This chapter discusses a number of key findings and recommendations that can support regulators and policymakers in developing effective risk-based regulation to increase the role of hydrogen in their societies. These recommendations concern various aspects of the governance of hydrogen, from risk assessment to policy development and from regulatory frameworks to regulatory delivery.

Risk-based Regulatory Design for the Safe Use of Hydrogen

1. Recommendations for the smooth development and rollout of hydrogen applications

Abstract

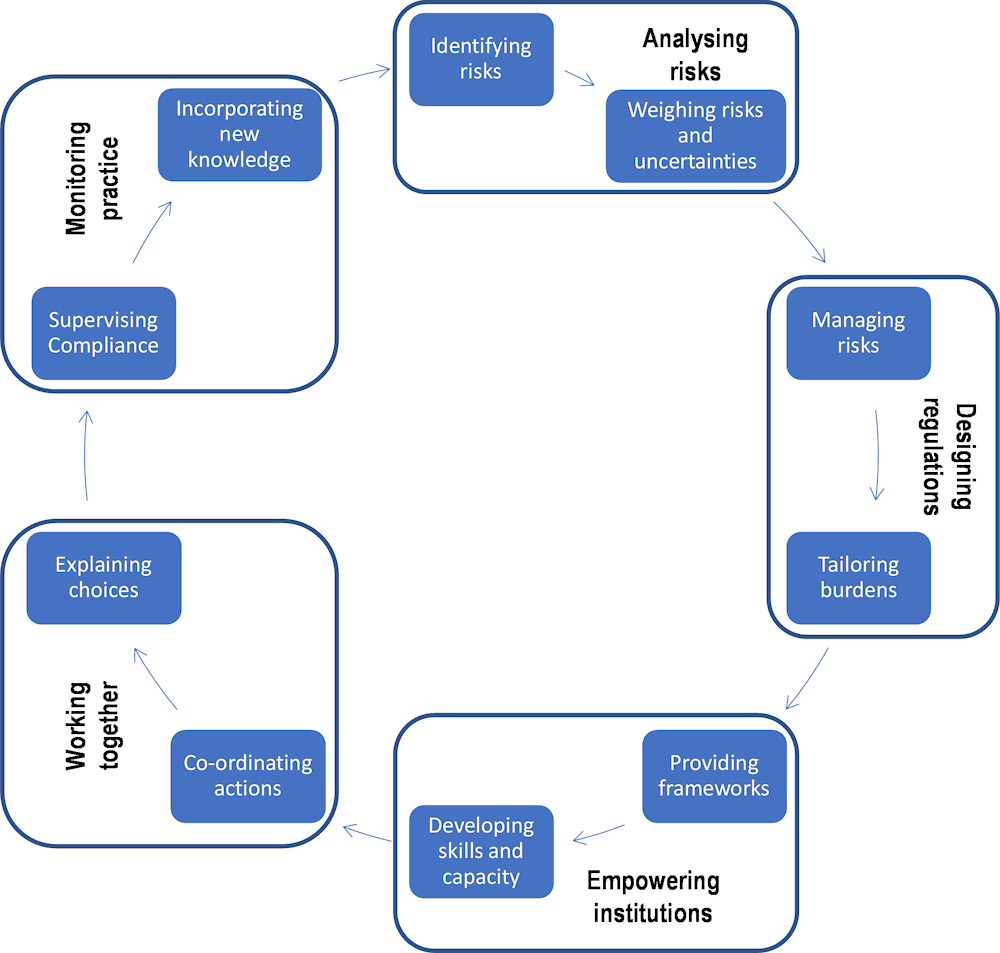

Effective regulation1 is essential for the success of the hydrogen transition. Their design matters because, while keeping safety a priority they need to support and facilitate the hydrogen transition rather than impede and complicate it. Commitments by countries to tackle global warming depend on innovation to develop and use new energy sources. Hydrogen is expected to play an important role in the future net zero world, but this potential depends on an enabling regulatory framework that allows for the smooth development and rollout of hydrogen applications. This requires regulation and regulatory delivery that are innovation-friendly, consistent and based on up-to-date evidence and knowledge of actual risks. Figure 1.1 identifies a number of elements in the cycle from risk-based regulatory design to delivery that should all be carefully designed to support the Dutch hydrogen transition while ensuring appropriate risk management. These elements will be discussed in detail in this chapter, by making assessments and recommendations.

Figure 1.1. Elements of risk-based regulatory design and delivery

Figure 1.1 provides a simplified framework that highlights several considerations during the stages of design and delivery. In practice, certain steps may overlap in time, or take place at several stages along the cycle. For example, while “explaining choices” identifies a moment for stakeholder engagement, engagement will take place at several other stages as well, such as when weighing risks and uncertainties and when developing frameworks. This is discussed in more detail throughout the chapter.

This chapter discusses a number of key findings and recommendations that can support regulators and policymakers in developing effective risk-based regulation to increase the role of hydrogen in their societies. These recommendations build on findings regarding (comparative) risks, regulation and trends in deployment for six distinct scenarios, as discussed in Chapter 5. Recommendations are tailored to some extent to the Dutch context, but could provide inspiration to the regulation in other countries as well, provided country-specific conditions are taken into account.

How safe, and how strictly regulated, is hydrogen? – Challenges in comparing different technologies and fuels

The impossibility of a reliable comparison of accident rates

Ideally, one would compare accident rates of hydrogen-fuelled (H2) vehicles against hydrocarbon-fuelled ones, or of refuelling stations against stations for different types of fuels, or of electrolysis facilities against oil refineries. However, the very small volume of hydrogen-powered vehicles and associated distribution and production, and the massive spread of hydrocarbon fuels worldwide, mean that such numbers cannot currently be reliably compared in terms of “damage per distance travelled” or “damage per energy unit”. Available databases of industrial accidents (eMars, HIAD, ENSAD, H2tools, etc.) include all types of hydrogen-involved accidents, including many where hydrogen is only a by-product of the accidental reaction, or even hydrogen compounds (e,g, “hydrogen sulfide”, “hydrogen chloride”, “hydrogen cyanide”, etc.), and not the cause or even one of the contributing drivers.

For instance, eMars (European Commission, 2023[1]) contains 142 accidents matching “hydrogen”, of which only 22 pertain to hydrogen rather than a compound, and of these, in at least 9 hydrogen was produced accidentally in an industrial process unrelated to the use of hydrogen. A typical example is the 2001 Corus UK accident (Curry and Hodges, 2001[2]), where hydrogen was produced accidentally after water penetrated a blast furnace. The remaining accidents might involve hydrogen produced as such, but usually in the presence of oxidising agents, and are not representative of hydrogen as a power source for vehicles, which is the main focus of this report.

Is hydrogen “reasonably safe” in its key applications for the energy transition?

There are several ways to consider this question, and it is essential to remember that safety should always be assessed here in comparison with whatever energy source would be the alternative to hydrogen (hydrocarbon fuels in most cases, electric batteries in some cases), and not with a “zero risk” hypothesis. In summary:

As part of preparing this report, a thorough literature review considered 99 publications spanning over 40 years, which led to the conclusion that hydrogen was overall often in the same range of safety as hydrocarbon fuels in the applications considered, while of course requiring safety measures and regulations adapted to its different physical behaviour compared to hydrocarbons (see Part I – “Literature review”).

The most serious and noteworthy hydrogen-involving accidents, or near-accidents, involve the simultaneous presence of hydrogen and of large quantities of oxidizing substances. For example, for rocket launches, liquid hydrogen and liquid oxygen are both present. These cases are totally different from the energy transition applications considered in this report, where hydrogen is not accompanied by any substantial amount of oxidising agents that could lead to explosion.

Accounting for risk reduction due to hydrogen use

Because of hydrogen’s specific physical and chemical behaviour, and of the considerable research efforts put into developing safer equipment, there are situations where hydrogen is safer than hydrocarbon fuels in a direct, immediate way (see Chapter 6 of Part I – Literature review). The main way in which hydrogen can overall reduce risks in a very important way is through its positive impact on climate change (assuming of course low-emission hydrogen is used, which this report focuses on). Reducing climate emissions means a considerable impact in terms of reduction of risks from catastrophic climate events. Finally, hydrocarbon fuels also present other major environmental and health risks, which hydrogen use would decrease. This is crucial particularly considering applications where other low-carbon alternatives such as electric batteries are inadequate for reasons of weight and range, e.g. transport of goods, particularly maritime transports but also road freight transport (see Box 2.1). To focus just on the climate angle, in the EU alone, transport is responsible for 800 Megatons of CO2 equivalent, of which close to 40% due to trucks (EEA, 2022[3]). Achieving carbon neutrality for Europe will entail a 90% reduction in transport emissions by 2050, and hydrogen is explicitly mentioned as a tool for that purpose in the EU Commission’s “Sustainable and Smart Mobility Strategy" (European Commission, n.d.[4]).

What levels of regulation does hydrogen face?

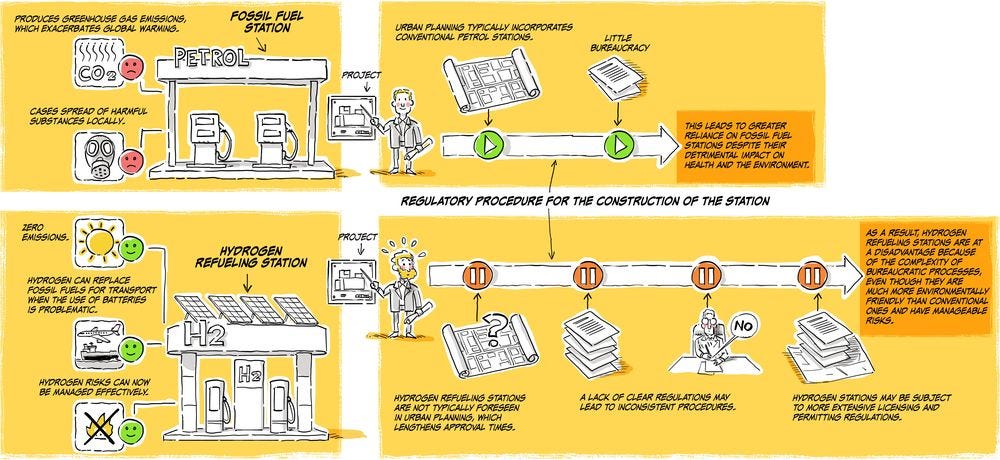

Defining levels of regulation (and possibly identifying “over-” or “under-” regulation) can only be done in comparison both to the risks specific to the application of hydrogen being considered, and with the regulation applied to hydrocarbon fuels for similar applications. This report only discusses a set of specific processes and applications (electrolysis, transport, refuelling, hydrogen-powered vehicles). Details of existing regulations are discussed in Part II – Regulatory review. The problem is often that these new applications of hydrogen have not been foreseen in existing legislation, and that they are thus “by default” either unaccounted for, subject to requirements that do not match its specific risks or facing regulatory uncertainty, particularly in terms of site approval and permitting. This does not in any way mean that hydrogen is generally over-regulated, and this report in any case does not cover the industrial processes involving hydrogen, which often benefit from long-established, specific regulations. Providing case-by-case comparison for every case and country would go beyond the scope of the report, we thus provided a comparison for one simple example: opening a hydrogen refuelling station (HRS), looking at three jurisdictions (California, England, and the Netherlands) (see Box 3.2). Even in the most favourable regime (California), opening a HRS remained longer and more difficult (restricted siting because of higher fire safety distances) (Harris et al., 2014[5]). While regulations are being eased to reduce safety distances, overall permitting procedures still take time. In England, it was much longer because of falling under gas licensing requirements and safety plus environmental permitting. In the Netherlands, it was both longer and more difficult because of no zoning provision for HRS and the need to obtain both zoning exemptions and environmental permits.

In summary: “Most [EU] countries currently lack specific regulation that target the dispensing of hydrogen in refuelling stations, as this is still new equipment that has not been targeted in regulations. For the HRS currently deployed, the permitting procedure follows existent guidelines on conventional fuelling stations combined with industrial hydrogen requirements or CNG specific regulation. Most countries agree that the lack of specific regulations increases the level of subjectivity in the permit decision" (MultHyFuel Project, 2021[6]).

Figure 1.2. Regulating hydrogen in practice: Opening a hydrogen refuelling station

Source: Stefano Tartarotti, 2023.

Identifying and enabling hydrogen innovations and their regulatory needs

Hydrogen as part of industrial processes is both long-known and long-regulated, through safety and environmental legislation covering industrial risks and emissions. The energy transition requires the large-scale roll-out of a number of hydrogen innovations, which generally do not currently have a specific regulatory framework – they include: production through low carbon electrolysis (long-known, but hitherto used on a very limited scale only), transport through pipelines and land transport, distribution through refuelling stations, use in private and commercial vehicles, and possibly in some cases use for domestic heating purposes. Because these uses are new, there are in many cases no specific rules for them, they are often not foreseen in zoning, and they can end up being covered by industrial permitting requirements, or require complex and lengthy ad hoc authorizations or derogations.

It is essential that these new uses of hydrogen be properly foreseen, enabled, and effectively regulated at the same time. As described in more details further on, technical rules need to be adopted that ensure best practices are used in a systematic way, including through “safe by design” installations whenever they are available. At the same time, planning authorities and regulators need to ensure that new hydrogen technologies and uses are effectively enabled, with requirements that are proportionate to the risks and benefits of these innovations, and regulatory processes that minimize unnecessary burden and delays, but rather focus on the essential risk factors (OECD, 2021[7]).

Recommendations

Identify hydrogen innovations that are a priority for scaling up, and present difficulties in the existing zoning and permitting frameworks. Governments have often already developed important plans for scaling up hydrogen production and/or use, but have not necessarily conducted a review of potential regulatory and planning bottlenecks. This is essential in order to enable this scaling up at the desired speed. It can largely be done through conversations with stakeholders, in particular permitting authorities and the industry.

Revise zoning and permitting for new hydrogen applications. Incorporating lessons from practice and research, define zoning rules that enable the development of hydrogen in a safe way, and define permitting processes that are risk-proportionate, particularly for lower-risk facilities and uses – for which high-risk industrial permitting requirements are likely to be disproportionately burdensome.

Ensure adequate safety through fit-for-purpose technical requirements informed by science and practice. Enabling zoning and simplified permitting do not mean lower safety – on the contrary, developing specific requirements covering the higher risk aspects of these new hydrogen applications (as discussed further) can help ensure that best practices and techniques are more systematically applied.

Analysing risks

Identifying risks

The design and delivery of risk-based hydrogen regulation will depend on how actual hydrogen risks compare to the risks of existing fuels and should factor in the growing understanding of hydrogen risks. Energy applications are never entirely risk-free. While the properties of hydrogen pose certain hazards (see Chapter 2, Understanding and managing hydrogen risk), hydrogen is overall not riskier than hydrocarbon fuels for many of the applications considered in this report if managed properly, even when considering only safety risk in the narrowest sense. Sometimes, with the right technology, it can already be safer. Improvements in technologies and scientific knowledge have significantly decreased the number of “unknown risks” for many hydrogen applications and contributed to building safer technologies. This therefore reduces the need for more cautionary approaches.

A siloed assessment of individual risks could result in suboptimal decisions from a social welfare perspective. Risks do not exist in isolation, but often the reduction of one risk may come at the expense of another. If one takes into account the climate impact and other adverse health and environmental impacts of hydrocarbon fuels, there is little doubt that hydrogen is not a riskier fuel, but quite the contrary. However, a sole focus on one specific risk can lead to excessively risk-averse approaches, the ignoring of countervailing risks and risk-risk trade-offs. This may be further complicated in cases where responsibilities for different risks may be spread across different authorities and levels of government, as is the case in the Netherlands, resulting in differing appetites for risk across authorities and an incomplete assessment of all risks. Specifically in the context of hydrogen, this could mean that measures to reduce safety risks – for example, by restricting the deployment of low-emission hydrogen2 applications – may ignore the very climate change risk that these technologies aim to tackle.

Recommendations

Use holistic approaches to consider all relevant risks, and risk-risk trade-offs, related to the deployment of hydrogen applications. Identifying the interaction that may exist between different risks – including health, safety, environmental and economic risks – can allow for a more comprehensive assessment of the implications of decisions and build a common understanding of the definition of risk. This would help to take into account risk-risk trade-offs, as well as systemic and cumulative risks, and would reduce suboptimal “siloed” decision making that could lead to a disproportional focus on safety risks at the expense of potential environmental benefits. Where different risks are assessed by different authorities, this holistic risk assessment will likely require additional information sharing and co-ordination between bodies (see Co-ordinating actions).

Quantify risks based on robust empirical data. The relative novelty of many hydrogen applications means that there is less knowledge and information available on risks. However, the increasing momentum for hydrogen, driven by hydrogen strategies across the globe, has led to a significant increase in scientific knowledge and robust data on risks for new applications. This will enable decision makers to objectively quantify the risks related to new hydrogen applications with more precision. By quantifying risks based on empirical data, governments can ensure that regulations and measures are focused on actual rather than hypothetical risks.

Put risks into context by comparing hydrogen’s risks to those of other energy sources such as natural gas. This comparison may highlight where hydrogen poses “familiar risks” that are similar to conventional energy sources, and those attributes that may result in risk profile differences. This analysis can then feed into decision making on the appropriate measures. By putting risks into context, where possible using quantitative risk assessments, decision makers can better assess the net effect on risks that changing to hydrogen applications would entail, including the effects on existing risks that might reduce or disappear. Moreover, by comparing hydrogen risks with those that are more familiar, the risk assessment can be prevented from becoming a theoretical exercise and made more understandable (see Chapter 5 – Hydrogen applications in practice; Part IV – Review on incident database and lessons learnt and Part VII – Quantitative risk assessment).

Weighing risks and uncertainty

Incomplete understandings of risks, public perceptions and behavioural biases may potentially result in a higher degree of risk aversion for new hydrogen applications. While there is no doubt that real risks are associated with hydrogen, there are often large gaps between risk perceptions and actual, science-based risk assessments. The rollout of hydrogen applications introduces new risks, some of which may be more uncertain than others due to a lower availability of scientific research and historical data. The level of risk aversion that policymakers will apply in response to these uncertainties depends on the context in which decisions are made. It is essential, however, that regulation of low-emission hydrogen not be more unfavourable, at comparable risk level, than regulation of fuels that are high CO2-emitters (hydrocarbons, mostly). This involves, in particular, looking at zoning plans and permitting procedures to ensure they are proportionate and adequately enabling.

An in-depth consideration on the public perception of hydrogen can be an important element for managing the energy transition, to increase the degree of awareness and the level of acceptance for the energy transition. Socio-political and psychological elements as well as public perception can play a decisive role, because risks of fire and explosion are often at the centre of the debate. In some cases, policymakers may “rush to judgement”, by excessively regulating certain risks without acknowledging the trade-offs with other risks. In particular, a lack of familiarity with hydrogen applications could result in a lower risk tolerance than for existing fuels, for which a certain degree of risk has already been accepted. Moreover, the “availability heuristic” may lead to an increasing focus on low-probability accidents and worst-case scenarios (see Chapter 3 – Behavioural biases and public perceptions). The “present bias” can lead people to give more importance to current needs and less importance to future needs. Finally, “path dependency” can result in difficulties when institutions try to change or reform existing processes.

The level of risk aversion may differ according to the type of hydrogen application, depending on the countervailing risk that “stalled innovation” could bring. This means that where certain types of hydrogen applications have a more prominent role in a country’s net zero strategy, safety risks have to be weighed against a higher risk of inaction (i.e. innovation is slowed down or prohibited). This could lead to countries accepting a higher level of risk (or implementing a lower level of risk aversion) for those technologies that will play a bigger role in combatting the climate crisis, especially where other “green alternatives” are limited.

As the level of knowledge on safety varies for different hydrogen technologies, it makes sense to regulate them differently. When scientific knowledge is more limited and risks are not obvious or simply unknown, additional pilots could be carried out to improve scientific knowledge. Hydrogen technologies can be divided into three broad categories, based on the level of existing knowledge and scientific research:

Category 1 – Mature technologies on which there is extensive scientific knowledge and data. These technologies often do not require additional caution compared with conventional fuels, but can be facilitated and managed using existing risk management approaches and findings from recent research and good practices;

Category 2 – Technologies for which a significant level of scientific knowledge exists but additional data may be needed. These technologies can be handled through risk management approaches using available scientific knowledge and experience with comparable technologies. However, they will require additional regulatory development, using iterative approaches, as scientific knowledge and technology advance;

Category 3 – Technologies for which risks are not yet completely understood. These technologies require further investigation and research through pilot projects to more reliably assess risks, identify suitable policy approaches, define regulatory requirements, and build public awareness.

Recommendations

Provide clear information to the public on risks, including any countervailing risks that hydrogen applications try to address. The provision at an early stage of understandable and objective information on all relevant risks across the full energy cycle of an application, including low-probability extreme events, can support the growth of trust and build wider awareness. As hydrogen currently only makes up a relatively small portion of the overall energy mix, there is a need to engage the wider society through a phased, transparent and inclusive communication strategy which enables informed decision making. Using clear communication to support knowledge, critical reasoning and elicit social assessments based on data can be an effective way to overcome social prejudices and fears. This will require on-going public engagement and behaviourally-informed information campaigns, in order to create a counterweight against potential mis- and disinformation or fear-mongering regarding risks and uncertainties. Emphasising and discussing not just risks to health and safety, but also the role of hydrogen projects within the Dutch climate ambitions to address climate risks, will enable society to better understand the importance of new hydrogen initiatives.

Proactively involve the public in decision making on hydrogen risks, safety measures and strategies. Governments could use open and transparent decision making on risks, uncertainties and risk management to invite wider input into cost-benefit analyses of prospective hydrogen policies and initiatives. This could contribute to better informed decision making, build ownership and trust, and increase the willingness of societal actors to accept risk-risk trade-offs. As part of this effort, public perception studies can be used to understand the values and interests at stake and allow governments to better respond to existing concerns.

Develop and make public the risk tolerance criteria against which existing and new technologies are compared. A common approach to risk management can support more harmonised actions between different authorities. To ensure policies and regulations are consistent, governments could define clear and consistent methodologies for risk assessment and the way in which different risks should be weighed and prioritised. In particular, such criteria should be used to frame the risks of new technologies in the context of existing risks, to avoid higher levels of risk aversion for newer (less familiar) technologies.

Designing regulation

Managing risks

The risks of hydrogen are decreasing as technologies and safety approaches mature, thereby reducing the need for additional caution around hydrogen as compared with other flammable gases. Research into the use of hydrogen has led to significant improvements in safety, making today’s technologies safer than older historical incident data may suggest (although new data already highlights this trend, see Scenario 1 – Production through water electrolysis in Chapter 5). Research suggests that current hydrogen production – making use of modern designs and safety regulations – could present a lower normalised fatality risk per Terawatt-hour (TWh) as compared to conventional fuels (see Part IV: Review on incident database and lessons learnt). For other hydrogen applications, incidents are often typical of those for other flammable gases, although exact risks differ across scenarios. It is thus essential to develop an effective regulatory framework, that ensures best safety practices are followed, and allows the development of hydrogen.

By updating regulatory approaches, governments aim to combine appropriate levels of caution with the necessity to innovate for cleaner energy sources. Responsible Research and Innovation and Safety-by-Design approaches place a stronger emphasis on anticipation and inclusion to foresee risks during product development. This limits the need for additional measures once technologies are being applied. Both approaches rely heavily on the regulatory capacity and resources to build open relationships, albeit within the constraints of available scientific knowledge and commercial sensitivities.

Recommendations

Apply responsible research and safety-by-design approaches to the prevent risks of hydrogen applications where this is reasonably possible. Approaches should prioritise safe designs that account for human error. This could favour applications with automatic shutdown mechanisms and safer materials, complemented by mitigation measures such as ventilation. For example, modern valve design has already contributed to a reduction in hydrogen accidents (see Part VI: Lessons learnt and preliminary findings regarding hydrogen safety elements). Regulators could certify safe components and equipment through “type approvals” that do not require individual assessment and use quantitative risk assessments to prioritise measures. This will require regulatory preparedness and earlier engagement with stakeholders through:

Informal exchange and outreach by regulators, for example through “innovation hubs” where innovators can discuss upcoming projects with authorities.

Improved guidance to innovators, including guidance material on engagement between innovators and authorities at early stages of innovation.

Prior assessments to better understand applications and risks early on.

Learn from international experience and standards to avoid having to “reinvent the wheel”. Regulations developed in other countries that are further ahead in achieving their hydrogen ambitions, as well as international standards such as those by the ISO (see Part II – Regulatory review), can provide a strong starting point for the Netherlands to design appropriate safety standards that are internationally aligned. This approach should favour more precise safety measures over outright bans of activities, thereby incentivising innovation.

Do not mitigate safety risks excessively beyond the desired risk targets or apply precaution to risks that are largely well-understood. Risk mitigation measures should be based on widely agreed levels of desired risk tolerance and clear, top-down guidance for implementing authorities. This is to avoid “risk regulation reflexes” and inconsistencies between inspectors. Moreover, precaution should be limited to those cases where it is absolutely necessary because risks are still largely unknown (scenarios such as this are declining rapidly due to advances in scientific knowledge and technology). Risk mitigation strategies should not aim to reduce risks beyond agreed levels of risk tolerance and should favour measures that are most effective at risk reduction, with the goal of achieving a well-managed balance of safety, health, environmental, social, political, financial and economic risks. As part of this approach, safety incidents should not lead to excessive restrictions or bans but should be used as learning opportunities to improve regulatory frameworks.

Chapter 5 discusses general safety measures and regulations in other countries for each scenario.

Tailoring burdens

Complex licensing procedures can slow down or impede the hydrogen transition. Licences often require significant effort, making the scaling up and development of new technologies such as hydrogen time and resource consuming. In practice, permit designs may be based on approaches that focus on a specific risk, without balancing risk-risk trade-offs against the risk of climate change. Other factors that may lead to less efficient licensing procedures include resource constraints and the overlapping mandates of authorities. Mandate overlaps can lead to duplication of efforts, additional burdens or inconsistencies in decisions. In certain cases, it can also result in conflicting policies, where licensing procedures slow down transitions that other policy instruments such as subsidies aim to accelerate. Moreover, the time at which hydrogen initiatives first get into contact with the Dutch authorities may differ by project and there are different parallel channels to establish these contacts.

Existing procedures may not match the exact risk reduction needs for new low-emission hydrogen applications. Hydrogen applications are often subject to more general licensing procedures designed for applications with dangerous substances or they may be asked to meet extensive safety requirements due to a lack of scientific understanding. Moreover, licensing requirements in the Netherlands are universal regardless of the type of hydrogen.

Recommendations

Use simplified procedures, fast-tracking and minimise the use of licensing to what is absolutely necessary. The burden of instruments should match the risks they try to manage, where targeted safety measures should be preferred over outright bans of activities. Licensing should not be the default, but should be used only to manage significant safety risks. For hydrogen applications that are lower risk or for which risks can be managed more easily, governments should consider fast-tracking, notification requirements or so-called silence is consent provisions that limit the duration of procedures. For higher-risk applications, prior assessments of safety risks at earlier stages may be used to decrease the length of procedures after the finalisation of projects. Reducing document requirements and standardising requirements and forms can reduce costs and time for applicants. Competent authorities should consider ways to minimise the number of interactions between governments and hydrogen developers.

Make use of one-stop shops and guidance for innovators to clarify and streamline procedures. A one-stop shop allows innovators to find all the requirements related to their project in a single location, saving them time and effort and reducing the number of authorities they need to engage with. This may be built from the online Environment Desk (Omgevingsloket), which already performs a number of one-stop shop functions and could include a dedicated platform with information for hydrogen projects (for example, information on the relevant authorities for different types of hydrogen applications and their contact information). A one-stop shop could be complemented by straight-forward guidance materials on relevant steps, to help innovators navigate the regulatory landscape and reduce uncertainty. Such guidance can support a reduction in the number of incorrect licence applications, thereby reducing the burden on both innovators and authorities.

Use outcome-based and risk-based regulatory models to target actual risks and outcomes. Safety does not depend on the existence of an extensive set of requirements, but rather on the presence of efficient measures to reduce risks. Efficient licensing regimes will require agility to focus on the most pressing concerns, while reducing those requirements that have a low impact on actual risks. Processes should avoid a focus on specific measures that may become outdated as technology advances, and instead specify the risk levels that innovators need to show they conform with. Such outcome-based models can harness the opportunities offered by digital technologies and data to improve efficiency.

Empowering institutions

Providing frameworks

The Dutch hydrogen ambitions create new sector segments, which could give rise to an initial lack of role clarity and regulatory uncertainty. The introduction of low-emission hydrogen applications raises the question of how new responsibilities fall within existing institutional mandates, which are often linked to specific energy sources. This could result in a duplication of efforts or situations where regulatory agencies do not have the appropriate powers to respond to regulatory issues, thereby affecting the pace of the hydrogen transition. Moreover, in the absence of a dedicated regulatory framework for hydrogen, applications are mostly regulated under more general regulatory requirements, such as Seveso requirements or other frameworks for dangerous substances. These regulations can provide a suitable solution to manage risks until assessments of regulatory requirements have been concluded. However, they may not necessarily be the most efficient option to address the actual risks of hydrogen in all scenarios.

The hydrogen transition creates a need for additional guidance and direction, to avoid inconsistencies in decision making between national and local levels that could harm climate goals. Many licensing and supervision functions in the Netherlands are executed at the provincial or local level. On the one hand, this will allow authorities to better factor in the local context in their decision making. However, in combination with the lower levels of scientific knowledge that exist for many hydrogen applications, it could also give rise to inconsistent approaches across regions or an excessive focus on (local) safety risks over more global risks such as climate change. There is therefore a need to safeguard the harmony between policy direction at the national level and local implementation.

Recommendations

Provide clarity on roles and responsibilities and identify areas with potential gaps or overlaps. Legislation should clearly set out the mandates, powers and objectives for authorities. Governments may wish to reconsider existing mandates where there are overlaps or gaps, and make sure responsibilities are clearly assigned. As it may not be possible to remove all “grey areas”, effective co-ordination mechanisms can be used to align actions and resolve any conflicts (see Co-ordinating actions). Where the responsibility for one specific risk is shared among different authorities, consolidation of responsibilities or “lead agencies” could be used to ensure accountability. These efforts could support a harmonised execution of regulatory tasks to achieve envisaged outcomes. Furthermore, assigning clear mandates to authorities, if matched with the necessary resources, could enable authorities to invest in their capacities.

Conduct a “stock assessment” of existing frameworks that apply to hydrogen to assess their impact, with the goal to build a simple and effective regulatory framework. This could for example include a public stocktake of existing frameworks for hydrogen to identify problem areas and solicit public views, or a principle-based review to focus on a specific performance area such as administrative burdens (OECD, 2020[8]). More general regulatory provisions and thresholds may need modification, in cases where they do not target actual risks of hydrogen, or they create regulatory gaps or unnecessary regulatory burdens that excessively restrict activities. Regulatory options should be decided upon through regulatory impact assessments and stakeholder engagement. In addition, where existing requirements allow for significant regulatory discretion, the Netherlands should consider providing additional guidance to implementing authorities at the local level through decrees, codes, guidelines and standards (for example guidelines on QRAs for hydrogen refuelling stations).

Provide temporary solutions only on a time-limited basis. Regulatory exemptions can facilitate the controlled trialling of new technologies and approaches in situations where regulatory frameworks are missing, for example through regulatory sandboxes. To provide predictability and ensure a level playing field, such exemptions should be time-limited and target a specific regulatory gap. Once scientific knowledge improves and legislation catches up, exemptions need to be phased out. Similarly, guidelines and other “soft law” may provide direction during early stages of developments while frameworks are absent, but should not replace legislative provisions that involve a higher level of scrutiny and engagement, and enhance predictability and legal protection.

Developing skills and capacity

The hydrogen transition is increasing the overall responsibilities of governments and regulatory authorities in the short term. As the application of hydrogen technologies throughout the Netherlands expands, policymakers and regulators will be asked to take on new responsibilities in fields they have relatively little familiarity with. These duties come on top of their existing responsibilities in other energy sectors, such as electricity, gas and (somewhat more recently) district heating. This will result in an increase in workload in the short term, though they may decrease in the longer term due to higher levels of experience and a reduction of activities towards energy systems that are phased out.

The effective delivery of new hydrogen responsibilities will depend on the ability to stay agile, build knowledge and skills, and keep abreast of new developments. Regulating hydrogen effectively will require an investment from public bodies to (1) understand hydrogen technologies, (2) incorporate the new economic, legal and safety realities of the hydrogen transition into their decision making, and (3) foresee upcoming developments through horizon scanning. This investment will put pressure on the overall resources of public bodies, where demands related to hydrogen compete with existing demands. Ultimately, their success in delivering on new hydrogen expectations will depend on the agility they have within their resource constraints to build new capacities and skills.

Recommendations

Conduct capacity assessments for public bodies at the organisation level and government-wide to understand skills needs. Such capacity assessments should factor in the nature of existing and upcoming hydrogen responsibilities, the expected trajectory of hydrogen deployment in the country and the necessity of knowledge retention within the organisation. To stay relevant, the assessment should identify required skills, experience and competencies on a continuous basis, using periodical review to factor in new experiences, developments and demands.

Develop training programmes for existing staff and hire new skills as necessary. Public bodies require new skills and knowledge to assess the impact of innovations on their work and to deliver upon new responsibilities with agility. This could be achieved through a mix of training existing staff and additional recruitment. Needs for new skills could be tied into the career development of existing staff by providing training and development opportunities and staff incentives. Where possible, training could be provided in collaboration with other public bodies and countries through online platforms to achieve economies of scale. This could be complemented by the hiring of new staff to meet skills needs, especially where these have changed significantly or where overall responsibilities increase. The contracting of external expertise should be considered mainly for more temporary skills needs or to fill urgent skills gaps in the short term.

Assign the appropriate resources for authorities to be able to respond with agility. Coherent and robust workforce planning can help build a forward-looking public service, a crucial element to incorporate the new responsibilities that the hydrogen transition will bring (OECD, 2021[9]). Conducting workforce plans at the level of organisations and government-wide can allow governments to translate skills assessments into human, financial and digital resource needs – in both the short and longer term – and assess and monitor the status quo. Moreover, more predictable resources will support public bodies in delivering effectively upon new demands, acknowledging the fact that it takes time to build new skills and capacities. Wherever reasonably possible, new responsibilities of a permanent nature should not be met with temporary resourcing mechanisms, as this could make it more difficult for bodies to develop and retain in-house skills.

Working together

Co-ordinating actions

The regulation of hydrogen in the Netherlands involves a range of actors at the local, national and EU level. Together, these actors will determine the success of the hydrogen transition. While hydrogen ambitions and policies are developed by EZK at the national level, they are implemented by a range of authorities at the national level (ACM, SodM, AT and NLA) and local level (provinces, municipalities, Ods and VRs). Moreover, regulations in the Netherlands depend on wider EU initiatives, with efforts to align policies at EU level through EU Directives and agreements such as the ADR.

Co-ordination of actions could bring efficiencies and burden reduction. Given the many actors involved, there is a need to ensure actions are co-ordinated and harmonised. In practice, there is not always sufficient clarity around the point in time when co-ordination between different bodies, such as between the OD and VR, is required. More co-ordinated action could decrease the burdens on regulated entities by reducing duplicated effort or inconsistencies in approach. As hydrogen ecosystems tend to cut across national and jurisdictional boundaries, there is an increasing need to co-ordinate regulatory action with authorities in neighbouring countries. Coherence of rules and approaches at the EU-level (and beyond) can support system integration, prevent regulatory arbitrage, improve the investment climate and allow for an international level playing field.

Recommendations

Identify areas for joined-up approaches and coherence in action between public bodies at different levels of government. The Netherlands could strengthen regulatory co-operation across policy-making departments and regulatory agencies by identifying gaps or overlaps in existing co-ordination mechanisms. A formalised co-ordination platform for public bodies involved with hydrogen at different levels of government – such as a network or a periodic meeting – could support consistency and enable shared planning or execution of regulatory activities (while respecting each body’s mandate, resources and level of autonomy). Frameworks should enable seamless co-ordination of approaches, where appropriate, through whole-of-government visions and approaches. This can prevent potential regulatory failures or suboptimal outcomes due to siloed approaches, support the proactive resolution of issues as they appear, and realise synergies. Joined-up approaches could also include an “emergency response plan”, to co-ordinate actions after accidents and bolster public trust in decision making.

Enable wide knowledge sharing across public authorities to harmonise approaches. The sharing of data, information and research findings across public authorities – through networks and joint research initiatives such as the EU Joint Research Centre (JRC) (see Chapter 4 – “Institutional context for hydrogen”) – can support a shared understanding of developments and risks assessments. Knowledge sharing will be especially relevant in a context where the sector is subject to significant development, as is the case with hydrogen. Furthermore, it could reduce the risk of differential treatment or excessive risk aversion beyond agreed levels of risk tolerance that can stem from isolated risk assessments. To enable knowledge sharing, authorities could consider collective knowledge databases, periodic workshops and conferences, including interdisciplinary challenge events.

Exchange experiences and practices internationally to establish international best practice. The Netherlands could use existing co-ordination platforms at the EU and international level to promote a continuous dialogue and engage in information and data exchange. This would enable mutual learning across countries and bring in the most relevant evidence and approaches to support its hydrogen ambition. Where necessary, additional co-ordination mechanisms could be considered, such as an EU network of hydrogen regulators or co-operation agreements. Moreover, ex ante impact assessments of policy options could include options that involve joint approaches with other jurisdictions, thereby addressing transboundary policy implications.

Explaining choices

Mechanisms of public accountability can support trust and public buy-in for the hydrogen transition. The Dutch hydrogen sector brings together many different public bodies. All are expected to contribute to the functioning of a healthy hydrogen sector, but through different roles and mandates. Accountability mechanisms can support the effectiveness of the respective actions of such public bodies, holding decision makers to account for their actions and supporting the integrity of their decision making. If done well, this can enable the public to scrutinise regulatory actions, identify cases in which authorities may have overstepped their mandate, and assess if public institutions do indeed contribute to the improvement of sector outcomes through their actions.

Increased transparency will benefit the predictability of regulatory frameworks, thereby giving companies the confidence to invest in hydrogen technologies. Regulatory frameworks are a key aspect for investors to consider when deciding whether to invest in a specific technology because they determine the constraints within which activities may be undertaken. The more transparent and predictable regulatory frameworks are, the lower the “regulatory uncertainty” to factor into decision making. Therefore, transparency in regulatory decision making can support a more positive investment climate. Transparency may be especially crucial in a context where there are higher levels of discretion in decision making by regulatory authorities, as it can explain to stakeholders how regulatory principles are applied in practice.

Recommendations

Provide clear and non-technical explanations of regulatory decisions. Such explanations should describe the different risks assessed and weighed by the authority. This should be in a clear and non-technical format and communicated proactively through a range of communication channels to support awareness. This enables the authorities to explain how decisions have been made and to put hydrogen risks in perspective by comparing them with the existing risks of conventional energy sources. Furthermore, as no application will be entirely risk-free, explanations can be used to acknowledge risk-risk trade-offs and any remaining risks. In particular, care should be taken to avoid technical discussion of a specific risk in isolation, without the appropriate context or comparisons, which could harm public perceptions.

Establish mechanisms for stakeholders to provide input into decision making and appeal decisions. These mechanisms create a challenge function to decision making and could for example include public consultation on draft decisions, or engagement with stakeholders at earlier stages of the regulatory process. The scope and impact of the regulatory decision will determine the design of any mechanisms to provide input into regulatory decisions. For more significant decisions, the authority could publish draft decisions to collect broader input and provide a response to comments to show how they have been taken on board. Appeal mechanisms should provide for an independent review of appeals on decisions, to support trust and the quality and integrity of decision making.

Report on the achievement of stated goals through a comprehensive set of indicators and targets. Through periodic reporting, public entities can report back to the public on how their actions have contributed towards the achievement of envisaged objectives (such as safety, health, environmental, social or economic objectives). This could allow society to assess if intended outcomes have indeed materialised, and support any learning by authorities in cases where approaches did not lead to the desired outcomes.

Monitoring practice

Supervising compliance

Inspections are one of the most important ways to enforce regulatory compliance and ensure conditions for risk reduction are met in practice. A smooth deployment of hydrogen applications will not only rely on the design of regulations, but also on how these regulations are implemented and enforced. Without appropriate inspections and enforcement, regulations risk being a “paper reality”, which could harm the effective achievement of their envisaged goals. Rigid processes and uniform control will be less effective in improving compliance than responsive3 and outcome-based regulation. Moreover, inspections can act as a sanity check on implemented measures, to see how well they address actual risks in practice and to assess if additional actions are needed. The main objective is to design inspection and enforcement mechanisms that deliver the highest level of compliance, while keeping the regulatory costs and administrative burdens on businesses as low as possible.

Regulators are increasingly expected to do “more with less” without compromising on protection of public interests. This is forcing them to reconsider how they can make their approaches to inspections and enforcement more efficient. Societies expect higher levels of safety, health and environmental protection, while regulators often face more significant budget constraints than in the past. Regulators therefore need to make their actions more targeted, addressing those areas that pose the biggest risks, while reducing efforts with relatively small impacts. This will require consistent risk methodologies and well-defined criteria and thresholds to identify low, medium and high-risk activities. This task has become even more challenging as innovations disrupt the sectors that regulators oversee. At the same time, pressures from political leadership, industry or concerned citizens can increase risk aversion or result in slower decision making.

Recommendations

Prioritise enforcement and inspections actions to ensure they are risk-based, proportional and outcome-focused. Regulators should plan inspections proactively based on evidence, where the frequency of inspections and resources employed are in proportion to the actual risk of the regulated activities. Rigid processes and detailed prescriptive rules should be avoided where possible, as they may not necessarily be most efficient at achieving the desired outcomes. This may be the case especially in a context where innovations rapidly transform regulated activities. Outcome-based approaches can allow regulators to promote compliance and target risk reduction more directly, while providing space for innovators to find the most efficient means to achieve those outcomes.

Modulate inspection and enforcement actions based on “responsive regulation” principles to incentivise compliance. Responsive regulation, which differentiates regulatory enforcement based on the behaviour of regulated entities and on the level of risk created by violations,4 can deliver better outcomes than a system of heavy sanctions for each and every violation – an approach that may not necessarily be most effective at increasing overall compliance. To respond effectively to different types of infractions, regulators should be armed with a set of sanction instruments, ranging from information provision and warnings to fines and closure. This gradation of sanctions can provide a credible deterrence: it gives regulators the flexibility to find the instrument that is most likely to improve overall compliance and potentially facilitates the creation of a more “forgiving environment” while regulation is still developing. Furthermore, approaches should correspond to the regulated entity’s track record to reward compliance, which could factor into the frequency of inspections or the type of instrument used.

Use new technologies and data-driven solutions to monitor compliance. Regulators can make use of digital technologies and big data to improve the monitoring of compliance, allowing for more remote and real-time monitoring, bringing down regulatory costs for authorities and regulated entities (see Chapter 3 – The agility of regulation). These technologies and solutions could provide more data and knowledge on compliance and risks, which in turn could support the build-up of scientific knowledge on hydrogen applications.

Incorporating new knowledge

The speed of innovation can lead to outdated procedures and requirements if regulation does not catch up in time. Regulations often respond with a delay to innovations and the availability of novel scientific research. This issue is referred to as the so-called “pacing problem”. Regulations that are tailored to yesterday’s hydrogen technology and scientific understanding of risks may not always be most efficient at targeting the actual risks of today’s hydrogen applications. In particular, as innovation and scientific research can support the development of safer technologies and a decrease in scientific uncertainty over time, this delay could lead to excessive risk reduction and disproportionally risk-averse approaches. This outcome increases the regulatory burden on regulated entities and could result in a slowing of the hydrogen transition.

There is a need for agility in regulation to enable and harness innovation, rather than hinder it. The regulation of hydrogen may require a different approach from that taken with other more mature energy technologies, due to the speed of innovation and scientific research. As hydrogen technologies and our understanding of risks improve, the application of caution and the risks related to hydrogen will also need to develop over time. Hydrogen regulations will be asked to respond and adapt to new developments, to ensure regulations do not become the bottleneck for the hydrogen transition.

Recommendations

Develop adaptive, iterative and flexible regulatory cycles to enable continuous learning and improvement. The periodic and frequent updating of regulations and procedures may be especially relevant for innovations, to reflect new knowledge and improvements in technologies and to improve the robustness and reliability of data on risks. It will require that policymakers and regulators move from “set and forget” to “adapt and learn” approaches to regulation. This more dynamic and continuous approach could for example include changes in requirements or guidance for impact assessments to consider the impacts on innovation, legislative requirements for systematic and period review or the use of sunset clauses and the shortening of timeframes throughout the policy cycle with more frequent analysis (which may at times be less thorough). As part of this approach, regulatory impact assessment, stakeholder engagement and ex post evaluations should not be seen as consecutive steps, but as complementary tools to inform the design of regulations.

Monitor international experience and the arrival of novel scientific research, to feed into the revision of existing approaches. The Netherlands can make use of the experiences of other countries that are at more advanced stages of their hydrogen transition, as well as findings from international research by platforms and bodies such as the EU JRC (see Chapter 4 – “Institutional context for hydrogen”). This can help to set adequate scientific standards, avoid making mistakes that have been made before, and improve the design of risk-based regulations over time.

Use horizon scanning and expectations on trends to make regulations more anticipatory, robust and future-proof. To foster innovation-robust and forward-looking regulations, knowledge on future developments can be taken on board in the design of regulations even before trends materialise. This will require institutional capacity to foresee changes, international exchange between regulators to share insights, a more open sharing of information between regulators and innovators and clarity on mandates to act upon developments. For example, the Regulatory Horizons Council in the United Kingdom acts as an independent expert committee to provide advice to the government on the implications of technological innovation and the need for regulatory reform.

Annex 1.A. Safety measures and regulations

This annex includes potential safety measures and highlights of regulations and standards for each of the six scenarios. It draws on the information as presented in Part II – “Regulatory review” and Part VI – “Lessons learnt and preliminary findings regarding hydrogen safety elements”. The values mentioned in this annex including those on safety distances, time and pressure are directly based on scientific studies which are available in the various Parts that follow this report. All references to the studies analysed can be found therein. Risk mitigation strategies should take into account the specific context and characteristics of a project, as well as desired risk targets and countervailing risks, to determine the most effective measures (see Managing risks). Box 3.5 discusses a number of methodologies for prioritisation and review of risk measures that can be considered.

Annex Box 1.A.1. General safety measures and regulations – Scenario 1 – Production through electrolysis

Safety recommendations

The following measures can be considered to reduce safety risks under this scenario:

Site layout

The inventory of the on-site hydrogen storage should be limited to the smallest practical amount required to meet operational demands.

The electrolyser should be located outdoors. If this is not possible, then any building or room in which an electrolyser is situated should be adequately ventilated to quickly disperse any hydrogen concentrations.

Hydrogen storage tubes should be situated outdoors.

Compressors should be located outdoors, or where this is not possible, indoors within a well-ventilated room. Compressors should be protected from impact by being located behind barriers or within a cage.

Safety distances between the different components of the production site should be implemented. In siting and layout design a safety distance of 6 m between all components and the compressors, which are considered the major risk contributors along with storage system, whereas a minimum of a 2-metre distance between electrolysers should be considered. Electrolyser size and capacity, local conditions, and pressure are additional factors and should be considered while adjusting minimum distance. This is because the size of the electrolyser determines the hydrogen production rate.

Protective walls can reduce the safety distances, because they can act as a physical barrier protecting from the expansion of a potential explosion, provided that their endurable pressure is higher than the explosion pressure. The location of the protective walls relative to the facility should be carefully designed as in case of ignition protective walls can lead to increased overpressures in the area that they enclose. Furthermore, the reflected shock waves may cause secondary damage in front of the wall.

Standards / materials

The installation of hydrogen generation systems should meet the requirements of relevant standards, like ISO 22734:2019 (construction, safety, and performance requirements for hydrogen gas generation appliances). Moreover, standards like the OSHA Standard 1910.103 can be considered as safety reference for separation distances between the storage system and certain types of exposures. In the United States NFPA 2 is the primary source for separation distances and is required by states or through direct reference in the International Fire Code.

Protective walls, if installed, should be constructed of non-combustible materials.

All equipment which is located within a potential flammable zone should comply with the ATEX Directive (European Commission, 2014[10]). The US on the other hand relies on NEC (NFPA 500)

Non-combustible materials should be used in compartments or locations containing hydrogen storage vessels or hydrogen pipelines.

Safety devices

Pressure relief valves (PRV) should be fitted to all components that operate at high pressure. Relief valves should direct any vented hydrogen upward.

Flammable gas detectors and alarm systems should be provided. Alarms should be activated before a flammable gas concentration reaches 2 vol% (half LFL of 4 vol%), while automatic safety shutdown devices are recommended to shut of the hydrogen supply at 3 vol% concentration levels. The International Electrotechnical Commission standard, IEC 60079-29-1, specifies general requirements for construction, testing and performance, and describes the test methods that apply to portable, transportable and fixed equipment for the detection and measurement of flammable gas or vapour concentrations with air. ISO 26142:2010 – Hydrogen detection apparatus — Stationary applications1 provides the performance requirements of hydrogen detection apparatus in stationary installations (ISO, 2010[11]). The provision in this International Standard covers the hydrogen detection apparatus used to achieve the single and/or multifaceted safety operations, such as nitrogen purging or ventilation combined with supply system shut-off according to a hydrogen leak concentration. Hydrogen detection apparatus certified under this Standard ensure functional performance requirements, such as reliability, response time, stability, measuring range, selectivity and contamination.

Automated shutdown systems and local emergency stop buttons should be fitted in the electrolyser, compressor and storage areas.

Practices

The production site should be kept clean, free of combustible materials and potential ignition sources and without obstructions.

Proper and clear marking of the area with visible warning signs in the electrolyser room, the compressor site and in the storage facility to minimise the risk of ignition.

The number of flanged joints to pipework should be minimised, as flanged joints pose a greater risk of hydrogen leakage. Welded connections for joining pipework are preferred as they can reduce the generation of flammable atmospheres from small scale leakages.

Emergency arrangements should include specification of site evacuation arrangements and the provision of cooling to compressors and storage tanks in the event of a fire. During an incident an exclusion zone of at least 50 m to keep the public away from an accident scene should be provided.

Controls

Regular visual inspections (at least weekly) and risk-based maintenance of the electrolyser, the compressor and the equipment components, including the pipework, is crucial. Incorrect operation of a water electrolyser can lead to oxygen ingression in the hydrogen stream, which may exceed the explosion threshold limit. Using two staff (two pairs of eyes) for maintenance activities can reduce the risk of human error.

Part VI – “Lessons learnt and preliminary findings regarding hydrogen safety elements” discusses safety measures for this scenario in more detail.

Regulations and standards across countries – highlights

In China, Korea and the United States, standards or codes are drawn up for the safe design and use of hydrogen production facilities, such as the OSHA standard and NFPA-2 in the United States.

In Japan, requirements for hydrogen production facilities are set under the regulation of high-pressure gas facilities.

In the EU, regulations are based on the maximum stored hydrogen inventory rather than the production capacity, and include requirements for safety policies and reports, emergency plans and licensing procedures (notification or authorisation) depending on this maximum inventory.

Part II – “Regulatory review” discusses regulations across countries for this scenario in more detail.

Annex Box 1.A.2. General safety measures and regulations – Scenario 2 – Pipeline transport

Safety recommendations

The following measures can be considered to reduce safety risks under this scenario:

Plan and design of pipeline system

For a new pipeline construction, perform route survey and planning to identify geological challenges and to select a stable route free from ground movement and erosion.

Use of buried pipelines. There is no “golden rule” for pipeline burial. Pipe diameter and length could be important factors to consider. Japanese regulation requires the pipelines to be buried at least 0.6 m below ground surface and in crossings of public roads, where vehicle traffic is particularly heavy, the depth shall be at least 1.2 m. However, larger depth might be necessary to avoid normal agricultural activities, surface water drainage works and imposed road loads. For the construction of new pipelines avoid populated and agricultural regions to reduce the likelihood of pipe damage due to external activities, like building construction, excavation, etc.

Appropriate separation distances between pipelines and nearby vulnerable populations. The methodologies used to determine separation distances vary across all the studies. To determine separation distances risk-based approaches should be used.

Pipe casings or load shields should be installed at railroad or road crossings or where unusual aboveground loading can occur.

Establish the quality of an existing pipe before it is used for hydrogen gas (or hydrogen blends) transport by conducting a quantitative risk analysis and deterministic analysis such as through Computational Fluid Dynamic Model (CFD) (Ministry of Transport and Water Management and Bilfinger Tebodin Consultancy, 2019[12]).

Standards/materials

Ensure that pipeline design and construction meet the requirements of relevant standards (e.g. NEN 3650 Requirements for pipeline systems – Part 1: General requirements, NEN 3651 Additional requirements for pipelines in or nearby important public works, ASME B31.12 Standard on Hydrogen Piping and Pipelines).

Limit joint flanges. Welded connections are preferred.

Safety devices

When possible and practical, use a sudden loss of pressure automated shut down systems to isolate any damaged section of the pipeline and limit any loss of containment.

Implement an automatic leak warning that notifies nearby residents.

Practices

Provide signs at regular space intervals (every 1 km) for underground hydrogen pipelines to advise against activities that can damage the pipes, like excavation and provide a contact number to report damage.

Land use planning policy and control development near the pipelines and to control development encroachment (e.g. in terms of safety distances from vulnerable populations and objects).

Give notification before starting any excavation activities to obtain information about pipelines (in the Netherlands this is called KLIC-notification) (Cable and Pipelines Information Centre, Kabels en Leidingen Informatie Centrum, KLIC).

Controls

Inspection and maintenance interventions for both underground and aboveground pipelines. Routine, 5 yearly, Non-Destructive Testing (NDT) examination of the internal surface and thickness testing.

Part VI – “Lessons learnt and preliminary findings regarding hydrogen safety elements” discusses safety measures for this scenario in more detail.

Regulations and standards across countries – highlights

Many countries, such as China, Japan and the United Kingdom, do not have specific regulations on hydrogen pipelines, but apply more general regulations for pipelines or sometimes more specifically pipelines with high-pressure or flammable gasses.

In the United States, a specific industry standard was developed for hydrogen pipelines safety (ASME B31.12).

The mixing of hydrogen as a blend into existing gas infrastructure is usually capped at a certain percentage share of total volume, as is the case in Australia, China and the United Kingdom, or is prohibited, as is currently the case in the Netherlands.

Part II – “Regulatory review” discusses regulations across countries for this scenario in more detail.

Annex Box 1.A.3. General safety measures and regulations – Scenario 3 – Road transport

Safety recommendations

The following measures can be considered to reduce safety risks under this scenario:

Design

Limit the maximum size of individual tube containers.

Limit the maximum pressure in tube trailers to not more than 25 MPa. Alternatively, size-based limits can also be considered for setting the maximum pressure i.e. tubes with pressure greater than 25 MPa could be smaller in size. An exemption can be made taking into consideration the travelling distances and the routes to avoid transporting high pressure vessels close to populated areas and vulnerable areas, like hospitals and schools.

The package securing system in tube trailers should be designed with adequate safety margins to assure that hydrogen cylinder packing remains secured to the transport trailer under adverse conditions.

In hydrogen FCEVs consider the use of new technologies, like TPRD-less (leak-no-burst) tank that would not release hydrogen through TPRD in extreme conditions, like engulfing fire in hydrogen tank. However, since studies in the TPRD-less technology is yet to be conclusive, such a technology should be considered along with the fire resistance of the tank.

Hydrogen transport and hydrogen-powered vehicles should be fitted with warning signs to alert emergency services approaching defective / crashed vehicle.

Safety devices

Pressure relief valves should be effectively connected to vent tubing to route hydrogen to the top of the truck to safely disperse in the atmosphere.

Systems involving more than one PRD should be designed to avoid simultaneous opening of all PRDs to limit the size of a flammable cloud in the event of an incident.

Safety measures in confined spaces

Mechanical ventilation in confined spaces where hydrogen transport and/or hydrogen-powered vehicles are allowed. Ventilation in garages should achieve at least 10 ACH (air change per hour) (Lach and Gaathaug, 2021[13]).

Practices

Train and educate drivers on the explosive characteristics of hydrogen. Haulage company’s policies should require safe driving practices under all conditions (Hydrogen Tools, 2017[14]).

Train first responders to deal with all safety aspects for a range of hydrogen applications and design emergency plans based on hydrogen safety science and engineering.

In case of an accident involving hydrogen FCEVs, first responders would be able to approach the vehicle, conservatively, approximately two minutes after pressure relief valve activation (hearing the hissing sound). For the safety of the general public, a perimeter of 100 metres is suggested to be set in the accident scene if no hissing sound is heard. However, the perimeter can be reduced to 10 metres once the hissing sound of hydrogen release is observed. The first responders should remain 6 m from the vehicle if there are no signs of hydrogen leakage.

Controls

Regular maintenance of the trailer, fastenings, manifolds and safety devices.

Part VI – “Lessons learnt and preliminary findings regarding hydrogen safety elements” discusses safety measures for this scenario in more detail.

Regulations and standards across countries – highlights

Most countries apply regulations developed for the road transport of flammable gasses to hydrogen road transport.

The ADR agreement that regulates road transport of flammable gasses in Europe does not require adjustment for hydrogen transport, as it is already fully incorporated.

Hydrogen-powered vehicles (FCEVs) are not covered by the same regulations as hydrogen road transport, and often face similar requirements as vehicles powered by conventional fuels.

Part II – “Regulatory review” discusses regulations across countries for this scenario in more detail.

Annex Box 1.A.4. General safety measures and regulations – Scenario 4 – Tunnels

Safety recommendations

The following measures can be considered to reduce safety risks under this scenario:

Design of vehicles

Design hydrogen vehicles based on United Nations Global Technical Regulation No. 13 (GTR #13).

Consider the use of new technologies, like TPRD-less (leak-no-burst) tank that would not release hydrogen through TPRD in extreme conditions, like engulfing fire in hydrogen tank. However, the TPRD-less technology should be considered along with the fire resistance of the tank.

Using multiple TPRDs to prevent the leak of the total mass of the tank in localised fires can be considered.

Hydrogen powered vehicles should be fitted with warning signs to alert emergency services.

Design of tunnels

Provide mechanical ventilation inside tunnels (1-2 m/s) to reduce the hydrogen vapour concentration in the event of a leakage.

Ensure sufficient distance of main tunnel and fittings and equipment, like dust collectors and exhaust fans that can trap hydrogen in flammable concentrations.

Avoid roof obstructions inside the tunnel, because they pose a potential risk in respect to possible fast deflagration or transition to detonation.

The design of future tunnels should include appropriate cross section design to avoid flammable mixture accumulating in the tunnel ceiling.

Set larger safety distances between vehicles when driving inside tunnels.

Safety devices

The TPRD size should be reduced to avoid a flammable mixture at the tunnel ceiling in the event of a leak. However, the size consideration should be made in a way that an extended-release time does not prolong the high-pressure state of hydrogen. The TPRD orientation in buses should be at the top of the vehicle.

Systems involving more than one PRDs should be designed to avoid simultaneous opening of all PRDs.

Additional protection could be provided by:

a battery fire suppression system within the battery pack;

a fire barrier between the battery pack area and the hydrogen tank;

increasing the tank integrity/fire resistance to thermal threats, and

a fire resisting deck to protect the upper deck area.

Practices

Risk-based categorisation of tunnels to define which ones allow or not H2 powered vehicles to enter. Similarly, vehicle class based considerations can be made to differentiate between Light Duty Vehicles (5 kgs onboard) and Class 8 fuel cell trucks (100+ kgs onboard)

Emergency responders should receive training for reaction to incidents that involve hydrogen vehicles. Some key elements are presented below:

Emergency responders should remain at least 2 min before approaching damaged vehicles following activation of TPRD.

If there’s no sign of hydrogen release, first responders should stand at least 6 m away from the vehicle.

Controls

Perform frequent safety checks on vehicle integrity by an independent, competent engineer.

Part VI – “Lessons learnt and preliminary findings regarding hydrogen safety elements” discusses safety measures for this scenario in more detail.

Regulations and standards across countries – highlights

In Europe, vehicles transporting hydrogen are forbidden to enter most tunnels based on the ADR agreement.

In Japan, vehicles transporting hydrogen are prohibited or restricted in long tunnels or those underwater.

There are currently no specific regulations that restrict FCEVs from entering tunnels.

Part II – “Regulatory review” discusses regulations across countries for this scenario in more detail.

Annex Box 1.A.5. General safety measures and regulations – Scenario 5 – Hydrogen refuelling stations

Safety recommendations

The following measures can be considered to reduce safety risks under this scenario:

Design

For on-site hydrogen production, water electrolysis is the recommended production process as it presents lower risk than steam methane reforming.

Limit the inventory in the storage facility as low as practical based on the average daily number of fillings of the HRS.

Transportation of hydrogen through high-pressure pipelines allows station to dispense fuel without onsite compression and storage and reduce the risk. However, this system should additionally consider the risk of operating high-pressure pipelines in residential areas.

A QRA study indicated that liquid hydrogen refuelling stations entail less risk than compressed hydrogen refuelling stations, but the differences were small. Based on that the use of liquid hydrogen instead of compressed hydrogen could be recommended, but further research on that topic is highly advised.

Site layout

Hydrogen processing systems, high pressure storage containers and generators should be sited outdoors in well ventilated areas.

Implementation of safety and separation distances:

Separation distances from exposures in GHRS can follow the NFPA-2 code.

Hydrogen storage tank (up to 40 MPa) should be configured 5 m from the location of the hydrogen onsite production facility.

Safety distances can be reduced when installed safety systems are effective and can be quickly activated, by employing for instance a dispenser which operates in parallel with an emergency shutdown valve.