This chapter discusses the major safety issues that may be encountered during the transportation of hydrogen through pipelines, most notably unintentional leakage. Key safety elements and recommendations are also presented.

Risk-based Regulatory Design for the Safe Use of Hydrogen

18. Pipeline transport: leakage from high pressure pipeline

Abstract

Hydrogen transmission pipelines

Transportation of compressed hydrogen gas over long distances through pipelines is more cost-effective and environmentally friendly option than other modes of transport like rail and road transport. More than 4 000 km of hydrogen pipelines are operated in several European countries, in the United Kingdom, in Canada and in the United States. The United States has the longest pipeline system of some 2 608 km in length (Statista Research Department, 2016[1]). Most pipelines are located within industrial sites, such as refineries and chemical plants, where hydrogen is used directly in production processes and as a feedstock.

Long-distance transmission pipelines normally operate at high pressures (up to 10 MPa). The pipeline diameter in European gas infrastructure ranges from 20 to 48 inches (Wang et al., 2020[2]). Hydrogen transmission pipelines are expected to have diameter also within this range, because the hydrogen infrastructure in Europe, The European Hydrogen backbone, will make use mainly of existing infrastructure, which will be properly converted.

Recently, the use of the existing natural gas pipeline infrastructure to transfer hydrogen has been a subject of extensive safety and practical research and has focused in overcoming technical concerns, such as hydrogen embrittlement of the steel pipelines and welds, and permeation leaks, etc. Blends with hydrogen up to 20 vol% require minimal changes in the existing infrastructure of natural gas network (Castek and Harkin, 2021[3]). In the short-term, such blends, instead of pure hydrogen, are recommended to obtain more evidence on the performance and durability of the pipelines and the required maintenance activities.

The Dutch Ministry of Infrastructure and Water Management and the Bilfinger Tebodin, a multidisciplinary consultancy and engineering company, has performed research on the technical aspects of using the existing gas pipelines for hydrogen transport. The findings of the research are published in the Tebodin report “Research into the Technical Aspects of Hydrogen in Existing Pipelines for the Energy Transition” (Dutch Ministry of Transport and Water Management and Bilfinger Tebodin Consultancy, 2019[4]) with the aim to provide guidance and considerations for repurposing of the natural gas pipelines to hydrogen gas applications and, on the other hand, to provide technical background for external safety research. Among the main conclusions of the research are the following:

The design factors that have been applied throughout the years for high pressure natural gas pipelines are in line with the design factors used for new hydrogen pipelines. Thus, the wall thickness of the existing pipes, corresponding to the relevant pipe diameters, design pressures and steel grades, are suitable for the use of hydrogen at a similar design pressure.

The damage mechanism that requires special attention for hydrogen applications under natural gas design conditions is cracks due to fatigue. For smaller pipes (≤ DN400) with lower steel quality there is no need for an extensive quantitative analysis when they are repurposed for hydrogen gas applications. For larger pipes (> DN400) with higher steel quality there is a real risk of fatigue rupture when larger pressure fluctuations are expected. In this case, a quantitative analysis will be required, which may result in operating restrictions through lower operating pressures and/or pressure fluctuations.

For leak-sensitive pipe components such as valves and flange joints, it should be verified that they are sufficiently leak-proof for hydrogen gas applications. If this cannot be demonstrated, these components shall be replaced by hydrogen gas-appropriate components.

Existing transmission pipelines are mainly buried underground for a safer and more reliable supply because the pipeline is better protected against accidental damage and frost. Similarly, new hydrogen pipelines are expected to be routed underground. Underground pipelines need to be protected against accidental excavation, shifting due to unstable soil, back fill damage to the external surface of pipe or the coating, and aboveground imposed loads such as vehicles or equipment moving over the path of the pipeline (European Industrial Gases Association, 2004[5]).

Existing technical norms

Safety standards for hydrogen pipelines include their design and construction in accordance with relevant industry codes and standards. For instance, requirements for piping in gaseous and liquid hydrogen service and pipelines in gaseous hydrogen service can be found in ASME B31.12 Standard on Hydrogen Piping and Pipelines (ASME, 2019[6]). This standard covers the requirements for materials, brazing, welding, heat treating, forming, testing, inspection, examination, operating, and maintenance. This Code is applicable up to and including the joint connecting the pipework to any associated pressure vessels and equipment but not to the vessels and equipment themselves.

Standards and regulations applied for high pressure pipelines are the basis for hydrogen pipelines in several countries,1 like for example in Japan. In the Netherlands, NEN 3650 series and NEN 3651 are the technical standards that cover the total life cycle of pipelines and provide safety requirements related to pipeline systems for transport of natural gas, oil and other gases and liquids.

Key safety / failure elements

A major concern in transporting hydrogen through pipelines is unintentional leakage and consequential ignition. Leakage can occur either through pipe joints or due to pipe damage. In the onshore gas transmission network of 145 000 km in Western Europe gas network of Europe approximately 20 incidents of unintentional gas release were reported each year. From 2004 to 2013, 35% of these incidents were caused by third party (external aggressions), 24% by corrosion, 16% by material weakness, and 13% by ground movement (EGIG, 2015[7]).

The typical pipeline leak size is a 12 mm breach and the main cause of such leaks is corrosion. If the leak takes place in a buried section of the pipe a crater can be formed. The possibility of a crater formation at given pipe depth depends on the pressure, the release orientation and the soil properties. Based on relevant experiments (Houssin-Agbomso, G. and D., 2018[8]) in buried pipelines at 1 m it was found that in soil with low plasticity and cohesiveness, like sand, a crater is formed by displacement of soil by the leak pressure at pressures higher than 40 bar. At pressures between 17-40 bar, an uplift of the soil is observed allowing the evacuation of hydrogen, which then is easily dispersed at the ground surface. On the contrary in a clayed soil, no crater is formed, only uplifts. Ignited methane exhibited similar behaviour.

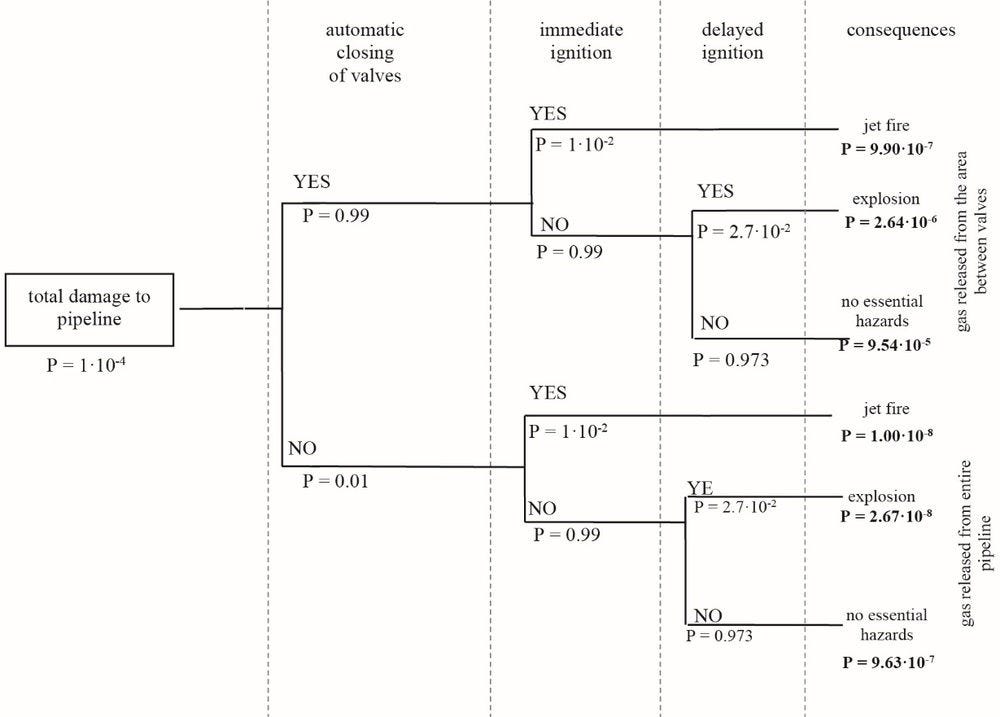

An uncontrollable hydrogen leakage would involve a pressure drop in the pipeline and should activate installed protection systems, i.e. the safety valves will close automatically, isolating the damaged section of the pipeline and limiting the quantity released. The magnitude of the consequences will depend on the successful operation of the safety system.

An event tree (see Figure 18.1) for damage to a hydrogen transport pipeline in (Witkowski et al., 2017[9]) suggests that the "no fire or explosion" event is more likely to occur, explosion follows and less likely is jet fire to occur. A probability of 0.01 for immediate ignition and of 0.027 for delayed ignition was applied in agreement with the proposed values from HYSAFE (Rodsaetre and Holmefjord, 2007[10]) and (Tchouvelev A.V., 2006[11]).

Figure 18.1. Event tree for damage to a hydrogen transport pipeline

Recommendations on key safety elements for hydrogen transmission pipelines

Plan and design of pipeline system

For a new pipeline construction, perform route survey and planning to identify geological challenges and to select a stable route free from ground movement and erosion.

Use of buried pipelines. There is no “golden rule” for pipeline burial. Pipe diameter and length could be important factors to consider. Japanese regulation requires the pipelines to be buried at least 0.6 m below ground surface and in crossings of public roads, where vehicle traffic is particularly heavy, the depth shall be at least 1.2 m. However, larger depth might be necessary to avoid normal agricultural activities, surface water drainage works and imposed road loads. For the construction of new pipelines avoid populated and agricultural regions to reduce the likelihood of pipe damage due to external activities, like building construction, excavation, etc.

Appropriate separation distances between pipelines and nearby vulnerable populations. The methodologies used to determine separation distances vary across all the studies. To determine separation distances risk-based approaches should be used.

Pipe casings or load shields should be installed at railroad or road crossings or where unusual aboveground loading can occur.

Establish the quality of an existing pipe before it is used for hydrogen gas (or hydrogen blends) transport by conducting a quantitative risk analysis and deterministic analysis such as through Computational Fluid Dynamic Model (CFD) (Dutch Ministry of Transport and Water Management and Bilfinger Tebodin Consultancy, 2019[4]).2

Standards/materials

Ensure that pipeline design and construction meets the requirements of relevant standards (e.g. NEN 3650 Requirements for pipeline systems – Part 1: General requirements, NEN 3651 Additional requirements for pipelines in or nearby important public works, ASME B31.12 Standard on Hydrogen Piping and Pipelines ).

Limit joint flanges. Welded connections are preferred.

Safety devices

When possible and practical, use a sudden loss of pressure automated shut down systems to isolate any damaged section of the pipeline and limit any loss of containment.

Implement an automatic leak warning that notifies nearby residents.

Practices

Provide signs at regular space intervals (every 1 km) for underground hydrogen pipelines to advise against activities that can damage the pipes, like excavation and provide a contact number to report damage.

Land use planning policy and control development near the pipelines and to control development encroachment (e.g. in terms of safety distances from vulnerable populations and objects).

Give notification before starting any excavation activities to obtain information about pipelines (in the Netherlands this is called KLIC-notification)

Controls

Inspection and maintenance interventions for both underground and aboveground pipelines. Routine, 5 yearly, Non-Destructive Testing (NDT) examination of the internal surface and thickness testing.

References

[6] ASME (2019), Hydrogen Piping and Pipelines, https://www.asme.org/codes-standards/find-codes-standards/b31-12-hydrogen-piping-pipelines.

[3] Castek, R. and S. Harkin (2021), Evidence review for hydrogen for heat in buildings.

[4] Dutch Ministry of Transport and Water Management and Bilfinger Tebodin Consultancy (2019), Research into the Technical Aspects of Hydrogen in Existing Pipelines for the Energy Transition.

[7] EGIG (2015), Gas Pipeline Incidents, 9th Report of the European Gas Pipeline Incident.

[5] European Industrial Gases Association (2004), Hydrogen Transportation Pipelines, https://h2tools.org/about.

[8] Houssin-Agbomso, D., B. G. and M. D. (2018), “Consequences of a 12-mm diameter high pressure gas release on a buried pipeline. Experimental setup and results”, Journal of Loss Prevention in the Process Industries, Vol. 54, pp. 183-189.

[10] Rodsaetre, L. and K. Holmefjord (2007), An ignition probability model for hydrogen risk analysis, DNV, HySafe Deliverable No. 71.

[1] Statista Research Department (2016), .

[11] Tchouvelev A.V., B. (2006), Quantitative Risk Comparison of Hydrogen and CNG Refuelling Option, Final Technical Report to Natural Resources Canada for the Codes and Standards Workshop of the CTFCA.

[2] Wang, A. et al. (2020), European hydrogen backbone.

[9] Witkowski, A. et al. (2017), “Comprehensive analysis of hydrogen compression and pipeline transportation from thermodynamics and safety aspects”, Energy, Vol. 141, pp. 2508-2518.