Knowledge gaps. Note that scientific insights on chemicals are not always available, because not all chemicals in a finished plastic product have been identified, and because hazard data may not be available for all known chemicals. It is also complex and difficult to have a complete assessment of the chemicals in products. Make sure to report the process as transparently as possible to note what is known and where data gaps were encountered, and of what type the data gaps were (e.g. chemical information and toxicological data).

Ongoing chemistry discovery, new substances, and material availability. Note that chemistry is a continuum of discovery, with new materials being brought to the marketplace over time. Designers should be mindful of new materials able to create improved outcomes for products and their operating environment.

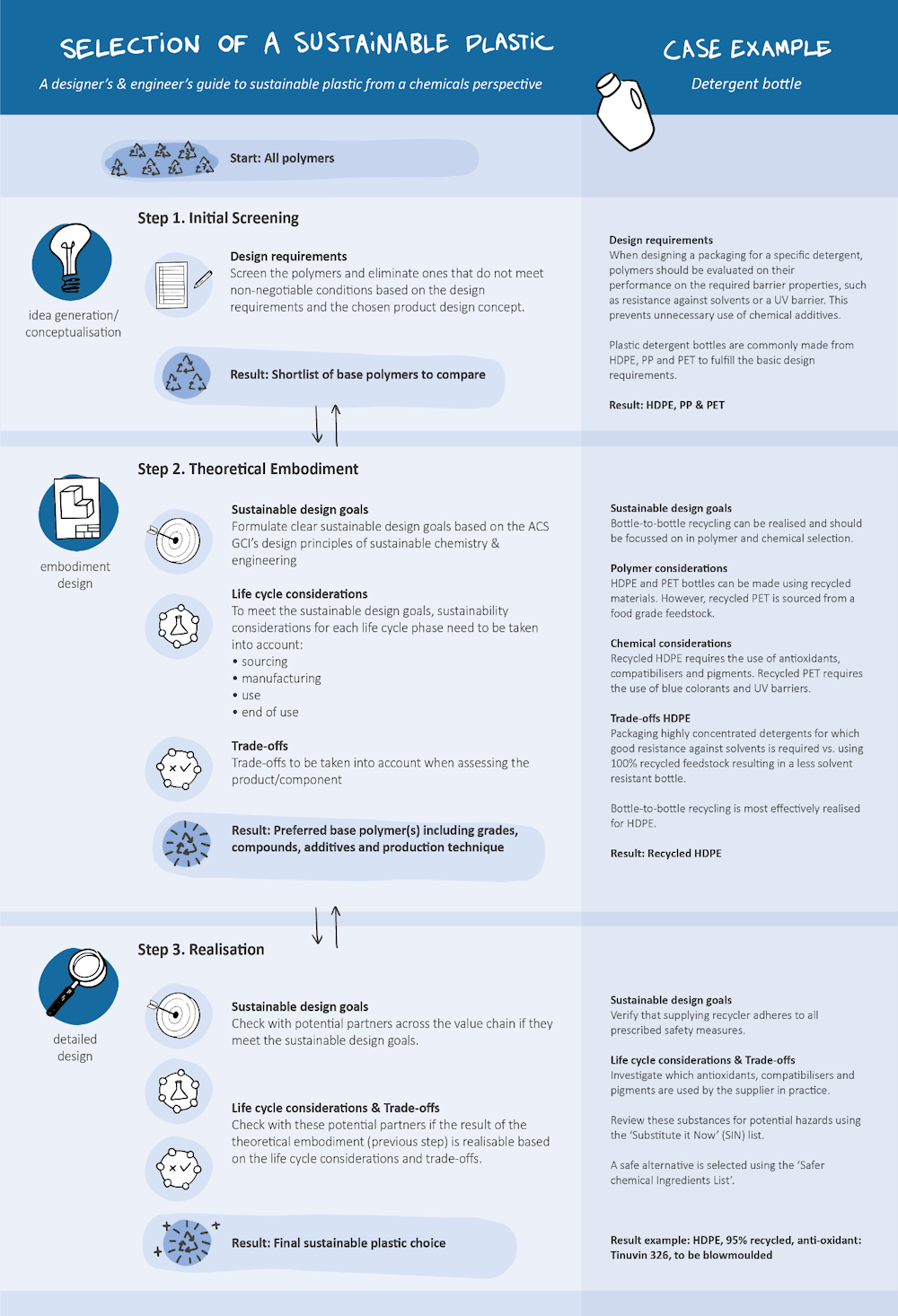

Integrate sustainability design goals earlier in the design process. In this study, the sustainable design goals are formulated in the second step of the sustainable plastic selection process. Implicitly, sustainability becomes less of a priority compared to the previous design requirements (e.g. mechanical and electrical properties). However, it is ideally taken into account earlier on in the design process. It was assumed that a Design for a circular economy approach was adopted, but sustainable design goals have to be an integral part of the design requirement stage of the design process (see Figure 1.2). As a result, ambitious innovations in system, service, product, and material design will be triggered earlier on.

Broaden the scope to include other material families. This study focused on sustainable plastics. However, plastic may not be the most sustainable family of materials for a specific (part of the) product to begin with. The chemical perspective could also consider, for instance, metals, ceramics, natural (wool and wood) or composite materials.

Involve more stakeholders. Designers and engineers were considered the main actors in selecting sustainable plastics. Nevertheless, in a circular economy, the whole value chain should be involved to implement more sustainable plastic solutions. Collaborations should be stimulated to foster innovations at a systems level. Also, designers and engineers often do not have full control over the design brief, meaning that decision makers should also be trained on the subject.