This chapter describes the design process and how material selection is connected to the design process. It also outlines the key aspects that guide designers to ensure integration of sustainable chemistry thinking at the design stage resulting in the general steps of sustainable plastic selection.

A Chemicals Perspective on Designing with Sustainable Plastics

Chapter 2. Methodology

Abstract

2.1. Positioning of Material Selection in the Design Process

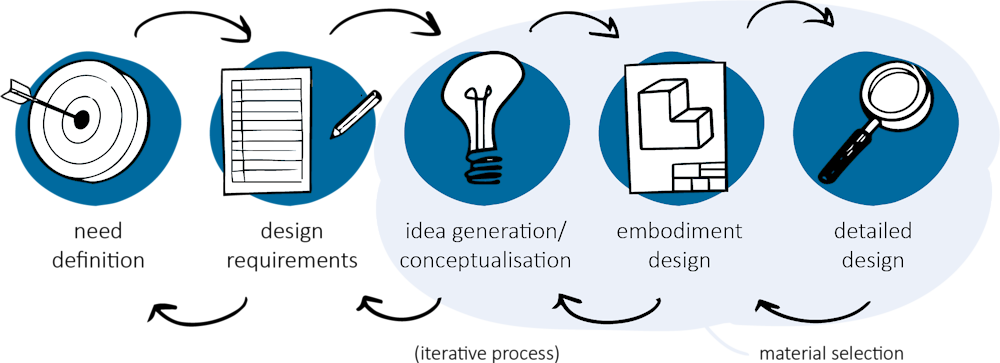

This study provides guidance to designers and engineers during the material selection across the design process. Through this design process, an individual or team transposes a need into a solution to this need. Note that, in this report, the design solutions are tangible products (vs services) that will require material selection. As shown in Figure 2.1, the material selection occurs at several levels throughout stages of the design process.

Figure 2.1. Design process stages and material selection

Note: The position of material selection is highlighted in light blue.

Source: Based on Ashby (2005)

The design process is iterative and does not occur linearly. Indeed, the material selection and product design are interconnected. In other words, the material choice influences the design and the design influences the material choice (Ashby, 2005). More specifically, material selection is interconnected with the function of the product/component, its shape, and the production process of the material (Ashby, 2005). For the sake of clarity however, the steps of the material selection are defined in a linear manner.

The starting point of this report is preceded by the need definition stage, the design requirements stage, and the idea generation and conceptualisation stage. These stages occur in consultation with the user or customer.

Need definition: The need for which a solution is being designed was recognised and a product application was identified.

Design requirements: A set of design specifications concerning technical, economic and stakeholder aspects are defined based on the problem analysis. Requirements include for instance performance, target product costs, size and aesthetics. These design requirements are categorised into non-negotiable conditions to be met by the designed product or negotiable conditions that are deemed desirable but are not required.

Idea Generation/Conceptualisation: Product design ideas and concepts were proposed. The concepts were evaluated and one concept was selected as it best fulfilled the design requirements. At this stage, the working principles and function structures of the product are thus determined. Here, needs for material data concern materials overall and require a low level of precision and detail. Plastic was selected as material subset for a specific part of the product.

It is assumed that designers and engineers adopted a Design for a Circular Economy (DfCE) approach during these stages. See Box 1.1 for more information on DfCE.

The material selection in this report starts with plastics and is refined during the embodiment and detailing stages.

Embodiment design: the concept is further developed. More precise and detailed material data is needed to narrow down the selection of the subset of materials (i.e., in this report’s case: plastics).

Detailed design: The embodiment design is further developed and results into final product specifications that will enable the production of the product. The highest level of precision and detail of the material data is necessary to make the final choice of a particular material and production process.

2.2. Approaching Sustainable Plastic Selection

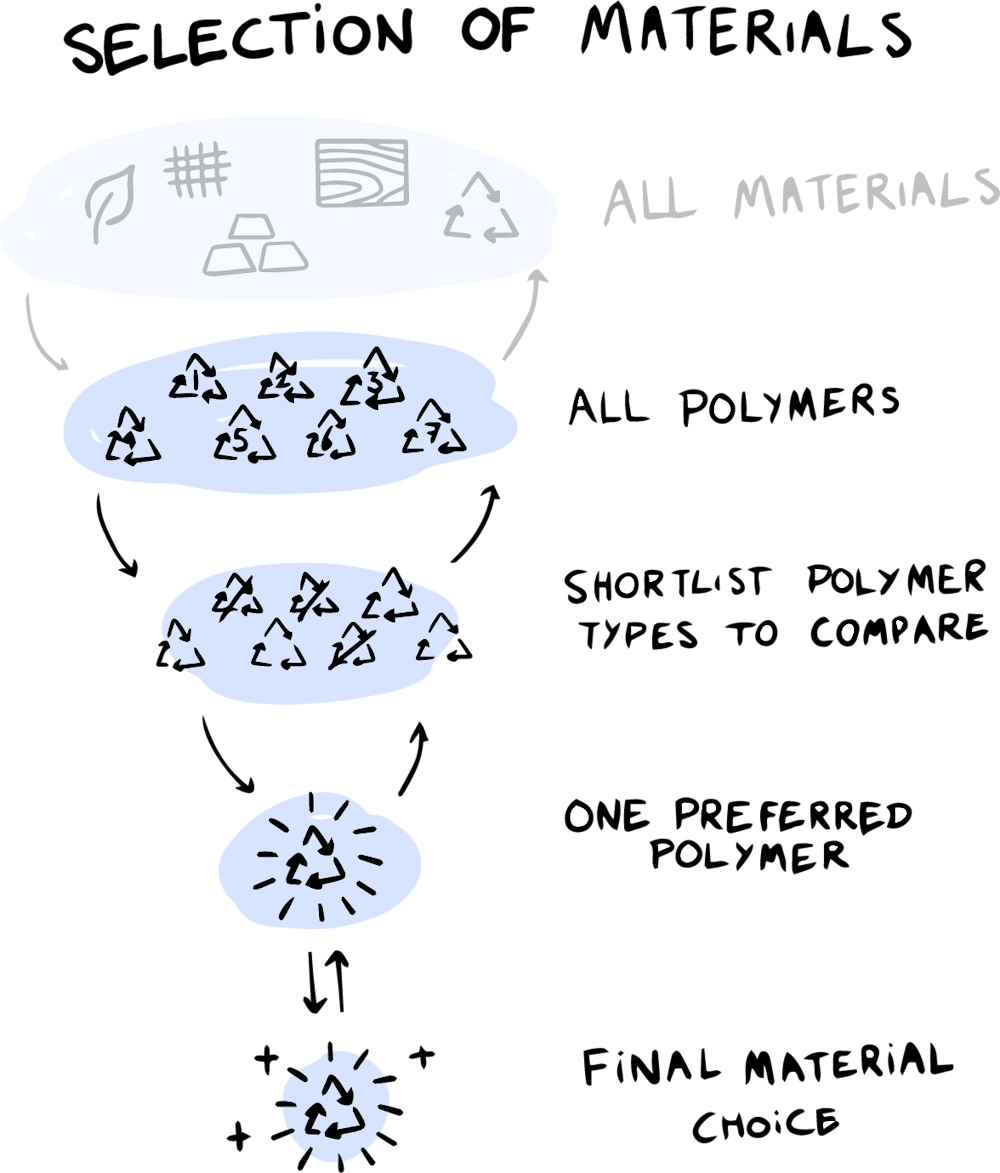

As illustrated in Figure 2.2, material selection narrows from the large variety of materials available to designers and engineers, to the specific choice of the material for the to-be-designed product/component. This report focuses on material selection once the material family of polymers was selected for (a part of) the product after a concept was chosen.

Figure 2.2. The general material selection process when choosing a sustainable plastic.

Note: The emphasised steps of the process are the focus of this report, namely the sustainable plastic selection

2.2.1. Levels of guidance during the sustainable plastic selection

Designers and engineers are guided by the following key aspects to integrate chemical thinking during the sustainable plastic selection:

Design requirements are the non-negotiable conditions to be met by the designed product (i.e., needs) and negotiable conditions that are deemed desirable (i.e., wants). These design requirements include general properties, mechanical, electrical, optical and environmental resistance properties. These are further sharpened based on the product concept selected. They have already been defined by the designers and engineers in the second and third stage of the design process as described above.

Sustainable design principles are the American Chemical Society (ACS) Green Chemistry Institute’s (GCI) design principles of sustainable chemistry and engineering listed in Chapter 1. All these design principles are applied simultaneously.

Sustainable design goals are derived from the sustainable design principles and provide a more concrete direction for the product design at hand. These have been consolidated from the OECD report on general considerations for sustainable plastic from a chemicals perspective (OECD, 2018a) and the four OECD case studies. They can be found in Chapter 3.

Chemistry-related sustainability considerations are practical chemical and sustainability matters to be taken into account throughout the life cycle of the to-be-designed product. They go deeper than the sustainability product design goals. These considerations have been consolidated from the five previously mentioned OECD reports. They can be found in Chapters 4-7.

Trade-offs occur when conflicting aspects need to be balanced during the material selection. The designers and engineers will need to transparently determine how these trade-offs will be resolved at the start of the material selection. These trade-offs have been consolidated from the five previously mentioned OECD reports. They can be found in Chapters 4-7 for trade-offs within life cycle stages and in Chapter 8 for trade-offs between life cycle stages.

Methods, tools and metrics are chemistry-related resources that designers and engineers can employ to come to decisions. Examples are provided in Annex A and in Technical Tools and Approaches in the Design of Sustainable Plastics (OECD 2018b). Guidance on the use of these tools is not within the scope of this report. As the necessary methods, tools, and metrics depend on the context of the product design, several suggestions are made per category (e.g. measuring circularity and Chemical Hazard Assessment or CHA) and designers and engineers can choose what to use.

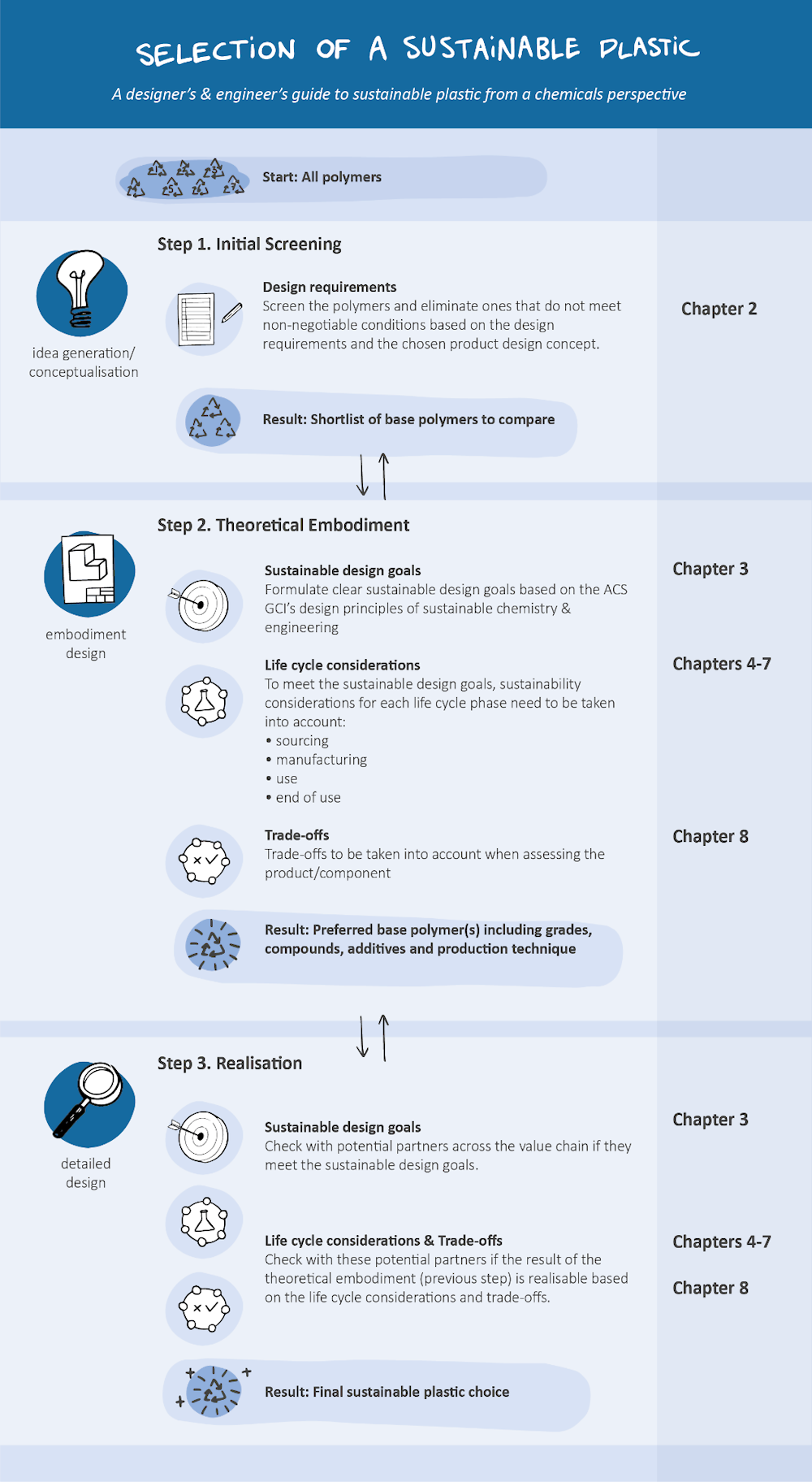

2.2.2. Steps of the sustainable plastic selection

The general steps of the sustainable plastic selection are summarised in Figure 2.3. These are based on Ashby (2005), the steps of sustainable plastic selection and continual improvement (OECD, 2018a) and the case studies (OECD, 2021a; OECD, 2021b; OECD, 2021c; OECD, 2021d). The sustainable chemical perspective is integrated throughout the material selection process systematically. Note that the process is iterative and enables continual improvement.

Figure 2.3. Steps of Sustainable Plastics Selection

References

Ashby, M. F. (2005), Materials Selection in Mechanical Design, 3rd Edition, Elsevier.

OECD (2018a), “Considerations and criteria for sustainable plastics from a chemicals perspective: Background paper 1. OECD Global Forum on Environment: Plastics in a Circular Economy”, Series on Risk Management, No. 51, OECD, Paris, https://www.oecd.org/chemicalsafety/risk-management/considerations-and-criteria-for-sustainable-plastics-from-a-chemicals-perspective.pdf

OECD (2018b), “Technical Tools and Approaches in the Design of Sustainable Plastics: Background paper 2. OECD Global Forum on Environment: Plastics in a Circular Economy”, Series on Risk Management, No. 52, OECD, Paris, https://www.oecd.org/chemicalsafety/risk-management/technical-tools-and-approaches-in-the-design-of-sustainable-plastics.pdf

OECD (2021a), “Case Study on Flooring; An example of chemical considerations for sustainable plastics design”, Series on Risk Management, No. 65, OECD, Paris.

OECD (2021b), “Case Study on Insulation: An example of chemical considerations for sustainable plastics design”, Series on Risk Management, No.66, OECD, Paris.

OECD (2021c), “Case Study on Detergent Bottles; An example of weighing sustainability criteria for rigid plastic non-food packaging”, Series on Risk Management, No. 63, OECD, Paris.

OECD (2021d), “Case Study on Biscuit Wrappers; An example of weighing sustainability criteria for plastic flexible food packaging from a chemicals perspective”, Series on Risk Management, No. 64, OECD, Paris.