in these sectors, have received comparatively less attention from scholars and policy makers. According to the most common definitions of a circular economy, the consumption of primary minerals and metals is simply to be reduced, while the focus of primary materials management is on circular production (manufacturing), consumption and waste management. As a result, these sectors are also often not included in circular economy strategies or roadmaps. Nevertheless, a few studies explore circular economy strategies that could be applied to mining and metal production value chains.

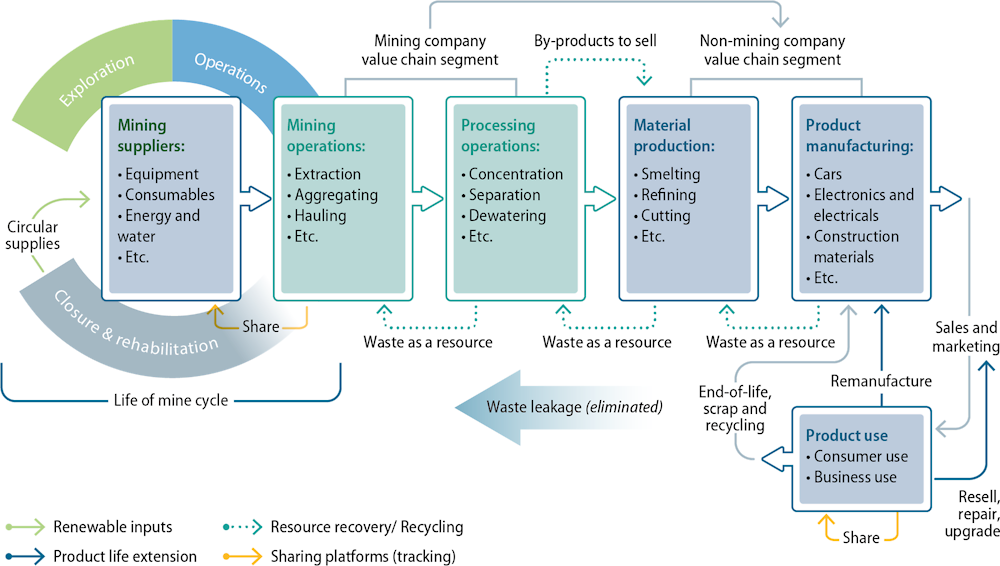

Based on such studies (Young, Barreto and Chovan, 2021[1]; Smart Prosperity Institute, 2021[2]), companies can apply different circular business models to make their value chains more circular (Figure 8.1) These are primarily resource recovery models but can also include circular supply and sharing models. Upstream circular practices could be classified into two blocks of actions (adapted from Young, Barreto and Chovan (2021[1]) and Smart Prosperity Institute (2021[2])):

1. Actions directed at more circular supply and use of the physical infrastructure, equipment and assets of a mining and processing company. This may include procurement of mining and material production equipment that is more circular (e.g. refurbished, used or bearing recycled content). It may also include recycling, upcycling, redeploying of products and equipment that are already on-site, and refurbishment and remanufacture of on-site products to extend their value. Companies can also share, rent, prolong and maintain their equipment to optimise use and value.

2. Actions directed at more circular management of resources that are extracted and used in mining and processing operations. This may include extracting embedded value from mining and processing wastes by recycling, repurposing, redirecting and reprocessing such wastes on-site. It may also include waste exchanges with other industries and selling by-products through industrial symbiosis.

Motivations for the selection of the mining and metallurgy sectors as a key priority area of the Roadmap

The mining and metallurgy sectors were selected as a key priority area of this roadmap because of their high economic importance, strong policy relevance and important decarbonisation potential. While the circular economy potential is less understood, these sectors could adopt a number of circular practices and business models that would lead to more circular supply and use of products and equipment that are used on-site and in metal processing as well as better management of extracted and used resources and waste.

Figure 8.1. The circular economy in the mining and material processing and production value chains in North Macedonia and their downstream linkages

Mining and quarrying accounted for 1.3% of gross domestic product (in 2018) and 10.9% of industrial production (in 2021) in North Macedonia and has a long history in the economy (Macedonian Mining Association, 2021[3]). North Macedonia is rich in different materials – metallic minerals found in its territory include copper, silver, gold, zinc and lead; non-metallic minerals include bentonite, talc, gypsum, quartz and quartz sand; and energy materials include coal (lignite) (Macedonian Mining Association, 2021[3]). The employment figures in this sector are relatively low compared to other sectors, but the sector accounts for 2.8% of total exports (Macedonian Mining Association, 2021[3]). The mining sector has been particularly backed by important foreign direct investment in the past decade due to lower restrictions on procedures for issuing permits and concessions. However, mining methods of extraction have resulted in long-lasting water and soil pollution, affecting biodiversity and the health of the local population.

Metallurgy, or basic metals production (most exported products include ferroalloys, hot-rolled steel, goateed flat-rolled steel, steel pipe and tubes, and steel bars) is one of the largest industrial sectors of the Macedonian economy. It is comprised of complex technical and technological stems for production as well as modern equipment and technologies for advanced processing of basic metals, making it significantly important and strategic for the economy (Invest North Macedonia, 2023[4]). Basic metals production represented 13.6% of exports in 2021, the vast majority being exported to the European Union (EU) (World Bank, 2023[5]), with iron and steel imports representing 8.9% of the European Union’s total imports from North Macedonia in 2022 (European Commission, 2023[6]).

A Strategy for Geological Research and Sustainable Use and Exploitation of Mineral Resources for 2025-2045 is currently being drafted – evidence of the increasing policy relevance of the mining sector in North Macedonia. The metal industry is also covered under the Industrial Strategy (2018-2027). While the strategy does not foresee sustainability and circular considerations, it does envisage the diversification of metal products through more complex production processes. This area has also been gaining increasing attention from governments around the world, as certain materials, in particular certain metals with high supply risks, are critical or strategic for their economies and green transitions in particular. Ensuring secure and sustainable supply chains of these so-called critical and strategic raw materials is a key objective of the European Union’s proposal for a Critical Raw Materials Act. For instance, copper, which can be found in North Macedonia, is a strategic raw material according to the 2023 list of critical raw materials for the European Union (European Commission, n.d.[7]).

These two sectors also have an important decarbonisation potential, as metals and minerals extraction and production account for a significant share of total greenhouse gas emissions. Estimates vary from around 45% to 67% of total emissions, depending on the geographical scope, the methodological approach (including the scope of activities and materials associated with materials management) and the time period of the analysis (OECD, 2022[8]). The majority of emissions related to materials are associated with the production of materials, goods and infrastructure and include energy-related emissions to manufacture products and materials. Considering the operationalisation of the European Union’s Carbon Border Adjustment Mechanism1 in 2026 and its impact on exports of goods with a high risk of carbon leakage (including iron, steel and aluminium), transitioning to circular production processes of metal products could be beneficial for North Macedonia.

Overview and approach to the selection of the proposed policy recommendations

The approach used for selecting the proposed policy recommendations that would consider the entire life cycle of a product or material as used in the textiles, construction, and biomass and food priority areas is less applicable to this area because of the area’s focus on upstream sectors only. The proposed policy recommendations for this priority area are, therefore, structured according to the different types of government support, including multi-stakeholder collaboration, awareness raising and education, financial and economic incentives, and regulatory measures (Table 8.1). Not all of the proposed policy recommendations are relevant for both mining and metals production value chains. Typically, metals production/metallurgy sectors already implement circular practices within their value chains, in particular, metals recycling and the use of scrap, as it is profitable to do so. It is mostly the application of circular practices in the mining value chain and the creation of the linkages between the different industrial sectors (e.g. through industrial symbiosis) to facilitate recycling and the use of secondary raw materials that could be supported further by policy intervention.

Table 8.1. Overview of the proposed policy recommendations in the priority area mining and metallurgy for North Macedonia

|

Short term |

Medium term |

Long term |

|---|---|---|

|

Develop a study to understand the circular economy potential in the mining and metal processing value chains in North Macedonia |

Facilitate industrial symbiosis to further support the use of waste from the mining and metal processing/production companies and creation of markets for secondary raw materials |

Apply circular principles in procedures for issuing permits and concessions |

|

Incorporate circularity principles in the new Strategy for Geological Research and Sustainable Use and Exploitation of Mineral Resources for 2025-2045 |

Improve understanding of circular practices on-site and data availability to map material flows of metals and minerals |

Consider introducing recovery obligations to support material recovery and secondary raw materials production |

|

Support upstream eco-innovation and research and development to enhance metal and mineral value chains for a low-carbon economy |

Key proposed policy recommendations

The key proposed recommendations are structured according to the type of policy instrument:

1. awareness-raising initiatives, education and multi-stakeholder co-operation to improve the understanding and application of circular practices in the upstream value chains

2. financial support measures and economic instruments to support upstream eco-innovation and research and development (R&D)

3. supporting legislation and policies for circular value chains in mining and metallurgy.

1. Improving stakeholder engagement, education and collaboration, and raising awareness

The understanding and application of circular principles in primary resource sectors is, in general, limited (Smart Prosperity Institute, 2021[2]). Moreover, there is limited evidence on the potential of applying circular practices in these sectors in North Macedonia. The country should also explore how green industrial zones could be used to facilitate waste exchange among different industries, including from mining and metallurgy processes. North Macedonia should thus introduce a set of measures to:

develop understanding of the circular economy potential in the mining and metal processing value chains in North Macedonia

improve understanding of circular practices on-site and data availability to map out material flows of metals and minerals

facilitate industrial symbiosis in green industrial zones.

Develop a study to understand the circular economy potential in the mining and metal processing value chains in North Macedonia

In the short term, North Macedonia should develop a study to better understand the circularity potential in its domestic mining and metal processing value chains. While applying a circular economy in the metallurgy sector is not new – for example, steel scrap is often used to produce steel – this may be less so for other materials and the mining value chain. The study could map relevant stakeholders in the mining and metal production value chains, analyse the current situation, identify data gaps and key issues, and propose solutions that are feasible within a certain time frame. The study can be commissioned by a dedicated working group on mining and metal processing, which could be formed and operate as a sub-group within the wider circular economy stakeholder group set up for the preparation and implementation of this roadmap. The action plan for the extractive industry developed in Finland provides a good practice example in this regard (Box 8.1). The study may also specifically focus on industrial symbiosis and using waste as a resource in the green industrial zones.

Improve understanding of circular practices on-site and data availability to map out material flows of metals and minerals

Once the circularity potential in the Macedonian mining and metallurgy sectors is better understood, North Macedonia should also improve understanding of circular practices on-site as well as data on material flows of metals and minerals in the medium term. There is a need to invest in increasing recognition and understanding of circular economy practices and potential “value from waste” at the mine site (Young, Barreto and Chovan, 2021[1]). In North Macedonia, this may require supporting the education and training of workers as well as setting up material flow data systems to inform prospective demand, and thereby investments and R&D priorities. The Macedonian Mining Association, in co-operation with the Ministry of Economy, could take the lead in conducting such trainings. For example, to support the development of regional markets for secondary raw materials among the mining, processing and construction industries, the Finnish circular economy strategy foresaw the organisation of a training seminar on the topic, where a working model for using secondary materials in infrastructure construction would be presented to key operators (Sitra, 2016[9]).

Box 8.1. Example of an action plan for the extractive industry developed in Finland

In 2013, the Finnish government developed an action plan together with mining companies, regional representatives and other stakeholders. The aim of the action plan was to make Finland a leader for the sustainable extractive industry. An Extractive Industry Working Group, consisting of officials from several ministries, monitors the implementation of the action plan through yearly roundtable forums. The action plan outlines a total of 35 measures and assigns a responsible stakeholder for each measure. Examples of measures are:

The creation of water management plans for mines and the development of water technology. Mining companies are responsible for the implementation of this measure.

A research strategy was prepared for the extractive industry, comprising key fields of research and the development of research infrastructure. Responsible stakeholders are, for example, research institutes, universities, extractive industry companies, and the Finnish Funding Agency for Technology and Innovation.

The energy efficiency of the extractive industry has been systematically addressed. The responsible parties for this include extractive industry companies and the Finnish Association of Extractive Resources Industry.

Obstacles to the recycling of metal scrap in the metal processing sector were identified and eliminated. In addition, instruments, steering methods and incentives were created for the recycling and reuse of side rock, tailings, construction masses and mineral products. Here, the government, several ministries, municipalities and government agencies are responsible.

Source: OECD (2019[10]).

Facilitate industrial symbiosis in green industrial zones

To further support the use of waste from the mining and metal processing/production companies and creation of markets for secondary raw materials, North Macedonia should enhance industrial symbiosis in the green industrial zones in the medium term. Green industrial zones or eco-industrial parks are a key policy approach to promote industrial symbiosis (Domenech et al., 2018[11]). As outlined in Chapter 4, ongoing amendments to the Law on Industrial and Green Zones could incorporate provisions to promote resource recovery and recycling among the mining industry, processing industry and construction, thereby creating an environment conducive to strengthening business partnerships and collaboration. Business partnerships could be further promoted by the proposed circular economy business platform. To support the scaling of industrial symbiosis in North Macedonia, the government could get inspiration from existing practices and policy guides in EU member states. For example, Ireland has developed a guide for policy making related to industrial symbiosis that provides insights for supporting greater implementation and scaling of industrial symbiosis (Impoco, Arodudu and Brennan, 2021[12]).

2. Financial support and economic incentives for upstream eco-innovation and R&D to enhance metal and mineral value chains for a low-carbon economy

Besides the decarbonisation potential of a circular economy in materials management, as outlined above, the circular economy also has a role to play in advancing strategic metal and mineral contributions to a low-carbon energy transition. This includes new research programmes, partnerships and policy initiatives to advance the potential for circularity in specific metal and mineral value chains that contribute to a low-carbon economy, as well as accelerating innovation and derisking circular economy investment with a high decarbonisation potential in strategic metals and minerals. Metal processing practices in North Macedonia tend to be outdated, dating back to before the 1990s (OECD, 2019[10]). In addition, as underlined during the stakeholder consultations, more incentives are needed for Macedonian companies to make a behavioural shift from using primary materials to using secondary and waste materials.

To achieve the net zero ambition by 2050, North Macedonia will need to support upstream eco-innovation and R&D to enhance metal and mineral value chains that contribute to a low-carbon economy in the medium term. This can be achieved by introducing new research programmes to foster building partnerships for upstream eco-innovation and R&D and to support innovative metal production techniques to accelerate innovation or innovative recovery technologies to recover strategic or critical raw materials that are relevant for a low-carbon economy transition (e.g. renewable technologies). For instance, in the upstream, innovative exploitation methods should minimise environmental nuisance, foster recycling, and further use co-products and by-products of mining and environmentally manage the waste produced as a result of the mining activity. Partnerships should include co-operation between academia and industry as well as industrial symbiosis. This was also highlighted during stakeholder consultations. Fostering the application of digital technology also has vast potential to improve circularity in the metal processing sector, for example, in the areas of storing and communicating information about the location, condition and availability of scrap. For example, Maersk, an integrated container logistics company, uses digital product passports to recover and sort steel from its decommissioned vessels more effectively, recycle it to a higher quality, and reuse it for building new vessels (Ellen MacArthur Foundation, 2019[13]; EPEA, 2011[14]). Likewise, digital technology, such as blockchain-based pilot projects, can improve traceability in logistics to enable optimal stock utilisation, thus reducing material waste and transport costs (OECD, 2019[10]; 2022[15]). Some of the funding programmes to increase circular business models (see Chapter 4), and in particular funding that will be available in the green industrial zones, could be used for this purpose.

Supporting upstream eco-innovation could also be supported by green public procurement (GPP) to promote the use of secondary raw materials when supplying products and works, in particular public construction works. For example, in Italy, the use of GPP criteria is mandatory for products and services for which such criteria have been defined (Italian Public Contract Code). This includes criteria for by-products from industrial symbiosis processes (Ministerial Decree 30/06/21) to support the use of recycled content.

3. Supporting legislation and policies for circular value chains in mining and metallurgy

Besides financial and economic incentives, North Macedonia will also need to develop a regulatory framework that supports circularity in domestic mining and metallurgy value chains. This is even more timely as the European Union and other countries around the world advocate for more circular supply chains of critical and strategic raw materials. The mining sector is currently regulated by the Law on Mining (2012), which was adopted with the aim of lowering restrictions on procedures for issuing permits and concessions to secure important foreign direct investment in the past decade. However, mining methods of extraction have resulted in long-lasting water and soil pollution,2 affecting biodiversity and the local population’s health. As a result, the legal and policy framework targeting raw materials and the mining sector are being reinforced to include social and environmental requirements. The law was amended in 2019 and 2021 to better protect the population’s health and the environment, after citizens led protests against the rapid increase of government-issued mining concessions. The Ministry of Economy is currently also developing a new Strategy for Geological Research and Sustainable Use and Exploitation of Mineral Resources for 2025-2045 in close consultation with the Macedonian Academy for Science and Arts and the Mining Association. The strategy will aim to further develop the mining sector, with a focus on sustainable use of resources and environmental protection standards (Chamber of Commerce of North Macedonia, 2023[16]).

Despite these developments, North Macedonia’s regulatory framework needs to be strengthened to make mining and metallurgy value chains more circular. It is proposed that the roadmap focus on three regulatory measures to enhance circularity in the mining and metallurgy sectors:

incorporating circularity principles into the new Strategy for Geological Research and Sustainable Use and Exploitation of Mineral Resources for 2025-2045

applying circular principles in procedures for issuing permits and concessions

considering introducing recovery obligations to support material recovery and secondary raw materials production.

Incorporating circularity principles into the new Strategy for Geological Research and Sustainable Use and Exploitation of Mineral Resources for 2025-2045

To address challenges inherent in the extraction of raw materials and support the development of mining projects that are environmentally as well as socially sustainable, a coherent and co-ordinated policy approach is needed that considers environmental, regional and economic policies.

In the short term, the government of North Macedonia should ensure that circularity principles are mainstreamed into the new Strategy for Geological Research and Sustainable Use and Exploitation of Mineral Resources for 2025-2045. These principles should include provisions that non-renewable natural resources be used sustainably and that mining side streams be utilised. During material processing and the material development stage, different materials should be returned into the value chain at the end of their useful life. To promote circularity in mining, and minerals and metals processing and production, North Macedonia could take inspiration from the OECD Handbook on Environmental Due Diligence in Mineral Supply Chains (OECD, 2023[17]), the EU Critical Raw Materials initiative or one of the EU member states that have adopted secondary raw materials policies (see the example of the Czech Republic in Box 8.2). North Macedonia’s future strategy could also include considerations for promoting regional industrial symbiosis.

Box 8.2. Secondary raw materials policy of the Czech Republic

Czechia’s Secondary Raw Materials Policy was developed in collaboration with experts from academia and industry, and approved by the Czech government in 2014. It is the first document establishing a national strategic framework for the use of secondary raw materials, defining 5 strategic objectives and 16 measures, with specific tasks being developed in a separate action plan. The policy includes the circular economy in its vision. It also sets out strategic goals for the extraction, processing and use of secondary raw materials from domestic and imported sources, with a focus on ten priority commodities that are of particular value for the country’s production and export. The policy’s overall objective is to increase the share of secondary raw materials in the total consumption of materials in the Czech economy to reduce the material and energy intensity of production. The five strategic objectives are:

1. increasing Czechia’s self-sufficiency in raw materials by substituting primary sources with secondary raw materials

2. supporting innovation and circular economy development in businesses

3. supporting the use of secondary raw materials as a tool to reduce the energy and material intensity of industrial production while at the same time eliminating the negative impacts on the environment and human health

4. supporting education and training in the area of the circular economy

5. updating statistical findings in the area of secondary raw materials to monitor and evaluate the circular economy.

The list of priority materials remains open to updates as business needs and the economy change.

Czechia also has a separate Raw Materials Policy, which addresses energy and non-energy raw materials, ore and non-ore commodities, including energy, construction and high-tech mineral resources. The strategy’s main goal is the security of supply of raw materials.

Sources: OECD (2021[18]; 2023[19]); Ministry of Industry and Trade of the Czech Republic (2016[20]).

North Macedonia’s strategy should outline an action plan developed together with mining companies, regional representatives and other stakeholders to achieve the goals of the new strategy. Such a plan may include, for example, a measure to establish a database of extractive waste facilities and require operators to submit waste management plans, including for hazardous waste, or a measure to introduce end-of-waste (EoW) criteria for certain wastes from the metallurgy sectors that could be used as by-products by other industries. For example, steel slag from steel production can be used for the production of construction aggregates if it complies with the EoW criteria. The EoW criteria would set out the quality criteria for how the aggregate should be produced so that it is no longer considered waste material. This will reduce the regulatory burden on the producers and users of steel slag aggregate. A number of countries have adopted EoW policies and criteria for steel slag. Box 8.3 presents examples from the United Kingdom. Moreover, considering the document’s 20-year timeline, a mid-term monitoring and evaluation mechanism should be embedded in the strategy to assess the continued relevance of the priorities and progress made towards achieving its planned objectives.

Box 8.3. Aggregate from waste steel slag: Quality protocol in the United Kingdom

The steel slag aggregate quality protocol was developed as a joint initiative between the Environment Agency and WRAP (Waste & Resources Action Programme) in consultation with Natural Resources Wales and the steel slag industry. It sets end-of-waste criteria for the production and use of steel slag aggregates in construction applications.

The quality protocol specifies that aggregate products made from waste steel slag will be regarded as fully recovered and no longer subject to waste controls provided it is shown that:

only the correct waste steel slag materials were used

only the permitted products were made

compliance is ensured with the relevant European standard, specification and quality controls for the relevant product, and all required tests have been passed

a manual of the factory production control exists

the product has been marked to the circular economy requirements of the Construction Products Regulations

the waste steel slag and the final product have been transported, stored, handled and processed following good practice guidelines

the customer has been supplied with delivery documents confirming the product meets the quality protocol.

Under the quality protocol, the correct waste steel slag can be processed to make specified unbound, semi-bound or fully bound aggregate products for use in the civil engineering and construction industries. End uses for unbound ones are aggregates for sub-base, capping, fills and pipe bedding. For semi-bound ones, the end use is aggregates for surface dressing and those for fully bound ones are both: aggregates for asphalt and concrete and aggregates and activators for hydraulically bound mixtures.

The quality protocol also provides good practices on necessary inspection, measuring and testing equipment; staff training; and paperwork and a records checklist.

Source: UK Environment Agency (2016[21]).

Applying circular principles in procedures for issuing permits and concessions

To ensure that mining value chains are sustainable, North Macedonia will need to apply circular principles in procedures for issuing permits and concessions in the long term. This may be done by incorporating the circular economy into environmental impact assessment studies preceding the issuance of permits. For example, the Greek National Circular Economy Strategy foresees the following steps to achieve this (Ministry of Environment and Energy of Greece, 2018[22]):

identifying the possibilities for improving environmental legislation to facilitate the uptake of circular economy approaches

integrating circular economy criteria into the environmental permits of investments and infrastructure and accelerating the relevant administrative procedures

investigating possibilities to facilitate industrial symbiosis, e.g. by not requiring a fully fledged environmental impact assessment when testing the possibility to use by-products in industrial processes and relying only on a technical assessment.

Moreover, the Finnish National Circular Economy Strategy includes as a measure the need to plan and describe the side streams produced during the project, such as surplus spoil in the environmental impact assessment and environmental permit processes (Sitra, 2016[9]). Other circular principles that can be considered include supporting recycling and off-site repurposing of end-of-life items; promoting and supporting environmental, social and governance standards across the mining and metal processing value chains; and introducing mandatory requirements to rehabilitate a mine site to eliminate contamination on-site and off-site. In Canada, for example, mine reclamation plans, including financial securities, are a condition of granting mine permits (Smart Prosperity Institute, 2021[2]).

Consider introducing recovery obligations to support material recovery and secondary raw materials production

In the long term, North Macedonia should further support material recovery and secondary raw materials production. Secondary raw materials production from mining sites involves extracting valuable materials from waste or by-products generated during the primary mining and processing of ores. Examples include reprocessing tailings (leftover materials after the valuable minerals have been extracted from ore); slag recycling (by-product formed during the smelting or refining of metals); recycling scrap metal from mining operations or recovery from waste rock, separated during the initial stages of mining (Blengini et al., 2019[23]). Supporting such processes can be done, for example, by establishing requirements to recover a share of valuable residual minerals from mining waste and historical mining waste sites. The European Commission has also outlined this in its Proposal for a Critical Raw Materials Act.3 Processing secondary raw materials from mining waste, which are already mined and crushed, can cost less than extracting them from primary deposits, particularly those located at substantial depths. Researchers suggest that the cost of reprocessing tailings can be 40% lower than that of primary sources (Marín, Kraslawski and Cisternas, 2022[24]). This might be particularly relevant for North Macedonia considering that mining waste represents 35% of total industrial waste. This may also help achieve substantial greenhouse gas emissions reductions. For example, roughly 95% of energy is saved per tonne in the production of aluminium using scraps compared to primary aluminium production (European Aluminium, 2016[25]). The recovery obligations may also include an obligation for operators to submit waste management plans outlining the potential recovery of certain raw materials from the extractive waste stored in the facility and from the extractive waste being generated, in current and historical mining sites.

However, material recovery policies by themselves are not sufficient. Competitive and environmentally sustainable practices should also include redesign (e.g. using products with less materials), reuse, repair, remanufacturing and refurbishment strategies to reduce and avoid waste in the metal processing sector (OECD, 2020[26]). North Macedonia may want to align with EU efforts on recycled content and aim to benefit from it by becoming a supplier of recycled metals.

References

[15] Barteková, E. and P. Börkey (2022), “Digitalisation for the transition to a resource efficient and circular economy”, OECD Environment Working Papers, No. 192, OECD Publishing, Paris, https://doi.org/10.1787/6f6d18e7-en.

[23] Blengini, G. et al. (2019), Recovery of Critical and Other Raw Materials from Mining Waste and Landfills, European Commission, Joint Research Centre, Publications Office of the European Union, Brussels.

[16] Chamber of Commerce of North Macedonia (2023), “Sustainable mining, key aspects of the Strategy for Geological Research and Sustainable Use of Mineral Resources 2025-2045”, web page, https://www.mchamber.mk/Default.aspx?mId=3&evid=130882&lng=1.

[11] Domenech, T. et al. (2018), Cooperation Fostering Industrial Symbiosis Market Potential, Good Practice and Policy Actions, Directorate-General for Internal Market, Industry, Entrepreneurship and SMEs, Publications Office of the European Union, Brussels, https://data.europa.eu/doi/10.2873/346873.

[13] Ellen MacArthur Foundation (2019), “Using product passports to improve the recovery and reuse of shipping steel: Maersk Line”, web page, https://www.ellenmacarthurfoundation.org/circular-examples/using-product-passports-to-improve-the-recovery-and-reuse-of-shipping-steel.

[14] EPEA (2011), Maersk Cradle to Cradle Passport: Total Vessel Recycling, EPEA, https://www.youtube.com/watch?v=PRgp9tcOwaw.

[25] European Aluminium (2016), Recycling Aluminium: A Pathway to a Sustainable Economy, European Aluminium.

[6] European Commission (2023), European Union, Trade in Goods with North Macedonia, European Commission, Brussels, https://webgate.ec.europa.eu/isdb_results/factsheets/country/details_north-macedonia_en.pdf.

[7] European Commission (n.d.), “Critical raw materials: Ensuring secure and sustainable supply chains for EU’s green and digital future”, web page, https://single-market-economy.ec.europa.eu/sectors/raw-materials/areas-specific-interest/critical-raw-materials_en.

[12] Impoco, G., O. Arodudu and G. Brennan (2021), Industrial Symbiosis: Guide for Policy Making, Irish Manufacturing Research, https://www.epa.ie/publications/circular-economy/resources/2021_REP_EPA_SymbioBeer_Policy_Guide_FIN.pdf.

[4] Invest North Macedonia (2023), “Electro-metal industry”, https://investnorthmacedonia.gov.mk/export-electro-metal-industry.

[3] Macedonian Mining Association (2021), Review of the Situation in the Mining and Quarrying Sector, https://www.mchamber.mk/upload/%D0%98%D0%9D%D0%A4%D0%9E%D0%A0%D0%9C%D0%90%D0%A6%D0%98%D0%88%D0%90_%D0%97%D0%90_%D0%A0%D0%A3%D0%94%D0%90%D0%A0%D0%A1%D0%A2%D0%92%D0%9E%D0%A2%D0%9E.pdf.

[24] Marín, O., A. Kraslawski and L. Cisternas (2022), “Estimating processing cost for the recovery of valuable elements from mine tailings using dimensional analysis”, Minerals Engineering, Vol. 184/107629, https://doi.org/10.1016/j.mineng.2022.107629.

[22] Ministry of Environment and Energy of Greece (2018), National Circular Economy Strategy, Greek Government, http://www.ypeka.gr/LinkClick.aspx?fileticket=pYSLQXgjjOU%3D&tabid=37&language=en-US.

[20] Ministry of Industry and Trade of the Czech Republic (2016), Secondary Raw Materials Policy of the Czech Republic, Ministry of Industry and Trade of the Czech Republic, https://www.mpo.cz/en/industry/politics-of-secondary-raw-materials-czech-republic/secondary-raw-materials-policy-of-the-czech-republic--221854.

[17] OECD (2023), Handbook on Environmental Due Diligence in Mineral Supply Chains, OECD Publishing, Paris, https://doi.org/10.1787/cef843bf-en.

[19] OECD (2023), Towards a National Circular Economy Strategy for Hungary, OECD Publishing, Paris, https://doi.org/10.1787/1178c379-en.

[8] OECD (2022), “Closing the loop in the Slovak Republic: A roadmap towards circularity for competitiveness, eco-innovation and sustainability”, OECD Environment Policy Papers, No. 30, OECD Publishing, Paris, https://doi.org/10.1787/acadd43a-en.

[18] OECD (2021), “Towards a national strategic framework for the circular economy in the Czech Republic: Analysis and a proposed set of key elements”, OECD Environment Policy Papers, No. 27, OECD Publishing, Paris, https://doi.org/10.1787/5d33734d-en.

[26] OECD (2020), OECD Workshop on International Trade and the Circular Economy: Summary Report, OECD, Paris, https://www.oecd.org/env/workshop-trade-circular-economy-summary-report.pdf.

[10] OECD (2019), Circular Approach and the Sustainability of the Agro-food System: Closing Resource Loops to Improve Sustainability (archived), OECD, Paris, https://www.oecd.org/agriculture/events/circular-approach-and-the-sustainability-of-the-agro-food-system-3-april-2019.htm.

[27] Sitra (2016), Leading the Cycle. Finnish Road Map to a Circular Economy 2016-2025, Sitra Studies 121, Finnish Innovation Fund, Helsinki, https://media.sitra.fi/2017/02/28142644/Selvityksia121.pdf.

[9] Sitra (2016), Leading the Cycle: Finnish Road Map to a Circular Economy 2016-2025, Sitra Studies 121, Finnish Innovation Fund, Helsinki, https://media.sitra.fi/2017/02/28142644/Selvityksia121.pdf.

[2] Smart Prosperity Institute (2021), Primary Materials in the Emerging Circular Economy: Implications for Upstream Resource Producers and Primary Material Exporters, Smart Prosperity Institute, https://institute.smartprosperity.ca/sites/default/files/emerging_circular_economy_report.pdf.

[21] UK Environment Agency (2016), “Aggregate from waste steel slag: Quality protocol”, web page, https://www.gov.uk/government/publications/aggregate-from-waste-steel-slag-quality-protocol/aggregate-from-waste-steel-slag-quality-protocol (accessed on 19 December 2023).

[5] World Bank (2023), “North Macedonia trade”, World Integrated Trade Solution, https://wits.worldbank.org/countrysnapshot/en/MKD (accessed on 16 November 2023).

[1] Young, A., M. Barreto and K. Chovan (2021), Towards a Circular Economy Approach to Mining Operations: Key Concepts, Drivers and Opportunities, Enviro Integration Strategies Inc., MERG, https://circulareconomyleaders.ca/wp-content/uploads/2022/01/Towards-a-Circular-Economy-Approach-to-Mining-Operations.pdf.

Notes

← 1. The Carbon Border Adjustment Mechanism is expected to become operational in 2026 and gradually apply to a selected number of goods with a high risk of carbon leakage (iron and steel, cement, fertiliser, aluminium, and electricity generation). As EU importers will buy carbon certificates corresponding to the carbon price that would have been paid had the goods been produced under the European Union’s carbon pricing rules, non-EU producers, such as North Macedonia, will be encouraged to green their processes and lower production-related emissions.

← 2. Concessions for mines in North Macedonia granted before the 2019 Amendment Law on Mining mainly used sulfuric acid, cyanide, thallium and arsenic to extract minerals from the ore.

← 3. The document outlines the European Commission’s proposals for ensuring stable access to critical raw materials crucial for strategic sectors like net zero and digital industries, aerospace, and defense. It prioritises setting action goals, identifying key materials, and establishing benchmarks for domestic capacity and supply chain diversification by 2030. It emphasises creating secure and resilient EU supply chains, simplifying permitting and supporting strategic projects. To address supply risks, the act introduces monitoring and co-ordination of critical raw material supply chains among EU member states. It mandates audits of strategic supply chains for certain large companies. The proposal stresses investment in research, innovation and skills to promote breakthrough technologies and partnerships relevant to critical raw materials. It highlights the importance of environmental protection through improved circularity in the European Union and globally. Internationally, the European Union aims to diversify critical raw material imports, engaging with reliable partners. Initiatives include establishing a Critical Raw Materials Club, strengthening the World Trade Organization, and forming strategic partnerships for economic development in emerging markets and developing economies (European Commission, n.d.[7]).