This chapter presents the sustainable design goals that should guide sustainable plastics design and also the factors that influence their definition and implementation. Minimally recommended sustainable design goals are describe and mechanisms to consider trade-offs are presented.

A Chemicals Perspective on Designing with Sustainable Plastics

Chapter 3. Sustainable Design Goals

Abstract

A design team will need to set sustainable design goals to guide the sustainable plastic material selection. This chapter first provides examples of sustainable design goals. It then moves to factors influencing the definition of the goals. Finally, this chapter shows how to prepare for future trade-offs emerging from the life cycle considerations.

Note that the process of defining sustainable design goals has to be transparent. The team should report who is responsible for setting the goals, how that is to be done and their minimum requirements.

3.1. Examples of Sustainable Design Goals

Sustainable design goals were formulated in the OECD background paper and the four sectoral case studies to guide material selection, based on the American Chemical Society (ACS) Green Chemistry Institute’s (GCI) design principles of sustainable chemistry and engineering.

Sustainable plastics are “plastics used in products that provide societal benefits while enhancing human and environmental health and safety across the entire product life cycle” (OECD, 2018a). As previously visualised in Figure 1.1, the chemicals perspective has repercussions on the material selection, as well as on the product and system design.

3.1.1. The following sustainable design goals are generally relevant:

Select materials with an inherently low risk/hazard

Hazardous chemicals, especially those with potential for exposure to workers, community, users, and environmental receptors, are eliminated at all life cycle phases or hazardous chemical content is mitigated to levels that do not present risks, including:

Base polymer and source materials manufacturing.

Product manufacturing, including the life cycles of additives, production residues and non-intentionally added substances (NIAS).

During installation and use, including new material combinations (e.g. glue while installing) and interactions with the product (e.g. skin contact).

End-of-use (i.e., when the current user ends the product use cycle, independent of the remaining value and utility of the product) including unplanned routes (e.g. littering).

Designers may adopt a least hazardous approach to chemical selection as a precautionary measure. This will protect against unintentional exposure to hazardous chemicals during circular processing of waste products.

Transparency in terms of content, hazard properties, emissions and data gaps are necessary at every step of the supply chain. Ideally, full hazard assessments for chemicals present in the finished plastics (and for the possible mixture of migrating chemicals from the plastic) are available.

Select materials that have a commercial ‘afterlife’

Products, services and systems are designed for circular processing at the end-of-use (i.e., reuse, refurbishment, remanufacturing and/or recycling).

Content transparency and traceability exists to support circular processing.

Corresponding infrastructure exists to support circular processing.

Materials are able to undergo multiple cycles of recycling.

Select materials that generate no waste

Manufacturing waste and waste generated during product installation is avoided at every step of the production process. If this is unavoidable, it should be recycled.

The plastic product’s end-of-use is known and accounted for during material selection so as to avoid the generation of waste.

Select materials that use secondary feedstock or biobased feedstock

Use biobased/rapidly renewable resources that do not compete with “higher” uses (i.e., avoids adverse social or ecological impacts and avoids competition with food production on the local, regional and/or global scale).

Use secondary feedstock (i.e., recycled/waste-derived materials). Products are recycled into new materials with the goal to have equal quality and performance or higher (i.e., upcycling).

Design teams are invited to use this non-exhaustive list of sustainable design goals to guide their design process. Teams can add complementary sustainability design goals to this based on their own ambition level.

3.2. Factors Influencing the Definition and Implementation of the Sustainable Design Goals

Choosing the right sustainable design goals at the start of the material selection involves a variety of factors. The following factors influence how the sustainable design goals are identified and to what extent the designers and engineers’ team have the ability reach these design goals.

3.2.1. Previous steps in the material selection process

As visualised in Figure 2.3, the definition and ranking of the sustainable design goals is based on the sustainable design principles mentioned in Chapter 1, design requirements defined by the designers and engineers earlier in the design process and the product concept that was consequently selected. Viability checks concerning the sustainable chemicals perspective include:

Sustainable design goals vs design requirements. Sustainability design goals need to be compared with and evaluated against the design requirements that the team formulated earlier in the design process (see Chapter 2). Non-negotiable conditions set out in the design requirements have to be met by the to-be-designed product (i.e., needs). However, negotiable conditions deemed desirable for the to-be-designed product (i.e., wants) can be altered to meet the sustainable design goals.

Technical aspects due to the product concept choice. What are the expected lifespan and durability of the product? What conditions will it have to resist (e.g. traffic, cleaning, etc.)?

Legal aspects coming from the market chosen for the product. What are the compliance aspects to take into account? Think of for example international actions and national/regional regulations and restrictions for certain chemical substances, such as the Stockholm Convention, EU regulation for the Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) (No 1907/2006) and Directive 2011/65/EU on the restriction of the use of certain hazardous substances in electrical and electronic equipment. As chemical regulation is not static, consider regulatory horizon scanning in terms of anticipated or potential regulatory changes to avoid surprises. Does the product have to attain a certain certification (e.g. Cradle-to-Cradle Platinum certification determines the set of possible substances)?

Other aspects. Does the designed product have to meet goals from voluntary industry initiatives? For instance, adhering to the European Plastic Pact leads to the target of reducing virgin plastic products by at least 20% (by weight) by 2025 with 10 % absolute reduction. In addition, are there specific procurement specifications?

3.2.2. The team

The team of designers and engineers (and beyond) is at the core of the design process. Sustainable chemistry aspects transpire within the team in different ways:

Cumulated knowledge on sustainability. Are team members trained on sustainable design principles and life-cycle thinking?

Cumulated knowledge on chemistry. Are team members trained on alternatives assessments, impact assessments tools, hazard/risk assessments and materials disclosure programmes?

Team objectives and values. Is the team considering short term or long-term change (i.e., organisational and supply chain changes)? Are the team members likely to consider, test and develop radical and/or incremental innovative designs and polymer choices?

3.2.3. The context of the team’s product design process

The team is influenced by the company context and the design brief:

The team’s company. What is the ambition level of the company when it comes to sustainability? Preferably, this is to pursue international best practices, aspire to inspire others, and collaborate across the value chain to strive for ambitious goals. To what extent is knowledge of sustainability and chemistry accessible within the group of company employees? What are internal existing circular infrastructures (e.g. refurbishment centre or takeback programme)? What is the latitude given to the team in terms of innovation (e.g. out of the box product concept or state of the art technologies) and organisational/supply chain change (e.g. collaborating with material suppliers or developing new system solutions)? Is it financially possible to invest in research and development for the integration of innovative product design, chemical substances and circular “waste” treatment structures? What are the geographical markets and channels to keep in mind?

Design brief. What are the envisioned geographical markets and users? Will the product be a redesign or a completely new product? Is the product meant to be reused, refurbished, remanufactured and/or recycled?

3.3. Preparing to Deal with Future Trade-Offs

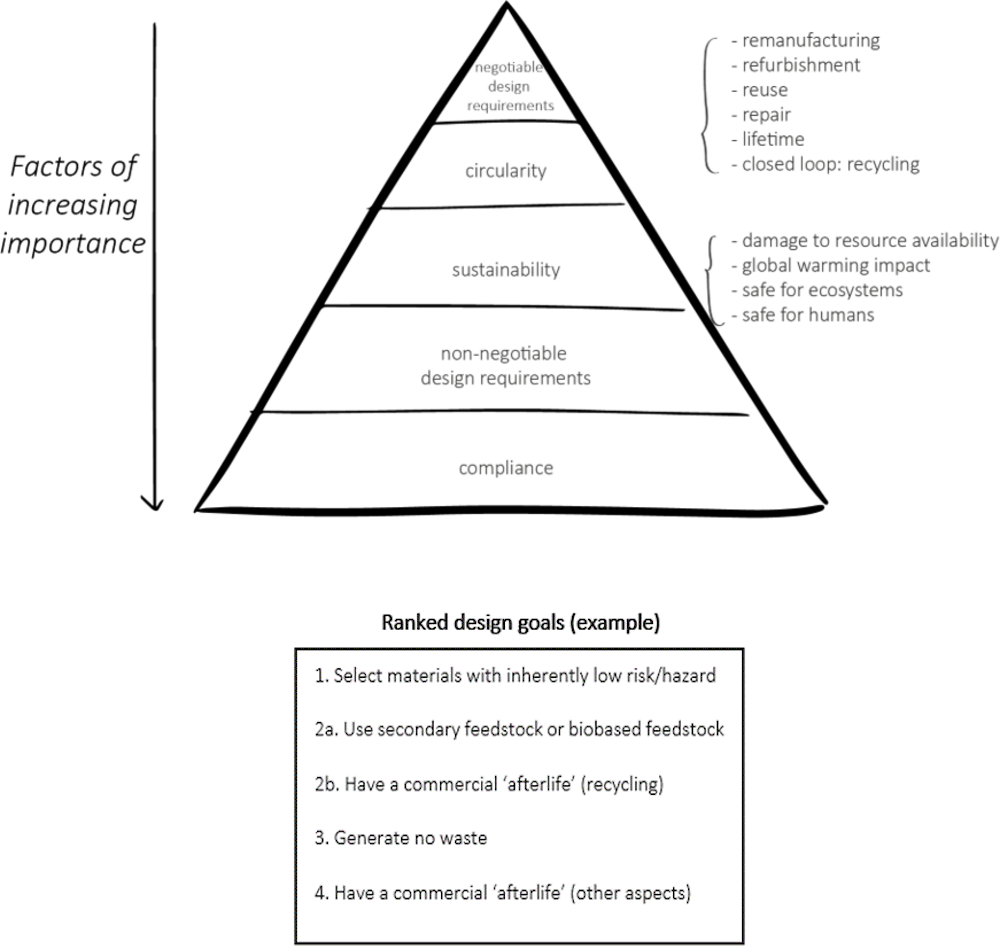

During the material selection process, the team is faced with trade-offs emerging from contradictory considerations throughout the life cycle of the product. To deal with these trade-offs, the sustainable design goals can be ranked by the team. Moreover, non-negotiable conditions can be drafted based on the sustainable design goals. Consideration should also be given to the potential for unintended consequences from material selection focused on a single application needing to work within an interdependent environment over its whole of life cycle.

3.3.1. Ranking sustainable design goals

The sustainable design goals can be ranked in order of importance for the design to help with weighing aspects of trade-offs.

The foundation of the ranking is compliance because the designed product will have to comply with the regulations relevant in the anticipated markets. The non-negotiable conditions from the design requirements will then have to be followed.

In terms of sustainable plastics, a certain prioritisation is made between and within sustainability and circularity factors. Note that circular solutions are not automatically sustainable (Geissdoerfer, Savaget, Bocken, and Hultink, 2016). The sustainability impact can be measured using a Life Cycle Assessment (LCA), which is standardised with ISO 14040 and 14044 (see Annex A: Overview of Relevant Methods, Tools and Metrics for specific methods and tools). The LCA indicators include global warming, eutrophication, acidification, damage to human health, damage to ecosystems and damage to resource availability. The field of circular economy incorporates the latter, which focuses on the increased extraction costs and energy costs. It complements it with maintaining the value and utility at a material, component, and product level at all times.

The circularity of solutions is measured using a variety of assessment methods (see Annex A: Overview of Relevant Methods, Tools and Metrics). This assessment is not yet standardised. ISO 59020 Measuring Circularity is expected in 2023. The position of recycling within the ranking varies depending on how circularity is measured by the team. One could consider the use of recycled plastics and recycling plastics at the end-of-use as a minimum requirement to limit the extraction of virgin materials and the loss of resources at the end-of-use. In contrast, one could choose not to prioritise recycling over other types of circular processing (e.g. repair and reuse) to focus on the extension of the lifetime of the product (Reikea, Vermeulen, and Witjes, 2018).

The ranking in Figure 3.1 is based on the former conceptualisation where closing resource loops is prioritised over slowing or narrowing resource loops. As mentioned earlier, the design team ideally already considered sustainability and circularity in the first stages of the design process, which resulted in design requirements already implementing sustainability and circularity. As this may not be the case in practice, Figure 3.1 explicitly incorporates sustainability and circularity between the non-negotiable design requirements (i.e., needs) and negotiable design requirements (i.e., wants) defined during the first stages of the design process.

Figure 3.1. Sustainable design goals ranking example if closing resource loops is prioritised over slowing and narrowing resource loops

3.3.2. Non-negotiable conditions based on the sustainable design goals

The design team has to decide what conditions are non-negotiable, preferably quantifying what has to be met for each goal. As a result, certain considerations can be evaluated as unacceptable if they fall under these conditions. For instance, a team may decide that it wishes to use as much recycled content as possible, but also that less than a specific amount of recycled content is unacceptable.

Now that the sustainable design goals have been defined and ranked, the considerations throughout the life cycle of the to-be-designed product to meet these sustainable design goals are explained in the following four chapters.

References

Geissdoerfer, M. et al. (2016), “The Circular Economy - A new sustainability paradigm?”, Journal of Cleaner Production, Vol. 143, pp. 757-768.

OECD (2018a), “Considerations and criteria for sustainable plastics from a chemicals perspective: Background paper 1. OECD Global Forum on Environment: Plastics in a Circular Economy”, Series on Risk Management, No. 51, OECD, Paris, https://www.oecd.org/chemicalsafety/risk-management/considerations-and-criteria-for-sustainable-plastics-from-a-chemicals-perspective.pdf

Reikea, D. et al. (2018), “The circular economy: New or Refurbished as CE 3.0? — Exploring Controversies in the Conceptualization of the Circular Economy through Focus on History and Resource Value Retention Options”, Resources, Conservation and Recycling, Vol. 135, pp. 246-264.

.