This chapter summarises the pilot projects both underway or completed in each of the selected nine countries. A short description of each project and source references are provided to facilitate future investigation. Where research has uncovered information about incidents and accidents which have occurred involving hydrogen, these too have been recorded either against the relevant scenario or at the end of each country's summary.

Risk-based Regulatory Design for the Safe Use of Hydrogen

12. Pilot projects by country

Abstract

China

Scenarios

|

Scenario 1: Production: Leakage from the pipe connected to electrolyser Due to the country's dependency on imported natural gas and abundant availability of renewable resources, hydrogen production from electrolysis is of significant interest (IEA, 2019[1]). In 2022, it was estimated (Bloomberg, 2022[2]) that China accounts for 62-66% of global electrolyser installations. This includes 2 refuelling stations with on-site electrolysing facilities (Meng et al., 2021[3]) . In recent years, no accidents were reported for renewable hydrogen production. None-the-less, two accidents associated with fossil fuel-based hydrogen production were reported (discussed in detail in Section 2.1.1). |

|||

|---|---|---|---|

|

S. No |

Year |

Project description |

Source |

|

1 |

2021, April (Completed) |

“National Demonstration project on Solar Energy Water Electrolysis for Hydrogen Production” -Location: NingXia, West of China -Electricity generation power: 2GW -Hydrogen production rate: 20,000 Nm3/h -Cost of production: € 0.19 (1.34 CNY) /m3 |

(2021, April 20) BaoFeng Solar energy water electrolysis project officially in production, Chinese Chemical Industry Press, Retrieved 14/03/2022 From: http://www.ccin.com.cn/detail/284767 Liu,X. (2020, December 18) NingXia BaoFeng Group: Extends green energy industry chain to reduce carbon footprint, XinHua News Agency Retrieved 22/02/2022 From: http://www.xinhuanet.com/2020-12/18/c_1126879207.htm |

|

Scenario 2: Pipeline transport: Leakage from high pressure pipeline Hydrogen transportation in China mainly relies on tube trailers (Beijing Hydrogen Industry Development Plan, 2021[4]) and therefore information/pilot projects on pipelines are limited. The company Sinopec had by 2020 completed at least 3 hydrogen pipelines with the longest being 43 km. Hydrogen is transported between 0.1 MPa to 4 MPa. No accidents have been reported. |

|||

|

S. No |

Year |

Project description |

Source |

|

2 |

2014 (Completed) |

“Balingyi – Changling” Hydrogen pipeline - Length: 43km 18.8km underground, 24.2 km overground - Newly build - Hydrogen purity: >=99.5% - Yearly operation: 8000h/ 333 days - Pressure: ca. 2.6MPa |

Final Environmental Impact Report “Balingyi – Changling” Hydrogen purification and transportation (2015), Retrieved 22/02/2022 http://sthjt.hunan.gov.cn/uploadfiles/201511/20151106152901331.pdf |

|

3 |

2015 (Completed) |

“Jiyuan-Luoyang’’ Hydrogen pipelines -Length: 25km -Pipe width: 508mm -Pipe thickness: 11.1mm- Pressure: 4Mpa -Capacity: 100.4 kt/year |

Sinopec Release (2015), Retrieved 22/02/2022 http://www.cnpc.com.cn/cnpc/trqxgdt/201511/0d99b30f7dfb43eebfb12583c1aa106b.shtml |

|

4 |

2019 (Completed) |

Short pipeline connecting a chemical company and Sinopec - Length: 3.2 km, overground - Hydrogen purity: >= 99.5% - Pressure: Atmospheric pressure - Capacity: 5 000m3/h |

Final Environmental Impact Report on Hydrogen Transportation, JinCheng Chemicals(2019), Retrieved 22/02/2022 http://www.kamtian.com/Public/userfiles/files/report181101.pd |

|

Scenario 3: Road transport: H2 leakage in a confined space/ built environment Despite manufactured more than 5 000 hydrogen vehicles (Beijing Government Plan on Fuel Cell Vehicles,, 2020[5]) by the end of 2019 and undertaking hydrogen transportation from production to refuelling stations mainly rely on road transportation (Hydrogen pipe trailers at 20 MPa (Beijing Hydrogen Industry Development Plan, 2021[4]),. There have been no hydrogen-related accidents associated with transportation. Scenario 4: Mobility and a partially confined space: a hydrogen city bus driving in a tunnel is involved in a traffic accidents More than Over 30 cities in the country have their own hydrogen projects which normally involve hydrogen city buses. Apart from one demonstration project started in Beijing in 2004, all other hydrogen buses start to operate in/after 2018. Although it is unclear whether risk assessment related to Scenario 4 was performed, there were no accidents reported regarding hydrogen bus operation. Selected pilots projects on hydrogen city bus: |

|||

|

S. No. |

Year |

Project Description |

Source |

|

6 |

2005 (Completed) |

Beijing (3) |

Xinhua News Agency (2005), Retrieved 22/02/2022 www.gov.cn/jrzg/2005-11/23/content_107446.htm |

|

7 |

2019 (Completed) |

Datong (50) |

Shanxi Government(2019), Retrieved 22/02/2022 http://www.shanxi.gov.cn/yw/zwlb/gsdt/201904/t20190417_527867_ewm.shtml |

|

8 |

2020 (Completed) |

Shanghai (6) 285 additional Hydrogen fuel cell vehicles operating in the city |

Xinhua News Agency (2019), Retrieved 22/02/2022 http://www.gov.cn/xinwen/2019-06/11/content_5399067.htm |

|

9 |

2020-2021 (Completed) |

Zhangjiakou (304) |

Hebei daily (2021), Retrieved 22/02/2022 http://jtt.hebei.gov.cn/jtyst/wap/zt/dah/mtjj/101630318221594.html |

|

10 |

2021 (Completed) |

Shanghai (6) |

LINGANG Group (2021),Retrieved 22/02/2022 https://www.shlingang.com/lg1/lingangjituan/xwzx/focusnewarea/202112/t20211207_23747.shtml |

|

11 |

2021 (Completed) |

Shenzhen (5) |

Shenzhen Transportation Bureau (2021), Retrieved 22/02/2022 http://jtys.sz.gov.cn/zwgk/jtzx/cxtx/content/post_9280522.html |

|

12 |

2021 (Completed) |

Nanjing (11) |

Xinhua News Agency (2021), Retrieved 22/02/2022 http://www.js.xinhuanet.com/2021-05/01/c_1127402127.htm |

|

13 |

2021-2022 (Completed) |

Beijing (212) |

Xinhua News Agency (2022),Retrieved 22/02/2022 http://bj.news.cn/2022-01/18/c_1128272686_2.htm |

|

Scenario 5: Mobility and partially confined space: accidents at a hydrogen fuel station With the first immobile hydrogen fuel station started its operation in 2007, the country currently has 61 refuelling stations in operation (Meng et al., 2021[3]) with most of them started operation in the last 5 years. Only one accident was reported at a hydrogen fuel station – the rupture of a connecting soft pipe causing local fire but no injury. Another accident with the same root event was reported (Section 2.1.1). |

|||

|

S. No |

Year |

Project description |

Source |

|

14 |

2007 (Completed) |

Shanghai -Hydrogen Storage: Increased gradually from 200 to 800kg -Hydrogen Source: Road Transport(8 tubes with volume of 2.3m3 at 20MPa) -Total Refuelling: 142.346Tons/33697 times -Refuelling Pressure: 35MPa Safety measures: 1) 24h manned 2) Trained staff member for operation 3) Regular checks for Pressured components |

Li, Z., Pan, X., & Ma, J. (2010). Quantitative risk assessment on a gaseous hydrogen refuelling station in Shanghai. International Journal of Hydrogen Energy, 35(13), 6822-6829. Pan, X(2021) Safety Analysis on Shanghai’s first Hydrogen Refuelling station, Shunhua New Energy Cooperation |

|

15 |

2019 (Completed) |

Dalian -Location: Northeast China -Hydrogen Storage: 200kg -Hydrogen Source: On-site water electrolysis -Refuelling Pressure: 35/70MPa -Daily Supply: 500kg |

Pan, X., Li, Z., Zhang, C., Lv, H., Liu, S., & Ma, J. (2016). Safety study of a wind–solar hybrid renewable hydrogen refuelling station in China.International Journal of Hydrogen Energy,41(30), 13315-13321. |

|

16 |

2020 (Completed) |

Beijing Largest hydrogen refuelling station in the world -3 minutes for one 9 kg hydrogen refuelling, which is sufficient for 350 km operation. -The station is expected to serve 800-1000 lorries on a daily basis. -Hydrogen Source: Pipeline -Refuelling Pressure: 35/70MPa -Daily supply: 4 000 kg |

People’s Daily (2021) Retrieved 22/02/2022 http://society.people.com.cn/n1/2021/0518/c1008-32106311.html |

|

Scenario 6: Residential use: Safety of hydrogen in buildings with focus on hydrogen cooking stoves and boilers Research (Haeseldonckx and D’Haeseleer, 2007[6]) suggested the current natural gas pipeline is feasible to transport hydrogen should the volume ratio be below 17%. |

|||

|

17 |

2019 (Completed) |

-Hydrogen produced by water electrolysis is then mixed with natural gas at 10% for transportation. -The gas mixture can then be used for cooking upon delivery -Location: Chaoyang City, Northeast of China -Safe operation for more than 1 year. |

State Power Investment Corporation (2021) Retrieved 22/02/2022 https://h2.in-en.com/html/h2-2408939.shtml Xinhua News Agency (2019), Retrieved 22/02/2022 http://m.xinhuanet.com/ln/2019-11/13/c_1125224994.htm |

|

Other projects worth mentioning: |

|||

|

18 |

2020 (Completed) |

Hydrogen Tram -Location: Foshan, Guangdong Province -First of its kind in the world -6.57km, 10 stations -Daily passenger 1101 (2020), 578 (2021) -Cost: ca. € 153.2 million (1070 million CNY) |

Gaoming District modern light railway demonstration line (2021) Wikipedia, Retrieved 22ed Feb, 2022 From https://zh.wikipedia.org/wiki/???????????? |

Incidents

|

No. |

Scenario-related |

Description |

Analysis |

|---|---|---|---|

|

1 |

5 |

Fire caused by the rupture of tube trailer's flexible hose connection during refuelling (20MPa) at a chemical plants producing propene, hydrogen etc. -Damage at ca. € 3 117 (21 760 CNY), no injury reported. - 1h18min passed between pipe rupture and fire suppression. |

The accident was initiated by the rupture of a flexible hose that is used for hydrogen refuelling. The flexible hose in question were faulty and ruptured at pressures below that of the designed maximum pressure. The hose failure happened at 7.5MPa for accidents 1 and 17.7 MPa for accidents 2. The flexible hose connection in question was purchased in April, 2020 and the accident happened in July 2020. Flexible hose connections should be thoroughly pressure tested before use, and potentially changed regularly. Regulation on the design of hydrogen refuelling stations (GB50177-2005) does not specify the safety distance between tube trailers or between tube trailers and a hydrogen supplying facility. |

|

2 |

N/A |

Long-term corrosion led to the rupture of a connecting pipe, which resulted in the leakage and explosion of a Naphtha/Hydrogen mixture. No injuries reported The accident can be classified to be “with H2 by chance” instead of “because of H2”. Therefore, no H2 specific action is required. |

The direct cause for this accident was the corrosion of a connection pipe. According to national regulation, pipelines operating under pressure should be tested regularly and the integrity data analysed. Despite the fact that data from 2020 were available, it is uncertain if the pipeline which ruptured was inspected. In addition, no analysis of the integrity of the pipeline from the inspection data was performed. |

|

3 |

N/A |

Fire involving hydrogen at a petrochemical production facility in Yunnan - It took 2h40min to extinguish the fire. - 4 personnel were slightly injured |

A detailed report not yet available. |

Concluding remarks: China

For the first time, China listed hydrogen as a form of energy in its energy portfolio in 2020, and only thereafter would hydrogen be included in the energy statistics released by the National bureau of statistics. As a result, a large proportion of the country's hydrogen pilot projects started in 2020 or later.

Being the largest country by population, China currently owns the largest water-electrolysis (2 GW) facilities (hydrogen production at 20 000 Nm3/h) in the world (Pilot Project 1) and there are plans to build an even larger facility (Xinhua News Agency, 2021[10]) for large-scale hydrogen production powered by renewable electricity. More than 30 cities have their own hydrogen plans and most of these plans involve hydrogen city bus operations. Besides the usual safety measures involving hydrogen use, our research suggests that most of the country's hydrogen vehicles are buses or larger vehicles for cargo transportation, reducing potential risks, given the fact that the drivers are trained acts as an extra safety measure.

With most of its pilot projects, as well as other hydrogen-related industries, operating without accidents, there were 4 hydrogen related accidents reported in the last 5 years: 2 at petrochemical production sites and 2 at refuelling facilities. While the former 2 are not within the scope of the current study the later 2 accidents were led by the same initiating event: Rupture of flexible hose connection. These hoses connect pressured hydrogen tubes to the refuelling facility and are crucial for the refuelling process. We therefore suggest that flexible hose connections should be thoroughly pressure tested before use, and potentially changed regularly.

Status of project: China

|

China |

Status |

|---|---|

|

National Demonstration project on Solar Energy Water Electrolysis for Hydrogen Production In operation since 2021 |

Completed |

|

“Balingyi – Changling” Hydrogen pipeline In operation since 2014 |

Completed |

|

“Jiyuan-Luoyang’’ Hydrogen pipelines In operation since 2019 |

Completed |

|

Shanghai Anting refuelling station In operation since 2007 |

Completed |

|

Dalian station First renewable hydrogen refuelling station in China. In operation since 2019 |

Completed |

|

Beijing Daxing refuelling station In operation since 2020 |

Completed |

|

Foshan hydrogen tram In operation since 2019 |

Completed |

|

Hydrogen city buses (more than 600 in operation) |

Under development |

|

Chaoyang hydrogen blending project |

Under development |

France

Scenarios

|

Scenario 1: Production: Leakage from the pipe connected to electrolyser |

|||

|---|---|---|---|

|

S. No |

Project Name |

Project description |

Source |

|

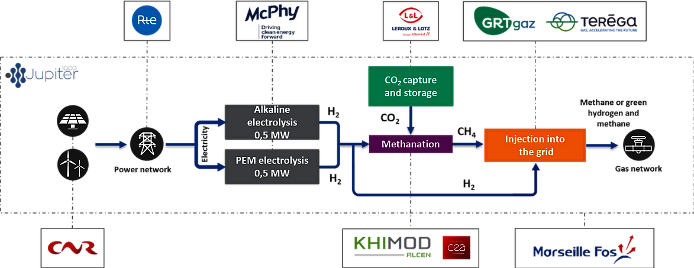

1 |

Jupiter 1000 (financed jointly by the European Union (ERDF), the French State (investments in future, entrusted to the ADEME) and the Provence-Alpes-Côte d'Azur Region of France) 2014-2023 (under development) |

This project is the first industrial demonstration of Power to Gas with a power rating of 1 MWe for electrolysis and a methanation process with carbon capture. The objective is to produce green hydrogen using two electrolysers involving different technologies, from 100% renewable energy. The installation of the methanation process will be based on an innovative methanation technology and CO2 will be captured on a nearby industrial site.  |

|

|

2 |

Masshylia project (Total and Engie) 2021-2024 (under development) |

It is France's largest renewable hydrogen production site at Châteauneuf-les-Martigues in the Provence-Alpes-Côte d'Azur South region. Located at the heart of Total's La Mède biorefinery and powered by solar farms with a total capacity of more than 100 MW, the 40 MW electrolyser will produce 5 tonnes of green hydrogen per day to meet the needs of the biofuel production process at Total's La Mède biorefinery, avoiding 15 000 tonnes of CO2 emissions per year. The project thus integrates the implementation of 5 innovations that prefigure the industry's decarbonation solutions, which is unprecedented without any precedent in Europe:

|

|

|

Scenario 1: Production: Leakage from the pipe connected to electrolyser Scenario 3: Road Transport: H2 leakage in a confined space/ built environment Scenario 5: Mobility and partially confined spaces: accidents at a hydrogen fuel station |

|||

|

3 |

VHyGO project (Grand Ouest Hydrogen Valley) (Completed) |

TIn VHyGO project is set up in a three-phase approach that takes account of each partner’s specific project timeframe. The completion dates for these phases are December 2020, March 2021 and September 2021. Phase 1 of the VHyGO project includes: Three new green hydrogen production sites using electrolysis. Three new refuelling stations. These will be located as close as possible to points of use. From an initial capacity of (1 900 kg a day in total), these stations will be scalable to accompany the ramp-up planned over the different project phases. Twenty-three 12-metre hydrogen buses, seven hydrogen-powered domestic refuse collectors, one retro-fitted hydrogen powered heavy goods vehicle, ten light commercial vehicles and thirty 18-metre hydrogen buses (funding for the latter will be requested in September). |

|

|

Scenario 1: Production: Leakage from the pipes connected to electrolysers |

|||

|

4 |

MONANhySSA project 2021-2024 (under development) |

The MONANhySSA project plans the installation in Nice of a hydrogen production station using electrolysis and a distribution station in Nice. |

|

|

5 |

HyGreen Provence 2021-2028 (under development) |

Production and massive storage of green hydrogen in saline cavities. The HyGreen Provence project will participate in the construction of a local renewable electricity of local renewable electricity, based on solar resource (sites located in the Provence-Alpes-Côte d'Azur région) among the most competitive in France, and selling the electricity produced produced either directly to energy buyers energy buyers, or in a chain of production of green hydrogen stored on a massive scale and intends for local use. |

|

|

Scenario 3: Road Transport: H2leakage in a confined space/ built environment |

|||

|

6 |

Hynomed, a new accelerator for hydrogen mobility 2020 - 2022 (under development) |

SAS Hynomed has as objective to to deploy a hydrogen ecosystem dedicated to land and sea mobility in the southern region. The Brégaillon port site, to the west of Toulon, is an important maritime, land and rail transport hub and is the proposed location for the first station. Expected to be operational by the end of 2022, the station will be able to power 7 to 10 hydrogen-powered buses in the city, around 50 light commercial vehicles and an innovative maritime shuttle with a capacity of 250 passengers. |

|

|

7 |

The GRHYD demonstration project, coordinated by ENGIE in association with 10 other partners, supported by the government as part of the Future Investment Program operated by ADEME and labeled by the Tenerrdis competitiveness cluster. (completed) |

The project was launched to inject hydrogen into the territory’s natural gas distribution network in order to meet the heating, hot water and cooking needs of the residents of the new neighborhood of Cappelle-la-Grand in terms of heating, hot water and cooking. |

https://www.engie.com/en/businesses/gas/hydrogen/power-to-gas/the-grhyd-demonstration-project |

Incidents – none reported in France.

Concluding remarks: France

Seven pilot projects were reviewed in France. Several projects aimed at deploying hydrogen ecosystems (dedicated not only to land but also sea mobility) were investigated. France is working on projects to install hydrogen production sites using water electrolysis but also intends to increase the number of hydrogen refuelling stations and hydrogen vehicles. It also seems to aim, specifically in one pilot, to optimise the integration of several solar photovoltaic farms supplying the electrolyser to minimise energy losses, limit grid congestion and enhance industrial safety thanks to the use of 3D digital models for each component of the installation. Moreover, a project with the first industrial demonstrator of power to gas with a power rating of 1 MWe for electrolysis and a methanation process with carbon capture was reported. In addition, another project attempting to inject hydrogen into the territory’s natural gas distribution network was launched via another project.

The projects seem to have run smoothly until now, since no accidents were reported.

Status of project: France

|

France |

Status |

|---|---|

|

GRHYD demonstration project 2014-2021 |

Completed |

|

Jupiter 1000: 2014-2023 |

Under development |

|

Hynomed, a new accelerator for hydrogen mobility 2020-2022 |

Under development |

|

Masshylia project (Total and Engie) 2021-2024 |

Under development |

|

MONANhySSA project 2021-2024 |

Under development |

|

HyGreen Provence 2021-2028 |

Under development |

Germany

Scenarios

|

Scenario 2: Pipeline transport: Leakage from high pressure pipeline |

|||

|---|---|---|---|

|

S. No. |

Project name |

Project description |

Source |

|

1 |

H2HoWi 2020-2023 (first phase) (under development) |

In the state of North Rhine-Westphalia, an existing public gas pipeline is being converted to convey pure hydrogen for the first time in Germany. Continuous scientific monitoring is being performed to confirm the impact of hydrogen on the structure of the pipe material and the suitability of the existing infrastructure. Current technical standards limit the addition of hydrogen to the natural gas network to 10%. individual projects are testing higher concentrations. H2HoWi is testing pure hydrogen to determine the feasibility of upgrading the existing gas pipeline infrastructure. An existing medium-pressure pipeline is first disconnected from the natural gas network and then connected to a hydrogen storage facility receiving a supply of hydrogen to service four commercial entities. The required space heating is to be generated by hydrogen. In addition to changing the line, adjustments to the existing customer installations were required and hydrogen compatible condensing boilers have been installed. |

|

|

2 |

H2 Starnetz 2030 2020- ~ (under development) |

World’s largest gas pipeline grid being planned by pipeline operators which is designed to cover 1 200 km. Consumption centres in North Rhine Westphalia and Lower Saxony will be linked to hydrogen production centres in the North. The completely new energy grid would emerge from existing gas grids giving large industries the opportunity to become climate neutral. 1100 km will be from existing gas grids while the remaining will be built new. |

|

|

Scenario 3: Road Transport: Hydrogen leakage in confined spaces/ built environments |

|||

|

S. No. |

Project Name |

Project Description |

Source |

|

3 |

Karlsruhe Institute of Technology (KIT) Hydrogen Shuttle Bus Service/ 2013 (completed) |

Fuel cell buses and refuelling stations were introduced in Karlsruhe university campus for shuttle operations between various KIT premises. The fuel station originally supplied 80 kgs of hydrogen per day, enough to fuel three buses. The capacity was one of the highest in south Germany. Refuelling takes about 20 minutes and the bus transports employees and students at no additional costs. An estimated 80,000 passengers per year is guaranteeing permanent high usage for the fuel station. |

|

|

4 |

H2 City Gold 23.12.2021 (first phase completed) |

Electrification of bus fleet- initiative by moBiel, public transport operator in Bielefeld. Four low floor buses fitted with Toyota fuel cell stack and 44KWh battery pack and offering a driving range of 400 kms. Capacity to carry 76 passengers. Buses have a home base at the new Sennestadt Lilienthalstrasse depot. A second working level has been installed for easy and safe access to the components installed on the roof of the bus. Hydrogen fuelling station is undergoing completion. Refuelling time is estimated at 9 minutes. |

|

|

5 |

E-Farm Project 17.06.2020 (under devlopment) |

Project launched by renewable energy solutions provider GP Joule GmbH. Wind power from older turbines converted to H2. Waste heat is used to heat buildings in the local area. Fuel is transported to two filling stations in Husum and Niebül where fuel cell powered buses, trucks and cars can fill up. Two fuel cell buses were purchased to demonstrate the project. Funded partly by the Federal Ministry of Transport and Digital Infrastructure. |

https://www.german-energy-solutions.de/GES/Redaktion/EN/News/2020/20200617-e-mobility-farm.html |

|

6 |

National Hydrogen and Fuel Cell Technology Innovation Program (NIP) (completed) |

Launched in 2007 to accelerate market preparation for hydrogen technology in Germany. NIP is divided into three program areas: Transport and Hydrogen Infrastructure; Stationary Energy Supply and Special Markets. Autostack Industrie initiative announced in 2017 aims to ensure the preconditions exist for commercial introduction of fuel cell vehicles by 2020. Competitive series production of fuel cells to be established rather than importing. The Bodensee project (2009) was started to capture mass markets through NIP’s Special Markets program. It focused on onboard power supply of camping vehicles (camper vans, mobile homes) and the power drive of leisure vehicles (boats, light vehicles) using fuel cell systems. The goal was increased publicity. |

|

|

7 |

Zero Regio (2004-2010) (completed) |

Five Mercedes Benz F-Cell vehicles including one with 700 bar storage tested in Frankfurt through real-life cycles over a period of three years. Findings: Breakaway coupling activated on two occasions presumably because of third party damage. Better monitoring procedures should be used for critical components such as breakaway coupling. A car collided with a conventional vehicle and the hydrogen dispenser was damaged but did not leak. Dispensers should be robustly designed to withstand foreseeable impact damage. |

|

|

Scenario 6: Residential use: Safety of hydrogen in buildings with focus on hydrogen use in cooking stoves and boilers |

|||

|

8 |

Callux (Lighthouse project under NIP) Since 2008 (several phases completed) |

Project intended to test fuel cell-based combined heat and power systems in residential applications for mass. Installation and operation of up to 800 fuel cell heating systems is the largest field trial for fuel cells in homes. 1,046 units in real customer homes with more than 5.5 million hours of reliable operation generating in excess of 4.5 GWh of electricity. Safety: FC CHP (Fuel Cell Combined Heat and Power) are used which are gas appliances running on gas from the grid. In FC CHP only very small amounts of H2 are present (less than 1 litre between reformer and stack) All safety requirements like any other tested gas appliance are met for use of FC CHP. |

|

Incidents

|

S. No. |

Scenario |

Description |

Analysis |

|---|---|---|---|

|

1 |

3 |

In 2001, a lorry crashed at a considerable speed into a hydrogen tube trailer on the A1 highway near Köln. The lorry driver was killed. The fire brigade let the gas burn and cooled the undamaged tanks. Other vehicles or persons were not involved. The evidence of a catastrophic accident involving HFCV is low. A few accidents involving HFCVs did not suffer hydrogen leakage. |

Hydrogen gas escaped from tubes and valves to three of the nine tanks, and ignited. |

|

2 |

3 |

In 2001, a hydrogen powered boat caught fire due to fault in the battery (and not in the hydrogen system). The fuel cell and hydrogen were not affected by the fire because of the design safety. |

Note: Hydrogen Incidents and Accidents Database (HIAD 2.0) requires special permission and is accessible at https://odin.jrc.ec.europa.eu/giada/.

Concluding remarks: Germany

Germany has plans of investing significant financial and research time into hydrogen transition. The next steps are aiming at producing and distributing green hydrogen. There are plans to establish 5 GW of generation capacity including offshore and onshore energy generation facilities by 2040 at the latest. However, since this covers only 1/7th of Germany’s projected energy demand for 2030, the gaps for energy demand are to be closed through import of hydrogen. Structural and infrastructure improvements through public-private partnerships and projects are also seeing a rise. At present, Germany has 90 hydrogen refuelling stations of which 45 (as of 2017) are publicly accessible. Plans are already in place for setting up a 1 200 km of pipeline network for hydrogen using existing natural gas pipelines- once again one of the largest pipeline networks in the world. However, publicly available data on safety studies and risk-assessment from pilot projects are scant and would require more research.

Status of project: Germany

|

Germany |

Status |

|---|---|

|

Karlsruhe Institute of Technology (KIT) Hydrogen Shuttle Bus Service/ 2013 |

Completed |

|

National Hydrogen and Fuel Cell Technology Innovation Program (NIP) |

Completed |

|

Zero Regio 2004-2010 |

Completed |

|

H2 City Gold 2021 - ~ |

First phase completed |

|

Callux (Lighthouse project under NIP) 2008 - ~ |

Several phases completed |

|

H2HoWi 2020-2023 (first phase) |

Under development |

|

H2 Starnetz 2030 2020 - ~ |

Under development |

|

E-Farm Project 2020 - ~ |

Under development |

Japan

Scenarios

|

Scenario 1: Production: Leakage from the pipe connected to electrolyser Scenario 2: Pipeline transport: leakage from high pressure pipeline |

|||

|---|---|---|---|

|

S. No |

Project name/ |

Project description |

Source |

|

1 |

Hydrogen Energy Supply Chain (HECS) Pilot Program 2018 - 2022 (under development) |

PIt produces hydrogen from coal in Latrobe Valley in Australia and transports it in liquid as liquid hydrogen form to Japan onboard the world’s first liquefied hydrogen carrier. This project recently started the Australian arm of its operations and is expected to begin shipments in the first half of 2022. |

|

|

Scenario 1: Production: Leakage from the pipe connected to electrolyser Scenario 2: Pipeline transport: leakage from high pressure pipeline Scenario 3: Road Transport: H2 leakage in a confined space/ built environment |

|||

|

2 |

Global Hydrogen Supply Chain Demonstration Project (Chiyoda Corporation, together with Mitsubishi Corporation, Mitsui & Co. Ltd. and NYK Line, the other members of the Advanced Hydrogen Energy chain Association for technology Development (AHEAD)) 2015 - 2020 (completed) |

Some Japanese companies completed the world’s first global hydrogen supply chain system on 25 December 2020. The project was conducted by AHEAD and subsidised by the New Energy and Industrial Technology Development Organization (NEDO). |

|

|

3 |

Fukushima Hydrogen Energy Research Field (FH2R - developed by NEDO, Toshiba ESS, Tohoku Electric Power and Iwatani Corporation) 2018 - 2020 (completed) |

FH2R uses 20 MW of solar power generation facilities on a 180 000 m2 site along with power from the grid to conduct electrolysis of water in a renewable energy-powered 10 MW-class hydrogen production unit., The largest in the world. It has the capacity to produce, store, and supply up to 1 200 Nm3 of hydrogen per hour (rated power operation). It uses a 10 MW electrolyser to convert renewable power from a 20 MW solar power unit.  |

|

|

4 |

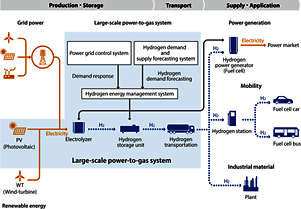

Japan H2 Mobility, LLC (abbreviation: JHyM) Participating companies: Toyota Motor, Nissan Motor, Honda Motor, JXTG Nippon Oil & Energy, Idemitsu Kosan, Iwatani Corporation, Tokyo Gas, Toho Gas, Air Liquide Japan, Nemoto Tsusho, Seiryu Power Energy, Toyota Tsusho, Development Bank of Japan, JA Mitsui Leasing, Sompo Japan Nipponkoa Insurance, Sumitomo Mitsui Finance and Leasing Company, NEC Capital Solutions, Mirai Creation Fund 2018 - 2021 (completed) |

A Japan-wide initiative to promote construction of hydrogen stations is created in 2018 1. Strategic deployment of hydrogen stations - 80 hydrogen stations nationwide by year 2021 - Deploy strategically hydrogen stations compatible with maximisation of both FCV demand and user convenience 2. Contribution to efficient operation of hydrogen stations (1) Improvement of convenience for FCV users - Better coordination of operating days and time between neighbouring stations (2) Promotion of sustainability of hydrogen stations business - Cost reduction and regulation review through collaboration with other related organisations 3. Positive information provider to convince the public of hydrogen society realisation Contribution to efficient operation of hydrogen stations |

PPT presentation Accelerating the Construction of Hydrogen Stations to Promote Widespread Use of Fuel Cell Vehicles Toward the Creation of a Hydrogen-based Society Sep. 11, 2018 Tomonari Komiyama Japan H2 Mobility, LLC |

|

Scenario 5: Mobility and partially confined spaces: accidents at a hydrogen fuel station |

|||

|

5 |

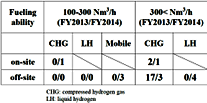

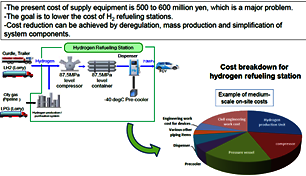

New Energy and Industrial Technology Development Organization(NEDO) 2011 - 2015 (completed) |

System of FCEV/Hydrogen Infrastructure Projects in Japan ~HRS with commercial scale fuelling ability Promotion of HRS Installation ~HRSs in Japan~ Prior to the market introduction of FCEVs (2015), 100 HRSs will be installed in 4-major-populated-areas (Tokyo, Aichi, Osaka, Fukuoka) METI will subsidise about 50% of the HRS’ installation cost (2014FY 7.2 billion JPY) Summary of the approved HRSs by type

Research and development on low-cost equipment for HRS  |

PPT presentation Hydrogen Infrastructure in Japan 2014 AMR June 19, 2014 Washington Marriott Wardman Park Hotel Washington, USA Shigenobu Watanabe New Energy and Industrial Technology Development Organization (NEDO) 2014 AMR June 19, 2014 Washington Marriott Wardman Park Hotel , Washington, United States |

Concluding remarks: Japan

Five pilot projects were reviewed in Japan. Country-wide initiatives to promote the construction of hydrogen stations were found, with the aim to contribute to the efficient operation of hydrogen stations and to commercialise scale fuelling ability (also promoting reduction in costs by reviewing regulations and standardising equipment). Japanese companies were also found to complete the world’s first global existing hydrogen supply chain system. This move also marks the first consumption of foreign-produced hydrogen for power generation. In addition, the world-first hydrogen energy supply Chain Project aims to safely produce and transport clean liquid hydrogen from Australia to Japan. A key objective of the pilot project is to demonstrate an end-to-end supply chain between both countries. A Japanese consortium launched a renewable energy-powered 10 MW-class hydrogen production unit, the largest-class in the world.

The projects seem to have run smoothly until now, since no accidents were reported, making us assume that safety strategies followed were sufficient and effective.

Status of project: Japan

|

Japan |

Status |

|---|---|

|

New Energy and Industrial Technology Development Organization (NEDO); 2011-2015 |

Completed |

|

Global Hydrogen Supply Chain Demonstration Project; 2015-2020 |

Completed |

|

Fukushima Hydrogen Energy Research Field (FH2R); 2018-2020 |

Completed |

|

Japan H2 Mobility, LLC (abbreviation: JHyM); 2018-2021 |

Completed |

|

Hydrogen Energy Supply Chain (HECS) Pilot Program; 2018-2022 |

Under development |

Norway

Scenarios

|

Scenario 1: Production: Leakage from the pipe connected to electrolyser |

|||

|---|---|---|---|

|

S. No. |

Project name |

Project description |

Source |

|

1 |

Electrolyser 2030- Cell and Stack (under development) |

1. Pilot focusing on techno-economic analysis of large scale PEM electrolysers. 2. Costs of electrolysers need to be reduced to make green hydrogen competitive with natural gas. 3. Better understanding of materials and components lifetime, optimal electrolyser cell and stack design 4. In-depth analysis at levels of electrolysis ranging from single cells to stack level. |

Source: Research Council of Norway Organisation: Institute-Technical Sectors, SINTEF AS, Trondheim https://prosjektbanken.forskningsradet.no/ Past study can be accessed at: |

|

Scenario 2: Pipeline transport: Leakage from high pressure pipeline |

|||

|

S. No. |

Project Name |

Project Description |

Source |

|

Safe Pipelines for Hydrogen Transport (under development) |

Comprehensive materials screening program of four vintage pipelines and one new steel pipeline carried out in 2020 (subsea transportation of hydrogen). Mechanical test results clearly show degradation of the old pipelines due to hydrogen. Further studies are being performed on two X65 pipeline steels for analysis of microchemical properties, fatigue and fracture resistance. |

Source: Research Council of Norway Organisation: Technical-Industrial Institutes, SINTEF AS, NTNU, Kyushu University Japan; Trondheim |

|

|

Scenario 3: Road Transport: H2 leakage in confined space/ built-up areas Scenario 4: Mobility and partially confined space: a hydrogen city bus driving in a tunnel is involved in a traffic accident Scenario 5: Mobility and partially confined space: accidents at a hydrogen fuel station |

|||

|

3 |

Infrastructure for Materials Research for Transporting Hydrogen (SMART-H) (under development) |

Study to tackle hydrogen embrittlement. SMART-H is a research infrastructure consisting of 4 labs to analyse hydrogen in metals, macro-scale mechanical testing in high pressure hydrogen, nano and micro-scale mechanical testing in hydrogen and materials informatics lac for consolidating experimental works. Research Issues: How much and how fast hydrogen enters and diffuses in various materials. Primary mechanisms that govern distribution of hydrogen in the structure of the material and the related material degradation. Effect of hydrogen gas pressure and temperature on material properties, strength, fracture and fatigue resistance. |

Source: Research council of Norway Organisation: Norway’s Technical Natural Science University, Trondheim |

|

4 |

H2Moves Scandinavia 2010-2012 (completed) |

The Scandinavian hydrogen highway partnership (SHHP) road-tested a fleet of hydrogen-fuelled cars and a state of the art refuelling station in Oslo. Project goal was to create a hydrogen-fuelled network of 15 main and 30 satellite refuelling stations along with a fleet of 100 buses, 500 cars and 500 specialty vehicles by 2015. The Oslo refuelling station which opened in 2011 has a capacity of 200 kg/day and refuelling of 20 kg/hour. The refuelling is as per SAE standards. Hydrogen is produced onsite as well as through truck delivery. |

https://cordis.europa.eu/article/id/90044-hydrogen-fuelled-transport-infrastructure |

|

5 |

Risk assessments of hydrogen refuelling station concepts based on onsite production (2003) (completed) |

Study commissioned under then EC funded research project European Integrated Hydrogen Project 2 (EIHP2) Analysis performed of both compressed gas and liquified systems. Some risk reducing measures suggested are as follows: i) Transportation of refrigerated ammonia (in case of ammonia splitting) should be considered. ii) Area should be cordoned off during ammonia unloading iii) Filling hose design to withstand external impact iv) Regular checks of rupture valves v) Driver should be present during refuelling In addition to this several other suggestions have been made including continuous measurement of H2 in O2, gas detection and emergency ventilation, appropriate material selection etc. Safety Distances: in addition to strict inspections and quality preconditions, sabotage should also be factored in. Walls and fences around the fuelling station should be designed in a way that allows for leaking hydrogen to escape upwards. Ignition Sources (forbidden): Prominently placed notices for smoking, open fire and mobile phone use should be placed. |

|

|

6 |

Hydrogen powered fuel cell forklifts, field demonstration and durability studies (HyLift-DEMO) (several phases completed) |

Large scale demonstration of hydrogen powered FC material handling vehicles, which enables a following deployment and commercial market introduction. 30 material handling vehicles and corresponding hydrogen refuelling infrastructure demonstrated. Project contributed to the establishment of appropriate regulations, codes and standards (RCS) framework. |

Source: Research council of Norway Organisation: SINTEF (for work package related to demonstration monitoring and target validation) https://cordis.europa.eu/project/id/256862/reporting HyLift-DEMO Final Report: https://cordis.europa.eu/docs/results/256/256862/final1-hylift-demo-final-report-v08.pdf |

Incidents

|

S. No. |

Scenario |

Description |

Analysis |

|---|---|---|---|

|

1 |

5 |

In 2012, hydrogen was found leaking from a HRS due to a defect in the high pressure dispenser hose. The leak was extremely small and the gas was directed upward. Secondly, all safety equipment worked as per design and the system automatically shut down. |

Possible reason for the defect was due to extreme temperature swings of -15º and -18º Celsius |

|

2 |

5 |

In 2019, 1.5 to 3 kg of hydrogen leaked from high pressure storage due to human error as the two bolts securing the gaskets were not tightened well. |

Human error was identified as the cause of the accident. The bolts which were to be tightened manually had not been done optimally. Stricter outer perimeter requirements to shield public, and stronger protocols from manufacturers and double witnesses at maintenance activities are some of the measures to mitigate risk. |

Concluding remarks: Norway

Studies from Norway suggest that while steps are being taken towards energy transition to hydrogen, much of the focus is on the large-scale use of hydrogen, for instance in maritime and industrial use. This is not to say that no efforts have been made for small scale use of hydrogen. The country has ambitious plans of ramping up its hydrogen infrastructure and is in partnership with other Scandinavian nations concerning this. Several projects funded by ENOVA and the Research Council of Norway under the National Strategy are studying the risks and potential benefits emerging from hydrogen use in urban mobility, pipeline infrastructure, material selection etc. Results from these projects will be ready in the coming years. Evidence of results from previous studies is still low suggesting that much of the information may still not be publicly available.

Three incidents involving hydrogen leaks from HRSs have been recorded in Norway. The latest, in 2019, resulted in the leakage of 1.5 to 3 kg of hydrogen from high pressure storage due to human error. Another incident in 2012 was due to a defect in a dispenser hose, caused likely by the very low temperatures. Stricter outer perimeter requirements to shield public, stronger protocols from manufacturers and double witnesses at maintenance activities are some of the suggested mitigation measures to make HRSs safer.

Status of project: Norway

|

Norway |

Status |

|---|---|

|

H2Moves Scandinavia 2010-2012 |

Completed |

|

Risk assessments of hydrogen refuelling station concepts based on onsite production 2003 |

Completed |

|

Hydrogen powered fuel cell forklifts, field demonstration and durability studies (HyLift-DEMO) |

Several phases completed |

|

Electrolyser 2030- Cell and Stack |

Under development |

|

Safe Pipelines for Hydrogen Transport |

Under development |

|

Infrastructure for Materials Research for Transporting Hydrogen (SMART-H) |

Under development |

Russia

Scenarios

|

S. No |

Project name |

Project description |

Source |

|---|---|---|---|

|

Scenario 1: Production: Leakage from the pipe connected to electrolyser |

|||

|

1 |

Hydrogen Clusters - Obasts (Under Development) Organizations: Rosatom, Federal Ministry for the Development of Far East and the Artic |

Creation of three unique regional hydrogen clusters in Russia: in the Far East (Sakhalin), the northwest (St. Petersburg) and the Arctic. In April 2021, Rosatom, the Sakhalin Government and Russia’s Federal Ministry for the Development of the Far East and the Arctic signed an official cooperation agreement on the creation and development of this cluster. Production of hydrogen to be exported to Japan and other asian countries. Production of hydrogen to be used in hay-duty mining equipment and passenger transport. The northwestern cluster will be located in St. Petersbourg and will focus on the production of hydrogen through electrolysis at the Leningradskaya power plant to be exported and used in the industrial process(Steel industry, cement production) and transportation. The Arctic cluster will focus on the use of hydrogen for energy storage in remote and isolated areas to ease the gap of remote areas not connected to the national grid. |

O.E. Aksyutin et al. The contribution of the gas industry to the formation of an energy model based on hydrogen. / Vesti gas science - scientific and technical collection. Environmental protection, energy saving and labor protection in the oil and gas complex. Special edition - 2017, p. 12 https://www.swp-berlin.org/10.18449/2021C34/ https://energy.skolkovo.ru/downloads/documents/SEneC/Research/SKOLKOVO_EneC_Hydrogen-economy_Eng.pdf |

|

2 |

Snezhinka zero-carbon international Arctic research station - (Under Development) planned to open in 2023 |

A pilot project using hydrogen-based solutions for energy storage and transportation. |

|

|

3 |

NLMK site (Under Development) Organizations: NLMK, Air liquide |

Cooperation between the leading steel producer in Russia NLMK and Air Liquide (France) in developing its hydrogen assets and reducing the carbon footprint of its steel. Air Liquide will invest around 100 million euros in the flagship site of NLMK in Lipetsk |

|

|

4 |

Gazprom Vodorod (Hydrogen) (Under Development) |

Gazprom announced in December 2021 the creation of a newco to develop its own technologies aimed at producing methane-hydrogen mixtures and hydrogen from methane without carbon dioxide emissions. The company also wants to build the infrastructure necessary for the product transportation aiming at involving the Nordstream2 project in the wider plan. |

|

|

5 |

Rusnano - Enel Russia Wind based Green Hydrogen power plant in Murmansk - 2021 (Under Development) Due 2024 |

Rusnano and Enel Russia agreed to implement Russia’s first project on green hydrogen production at a wind power plant in the Murmansk region. The project is planned to produce 12 thousand tonnes of hydrogen per year and to export it to the EU; Estimated investment $320 million. |

https://www.enelrussia.ru/en/media/news/d2021-6/08062021 https://www.h2bulletin.com/enel-russia-rusnano-green-hydrogen/ |

|

6 |

Kolskaya NPP - 2020 (Completed) |

A pilot project to construct infrastructure for the development of hydrogen energy technologies and electrolysis production is to be implemented at Kolskaya NPP in the Murmansk region. |

|

|

Scenario 2: Pipeline Transport: Leakage from high pressure: Leakage from high pressure pipeline |

|||

|

7 |

Russian-Japan agreement 2020-2021 (agreement signed. Supply yet to start) |

In september 2019 Rusatom Overseas, the subsidiary of the state company Rosatom, signed an agreement with the Agency for Natural Resources and Energy of the Ministry of Economy, Trade and Industry of Japan to start a feasibility study of a pilot project for the hydrogen export from Russia to Japan. A pilot export project considers the possibility of producing hydrogen for the Japanese market by electrolysis. The ambition is to supply up to 40% of Japan’s demand by 2030, and potentially to other Asian Pacific countries. |

|

|

Scenario 3: Road Transport: H2 leakage in a confined space/ built environment |

|||

|

8 |

Liquefied Hydrogen for the national Space Programme. (Completed) |

Scientific and experimental developments in the field of liquefying and transporting hydrogen in a liquefied state were carried out by the NPO Geliymash94 for the space programme of Russia and by PJSC Cryogenmash The creation of cryogenic complexes for hydrogen liquefaction, its long-term storage and transportation by railroads and highways began in the 1960s, primarily in connection with the widespread use of liquid hydrogen as a fuel for rocket and space systems. |

|

|

Scenario 4: Mobility and partially confined space: a hydrogen city bus driving in a tunnel is involved in a traffic accidents |

|||

|

9 |

Vtek project Yekaterinburg - 2015 (Completed) |

In 2015 a pilot project of a hydrogen transportation and energy complex (vtek) was launched in the city of Yekaterinburg on the bus route of the railway station and airport "koltsovo". |

|

|

10 |

Sakhalin H2 Train - 2019 (Completed) Organizations: Rosatom, RZD, Sakhalin Oblast Government |

In 2019 a cooperation between Rosatom, Russian Railways (RZD), Transmashholding and the Sakhalin Oblast regional government signed an agreement to develop the first project on the use of hydrogen in rail transport. This will see the launch by 2025 of seven suburban hydrogen trains with 13 more by 2030. |

|

|

11 |

St. Petersburg retrofitted single-section LM-68M2 hydrogen-powered tram - 2019 (Completed) Organizations: City council, Central Research Institute of Electrical & Marine Technology. |

On November 1 2019 the city of St. Petersburg operated the testing of a hydrogen fuel cell retrofitted single-section LM-68M2 tram created jointly by the operator Gorelektrotrans and the Central Research Institute of Electrical & Marine Technology. |

https://fuelcellsworks.com/news/russia-hydrogen-fuel-cell-tram-tested-in-st-petersburg/ |

|

12 |

Hydrogen buses - 2020 (Under Development) Organizations: InEnergy, KAMAZ |

The fast growing startup InEnergy is partnered with Russia’s truck making giant, KAMAZ which recently included hydrogen-powered buses and trucks in its R&D programme for 2021, to develop hydrogen bus prototypes, with expected presentation this year. |

|

|

Scenario 5: Mobility and partially confined space: accidents at a hydrogen fuel station |

|||

|

13 |

Refuelling stations - National Hydrogen strategy 2030 (Under development) Organizations: Federal Government |

Currently Russia has only one refuelling station in Chernogolovka. The country’s hydrogen strategy projects the build-up of 100 refuelling stations by 2025. And to reach 300 in 2028 and 200 hydrogen refuelling sites — in each of 2029 and 2030. |

|

|

Scenario 6: Residential use: Safety of Hydrogen in buildings with focus on hydrogen cooking stoves and boilers |

|||

|

No examples found of pilot projects under this scenario |

|||

Concluding remarks: Russia

Russia is one of the major energy producers with major companies such as Gazprom, Rusatom and Novatek leading at global level. With export of gas accounting for a great share of its economy, the country is focusing on seizing its opportunity on hydrogen by exploiting its advanced gas transportation infrastructure and its longstanding hydrogen production history for military and space exploration purposes. On this note the hydrogen strategy of the country is rounded up on three main pillars: Development of pilot projects for hydrogen exports, development of hydrogen clusters in the domestic market and development of fundamental and applied research on hydrogen.

The three main pillars support the production side with a focus on technologies for producing “grey” hydrogen in Russia. They are deployed at oil and gas processing plants (methane conversion) and power plants (electrolysis). All hydrogen produced is used onsite - for example, to improve the quality of hydrocarbon processing or in the cooling systems of power generators. Russia is focusing on projects to export hydrogen to targeted markets such as Japan and Germany/Europe.

Concerning the other 5 scenarios, few projects are in place, based mostly on three main production clusters to support key industries, all mostly based on the initiative by private companies.

The mobility sector is set to become the first hydrogen technology niche in Russia for a number of reasons: there are emerging Russian technology providers, concrete pilot projects (such as the Sakhalin hydrogen train), and an interest on the part of investors. This is supported by the project of building several refuelling stations beyond the only one present in the country. An exception to the relatively new interest in hydrogen is provided by the state’s Space Program that has been experimenting on the use - as fuel for its rocket since the 1960s - of liquified hydrogen transported via road by tanks.

There is no evidence of projects concerning the residential use of hydrogen for domestic heating and cooking.

Status of project: Russia

|

Russia |

Status |

|---|---|

|

Liquefied Hydrogen for the national Space Programme. |

Completed |

|

Vtek project Yekaterinburg - 2015 |

Completed |

|

Sakhalin H2 Train - 2019 |

Completed |

|

St. Petersburg retrofitted single-section LM-68M2 hydrogen-powered tram - 2019 |

Completed |

|

Kolskaya NPP - 2020 |

Completed |

|

Hydrogen Clusters - Obasts |

Under development |

|

Snezhinka zero-carbon international Arctic research station - planned to open in 2023 |

Under development |

|

NLMK site |

Under development |

|

Gazprom Vodorod (Hydrogen) |

Under development |

|

Rusnano - Enel Russia Wind based Green Hydrogen power plant in Murmansk - 2021-2024 |

Under development |

|

Russian-Japan agreement 2020-2021 (agreement signed. Supply yet to start) |

Under development |

|

Hydrogen buses - 2020 |

Under development |

|

Refuelling stations - National Hydrogen strategy 2030 |

Under development |

South Korea

Scenarios

|

S. No |

Project Name |

Project description |

Source |

|---|---|---|---|

|

1 |

Hydrogen pilot cities, 2019 (under development) |

In 2019, the Korean government identified three cities that will serve as “hydrogen pilot cities”. These cities are Ulsan, Ansan, and Wanju. As part of the hydrogen pilot city program, the necessary infrastructure will be built for hydrogen production and distribution, so that the produced hydrogen will be used for heating, cooling, transport and electricity supply. The pilot cities will launch demonstration projects and begin testing the application of hydrogen in transportation, industry, and space heating in 2022. The cities will obtain their hydrogen from different sources. Ulsan seeks to produce hydrogen from local petrochemical complexes to power buildings and to refuel FCEVs and ships. Ansan, while still getting most of its hydrogen supply from natural gas reforming, also plans to supply green hydrogen from the Sihwa Lake Tidal Power Station (254 MW). Wanju will also serve as a hydrogen production site, while the nearby city of Jeonju will act as a demand centre. |

South Korea’s hydrogen strategy and industrial perspectives (Kan, 2018[11]). |

|

Scenario 1: Production: Leakage from the pipe connected to electrolyser |

|||

|

2 |

Green hydrogen floater, (2021-2030) (under development) |

South Korea is researching a scheme to develop an offshore green hydrogen plant based on a floating production, storage and offloading vessel using offshore wind power to produce the hydrogen. A consortium was established to spearhead initial engineering of a newbuild hydrogen FPSO (Floating production storage and offloading), which will later be rolled into a pilot project. The consortium, led by Korea Maritime & Ocean University (KMOU), aims to produce a 1 MW pilot plant in 2022 before developing and demonstrating a gigawatt-class plant in 2030. KMOU will carry out the research, development and demonstration of the H-FPSO using the university’s patented floating technology from a previous project in which it built a floating nuclear power system. |

|

|

3 |

Donghae offshore wind plant and green hydrogen plant (2021-2025) (under development) |

The Korea National Oil Corporation (KNOC) and the Korean power company Korea East-West Power (EWP) plan to develop Korea’s first large-scale floating offshore wind farm with a preliminary feasibility study, conducted by the Korea Development Institute (KDI), completed in 2021. This wind farm, if completed as proposed, will be the largest in the world. The project will commence construction in 2022 with the aim of generating power by 2024. Along the 200 MW wind farm, a 100 MW hydrogen plant will be built in the East Sea with the aim of generating green hydrogen. Hydrogen will be produced from seawater using the electricity generated from the wind farm. |

|

|

4 |

P2G demonstration project and hydrogen tank explosion at Gangwon Technopark, in Gangneung (2016 - 2019) (interrupted) |

A government-funded, three-year demonstration project about electricity generation from hydrogen took place at Gangwon Technopark. As part of this project, electricity generated by photovoltaic arrays was used to generate hydrogen using a water electrolyser. During the final year of the project, (May 2019) a hydrogen tank exploded, leaving two people dead and six injured. Three hydrogen storage tanks with a capacity of 400 m3 each (operating pressure of 1 MPa) were destroyed in the explosion. There was no secondary fire and the damage was caused merely by the detonation pressure. The equivalent TNT of the explosion was estimated to be of about 50 Kg based on the damage nearby. Within a 15 m distance from the hydrogen tank, the structure beam of the building was damaged and most of the windows of a 5-story building about 100 m away were crushed. A preliminary investigation concluded that the hydrogen and buffer tanks exploded due to a static spark in the hydrogen buffer tank, with oxygen concentration exceeding 6%, which is the explosion threshold. The presence of oxygen in the hydrogen stream was due to the wrong operation of the water electrolyser. The system had to be operated above 98 kWh, however, due to the characteristics of the solar panels providing the power, the system often operated below this threshold. The investigation has also identified contributing causes: An oxygen removing component was not used in the final design, as well as a static spark remover in the hydrogen buffer tank. This was probably done to reduce costs. When oxygen concentrations higher than 3% were detected, it was decided to continue operation to achieve the 1000 hrs of operation necessary to validate the tests. The hydrogen quality was not tested daily as required. This accident would not have happened if the appropriate operating procedures had been followed and if the required safety measures had been put into place. Lessons learnt The following corrective actions are required: Investigation into the relationship between the gas permeability of the electrolyser membrane and dynamic operation range caused by the variability of renewable power sources Improvement of standardised performance and safety tests, aiming at defining more realistic testing requirements and conditions at partial/low load cycles. Further mitigation measures should be put into place, e.g. an in-situ diagnostic system able to trigger emergency stops of the hydrogen production system and an automatic isolation of the storage. |

HIAD 2.0 hydrogen incident and accident database |

|

Scenario 4: Mobility and partially confined space: a hydrogen city bus driving in a tunnel is involved in a traffic accident |

|||

|

5 |

Hydrogen buses (2022) (under development) |

The South Korean government has announced its intention to subsidise the purchase of 624 hydrogen buses that will operate in the southern provinces of the country by the end of 2025. Local private bus companies in Busan, Ulsan and Gyeongnam province will therefore only pay 320 million won (235 000 euros) per hydrogen bus to replace the diesel and compressed natural gas buses that are currently in operation. It is intended that hydrogen buses will begin operating in pilot projects in the three provinces in the first half of 2022. |

|

|

Scenario 5: Mobility and partially confined spaces: accidents at a hydrogen fuel station |

|||

|

6 |

Hydrogen Energy Network (HyNet), (2019-2029) (under development) |

Hydrogen Energy Network (HyNet) was established as a joint venture between 13 leading industrial companies in South Korea, with the aim of expanding the nation's hydrogen refuelling infrastructure by installing 100 stations by 2022 and operating them until 2029.1 As of January 2022, South Korea has 112 hydrogen refuelling stations (HRSs). The government’s intention is to roll out at least 2000 HRSs by 2050.2 As of 2019, Korean regulation dictates that only trained personnel are allowed to do the hydrogen fuelling.3 |

|

|

7 |

Mobile liquid hydrogen refuelling station (2018) (completed) |

The world's first mobile liquid hydrogen refuelling station was launched in Korea by Hylium Industries. The station is a five-tonne truck carrying fuelling equipment, consisting of a liquid H2 pump, a vaporiser, and a dispenser. It has a capacity of 7,500 litres of low-pressure (3 bar) liquid H2 and can provide fuel for up to 100 H2-powered cars per day. The liquid H2 used has a high purity of over 99.995%. The main advantage of the refuelling station is that it uses a 900 bar liquid H2 pump system. As a result, it eliminates the need for a compressor and cooling system, significantly reducing equipment and driving costs. |

http://www.ihfca.org.cn/index.php?m=content&c=index&a=show&catid=8&id=121 |

|

Other projects |

|||

|

8 |

Hyosung pilot project (2021-2022) (under development) |

The company Hyosung has launched a demonstration project that will generate electricity from the hydrogen byproduct produced at its Hyosung Chemical Yongyeon Plant facility. The plant produces propylene through propane de-hydrogenation and up to 13 000 tons of hydrogen byproduct are generated annually during this process. The demonstration project will result in a reduction in Hyosung’s carbon emissions, while at the same time providing electricity for the facilities’ operations. Hyosung selected INNIO Jenbacher hydrogen engine technology for their demonstration project, in what is South Korea’s first demonstration project using an engine fueled by hydrogen to produce electricity. |

|

|

9 |

Shinhincheon Bitdream Centre (2017-2021) (Completed) |

The Shinincheon Bitdream Fuel Cell Power Plant in Incheon is a power plant with a total capacity of 78 MW constructed at the Shinincheon Bitdream headquarters of Korea Southern Power by using fuel cells supplied by POSCO Energy and Doosan Fuel Cell. It is the world's largest fuel cell power plant currently in operation, capable of supplying electricity to 250.000 households annually. The expected benefits from its operation are: a) the provision of clean air to local residents by purifying fine dust emitted from the LNG (liquefied natural gas) thermal power plant at the Shinincheon Bitdream headquarters, b) the production of hot water for heating for 44 000 households and c) the supply of inexpensive heat through local heating companies. |

|

|

10 |

Bloom Energy and SK Engineering & Construction Co Ltd pilot plant (2020) (under development) |

Bloom Energy and SK Engineering & Construction Co Ltd have deployed in South Korea 100 kW of solid-oxide fuel cells (SOFC) that are powered by hydrogen, as part of a demonstration project announced in July 2020. The SOFCs will use the hydrogen byproduct generated by SK Advanced to produce electricity. A 1-MW unit of Bloom Energy’s Energy Server fuel cell-based distributed power generation system will be installed by 2022. In 2022, Bloom Energy will also ship solid-oxide electrolyser cells (SOEC) to South Korea for the production of green hydrogen, which will be used to power the SOFC. |

|

|

11 |

Hyundai Oilbank blue hydrogen ecosystem (2021-2025) (under development) |

Hyundai Oilbank will establish by 2025 a “blue hydrogen ecosystem” that will produce 100,000 metric tons of blue hydrogen annually. The carbon byproducts generated by the production process will be used in commercial products such as dry ice. Hyundai Oilbank will collaborate with Air Products and use its blue hydrogen technologies for the blue hydrogen ecosystem, aiming to later on expand the partnership to the generation of green hydrogen. |

|

Concluding remarks: South Korea

In 2019, South Korea published a roadmap for the promotion of a hydrogen-based economy focusing mainly on the use of hydrogen in the transportation sector, on decarbonising industry and buildings, and on the building of the necessary infrastructure for the production and distribution of hydrogen. With the eventual aim of powering 10% of the country with hydrogen by 2030, the Korean government identified three cities as “hydrogen pilot cities” (Ulsan, Ansan, and Wanju). These pilot cities will begin testing the application of hydrogen in transportation, industry, and space heating in 2022. A Hydrogen Law was put into place to lay the legal foundations for the government’s promotion of hydrogen and the implementation of safety standards for facilities. This law went into effect in 2021 and stipulates several important industrial strategy elements, such as supporting hydrogen-focused companies through research and development (R&D) subsidies, loans, and tax exemptions.

South Korea’s hydrogen strategy is very ambitious, but it is mainly focusing on the scale up of the production of carbon-intensive hydrogen generated by petrochemical plants or by natural gas reforming. As such, this strategy is not as climate-friendly as that of other countries’, since there are no immediate plans in place to decarbonise the industry sector.

A lot of South Korea’s R&D efforts revolve around liquefied hydrogen storage technology and the reduction of transportation costs. Additionally, the government’s long-term aim is to build a hydrogen pipeline network across the country, with the development of the appropriate infrastructure beginning in 2022. The Korean government has also committed $2.34 billion (2.14 billion euros) to the establishment of a public-private hydrogen vehicle industry by 2022.

A major accident took place in Gangneung, Korea in 2019, during a demonstration project involving electricity generation from hydrogen. The accident caused the deaths of two people and injured six. Hydrogen and buffer tanks in the facility exploded due to a static spark in the hydrogen buffer tank. Oxygen was present in the hydrogen tank due to wrong operation of a water electrolyser, which was coupled to solar panels. The accident could have been prevented if the proper operating and safety procedures had been followed. To prevent future incidents, investigation is required into the proper operating conditions for the electrolyser. The standardised performance and safety tests should also be improved, and further mitigation measures should be put into place, such as, e.g., an in-situ diagnostic system able to trigger emergency stops of the hydrogen production system and an automatic isolation of the storage.

Status of project: South Korea

|

South Korea |

Status |

|---|---|

|

P2G demonstration project at Gangwon Technopark, Gangneung – 2016-2019 |

Interrupted |

|

Shinhincheon Bitdream Centre – 2017-2021 |

Completed |

|

Mobile liquid hydrogen refuelling station – 2018 |

Completed |

|

Hydrogen pilot cities – 2019-~ |

Under development |

|

Green hydrogen floater – 2021-2030 |

Under development |

|

Donghae offshore wind plant and green hydrogen plant – 2021-2025 |

Under development |

|

Hydrogen buses – 2022- |

Under development |

|

Hydrogen Energy Network (HyNet) – 2019-2029 |

Under development |

|

Hyosung pilot project – 2021-2022 |

Under development |

|

Bloom Energy and SK Engineering & Construction Co Ltd pilot plant – 2020 - |

Under development |

|

Hyundai Oilbank blue hydrogen ecosystem – 2021-2025 |

Under development |

United Kingdom

Scenarios

|

S. No |

Project Name |

Project description |

Source |

|---|---|---|---|

|

Scenario 1: Production: Leakage from the pipe connected to electrolyser |

|||

|

1 |

Trafford Green Hydrogen - 2021 (Under development) |

H2 Electrolyser (10 MWe – 200 Mwe) Carlton Power’s Trafford Green Hydrogen is developing a 10 MWe hydrogen electrolyser plant at Carrington in Greater Manchester. The project will use onsite and offsite renewable energy to produce green hydrogen fuel for transport and heating. |

|

|

2 |

HyGreen Teesside project - 2025 (Under development) |

60 MWe of ‘green’ hydrogen production by 2025? strengthening Teesside role as UK’s leading hydrogen hub to decarbonize industry ?and heavy transport The two projects combined will potentially deliver 30% of the UK’s ??2030 target for hydrogen production?. |

https://www.bp.com/en/global/corporate/what-we-do/gas-and-low-carbon-energy/h2teesside.html |

|

3 |

HyNet North West - 2025 (Under development) |

The focus of the project is to produce, store and distribute low carbon hydrogen as well as capture and lock up carbon dioxide emissions from industry. It will develop a 100 000 Nm3 per hour clean hydrogen production facility for deployment as part of the HyNet Cluster By the year 2030 it will cut carbon emissions by 10 million tonnes every year – the equivalent of taking 4 m cars off the road |

|

|

4 |

Gigastack (Under development) |

Developing electrolyser technology to produce renewable hydrogen at large-scale the project is also aimed at developing a system that uses electricity from Orsted’s Hornsea. Two offshore wind farm to generate renewable hydrogen for the Phillips 66 Humber Refinery |

|

|

5 |

Acorn Hydrogen Project (Under development) |

The project will reuse 420 km of existing offshore pipeline through the National Transmission System to transport hydrogen into homes, offices and factories across the UK |

|

|

Scenario 3: Road Transport: H2 leakage in a confined space/ built environment |

|||

|

6 |

NPROXX type 4 vessels. (Completed) |

NPROXX developed the first certified Type 4 pressure vessel for hydrogen storage infrastructure, refuelling stations and hydrogen-powered vehicles with a working pressure of 350 bar, 500 bar and 700 bar. The 500 bar pressure vessels offer a usable H2 capacity of 6.2kg |

https://www.nproxx.com/capabilities/type-4-pressure-vessels/ |

|

7 |

Project Hystor (Completed) |

High-Pressure storage hydrogen tank was developed by a consortium of UK aimed for use in large good vehicles (HGV), bus and off highway applications. |

|

|

Scenario 4: Mobility and partially confined space: a hydrogen city bus driving in a tunnel is involved in a traffic accidents |

|||

|

8 |

Hydrogen Transport Programme (HTP) - 2017 (Under development) |

The HTP program is an umbrella funding program aimed at the deployment of 5 new hydrogen refuelling stations, 73 fuel cell electric vehicles and 33 fuel cell electric buses. The winning projects are dispersed across the UK with activities in Northern Ireland (Belfast), Scotland (Aberdeen), Wales (Monmouthshire) and England (Crawley, St. Helens, Middlesbrough and Stockton on Tees). |

|

|

9 |

UK H2Mobility (Under development) |

It is a consortium partnership of leading UK industrial players with an interest in hydrogen mobility, working with the Government to develop hydrogen-fuelled transport. |

|

|

10 |

Air Products Go-Ahead Hydrogen bus supply - June 2022 (Under development) |

The project aims at decarbonising the UK's transport sector with the partnership between Air Products and Go-Ahead to provide a fleet of 20 hydrogen fuel cell buses that will be deployed in Crawley, Horley, and the Gatwick Airport areas of the United Kingdom. |

|

|

11 |

Tees Valley multi-modal hydrogen transport hub - 2025 (Under development) |

Tees Valley to become home to the UK’s first-ever hydrogen transport hub Pop-up trials could see local shops, supermarkets and transport benefitting from cutting-edge hydrogen tech to power transport and move goods The hub could be fully operational by 2025 The UK government is funding several projects to accelerate the use of hydrogen transport in the Tees Valley region, including diesel buses retrofitted with hydrogen fuel cells, supermarket chains benefiting from hydrogen delivery vans, and the police and National Health Service using hydrogen vehicles. |

|

|

12 |

Hydroflex (Hydrogen train) trial - 2020 (Completed) |

After two years of development the HydroFLEX train went out on trial on UK’s mainline travelling for 40 km through Warwickshire and Worcestershire. The ground-breaking technology behind the trains will also be available by 2023 to retrofit current in-service trains to hydrogen. |

|

|

13 |

Alstom - Eversholt Rail agreement to build hydrogen train fleet (Under development) |

The two companies agreed to design, build, commission and support a fleet of 10 three-car hydrogen multiple units (HMUs) |

|

|

14 |

The FlyZero project - 2021 (Under development) |

The FlyZero project, led by the ATI and funded by the UK government, has developed a concept for a midsize aircraft powered by liquid hydrogen. It is capable of flying 279 passengers halfway around the world without a stop or anywhere in the world with just one stop to refuel. |

|

|

Scenario 5: Mobility and partially confined space: accidents at a hydrogen fuel station |

|||

|

15 |

Kittybrewster, Aberdeen - 2015 (Completed) |

Aberdeen City Council partnered with BOC to deliver a commercially viable hydrogen refuelling station using proven technology to power one of Europe’s largest fleets of hydrogen buses. Fast refuelling – 10 minutes for a bus, 5 minutes for a car opened in 2015 to refuel single-deck buses. Scaled up in 2018 for cars and vans, and in 2019 double decker buses. |

|

|

16 |

Element 2 Ways2H project (Under development) |

Partnership between Element 2 and Ways2H to deliver 40 waste-to-hydrogen (facilities that convert waste into hydrogen gas) refuelling stations in the UK as part of Element 2’s plans to deploy over 800 hydrogen pumps in the UK by 2027, and 2 000 by 2030. |

|

|

17 |

Hydrogen stations (Completed) |

11 hydrogen stations are open and active in the United Kingdom. |

|

|

Scenario 6: Residential use: Safety of Hydrogen in buildings with focus on hydrogen cooking stoves and boilers |

|||

|

18 |

H21 Hydrogen for Leeds (Under development) |

The project aims at supplying the population 760,000 of leeds hydrogen for heating and cooking over the next fifteen years. It will repurpose the existing gas infrastructure by redesigning the gas network to establish a high pressure (17 bar) outer city ring main transporting methane (CH4) to steam methane reforming (SMR) plants for distribution into the network (below 7 bar). |

|

Concluding remarks: United Kingdom

The UK envisages hydrogen as a new low carbon solution which can help the UK to achieve net zero by 2050, and its Sixth Carbon Budget target by 2035. The main focus is to capture the economic benefits of growing the UK hydrogen economy, supporting innovation and stimulating investment to develop the supply chains and skills needed and create jobs and export opportunities for the UK. On this note the government is directly investing in hydrogen pilot projects working with industry to achieve a 5 GW of low carbon hydrogen production capacity by 2030 as set out in the 10 point plan for a green industrial revolution.

The government released its Hydrogen strategy in August 2021, outlining a comprehensive roadmap for the development of the wider hydrogen economy over the 2020s to deliver its 2030 5 GW ambition.