This chapter outlines the problem formulation regarding design of sustainable plastics from a chemicals perspective and provides an overview of the objectives, scope and outline of the document.

A Chemicals Perspective on Designing with Sustainable Plastics

Chapter 1. Sustainable Design of Plastics: Problem Formulation, Objectives and Scope

Abstract

1.1. Rationale

1.1.1. The problem

Annual global plastics production reached 430 million metric tons in 2019 and could continue to grow to 1,150 million metric tons in 2060 (OECD, forthcoming). While plastics deliver many benefits to society, the chemical components of plastics can have negative impacts on human health and the environment. Potential chemical hazards can arise in all lifecycle phases from sourcing until end-of-life. More than 10 000 chemicals including monomers, additives and processing aides have been identified to be used in plastics, with almost one quarter of them of potential concern (Wiesinger et al., 2021).

The development of plastic products currently does not always take sustainability into account. As defined by the OECD, sustainable plastics are “plastics used in products that provide societal benefits while enhancing human and environmental health and safety across the entire product life cycle” (OECD, 2018a). Sustainable plastics should limit the creation of waste, toxins and pollution from their inception to their next use or end-of-life. They should thus have a reduced (negative) impact on the climate, help promote a more circular economy and help meet the objectives of the United Nations Sustainable Development Goals.

The challenge in creating sustainable plastic products revolves around the selection of sustainable materials, but also the overall system within which the product circulates. As visualised in Figure 1.1, when studying sustainable plastics, the system, product, materials and chemical aspects are interrelated. A sustainable plastic product operates in a system, to which the design of the product and its plastic materials are adapted. For example, at the end-of-life, the product should be able to be collected, the plastics sorted and recycled in the facilities that are operational at the time of disposal in that geographical area.

Figure 1.1. Relationship between system, product, materials and a chemicals perspective. The chemicals perspective is interconnected with design decisions made at a system, product and material level.

In a circular economy, the system is restorative by design and keeps the value and utility of products, components, and materials at their highest level over time (Webster, 2015). The body of work on designing for a circular economy provides guidance to designers and engineers at a system and product design level (see Box 1.1).

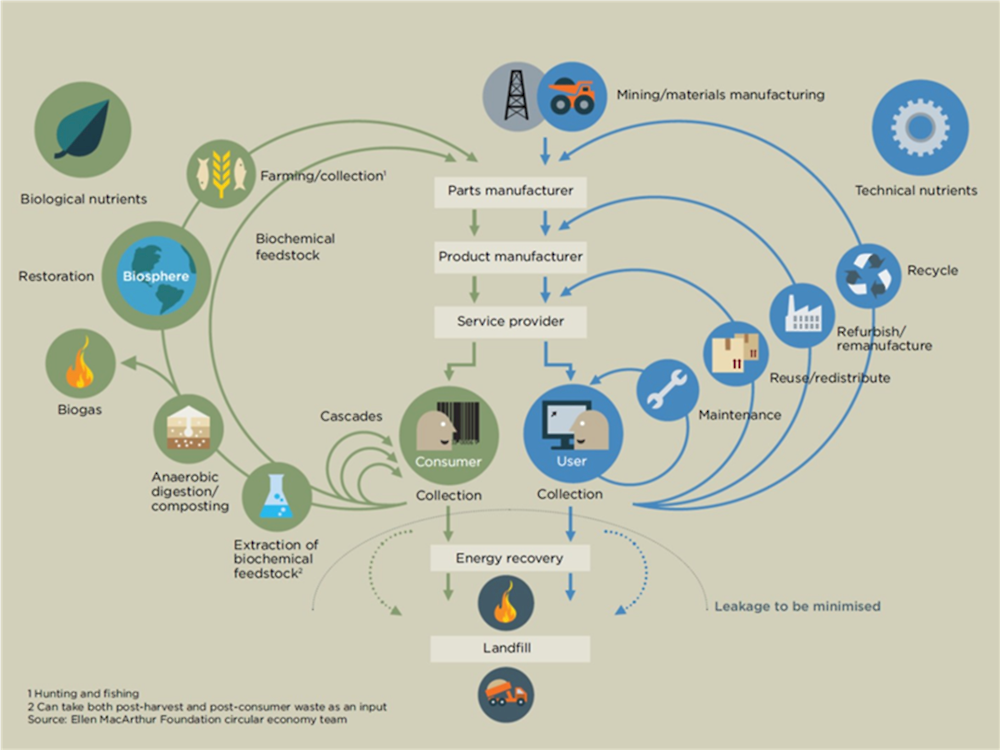

Box 1.1. Design for a Circular Economy (DfCE)

In a circular economy, products and components are designed to be kept at their highest utility and value at all times, and the system around them is regenerative by design (Ellen MacArthur Foundation, 2013). As illustrated on the right in Figure 1.2, the product is designed to be preferably repaired, reused, then refurbished and remanufactured, and if little value remains, finally recycled. The mining of virgin materials and leakages (i.e., energy recovery and landfill) are to be minimised. Biological nutrients, represented on the left-hand side of Figure 1.2, are resources that can return to the biosphere to biodegrade after their use.

The basics of circular economy

DfCE is guided by the following main principles (Ellen MacArthur Foundation, 2013):

Design out waste by designing systems and products using resources that will never be lost

Distinguish biological and technological nutrients to find the most appropriate solutions for consumables and durable products

Use renewable energy

Design and business strategies

Various design strategies can be implemented to enable a transition towards a circular economy. These, for instance, include designing for long-life products, design for product-life extension, and design for dis- and reassembly (Moreno, De los Rios, Rowe, and Charnley, 2016).

Business model strategies are also of essence in a circular economy. Different design interventions are needed depending on whether the product is accessed by the user through an access or performance model versus in a classic long life (Bocken, de Pauw, and Bakker, 2016).

DfCE methods and tools

DfCE methods and tools are summarised amongst others in the Circular Design Guide developed by IDEO and the Ellen MacArthur Foundation (IDEO and Ellen MacArthur Foundation, 2017), and the Massive Open Online Course ‘Circular Economy: An Introduction’ by Delft University of Technology (TU Delft, 2021).

Figure 1.2. The Circular Economy according to the Ellen MacArthur Foundation

Source: Copyright © Ellen MacArthur Foundation, Towards the circular economy Volume 1: Economic and business rationale for an accelerated transition (2013).

At the foundational level of Figure 1.1, the chemicals perspective encompasses various aspects:

Polymer class: classification of polymers based on properties (e.g. thermoplastics or thermosets)

Polymer type: a specific sort of polymer within a polymer class (e.g. PET or PP)

Grade: a specific structure and molecular mass within a polymer type

Additives: substances added to the polymer to improve its properties (e.g. pigment or flame retardant)

Blends: combination of polymers (e.g. thermoplastic-thermoplastic blend)

Production residues: substances that do not deliberately remain in the material (e.g. catalyst or monomer)

Non-intentionally added substances (NIAS): substances that have not been deliberately added to the material or unplanned new substances resulting from contact to other materials (e.g. due to degradation substances that leach into the material)

Unfortunately, the knowledge required to develop sustainable plastics from a chemicals perspective may not be well known to designers and engineers who do not have specialised knowledge of chemistry. Ideally, a design team should work closely with chemical sustainability experts to navigate the design process in order to create sustainable plastic products while considering a chemicals perspective.

1.1.2. Chemicals perspective on sustainable plastic

To guide in the creation of sustainable plastic products, a sustainable chemical perspective can be adopted. Sustainable chemistry seeks to improve the efficiency, effectiveness, safety and environmental impact of chemical substances and processes (OECD, n.d.).

The sustainable design goals and considerations discussed in this report and the source reports (OECD, 2018a; OECD, 2021a; OECD, 2021b; OECD, 2021c; OECD, 2021d) build upon the American Chemical Society (ACS) Green Chemistry Institute’s (GCI) design principles for sustainable chemistry and engineering (American Chemical Society Green Chemistry Institute, 2015). These design principles were based on inter alia Anastas and Warner (1998) and Abraham and Nguyen (2003).

The ACS GCI’s design principles were clustered in three categories and need to be applied simultaneously (OECD, 2018a):

Maximise resource efficiency. Resource efficiency means doing more with less while preserving natural capital. Renewable resources should be used at a pace enabling regeneration. Non-renewable resources should be kept in the loop, as waste is the result of system inefficiency.

Eliminate and minimise hazards and pollution. By reducing the hazards of chemicals and the human and environmental exposure to these hazards, the negative impact of plastics on human health and the environment decreases. This, for instance, includes direct effects of plastic chemicals on human health and other species as well as indirect effects of plastic pollution from littering, which exposes wildlife to waste and in turn likely cause toxic effects as well as enters food chains.

Design systems holistically and using life cycle thinking. As visualised in Figure 1.1, sustainable plastic does not exist in isolation but is rather interrelated to the product and system around it. Also, all the stages in the life cycle of the product have to be studied for the selection of the most sustainable plastic.

In response to the United Nations Environment Assembly (UNEA) Resolution 4/8, UNEP developed a Green and Sustainable Chemistry Framework Manual (United Nations Environment Programme, 2020). It presents ten objectives and guiding considerations for what green and sustainable chemistry seeks to achieve, namely:

1. minimising chemical hazards;

2. avoiding regrettable substitutions and alternatives;

3. sustainable sourcing of resources and feedstocks;

4. advancing sustainability of production processes;

5. advancing sustainability of products;

6. minimising chemical releases and pollution;

7. enabling non-toxic circularity;

8. maximising social benefits;

9. protecting workers, consumers and vulnerable populations; and,

10. developing solutions for sustainability challenges.

Green and sustainable chemistry is an active field. Reports with new insights are published at a rapid pace. Technology to assess and identify hazards or NIAS is being developed. These, in turn, are influenced by the evolution of regulatory frameworks and by technological challenges in assessing toxicity. There are also still many uncertainties and blind spots. When available, product composition inventories are limited by current knowledge as especially not all additives and NIAS are listed. Designers are trained to deal with many uncertainties, but they should be aware of what is certain and what is uncertain in order to make the best decisions.

1.1.3. Background of this report

In 2018, the OECD organised a Global Forum on Environment focused on "Plastics in a Circular Economy: Design of Sustainable Plastics from a Chemicals Perspective". The Forum aimed to incentivise a shift in sustainable chemistry thinking during product design by identifying good practices and a policy framework to reduce the environmental and health impacts of plastics.

The Global Forum included a background paper on the sustainability of plastics from a chemical perspective: ‘Background Paper 1 - Considerations and Criteria for Sustainable Plastics from a Chemical Perspective’ (OECD, 2018a). The Global Forum concluded that additional OECD work could be done to develop criteria and guidance for sustainable plastics. To differentiate potential sustainability criteria across product categories, four case studies were conducted from the packaging and construction sectors (OECD, 2021a; OECD, 2021b; OECD, 2021c; OECD, 2021d). The general considerations from the background paper form the basis of this report. The case studies were used to deepen the insights from the background paper with practical implications for designers.

1.2. Objective

The objective of this report is to enable the creation of inherently sustainable plastic products by integrating sustainable chemistry thinking in the design process.

This report thus puts sustainable chemistry thinking at the core of the material selection process and provides guidance in how to manage the complexity of sustainable design goals, considerations, and trade-offs. After considering the elements of this report, design teams will be well equipped to select sustainable plastic for their designs and will have increased their awareness on key environmental and health elements.

1.3. Scope

The sustainable design goals, life cycle considerations and trade-offs emanating from this study focus on the sustainable chemical perspective. They support designers and engineers in navigating the uncertainties in the world of chemicals, and the ongoing evolution of chemistry discovery, polymer and product technologies in the world of chemicals. This report does not provide a universal solution to developing sustainable plastics, as designing is not a one-size-fits-all activity. Designing is an iterative process with progressive insights gained over time feeding and altering previous steps. It is also highly dependent on the product, market, systems, the team, and the company, to name but a few factors. Economic factors, which are also key to sustainable solutions, are not within the scope of the report. However, this report gives the necessary knowledge at specific moments of the design process to deal with chemical questions when aiming for the use of sustainable plastic. These sustainable design goals, life cycle considerations and trade-offs inform the material selection on the efficiency, effectiveness, safety on human health and environmental impact of chemical substances and processes.

The study concentrates on the material selection after choosing one product concept and selecting plastic as the optimal material family with which to manufacture a specific part. The first stages in the design process (i.e., need definition and design requirement formulation) are thus out of scope. Nevertheless, as considerable impact can be spared at these stages, it is assumed that a DfCE approach was adopted (see Box 1.1). Material selection goes hand in hand with the manufacturing process, the function of the envisioned product and its shape (Ashby, 2005). This report therefore also mentions repercussions of certain chemical decisions on system, product and material design choices. This positioning in the design process is elaborated further in Chapter 2 on Methodology.

The target audience of this study is broad but primarily focuses on designers and engineers. Nevertheless, designers and engineers do not always have the power and room for these improvements. Therefore, decision makers writing the design briefs and policymakers are also seen as a secondary target audience. The report may also be informative to scientists, including material scientists, chemists, chemical engineers and anyone conducting risk or hazard assessment. System changes will also have to be stimulated by policy makers to bring competitors to collaborate with each other to gain scale and reach the mentioned sustainable design goals. Consequently, although it is assumed that the designers and engineers already have acquired the design/engineering basics, this report gives an overview of these basics to inform policy makers.

The study is not limited to a specific type of plastic or product, nor does it focus on a particular geographical region.

1.4. Outline of this report

This report starts with methodological aspects regarding positioning of material selection in the design process and summarising the key material selection steps for designers and engineers (Chapter 2). Sustainable design goals with respect to chemistry are then clarified (Chapter 3). To achieve these goals, the following chapters dive into the considerations for each stage of the lifecycle, namely sourcing (Chapter 4), manufacturing (Chapter 5), use (Chapter 6) and end-of-use (Chapter 7). The report subsequently zooms out to assess the whole product and explores how the material selection can be optimised for the sustainable design goals (Chapter 8). The report finally summarises the main findings and recommends next steps (Chapter 9).

References

Abraham, M. A. and N. Nguyen (2003), “Green Engineering: Defining the Principles. San Destin Conference”, Environmental Progress, Vol. 22, No.4, pp. 233-236.

American Chemical Society Green Chemistry Institute (2015), Design Principles for Sustainable Green Chemistry and Engineering, https://www.acs.org/content/dam/acsorg/greenchemistry/resources/2015-gci-design-principles.pdf.

Anastas, P. T. and J.C. Warner (1998), Green Chemistry: Theory and Practice, Oxford University Press, New York.

Ashby, M. F. (2005), Materials Selection in Mechanical Design, 3rd Edition, Elsevier.

Bocken, N. et al. (2016), “Product design and business model strategies for a circular economy”, Journal of Industrial and Production Engineering, Vol. 22, No.5, pp. 308-320.

Ellen MacArthur Foundation (2013), Towards the circular economy. Volume 1: Economic and business rationale for an accelerated transition, United Kingdom, https://ellenmacarthurfoundation.org/towards-the-circular-economy-vol-1-an-economic-and-business-rationale-for-an

IDEO and Ellen MacArthur Foundation (2017), Circular Design Guide, Ellen MacArthur Foundation, United Kingdom, https://www.circulardesignguide.com/

Moreno, M. et al. (2016), “A conceptual framework for circular design”, Sustainability, Vol. 8, No. 9, pp. 937.

OECD (n.d.). “A Definition of Sustainable Chemistry”. Retrieved from OECD, Paris. http://www.oecd.org/chemicalsafety/risk-management/sustainablechemistry.htm#:~:text=A%20Definition%20of%20Sustainable%20Chemistry&text=Sustainable%20chemistry%20encompasses%20the%20design,benign%20chemical%20products%20and%20processes.%22

OECD (2018a), “Considerations and criteria for sustainable plastics from a chemicals perspective: Background paper 1. OECD Global Forum on Environment: Plastics in a Circular Economy”, Series on Risk Management, No. 51, OECD, Paris, https://www.oecd.org/chemicalsafety/risk-management/considerations-and-criteria-for-sustainable-plastics-from-a-chemicals-perspective.pdf

OECD (2021a), “Case Study on Flooring; An example of chemical considerations for sustainable plastics design”, Series on Risk Management, No. 65, OECD, Paris.

OECD (2021b), “Case Study on Insulation: An example of chemical considerations for sustainable plastics design”, Series on Risk Management, No.66, OECD, Paris.

OECD (2021c), “Case Study on Detergent Bottles; An example of weighing sustainability criteria for rigid plastic non-food packaging”, Series on Risk Management, No. 63, OECD, Paris.

OECD (2021d), “Case Study on Biscuit Wrappers; An example of weighing sustainability criteria for plastic flexible food packaging from a chemicals perspective”, Series on Risk Management, No. 64, OECD, Paris.

TU Delft (2021), Circular Economy: An introduction, Online course from Delft University of Technology, Netherlands, https://online-learning.tudelft.nl/courses/circular-economy-design-and-technology/

United Nations Environment Programme (2020), Green and sustainable chemistry: Framework manual, Geneva, Switzerland, https://wedocs.unep.org/handle/20.500.11822/34338;jsessionid=90C235C3E0B2E94827A3336BC3EA8E93

Webster, K. (2015), The Circular Economy - A Wealth of Flows, Ellen MacArthur Foundation, United Kingdom, https://ellenmacarthurfoundation.org/the-circular-economy-a-wealth-of-flows-2nd-edition

Wiesinger, H. et al. (2021), “Deep Dive into Plastic Monomers, Additives, and Processing Aids”, Environmental Science and Technology Vol. 55, No.13, pp. 9339-9351